Super-leveling mirror powder coating and preparation method thereof

A powder coating and leveling technology, used in powder coatings, polyester coatings, coatings, etc., can solve the problems of poor leveling and mirror effect on the surface of the coating, improve wettability, enhance gloss, improve Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

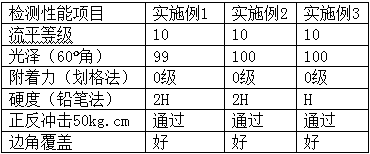

Embodiment 1

[0030] A super-leveling mirror powder coating, which is composed of the following raw materials in parts by weight: 300 parts of polyester resin, 25 parts of TGIC, 3 parts of leveling agent, 3 parts of brightener, 1.5 parts of benzoin, 0.6 parts of high-dispersion pigment, wax powder 0.6 parts.

[0031] The molecular chain segment of the polyester resin contains butyl propionate, heptyl propionate, and neopentyl glycol propionate; the acid value of the polyester resin is 28-35mgKOH / g, and the softening point is 110-120°C .

[0032]The leveling agent contains hydroxyl groups and benzene rings, the number average molecular weight Mn is 6000, and the molecular weight distribution PDI is 1.5.

[0033] The brightener is 701 auxiliary agent, purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0034] The benzoin was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0035] The high-dispersion pigment is high-dispersion permanent red, purc...

Embodiment 2

[0039] A super-leveling mirror powder coating, which is composed of the following raw materials in parts by weight: 450 parts of polyester resin, 37 parts of TGIC, 4.5 parts of leveling agent, 4.5 parts of brightener, 2.3 parts of benzoin, 0.9 parts of high-dispersion pigment, wax powder 0.9 servings.

[0040] The molecular chain segment of the polyester resin contains butyl propionate, heptyl propionate and neopentyl glycol propionate; the acid value of the polyester resin is 28-35mgKOH / g, and the softening point is 110-120°C .

[0041] The leveling agent contains hydroxyl groups and benzene rings, the number average molecular weight Mn is 6930, and the molecular weight is 2.39.

[0042] The brightener is 701 auxiliary agent, purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0043] The benzoin was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0044] The high-dispersion pigment is high-dispersion permanent yellow, purchased ...

Embodiment 3

[0048] A super-leveling mirror powder coating, which is composed of the following raw materials in parts by weight: 600 parts of polyester resin, 50 parts of TGIC, 6 parts of leveling agent, 6 parts of brightener, 3 parts of benzoin, 1.2 parts of high-dispersion pigment, 1.2 parts of wax powder share.

[0049] The molecular chain segment of the polyester resin contains butyl propionate, heptyl propionate and neopentyl glycol propionate; the acid value of the polyester resin is 28-35mgKOH / g, and the softening point is 110-120°C .

[0050] The leveling agent contains hydroxyl groups and benzene rings, the number average molecular weight Mn is 7000, and the molecular weight distribution PDI is 2.8.

[0051] The brightener is 701 auxiliary agent, purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0052] The benzoin was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0053] The high-dispersion pigment is high-dispersion permanent ye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com