Construction technique for self-leading hole at pile tip of embrace press type PHC tubular pile to enter rock through static pressure

A PHC pipe pile and construction technology technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of pollution, difficult to penetrate the pile end, change the piling method, etc., to achieve good penetration effect, high work efficiency, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

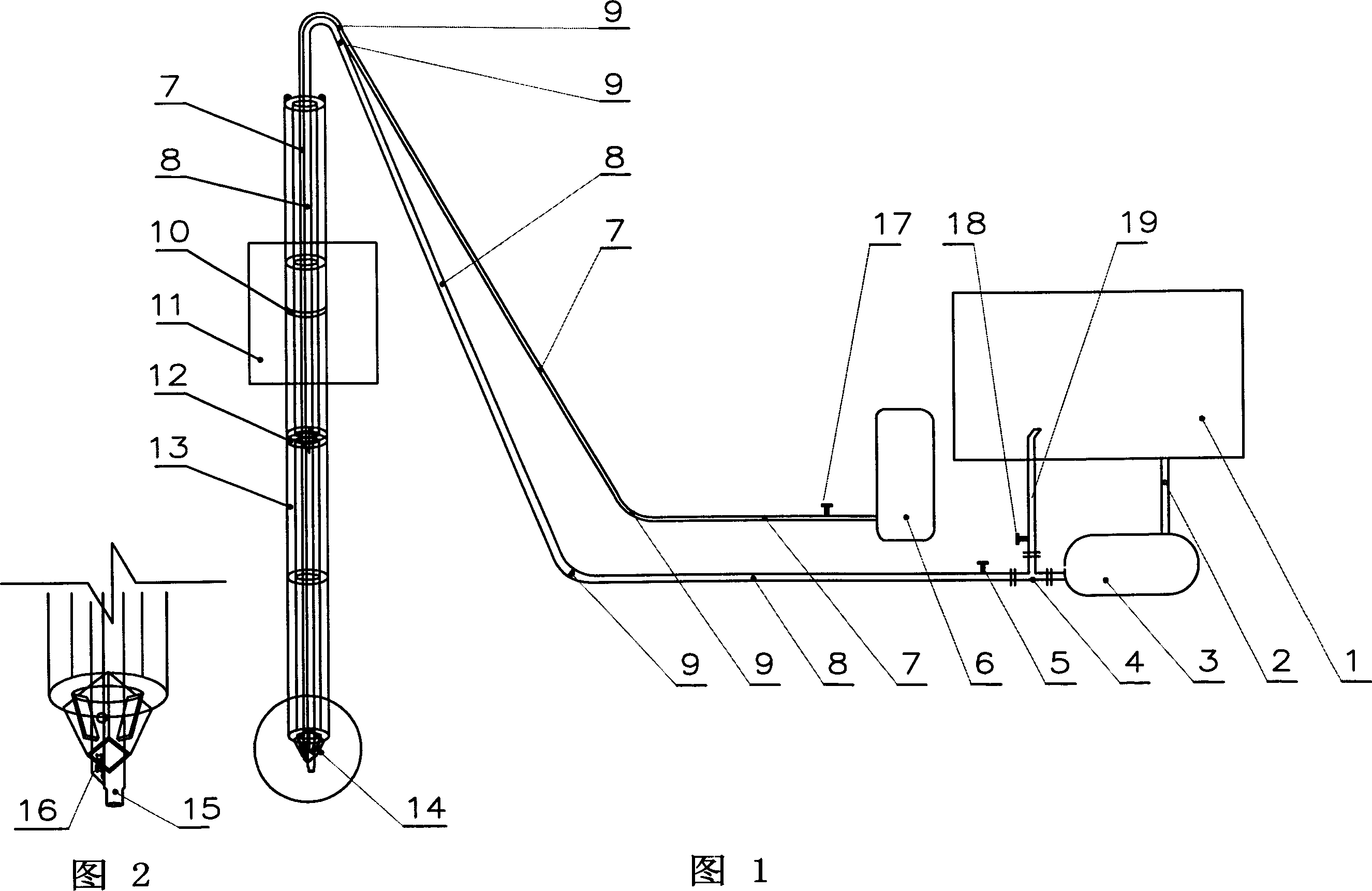

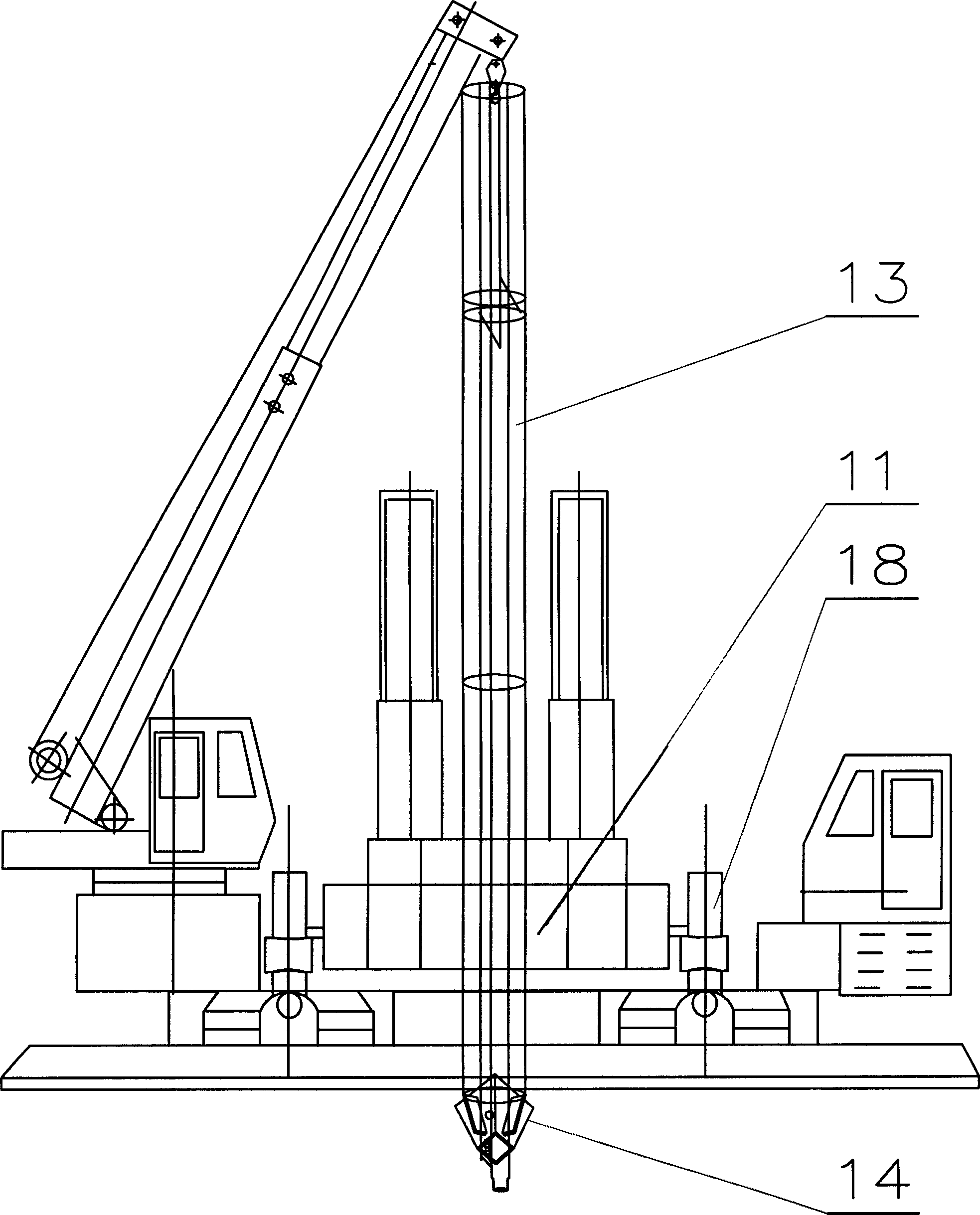

[0017] Embodiment 1 is shown in Figure 1-6:

[0018] A kind of construction equipment for pressure-embracing PHC pipe pile self-guiding hole static pressure into rock, the hydraulic control pile clamp (11) of the conventional full hydraulic static pile driver (20) clamps the pile feeder (12) , the latter is socketed and fixed on the outer wall of the hollow pipe pile and the steel plate at the end of the pile; the hydraulic control pile clamp (11) and pile feeder (12) of the conventional full hydraulic static pile driver (20) An annular anti-slip hoop (10) is added between them.

[0019] The present invention continues to use part of the high-pressure water and air grouting equipment in the invention patent with the application number 200610052169.7 "Construction device for anti-rust cap of PHC pipe tip with grouting self-leading hole and its construction technology". One end of the high-pressure water delivery hose (8) penetrates the inner cavity of the hollow pipe pile (13)...

Embodiment 2

[0020] Example 2: A construction process of pressure-embracing PHC pipe piles with self-introducing holes at the pile tip for static pressure entry into rock:

[0021] ① Add an annular anti-slip hoop (10) between the hydraulically controlled pile clamp (11) and the pile feeder (12) of the conventional full hydraulic static pile driver (20), and connect the pile clamp and the pile feeder. The maximum tight-fitting pile pressure between the piles is increased from 550 tons of the traditional static hydraulic pile driver to 600-1200 tons, which can make it difficult to slip when sending piles, and it is easier to enter the rock by static pressure, and when encountering hard gravel There is no need to immediately change the piling method at the layer level, and the static pressure pile can continue to enter the gravel sand layer to a depth within 2m; beyond this depth, the conventional dry static pressure pile into the rock is powerless, and the embrace pressure PHC pipe pile is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com