Method for surface metal coating of flexible strip-like articles and dedicated device therefor

A technology of surface metal and special equipment, applied in metal material coating process, sputtering plating, ion implantation plating and other directions, can solve the problems of not allowing tensile deformation, unsuitable for plating, and unable to withstand higher temperatures , to achieve the effect of eliminating the influence of temperature rise, low cost and good plating permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

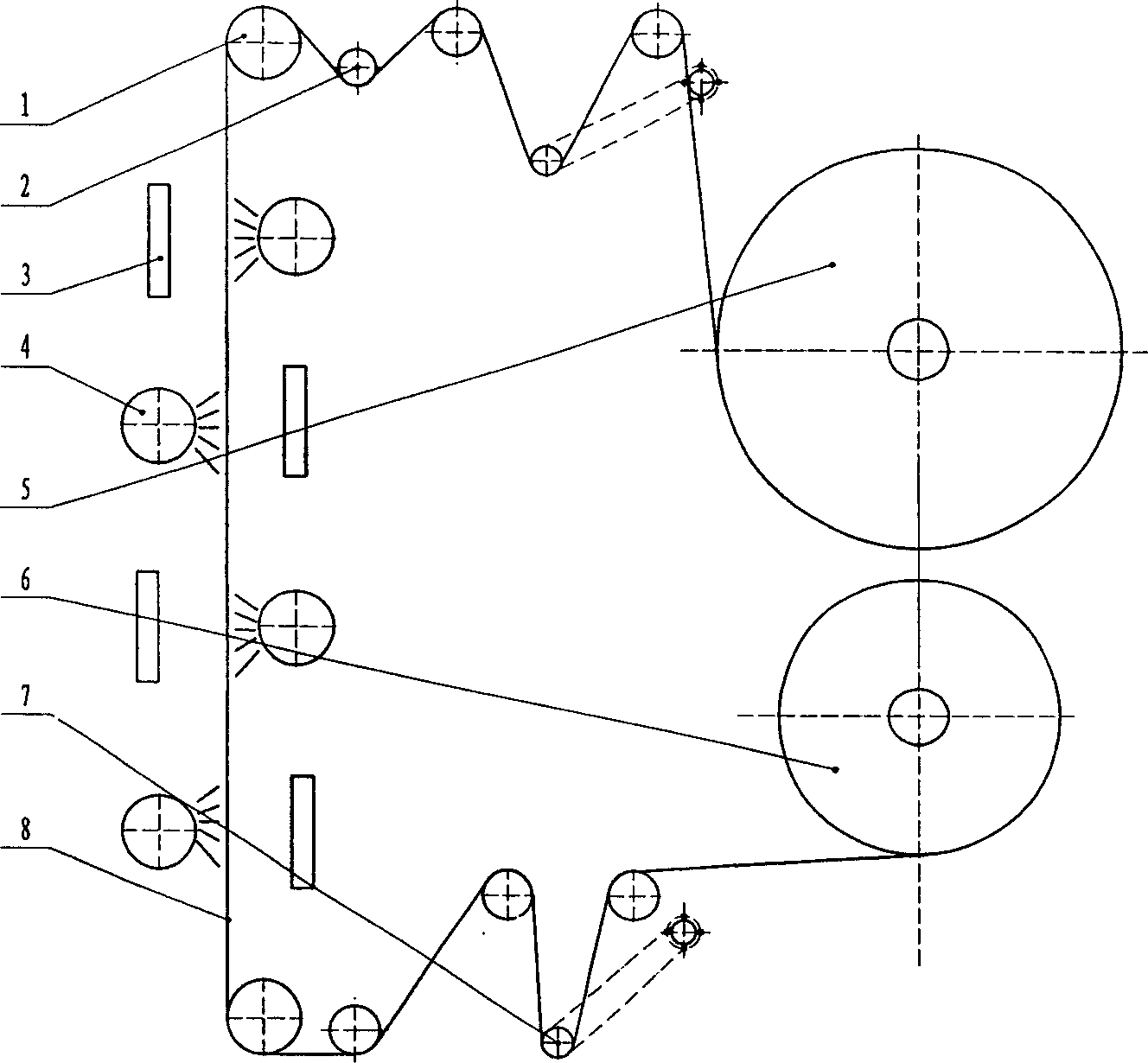

[0019] Depend on figure 1 It can be seen that the present invention is mainly composed of the following parts: vacuum chamber 13, target gate, transmission gate and vacuum system.

[0020] In order to make the vacuum chamber 13 rapidly reach the requirement of vacuum degree and keep the vacuum degree uniform, a set of vacuum system is respectively arranged on both sides of the housing, which is composed of mechanical pump 10, Roots pump 9, diffusion pump 11 and valves, etc. Conventional high vacuum system composed of accessories.

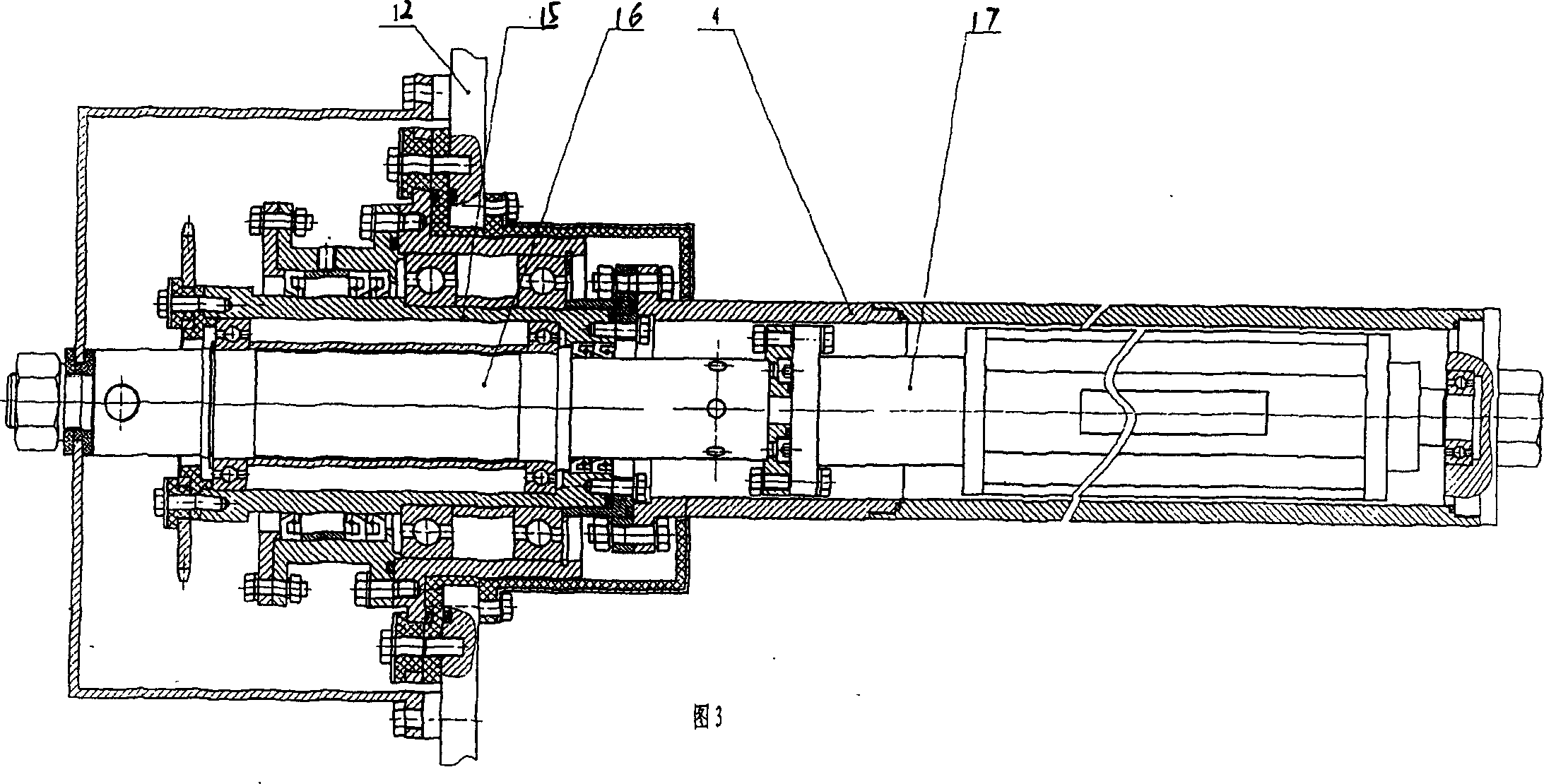

[0021] Depend on figure 1 It can be seen that, except that the vacuum system is installed on both sides, the casing of the present invention also has a transmission moving door 14 and a target moving door 12. For the convenience of operation, the magnetron sputtering target is installed on the target moving door 12, And the coiling mechanism of plated object is then installed on the transmission mobile door 14, and housing is provided with the sea...

Embodiment 2

[0027] The object to be plated 8 starts from the unwinding shaft 5, passes through the guide shaft, then is wound on the winding shaft 5 by the traction shaft 1, and then passes through the transition shaft 2. In the sputtering area, two sets of targets 4 are used to sputter and coat both sides of the object to be plated 8 at the same time, and the metallization coating on both sides of the object to be plated 8 is completed at one time.

[0028] The power of the embodiment of the present invention is 80-100 kilowatts, the voltage is 400-600 volts, and the linear velocity of the coating film is 0.5-10 m / min. It can plate all kinds of flexible strip materials with a width of 500-2000mm and a thickness of 0.05-10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com