Construction technology for waterproof system

A technology of construction technology and waterproof coating, applied in the direction of building components, building insulation materials, etc., can solve the problems of poor integrity and achieve good waterproof performance, excellent penetration, and simple and easy construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

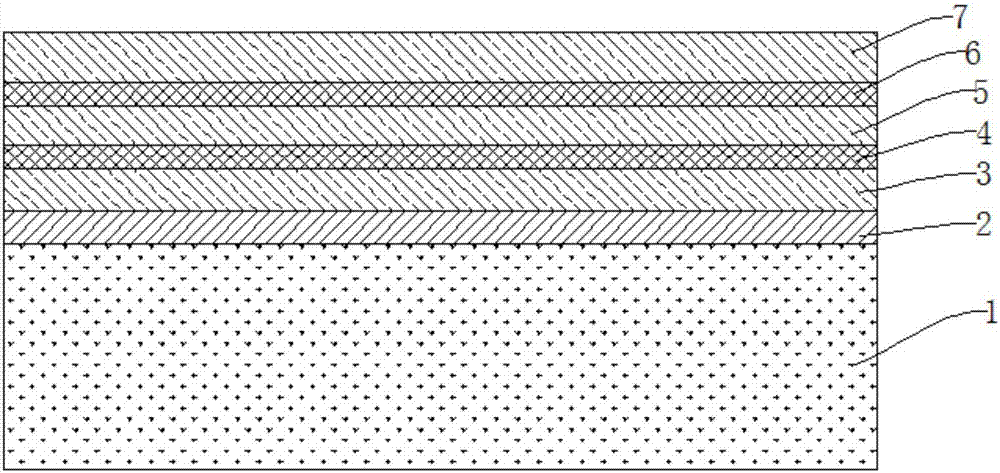

[0026] The construction technique of the waterproof system provided by this embodiment comprises the following steps:

[0027] (a) Base 1 treatment;

[0028] (b) coating the rubber asphalt waterproof coating layer 3 on the base layer 1;

[0029] (c) The first reinforcing layer 4 is laid on the rubber asphalt waterproof coating layer 3;

[0030] (d) Coating the first asphalt compound layer 5 on the first reinforcing layer 4;

[0031] (e) laying the second reinforcing layer 6 on the first asphalt compound layer 5;

[0032] (f) The second reinforcement layer 6 is coated with the second asphalt size layer 7 .

[0033] The rubber asphalt waterproof coating layer 3, the first asphalt rubber material layer 5 and the second asphalt rubber material layer 7 of the present embodiment are all asphalt-based coatings, which are compatible and can be integrated. The rubber asphalt waterproof coating layer 3 and the base layer 1. It can be firmly bonded; the first asphalt rubber layer 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com