Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109 results about "Particulate media" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

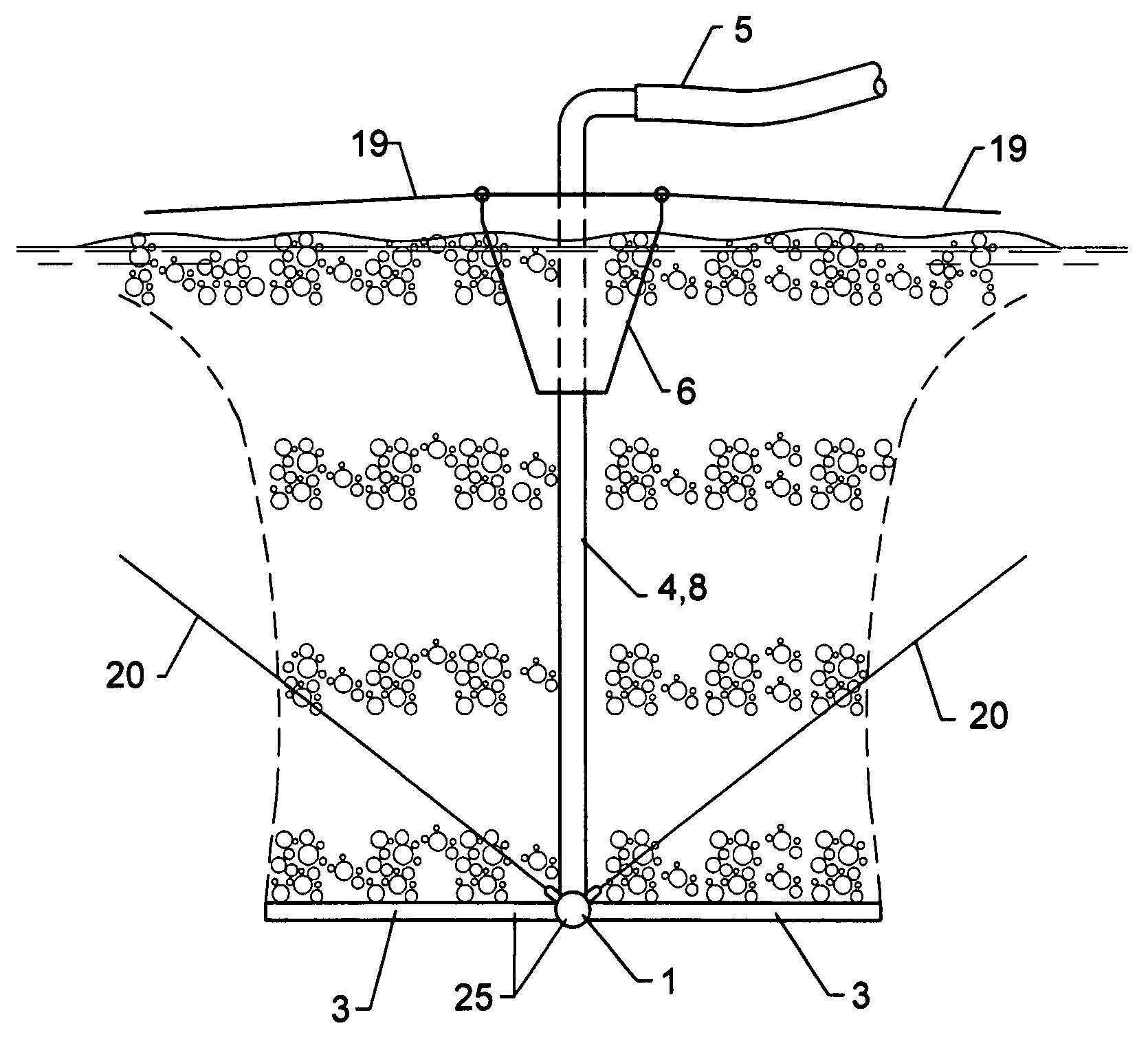

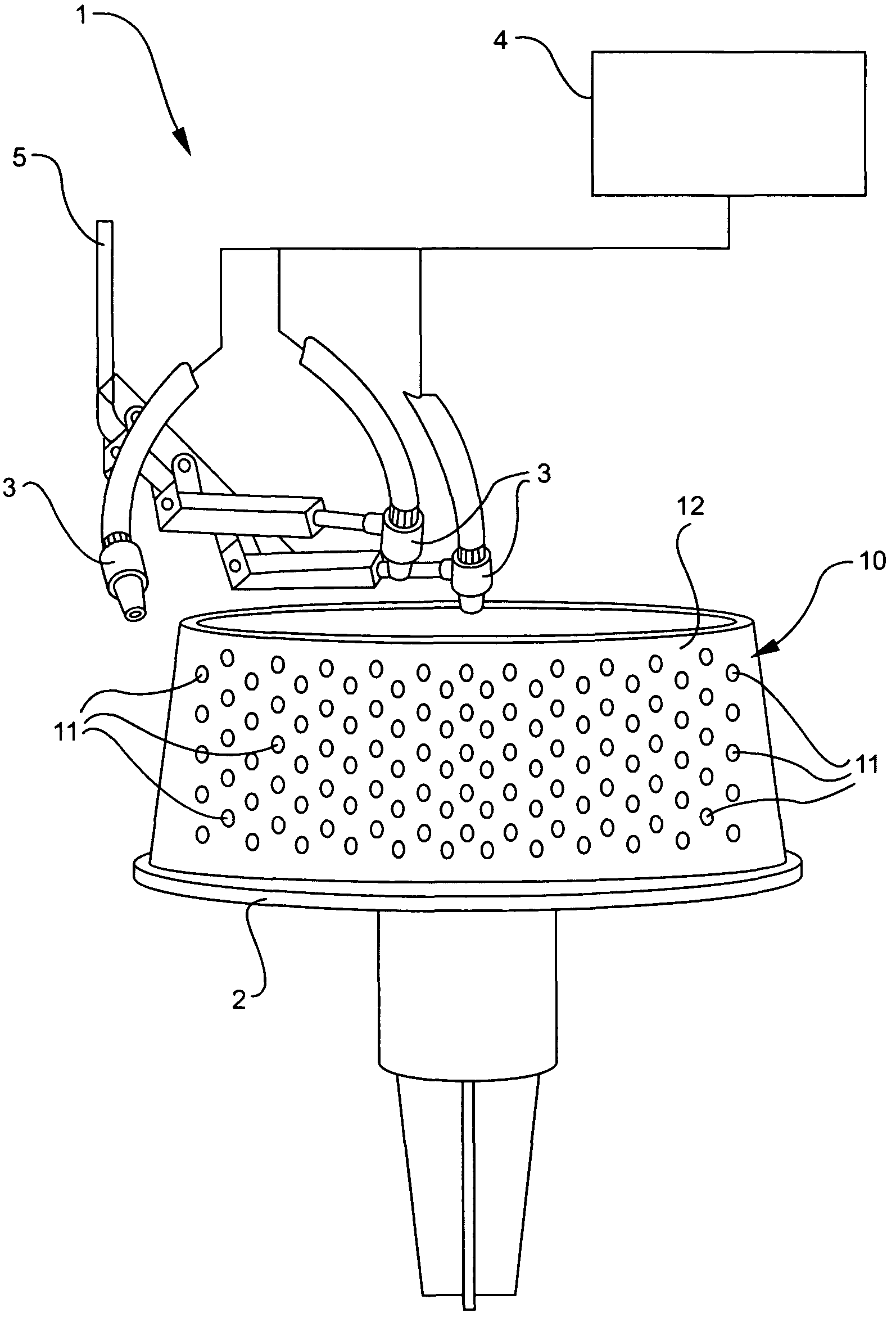

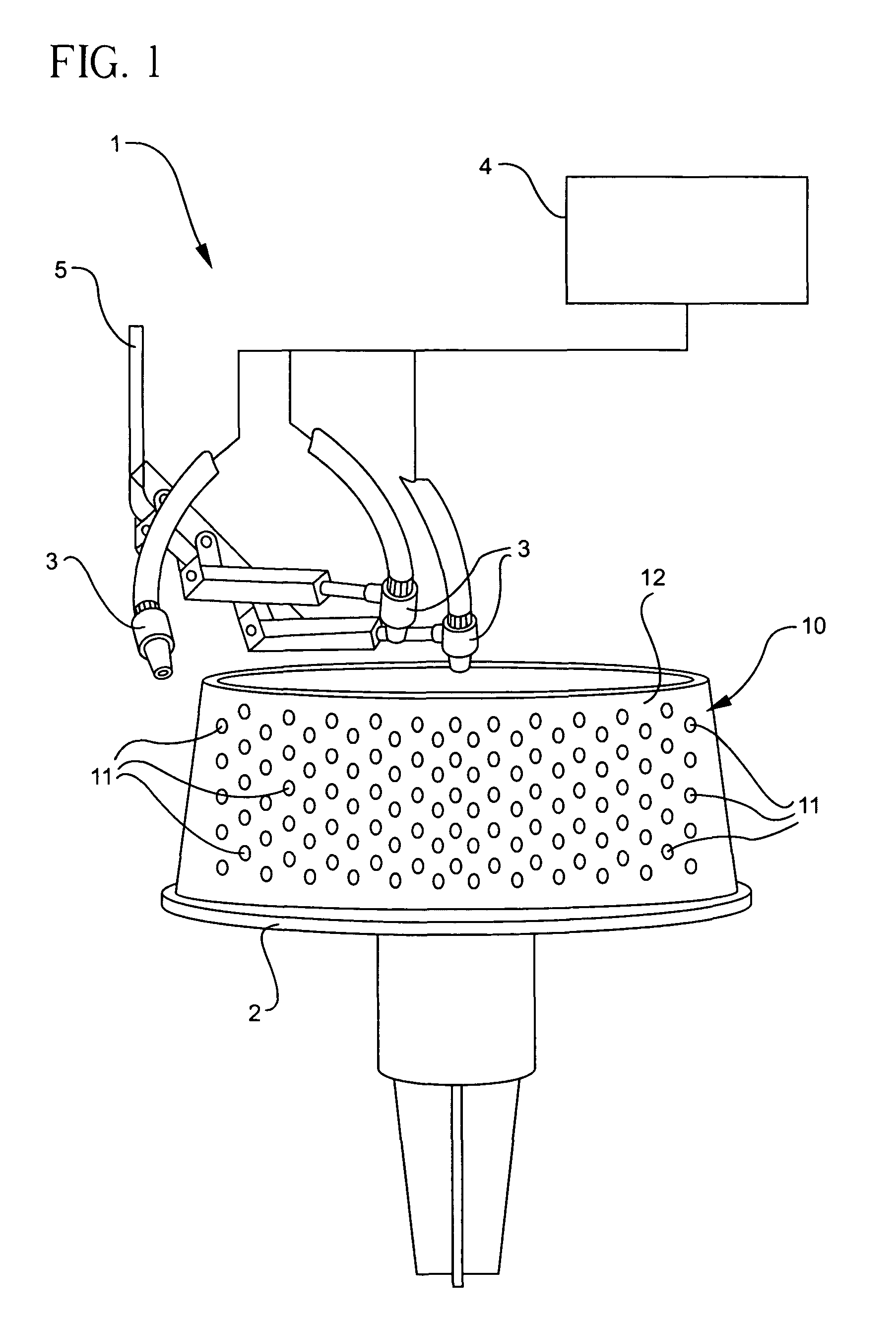

Pulsating reactors

InactiveUS20050098497A1High densityTreatment using aerobic processesTransportation and packagingFlocculationLiquid medium

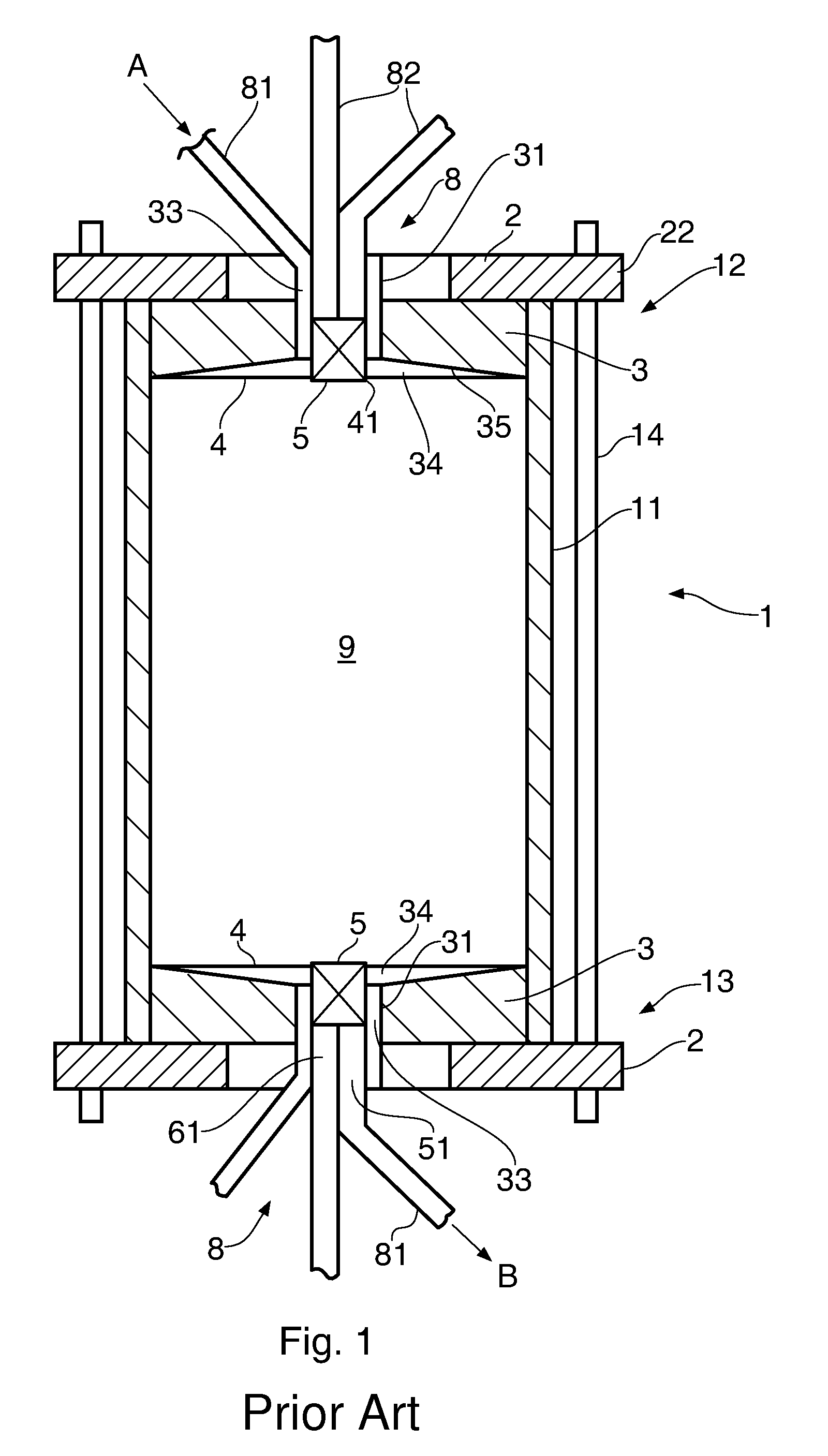

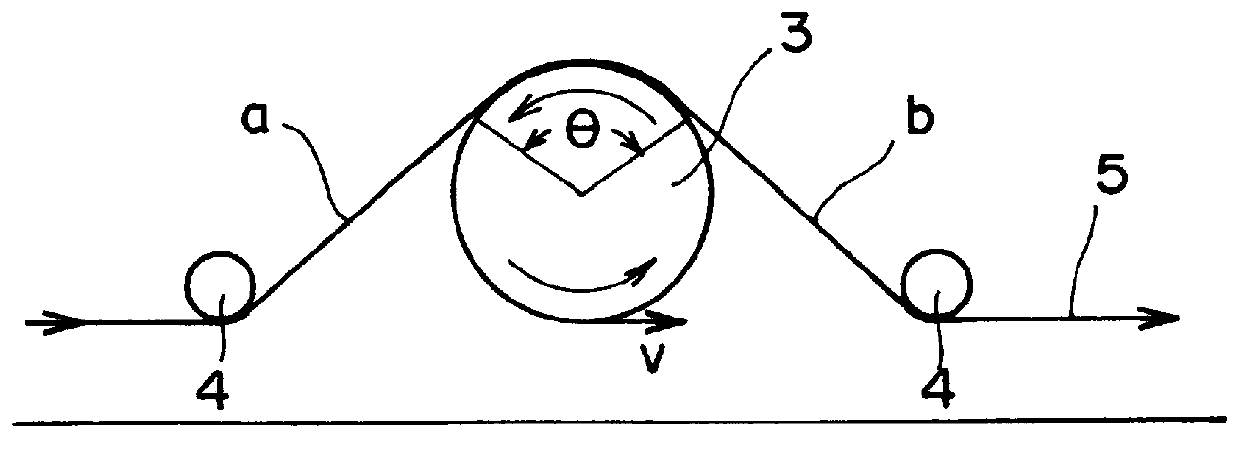

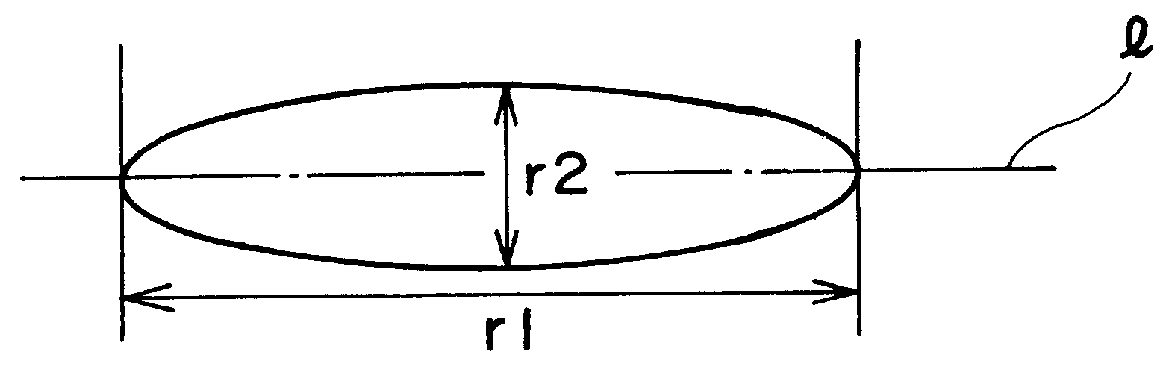

This is a method and apparatus for treatment of liquid media making use of at least one float positioned at the top of the liquid and at least one gas diffuser placed under the float and connected to this float by at least one brace, the diffuser is connected to a gas source by at least one flexible conduit. The gas emitted from the diffuser produces a mixture with liquid having density lower than the liquid and the float partially sinks in the liquid thus increasing the submergence of the diffuser and lowering the gas flow through the diffuser. At increased submergence, the gas flow is reduced, the mixture density increases, and the float rises. A repeatable motion up and down of the float-diffuser is established producing pulsations in the liquid. The method and apparatus can be used in a multitude of chemical, pharmaceutical, petrochemical, environmental and other industries for carrying out mass transfer, chemical and biological transformations, phase separations, thickening of suspensions, mixing, suspending of particles, washing, coagulation-flocculation, membrane filtration, filtration across particulate media, filtration across floating media, mass transfer across membrane, and other processes.

Owner:KHUDENKO BORIS MIKHAILOVICH

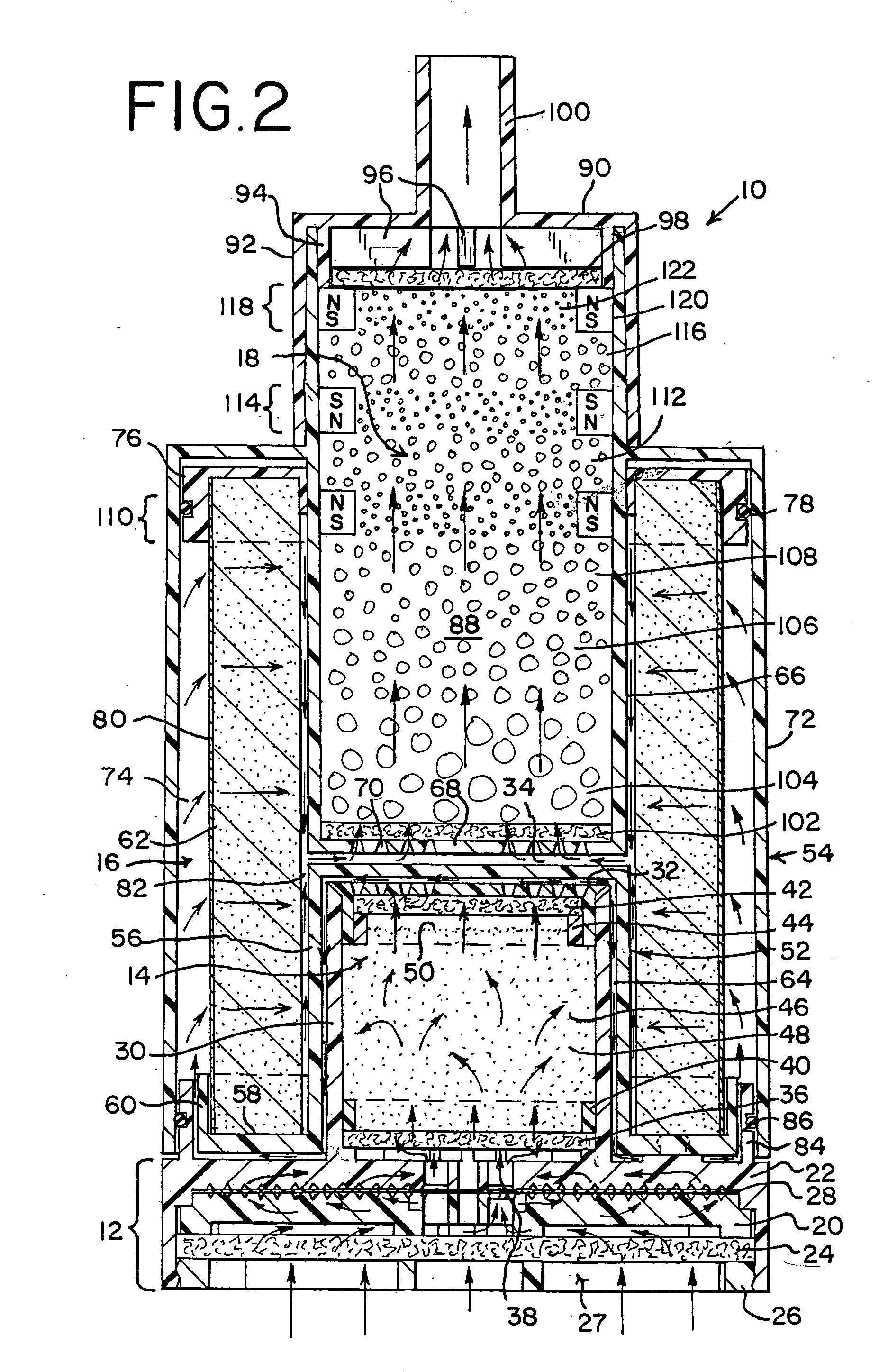

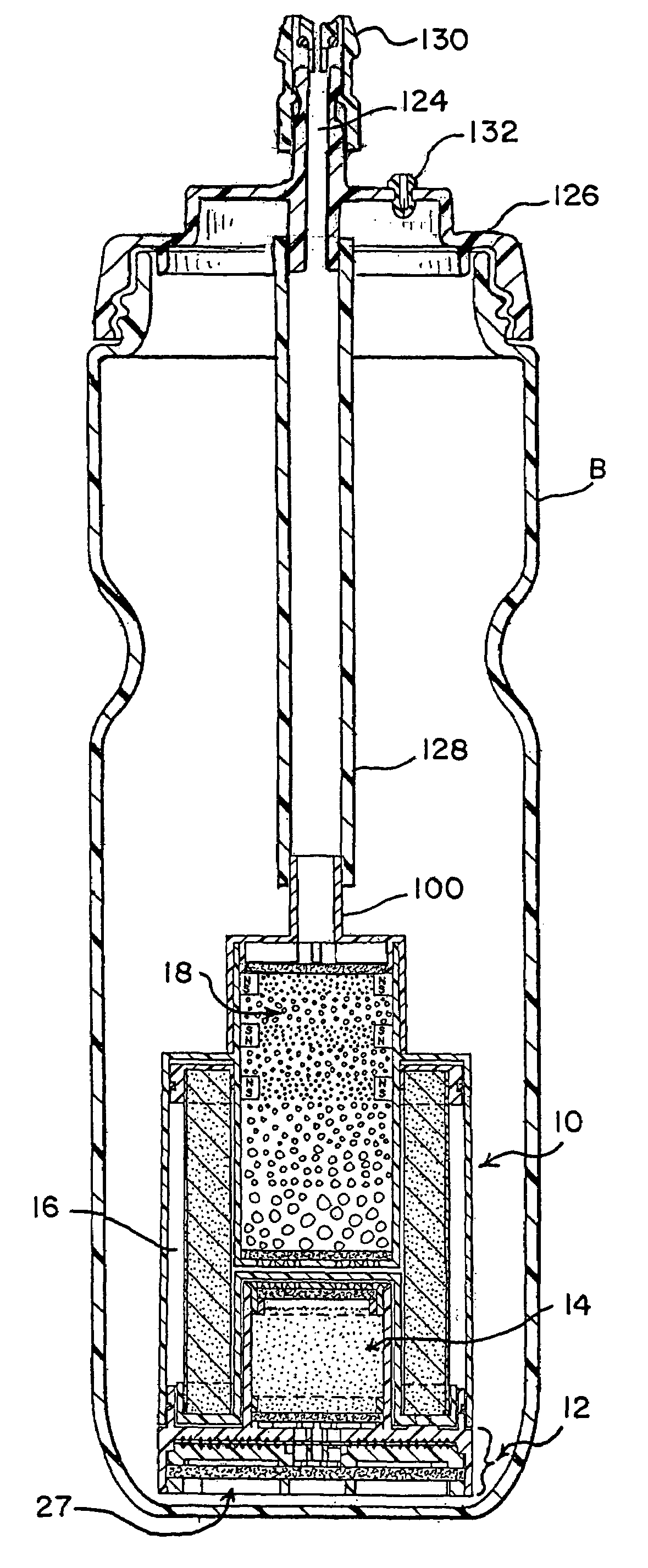

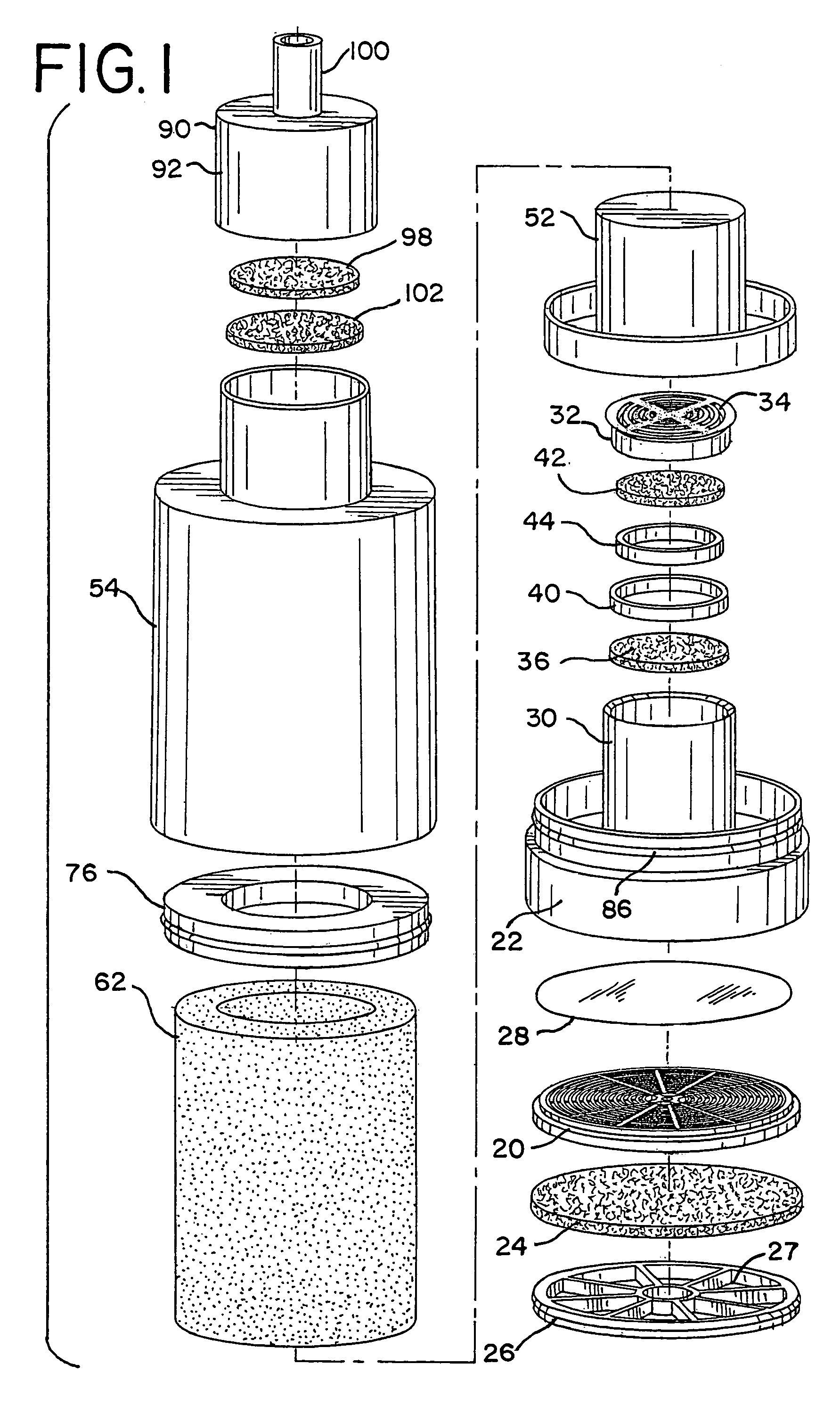

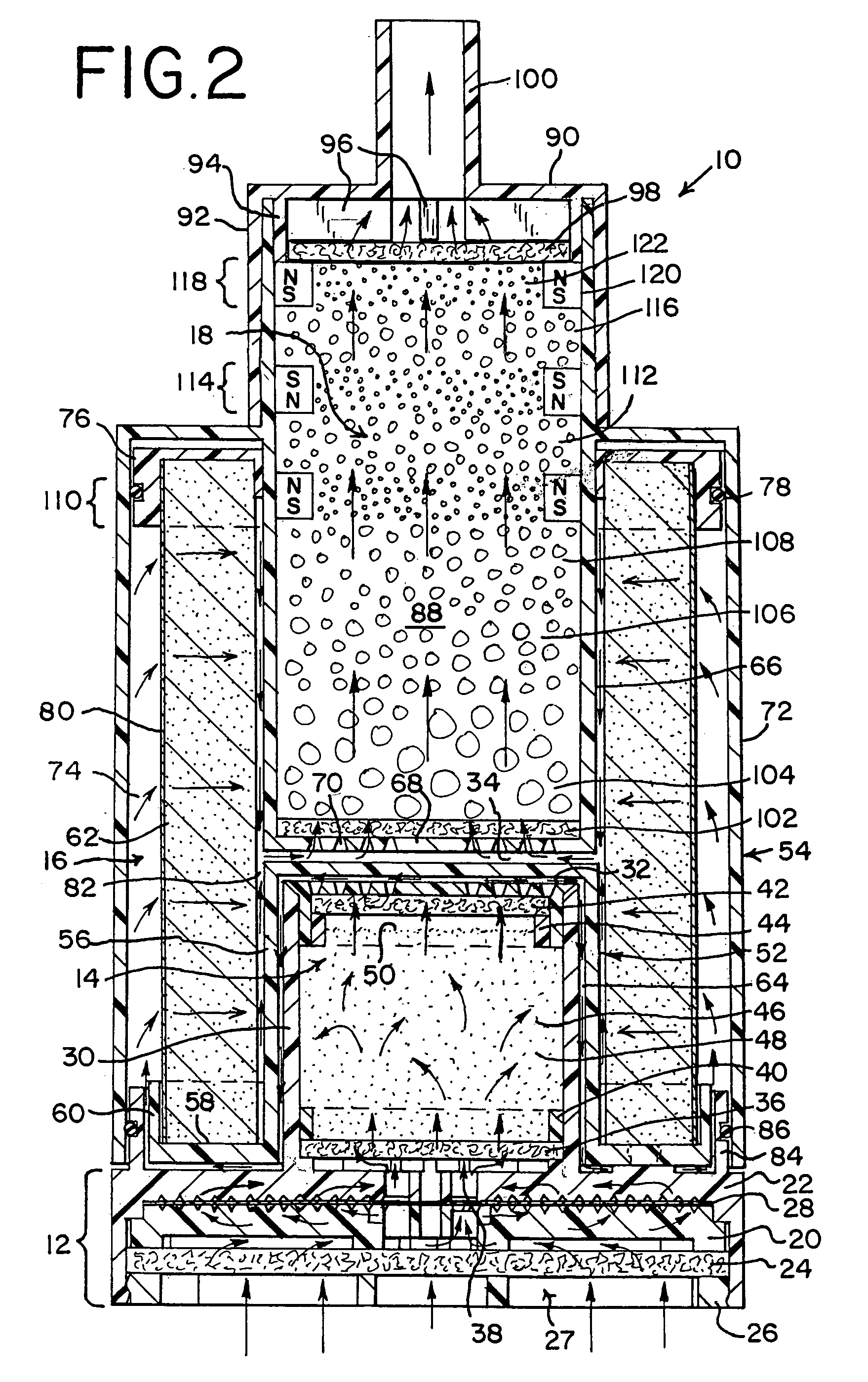

Water treatment unit for bottle or pitcher

InactiveUS20050252844A1Convenient to accommodateExhaust fastTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsBottleTreated water

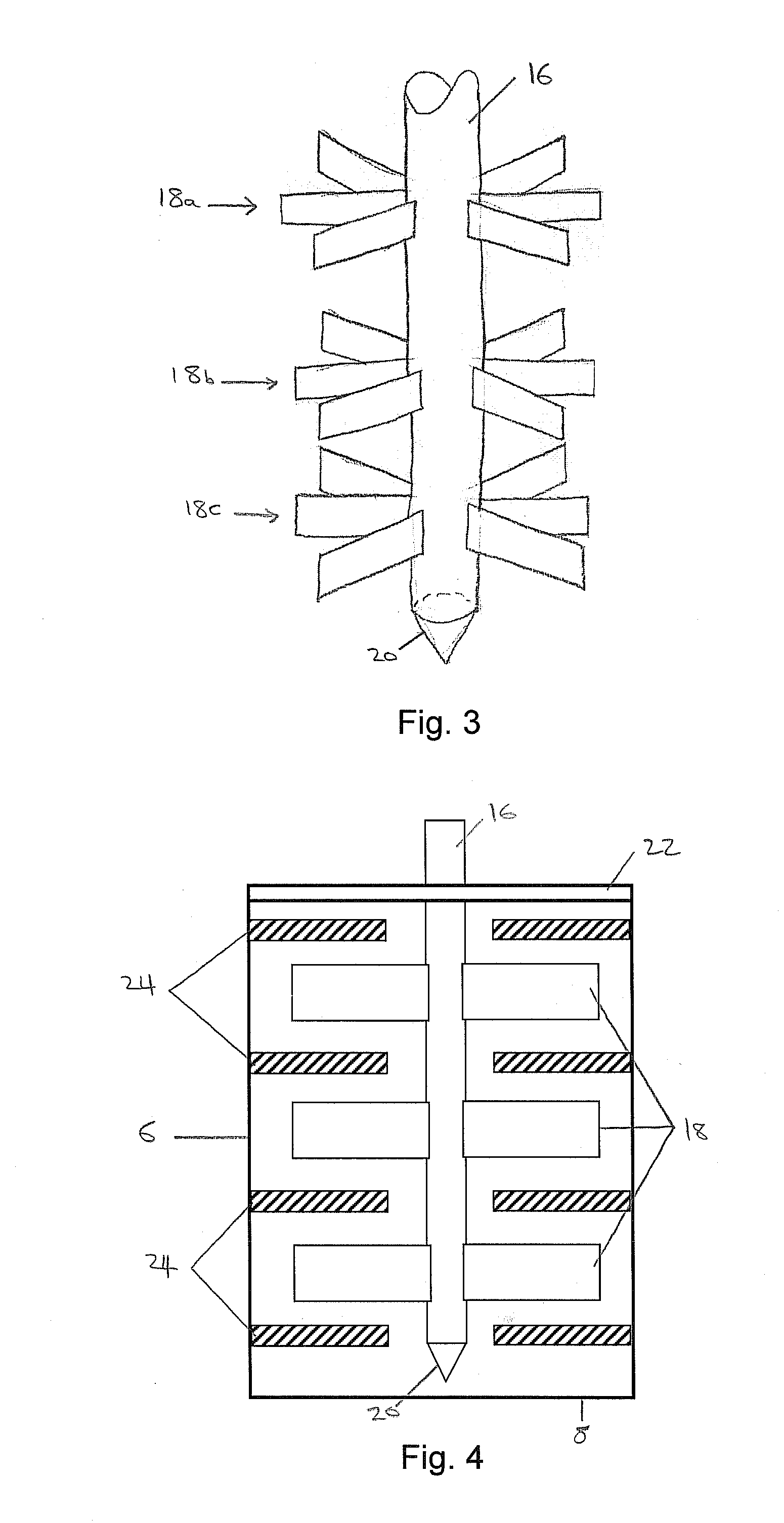

A water treatment unit for positioning in a sport bottle or container for treating water includes a prefilter section, a pretreatment section, a treatment section and a post treatment section. A first chamber in the pretreatment section contains a first treatment medium which comprises at least one loose particulate medium through which the water to be treated flows in a vertical upward direction during treatment to lift the medium. A second chamber in the treatment section contains a second treatment medium through which the treated water flows in a radial horizontal direction during treatment. And a third chamber in the post treatment section contains a third treatment medium through which the water to be treated flows during treatment.

Owner:CHAU YIU CHAU

Water treatment unit for bottle or pitcher

InactiveUS7427355B2Solution to short lifeSignificant to useTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsBottleTreated water

A water treatment unit for positioning in a sport bottle or container for treating water includes a prefilter section, a pretreatment section, a treatment section and a post treatment section. A first chamber in the pretreatment section contains a first treatment medium which comprises at least one loose particulate medium through which the water to be treated flows in a vertical upward direction during treatment to lift the medium. A second chamber in the treatment section contains a second treatment medium through which the treated water flows in a radial horizontal direction during treatment. And a third chamber in the post treatment section contains a third treatment medium through which the water to be treated flows during treatment.

Owner:CHAU YIU CHAU

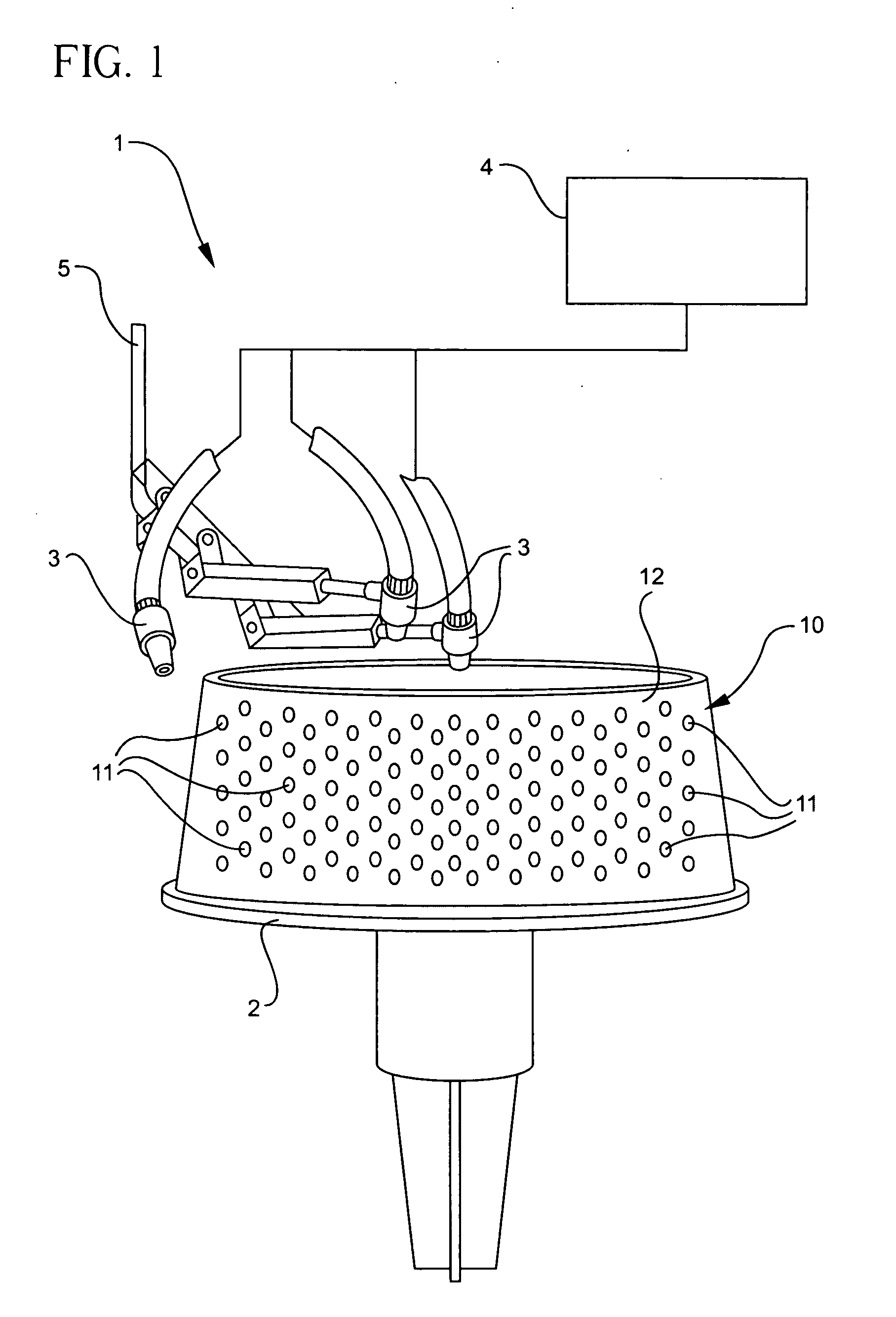

Process for removing thermal barrier coatings

InactiveUS20050126001A1Molten spray coatingHollow article cleaningThermal barrier coatingMetallic substrate

Briefly, the present invention provides a process which uses an air jet containing non-abrasive particulate media at a low pressure which selectively removes thermal barrier coatings from components without damaging the metallic substrate. This process selectively removes thermal barrier coatings from the cooling holes of components.

Owner:TURBOCOMBUSTOR TECH

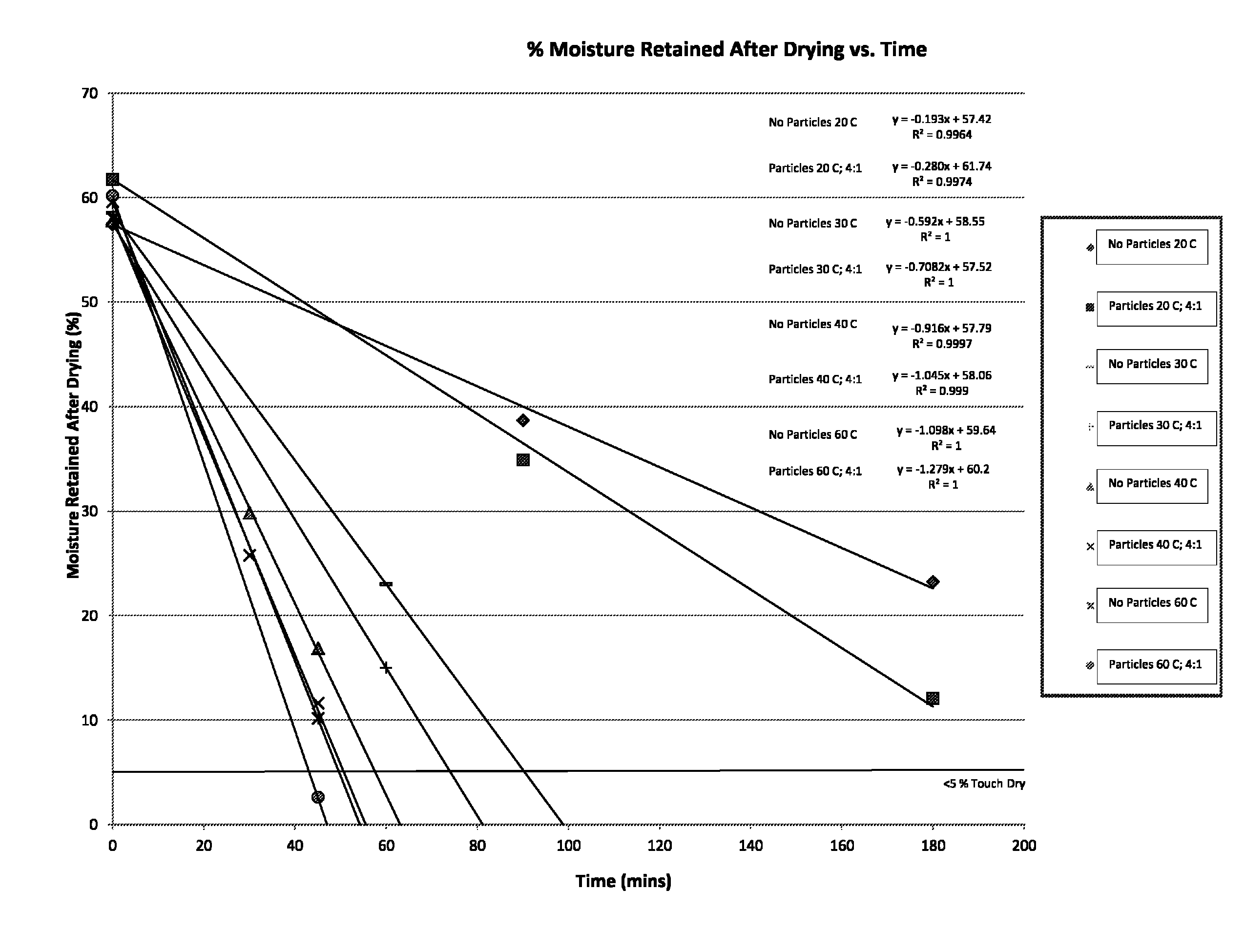

Drying method

InactiveUS9127882B2Facilitate increased mechanical actionKeep dryDrying solid materials with heatTextiles and paperSolid particleEngineering

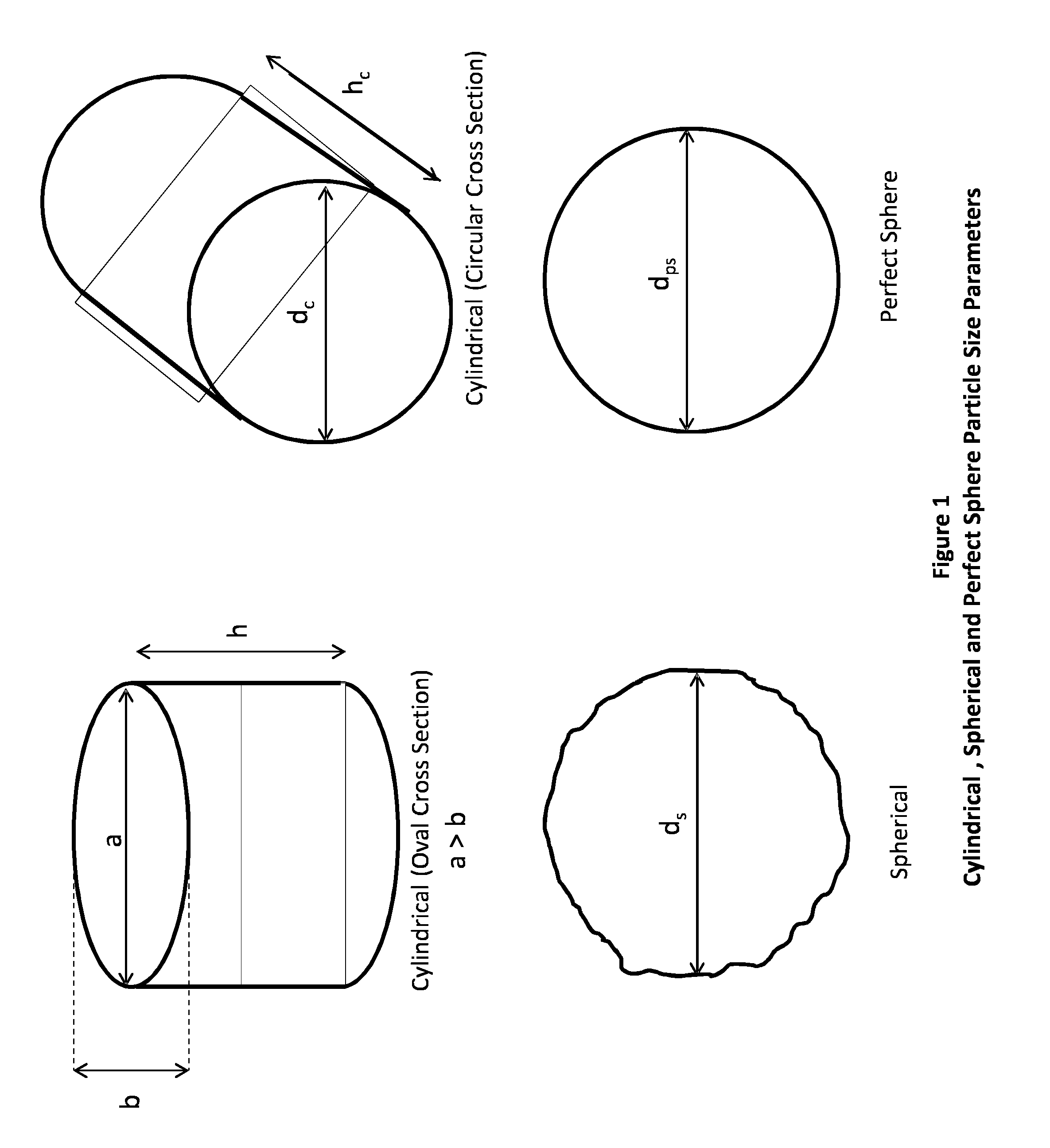

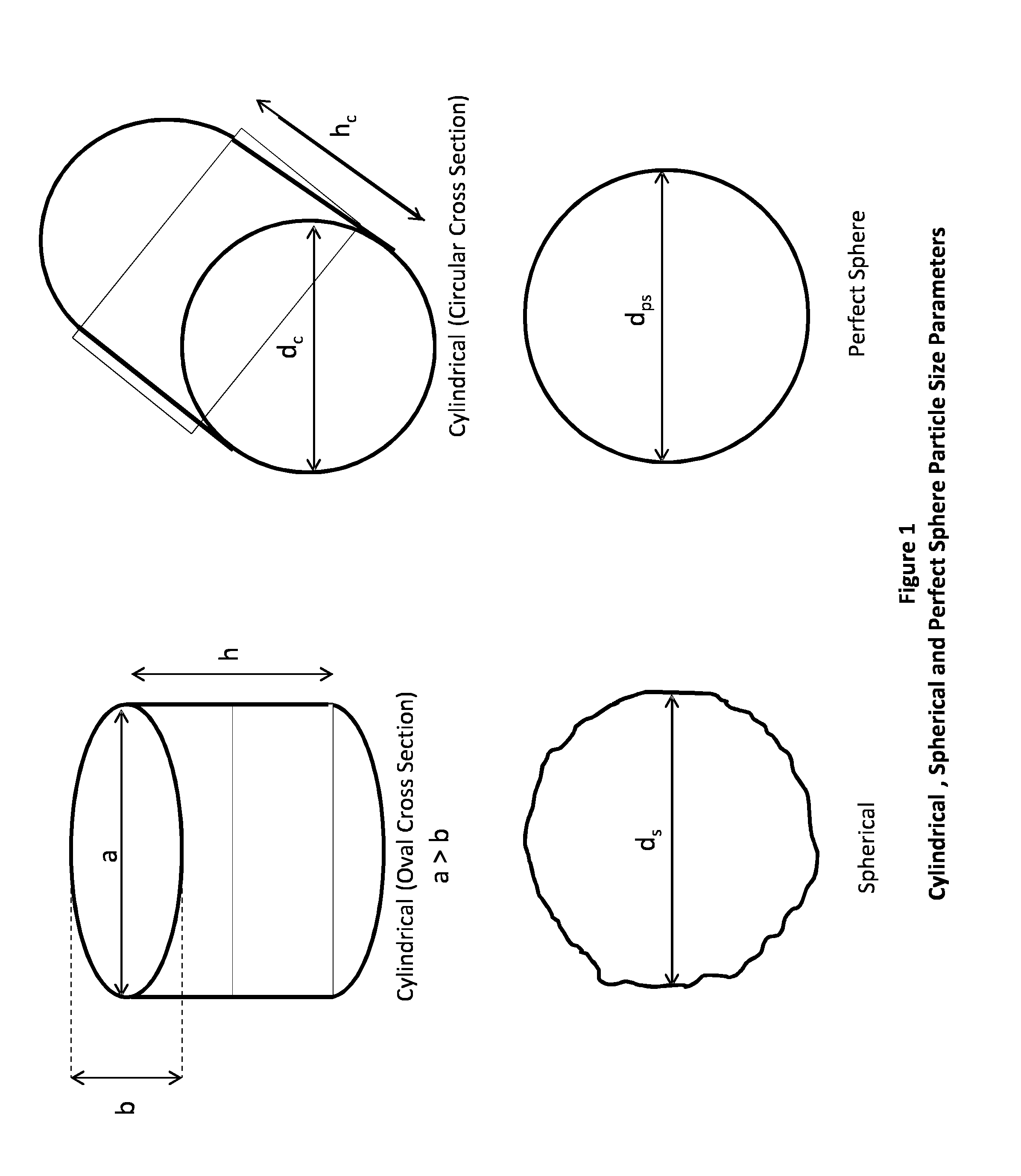

The invention provides a method for the drying of a wet substrate, the method comprising treating the substrate with a solid particulate material at ambient or elevated temperature, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls, wherein the drum comprising perforated side walls is rotated so as to facilitate increased mechanical action between the substrate and the particulate material. Preferably, the drum comprising perforated side walls has a capacity of between 5 and 50 liters for each kg of fabric in the load and is rotated at a speed which generates G forces in the range of from 0.05 to 0.99 G, and the method is carried out at a temperature of between 5° and 120° C. Preferably, the solid particulate material comprises a multiplicity of particles at a particle to fabric addition level of 0.1:1-10:1 by mass, wherein the particles comprise polymeric particles, non-polymeric particles, or mixtures of polymeric and non-polymeric particles. All particles may be solid or hollow in their structure, have smooth or irregular surface features, and are of such a shape and size as to allow for good flowability and intimate contact with the wet substrate. The invention provides optimum drying performance as a result of improved mechanical interaction between substrate and particulate media and is preferably used for the drying of textile fabrics. The method allows for significant reduction in the consumption of energy when compared with the conventional tumble drying of textile fabrics, and also facilitates reduced textile fabric damage.

Owner:XEROS LTD

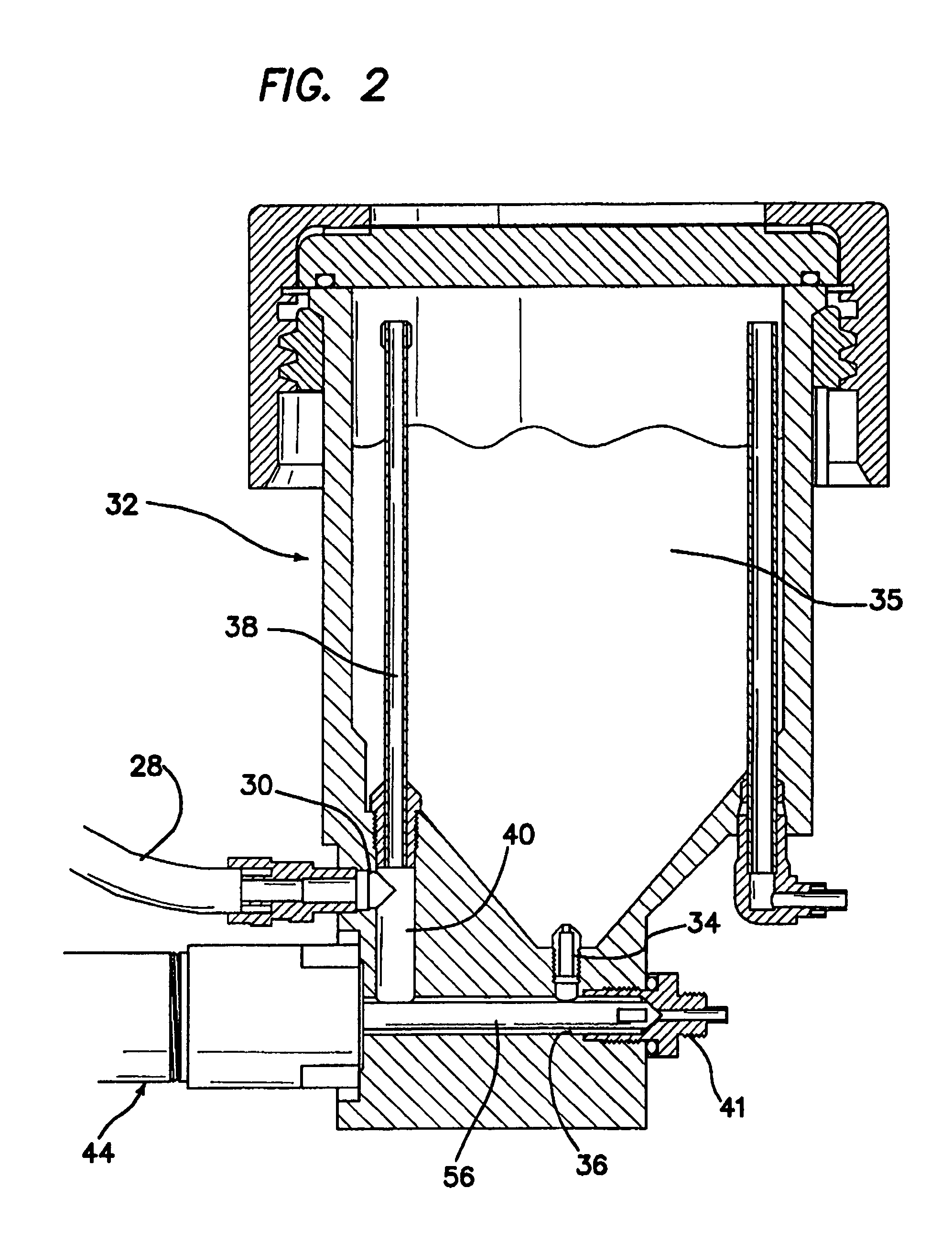

Packing system and method for chromatography columns

ActiveUS20080217248A1Improve bed stabilityHigh column efficiencyIon-exchange process apparatusComponent separationChromatography columnParticulate media

The invention relates to a system for packing chromatography columns with a chromatography medium and packing method for use in such columns. In particular, the invention relates to a method and system for packing chromatography columns which utilises an external drive means to compress a bed of particulate medium to a target bed height.

Owner:CYTIVA BIOPROCESS R&D AB

Treatment of liquid using porous polymer containment member

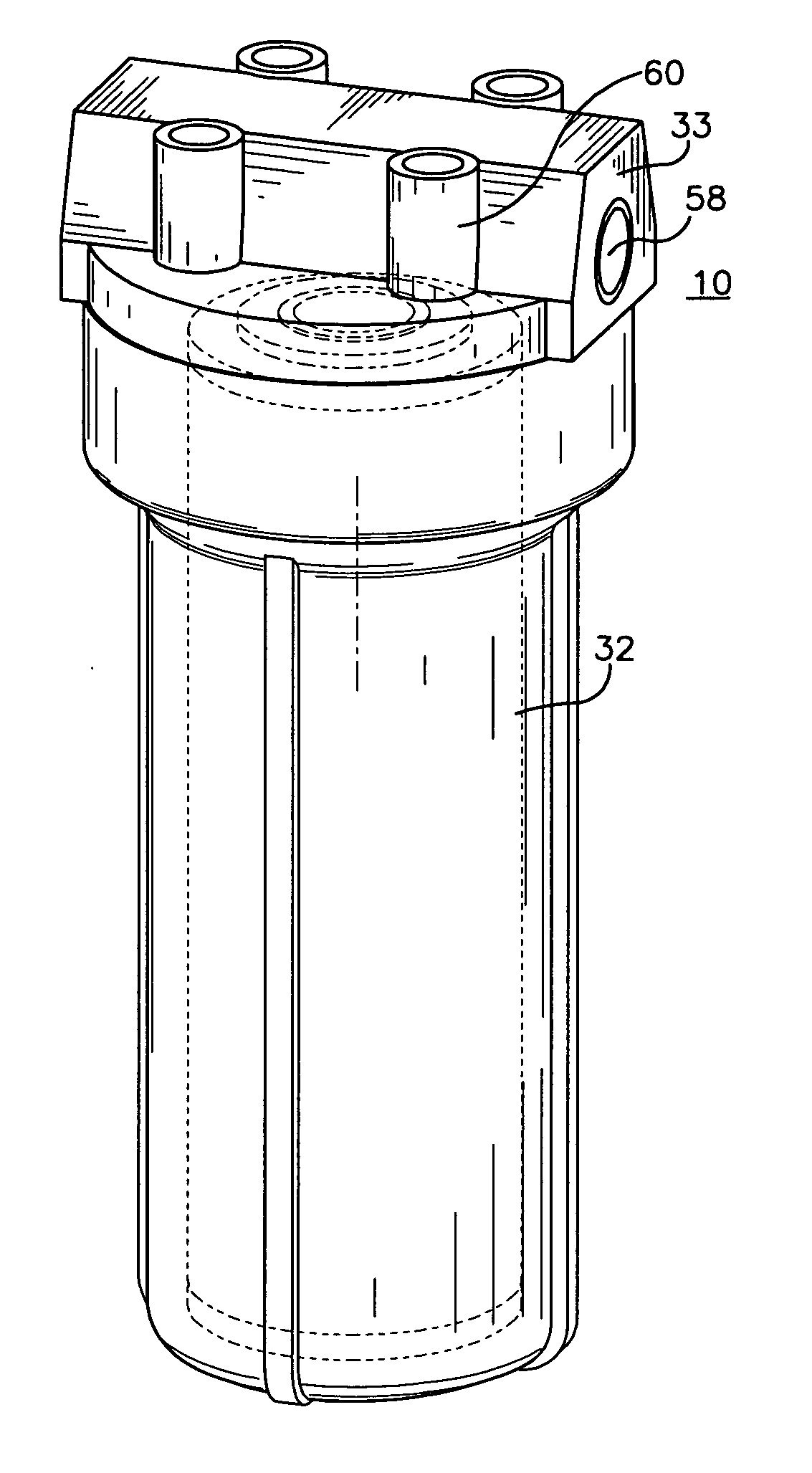

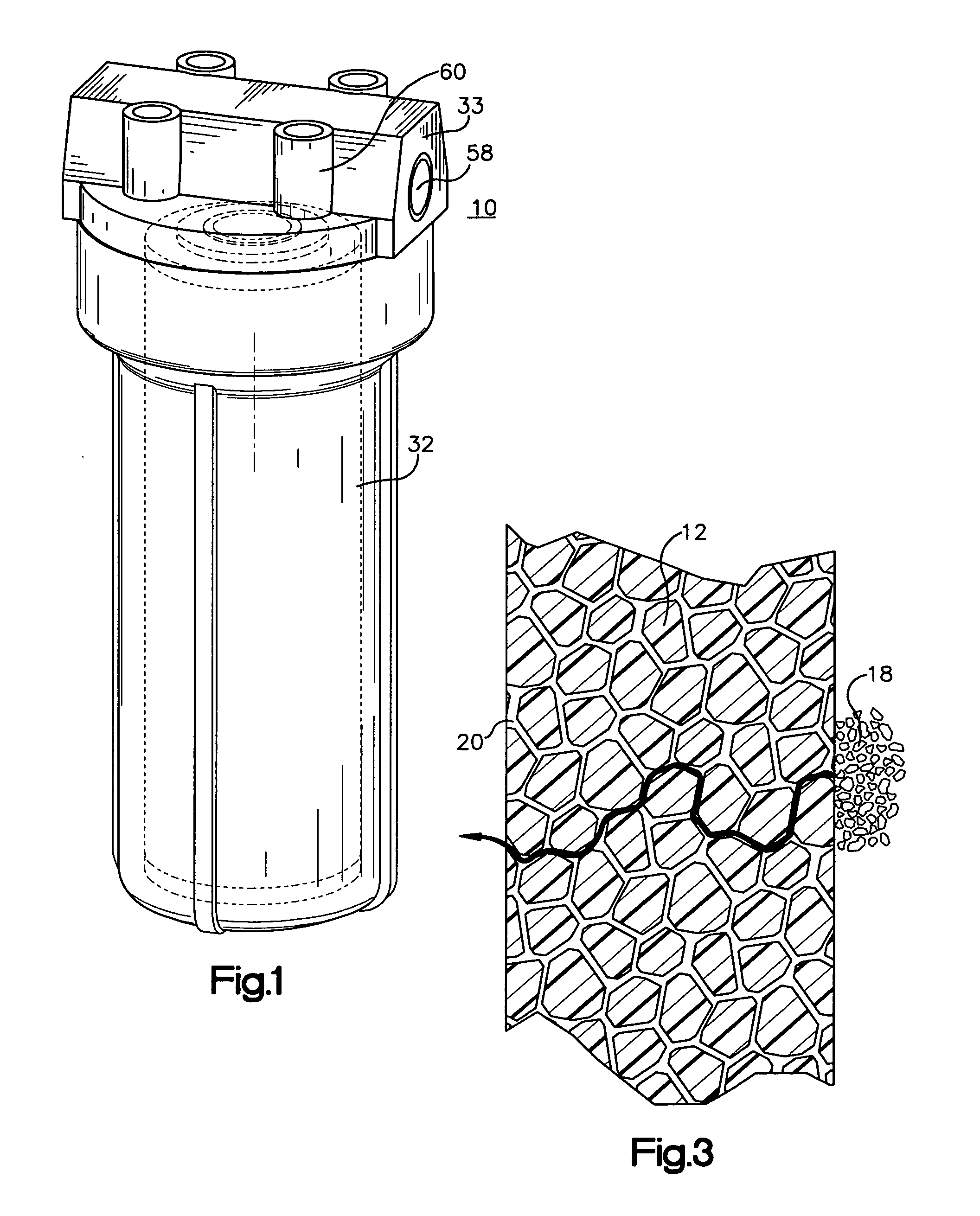

InactiveUS20050077246A1Reliable and economical to fabricateEconomical and reliable operationCation exchanger materialsIon-exchanger regenerationEngineeringParticulate media

The present invention features a device for treating liquid including a containment member comprised of rigid porous polymer configured to form a containment space. Nonbonded particulate media is disposed in the space in contact with and contained by the containment member. Pores in the containment member are characterized by pore paths and pore sizes effective to permit flow of liquid through the pores while preventing the media from traveling through the pores. The containment member may be in various shapes and include different numbers of components. One variation of the containment member includes first and second containment layers comprised of the rigid porous polymer, which are configured and arranged so as to form a space therebetween in which the media is contained. Another variation of the containment member includes first and second porous polymer tubes forming a space in which the media is contained. Also featured is a method of using the device. Another aspect of the invention is a system that includes the device and a pH adjuster device that may function as an acidifier or basifier, which improves the performance of the liquid treatment device in removing substances from liquids by raising or lowering the pH of the influent traveling through the media of the liquid treatment device.

Owner:MAGNESIUM ELEKTRON INC

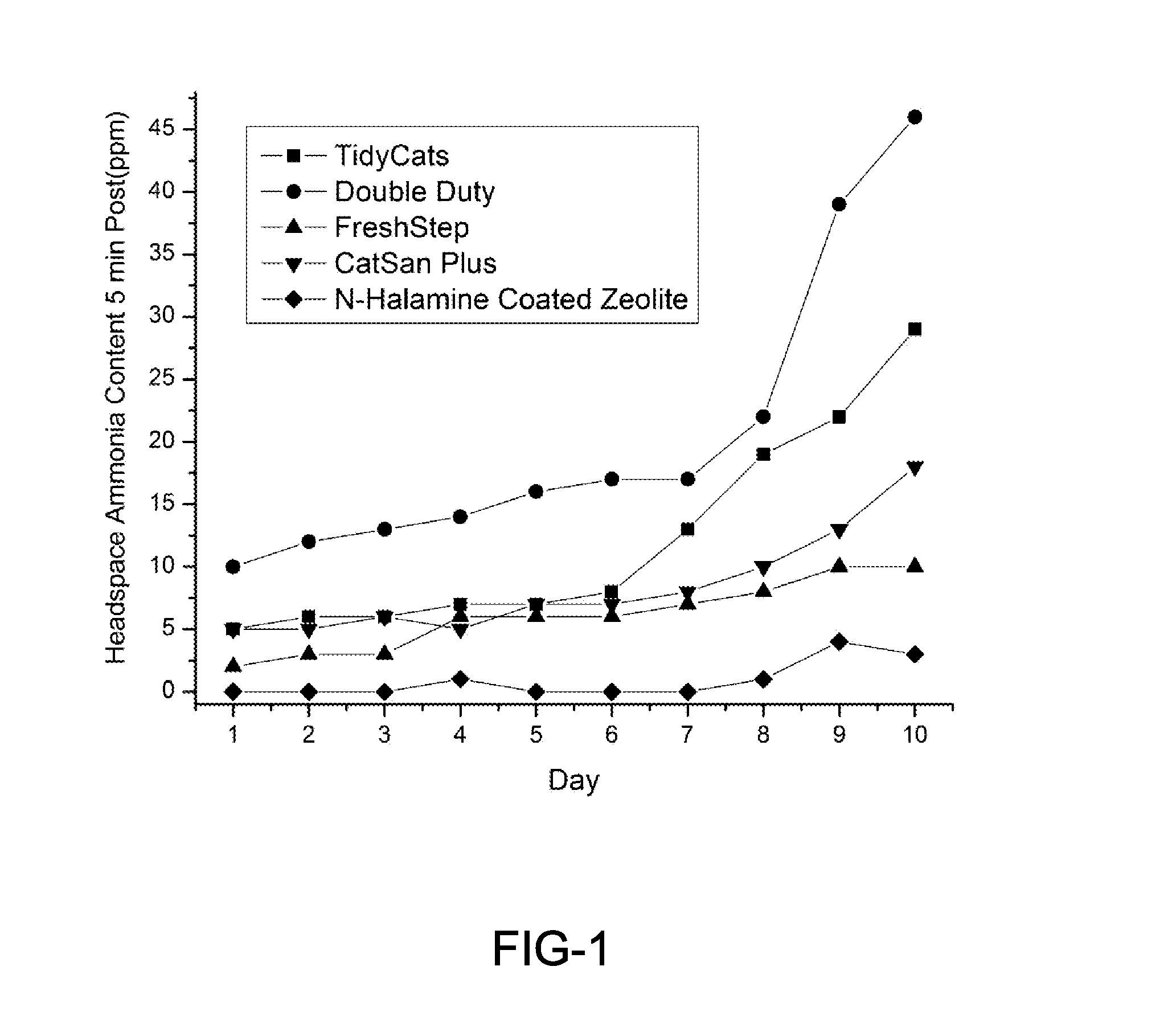

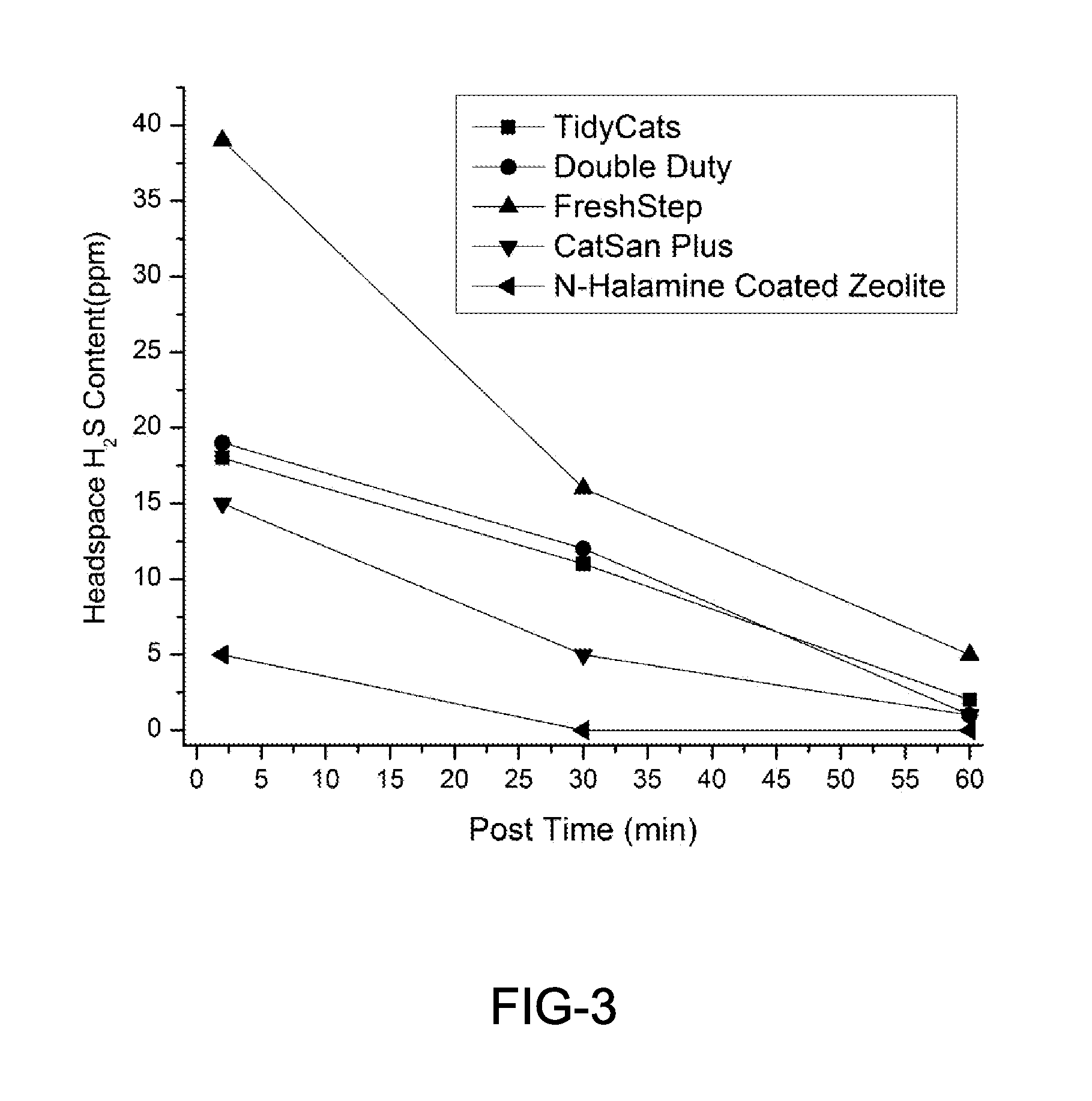

Antimicrobial compositions and methods with novel polymeric binding system

ActiveUS20160058008A1Reduce odorStrong binding/stabilizing capabilityBiocidePretreated surfacesSkin damageAnimal skin

The present invention includes multifunctional compositions, methods and binding systems to provide disinfecting and deodorizing coatings for hard and soft surfaces, inorganic and organic solid surfaces and particulate media and other related substrates, including human and animal skin and skin lesions; to provide neutralizing functions for malodors generated by both human, animal and industrial fluids and solid wastes; and to provide neutralizing and degrading functions for nuisance and noxious chemicals. The present invention provides compositions and methods for producing disinfecting, oxidizing and enzyme-inhibiting fluids enabling preparation of durable, stable biocidal and deodorizing coatings and media which can be widely used for biological agent control, prevention and elimination of odors, and degradation of noxious agents susceptible to chemical oxidation, and which take forms that are inoffensive to users and offer high convenience.

Owner:OXISCI LLC

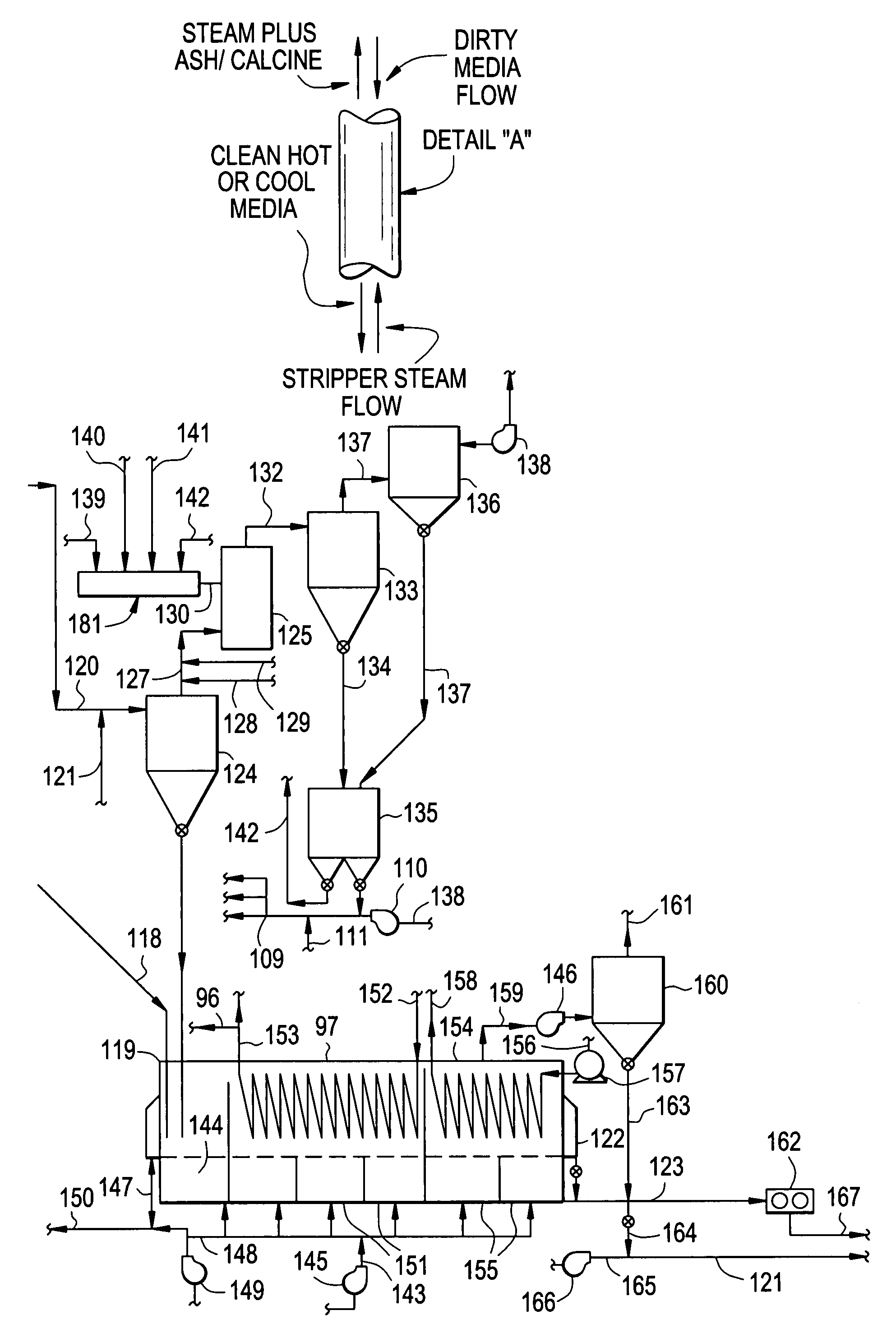

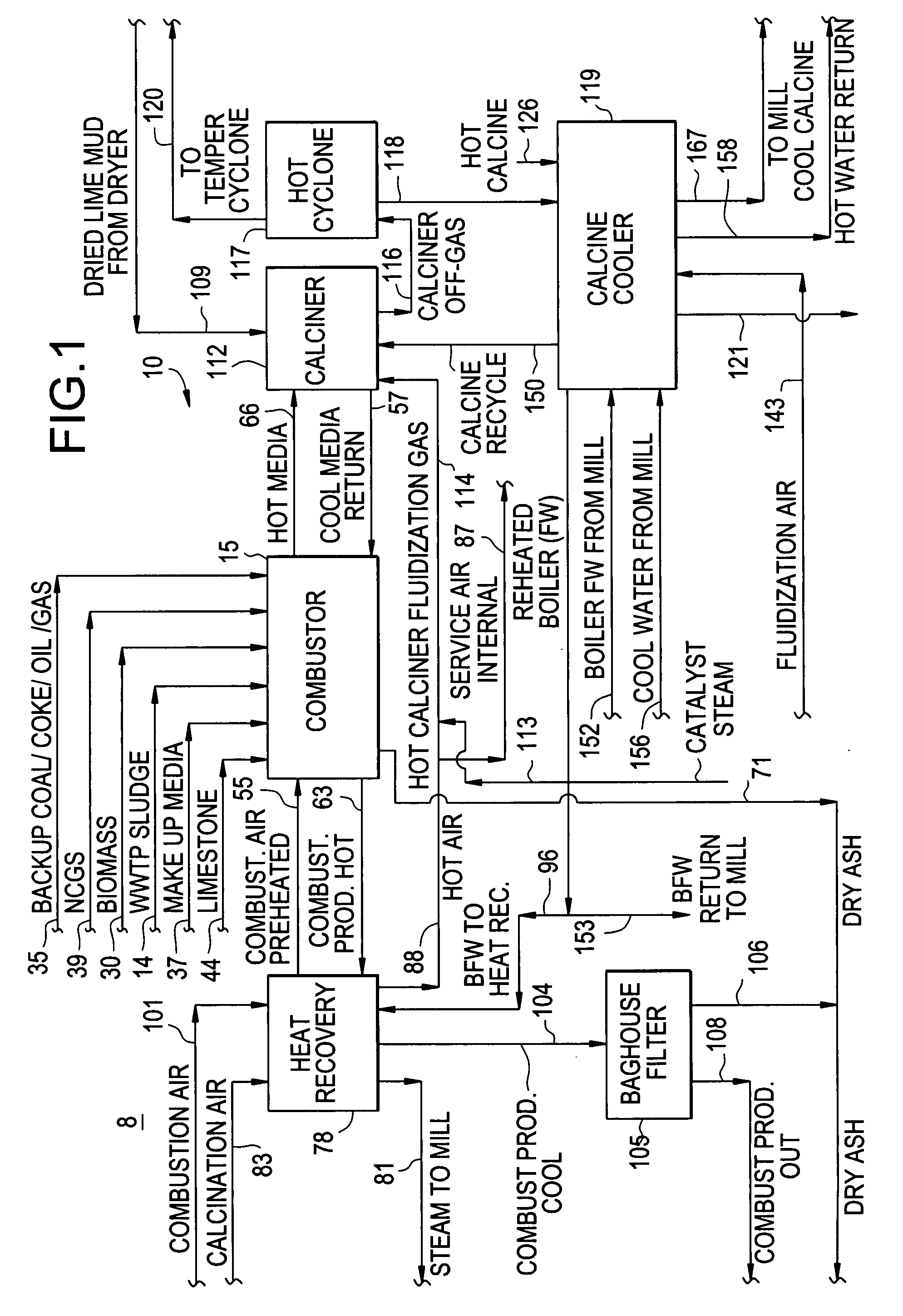

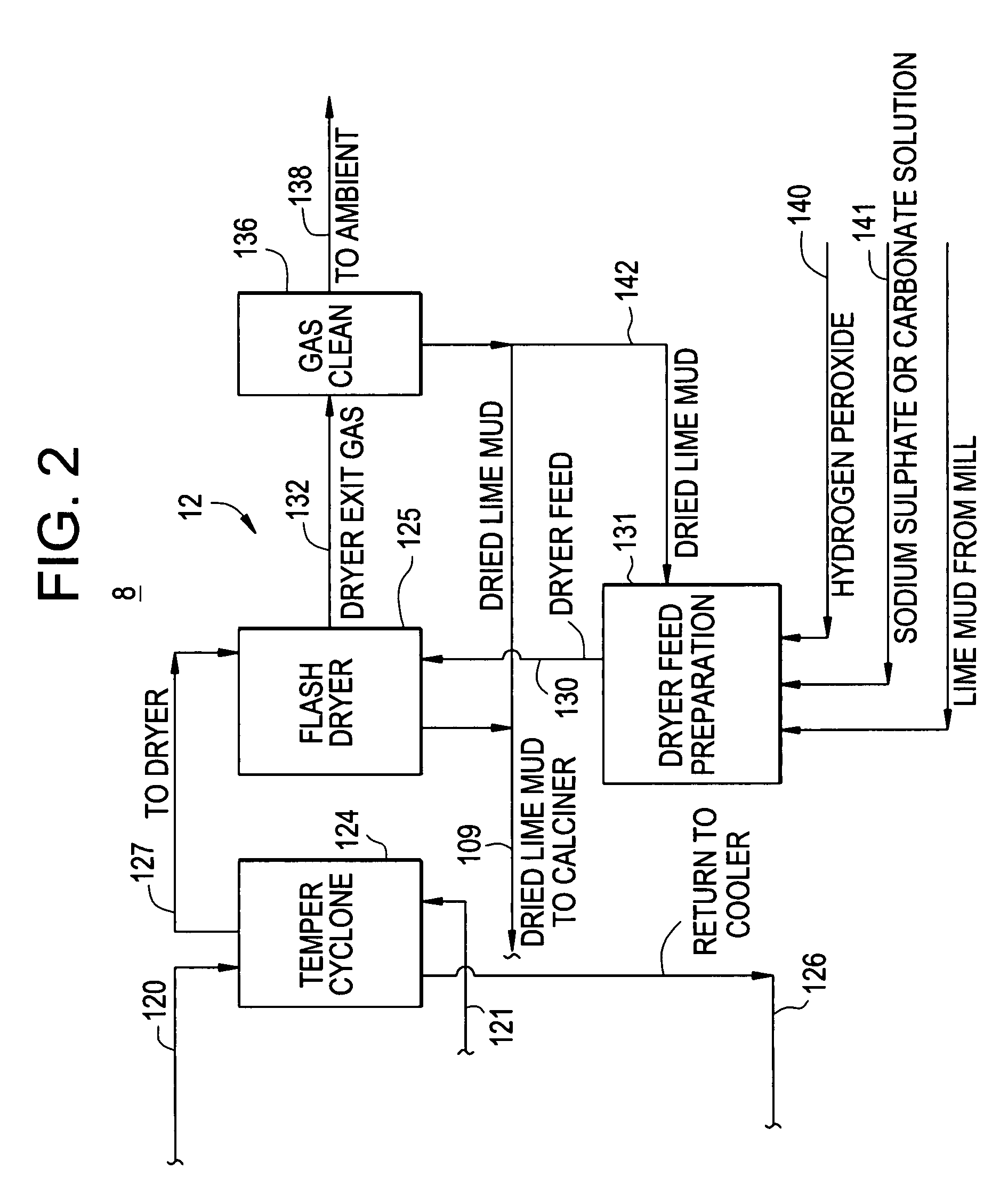

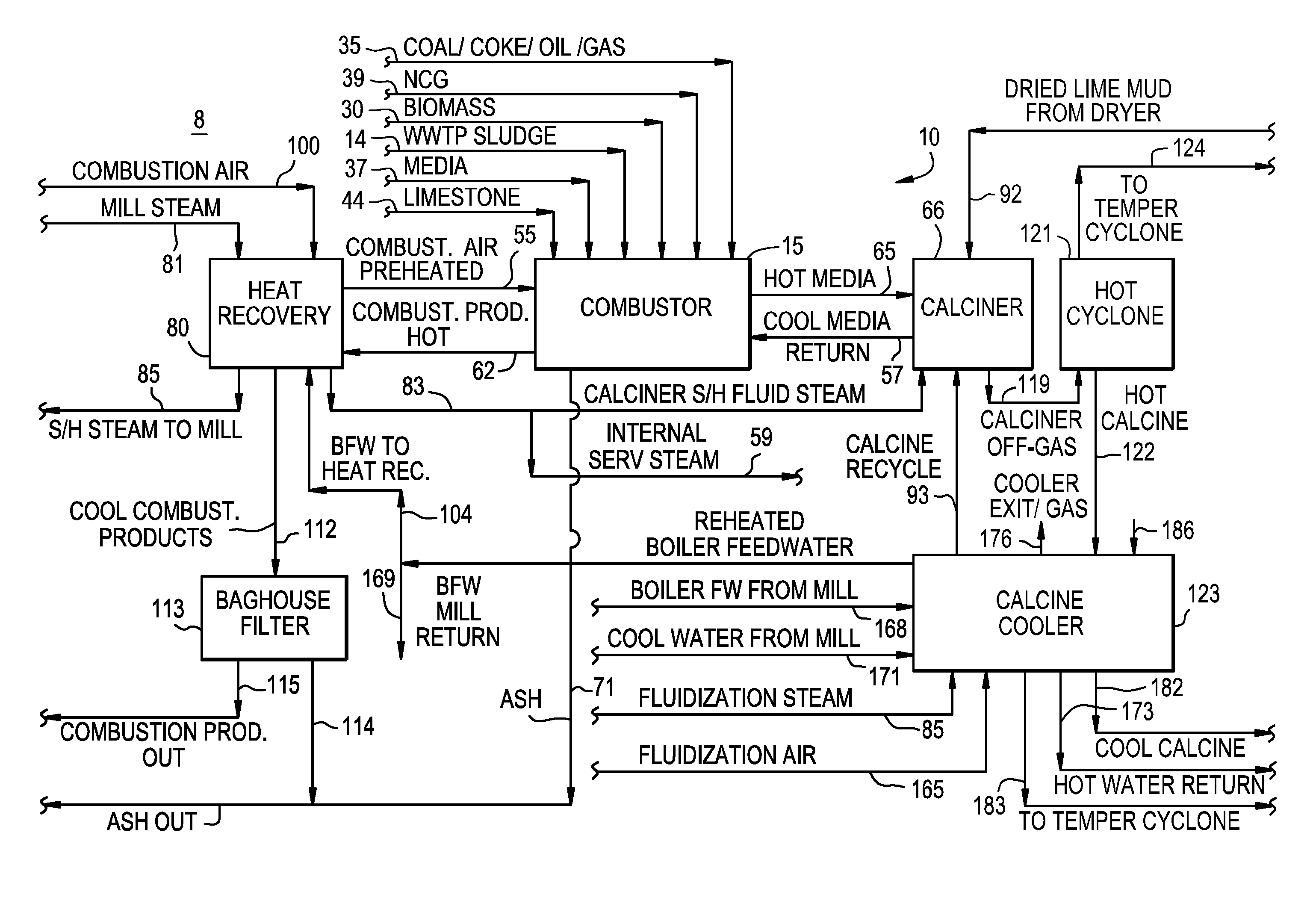

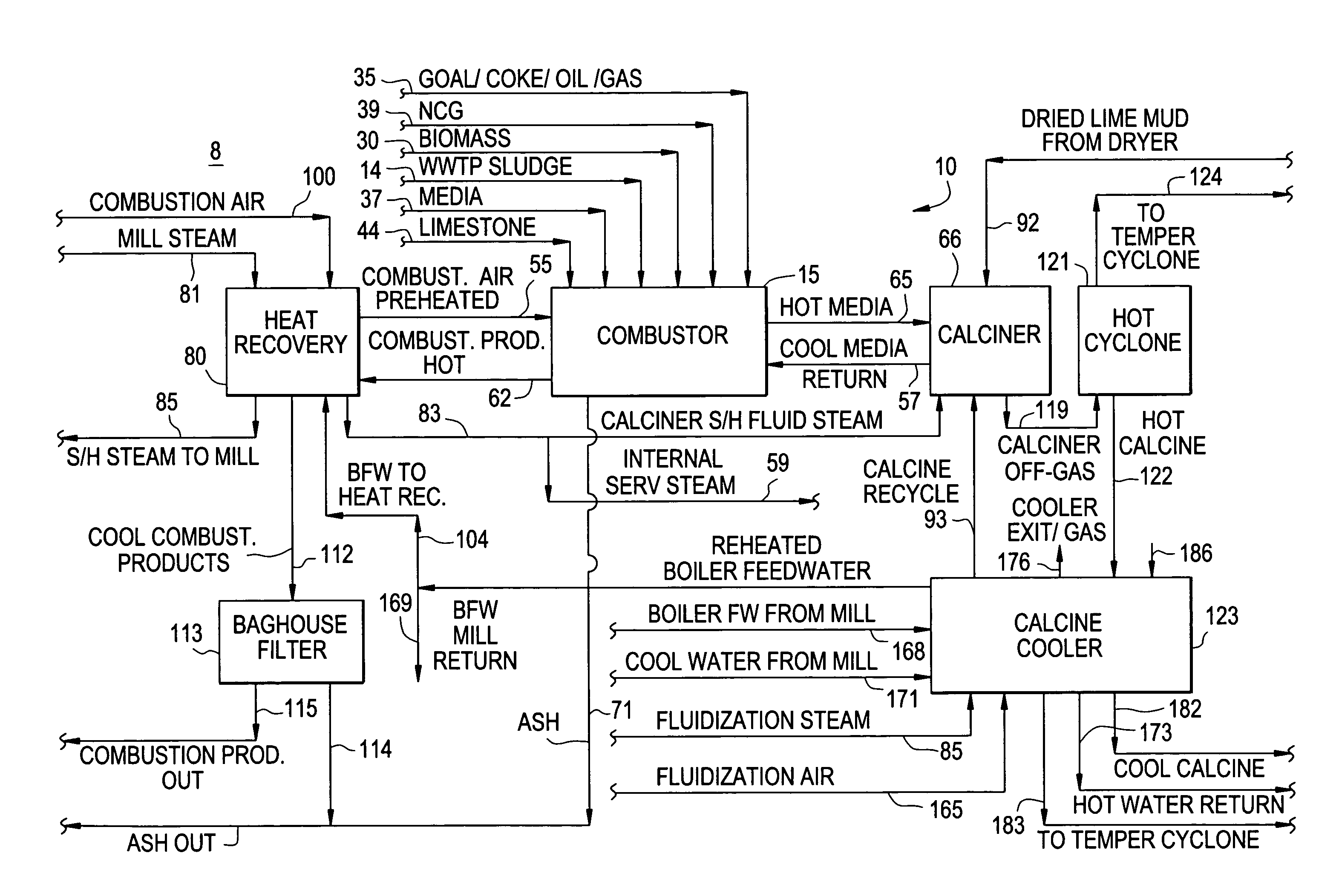

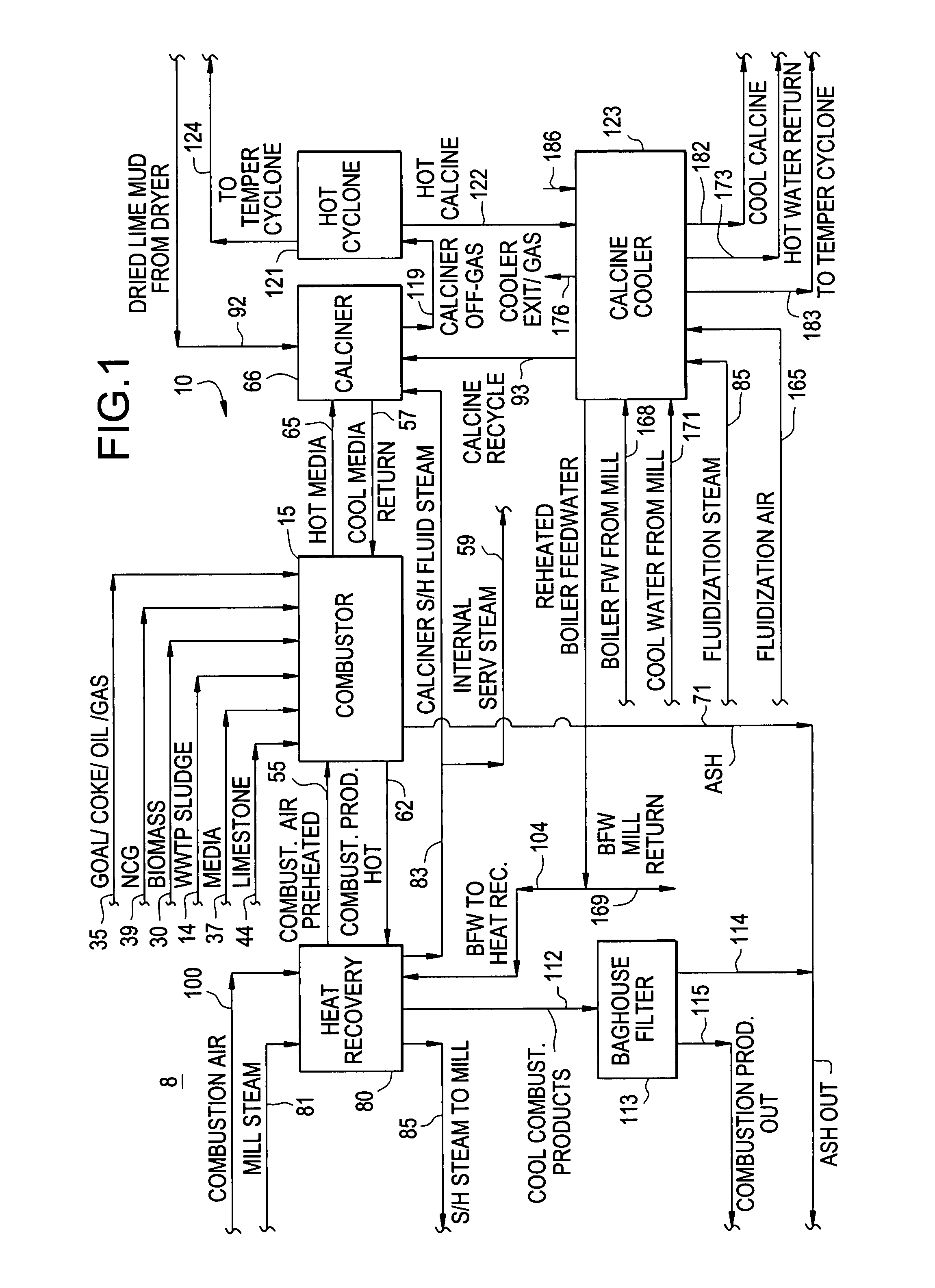

Process and system for calcination of high solids kraft paper pulp mill lime mud

InactiveUS20090114352A1High melting pointMitigate calciner scaling and fouling and unwanted gaseous emissionsCarbon compoundsDryer sectionSludgeSolid particle

The invention features methods and systems for calcining wet calcium carbonate lime mud produced in a re-causticizing manufacturing operation, for instance, Kraft pulp mill lime mud (“lime mud”) and converting it to re-burned lime by (a) feeding wet lime mud obtained from a re-causticizing manufacturing process into a flash dryer and then feeding the dried lime mud into a bubbling fluid bed calciner thermally linked by moving media heat transfer (MMHT) utilizing solid particulate media to a circulating fluid bed combustor wherein the MMHT provides heat input for calcination and drying; (b) recycling the media being from said calciner to said combustor wherein said combustor receives mill WWTP sludge, or precipitated lignins, or biomass, or NCGs as fuels to re-heat the solid particulate media; and (c) recovering calcined “soft-burned” lime mud from the fluid bed calciner. Steam and heated boiler feed-water are also generated and exported to the mill's steam distribution and generation system as well as hot process water for use in the mill's boiler house and manufacturing operation. The system for calcining calcium carbonate lime mud produced from a re-causticizing manufacturing operation and converting it to re-burned lime comprises a calciner and a combustor linked by a moving media heat transfer MMHT system or apparatus. The MMHT system or apparatus thermally links separate fluid bed combustion (exothermic) and calcination (endothermic) stages. The system further comprises a flash dryer or spray dryer that utilizes exhausted heat from the calcination stage.

Owner:ROSSI ROBERT A

Drying method

ActiveUS20130305560A1Keep dryExtended drying timeDrying solid materials with heatTextiles and paperSolid particleEngineering

The invention provides a method for the drying of a wet substrate, the method comprising treating the substrate with a solid particulate material at ambient or elevated temperature, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls, wherein the drum comprising perforated side walls is rotated so as to facilitate increased mechanical action between the substrate and the particulate material. Preferably, the drum comprising perforated side walls has a capacity of between 5 and 50 litres for each kg of fabric in the load and is rotated at a speed which generates G forces in the range of from 0.05 to 0.99 G, and the method is carried out at a temperature of between 5° and 120° C. Preferably, the solid particulate material comprises a multiplicity of particles at a particle to fabric addition level of 0.1:1-10:1 by mass, wherein the particles comprise polymeric particles, non-polymeric particles, or mixtures of polymeric and non-polymeric particles. All particles may be solid or hollow in their structure, have smooth or irregular surface features, and are of such a shape and size as to allow for good flowability and intimate contact with the wet substrate. The invention provides optimum drying performance as a result of improved mechanical interaction between substrate and particulate media and is preferably used for the drying of textile fabrics. The method allows for significant reduction in the consumption of energy when compared with the conventional tumble drying of textile fabrics, and also facilitates reduced textile fabric damage.

Owner:XEROS LTD

Process for removing thermal barrier coatings

InactiveUS7805822B2Molten spray coatingHollow article cleaningThermal barrier coatingMetallic substrate

A process which uses an air jet containing non-abrasive particulate media at a low pressure which selectively removes thermal barrier coatings from components without damaging the metallic substrate. This process selectively removes thermal barrier coatings from the cooling holes of components.

Owner:TURBOCOMBUSTOR TECH

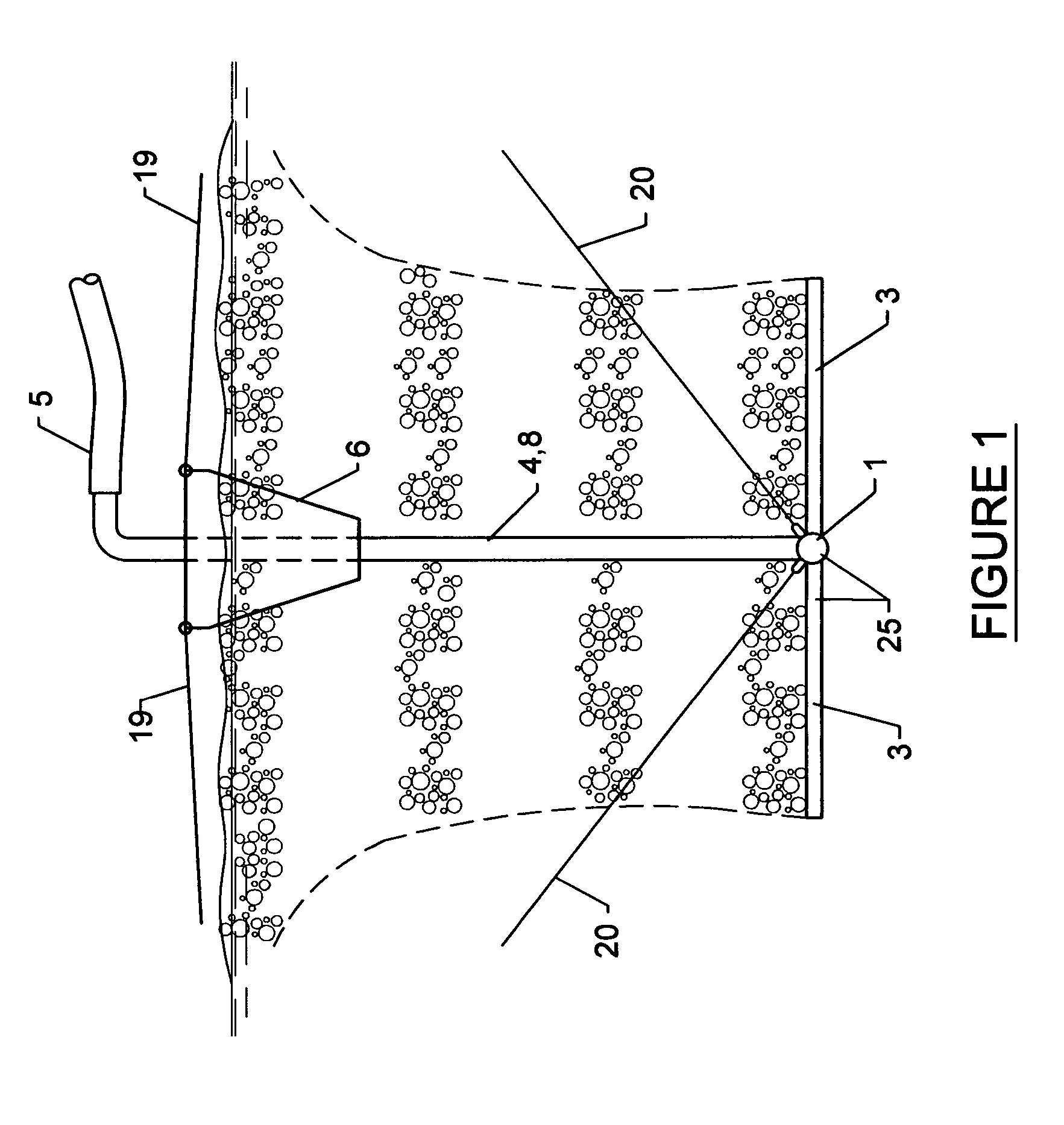

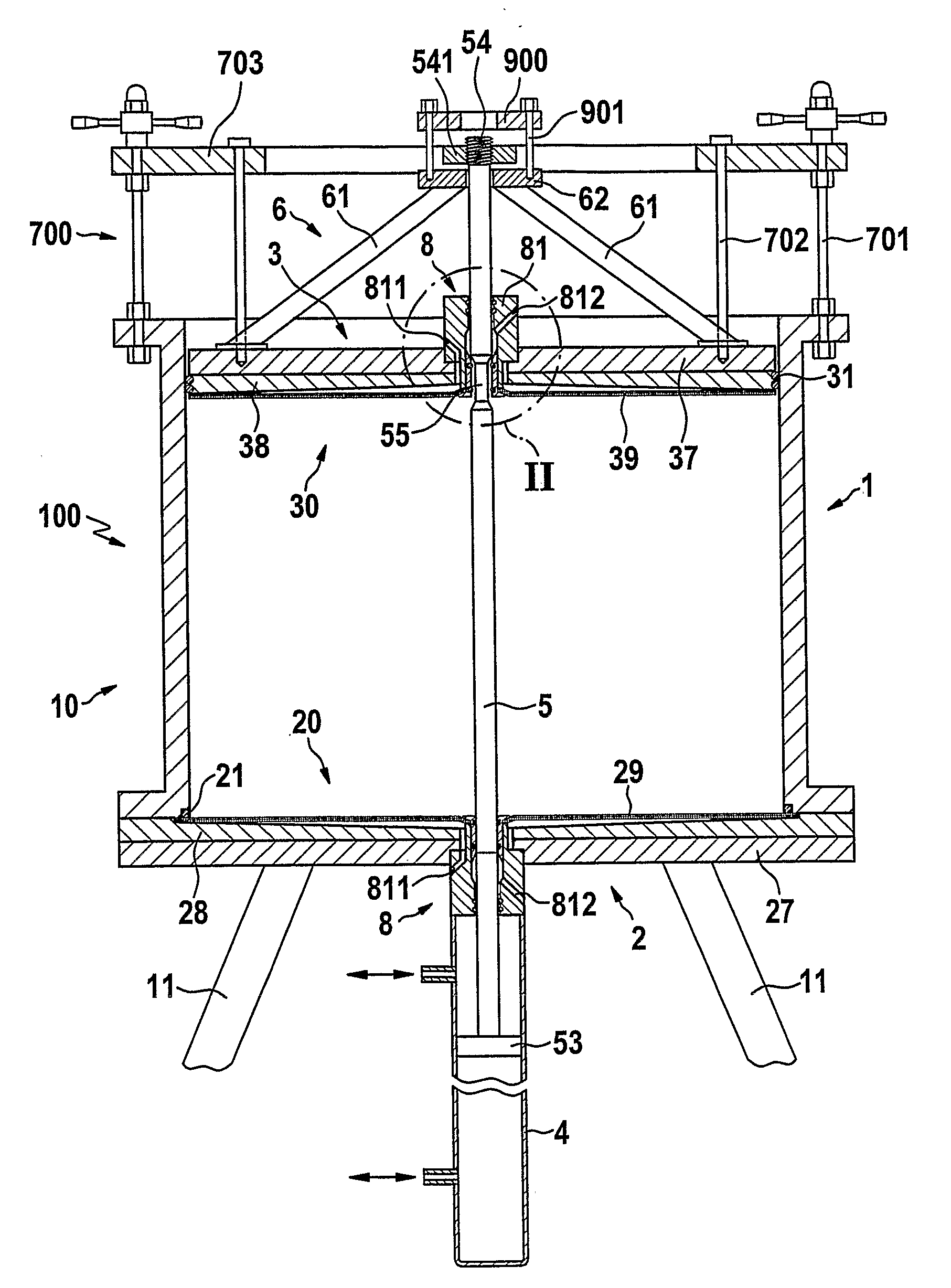

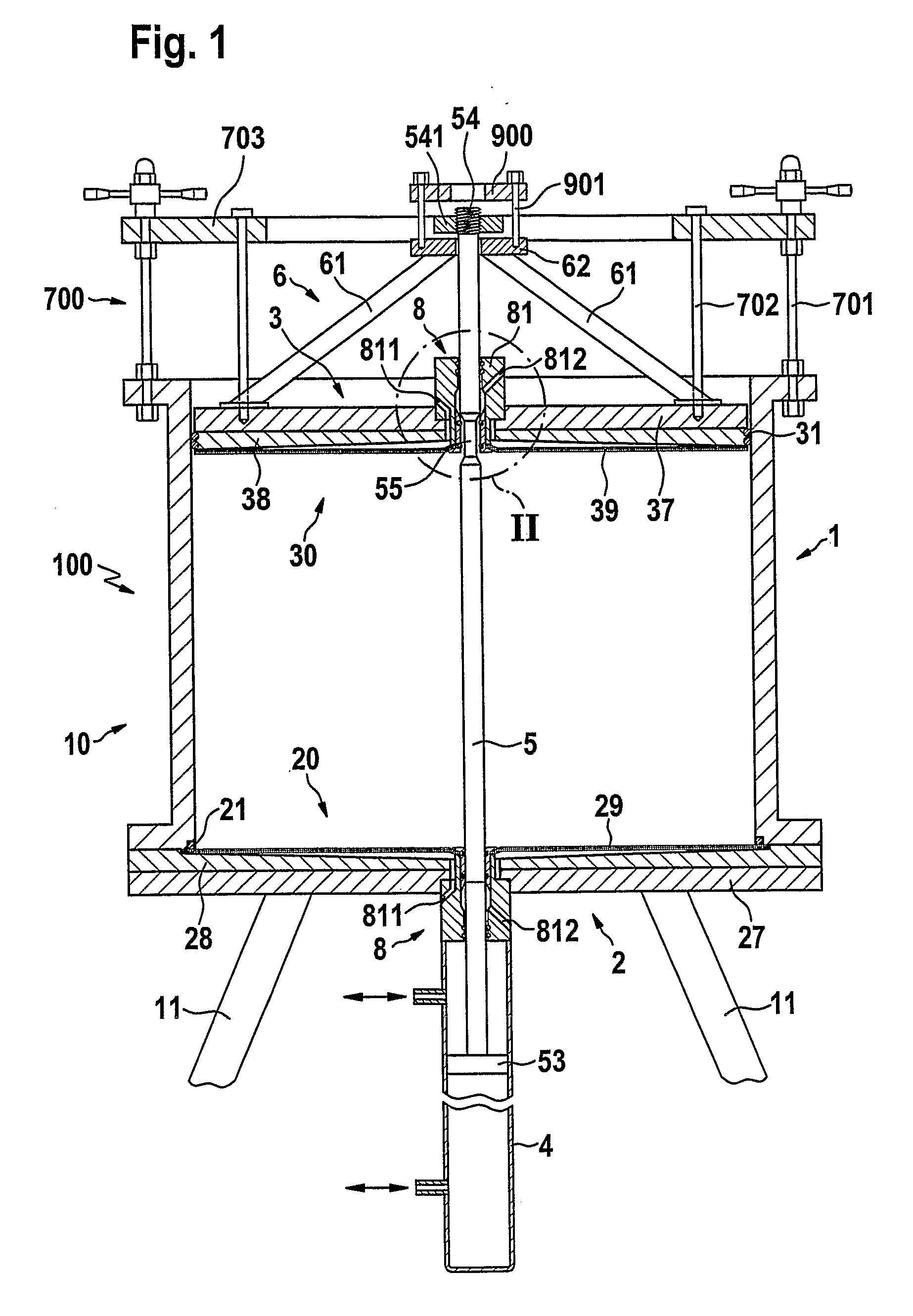

Chromatography Columns and Their Operation

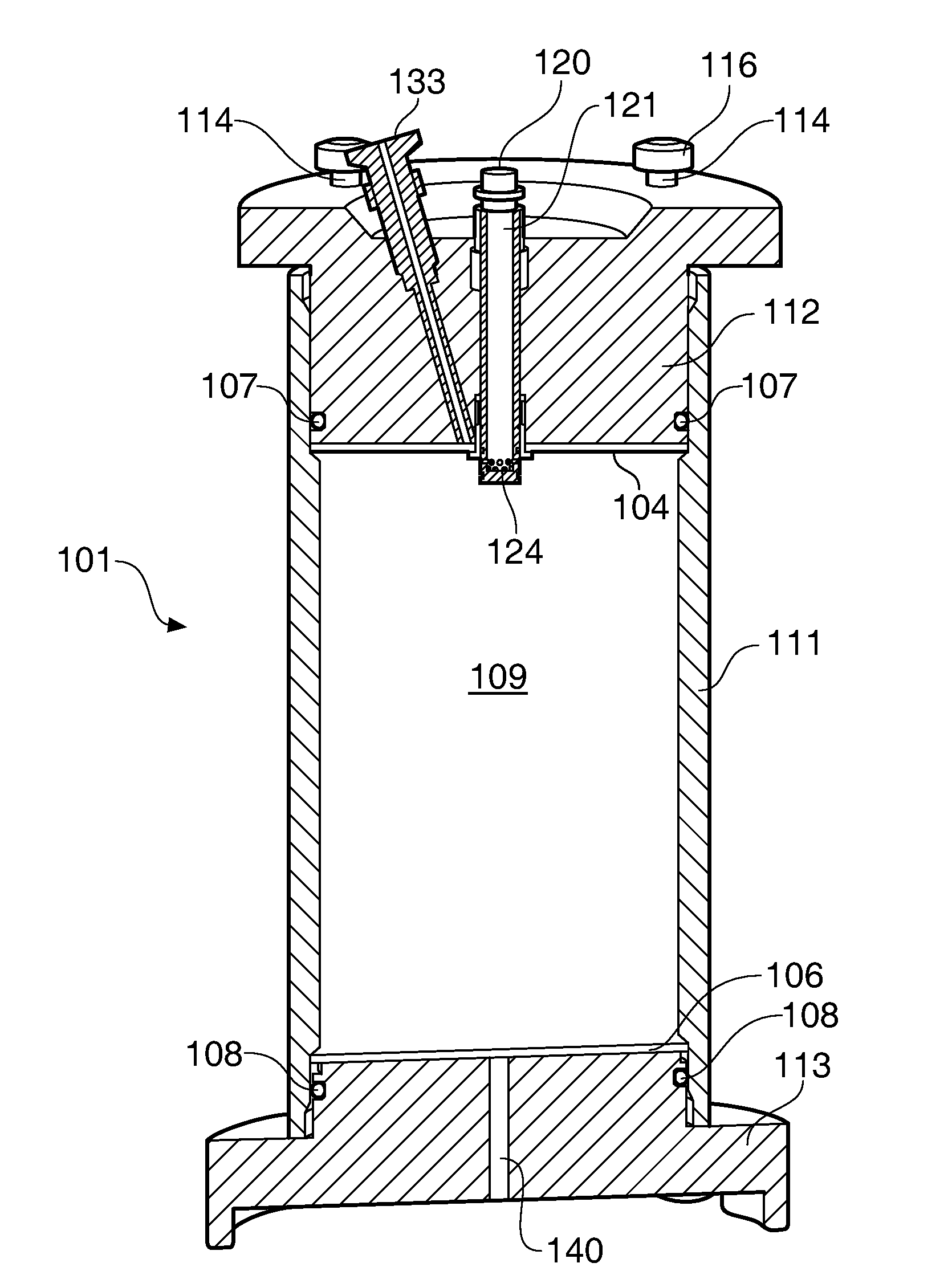

InactiveUS20080272042A1Ion-exchange process apparatusComponent separationDriven elementChromatography column

A chromatography column (100) is disclosed comprising a housing (10) comprising a tubular side wall (1); opposed, axially spaced end units (2,3) which together with the side wall define an enclosed bed space to contain a bed of particulate medium, at least one of the end units being slidable in axial direction; an axial drive element (5) connected to the slidable end unit, said drive element extending internally in the column bed space; a drive (4) positioned on or beyond the opposite end unit and connected to the drive element.

Owner:PALL CORP

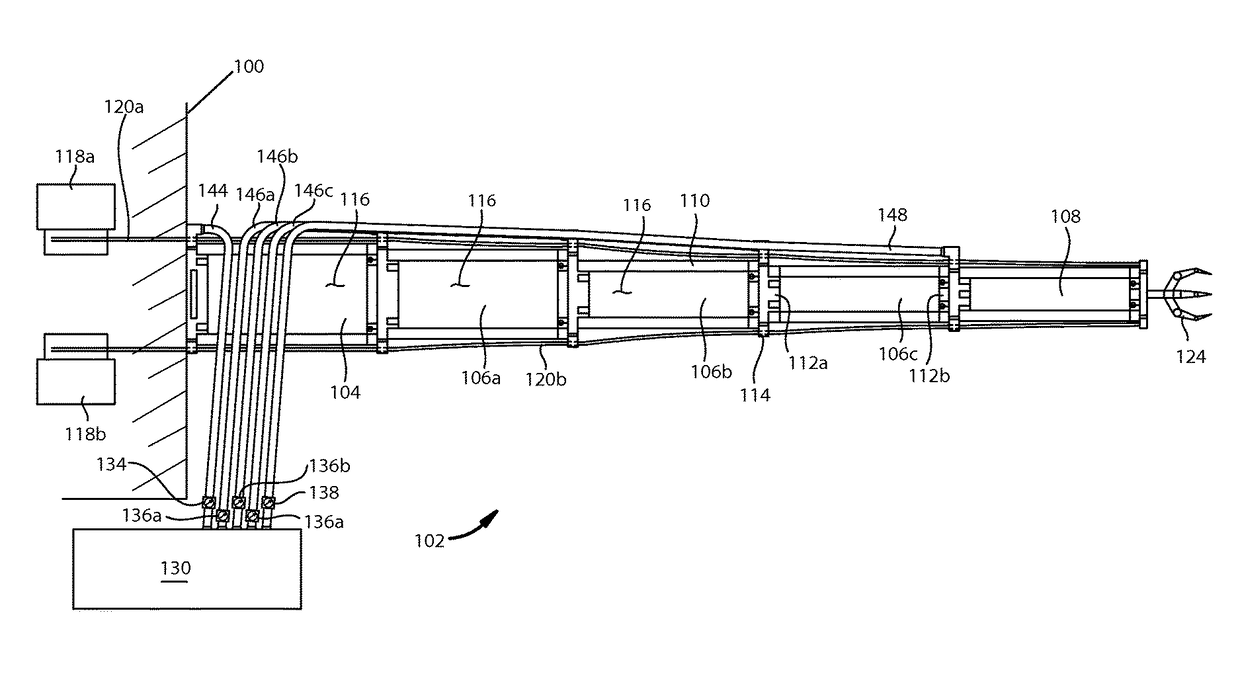

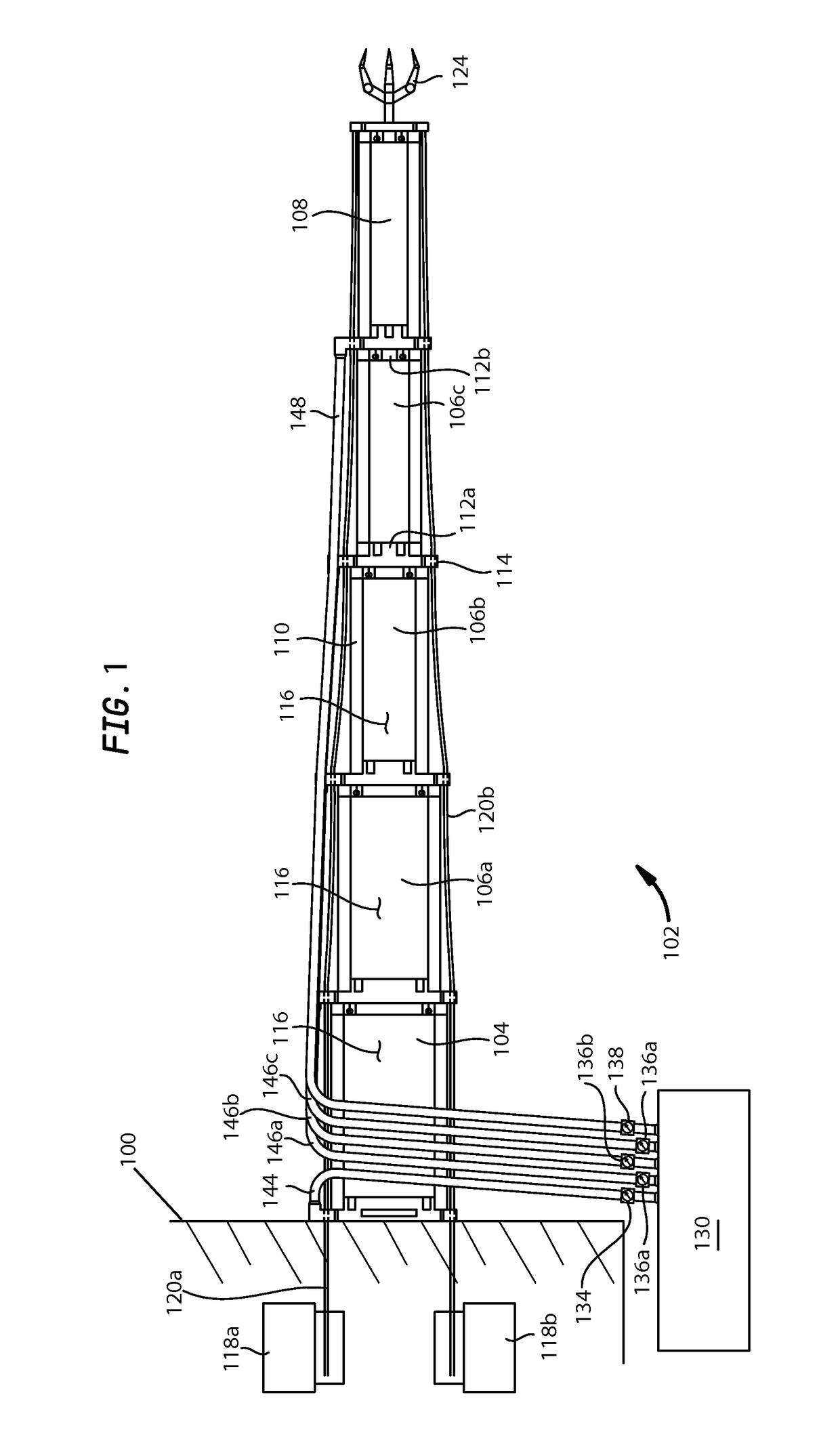

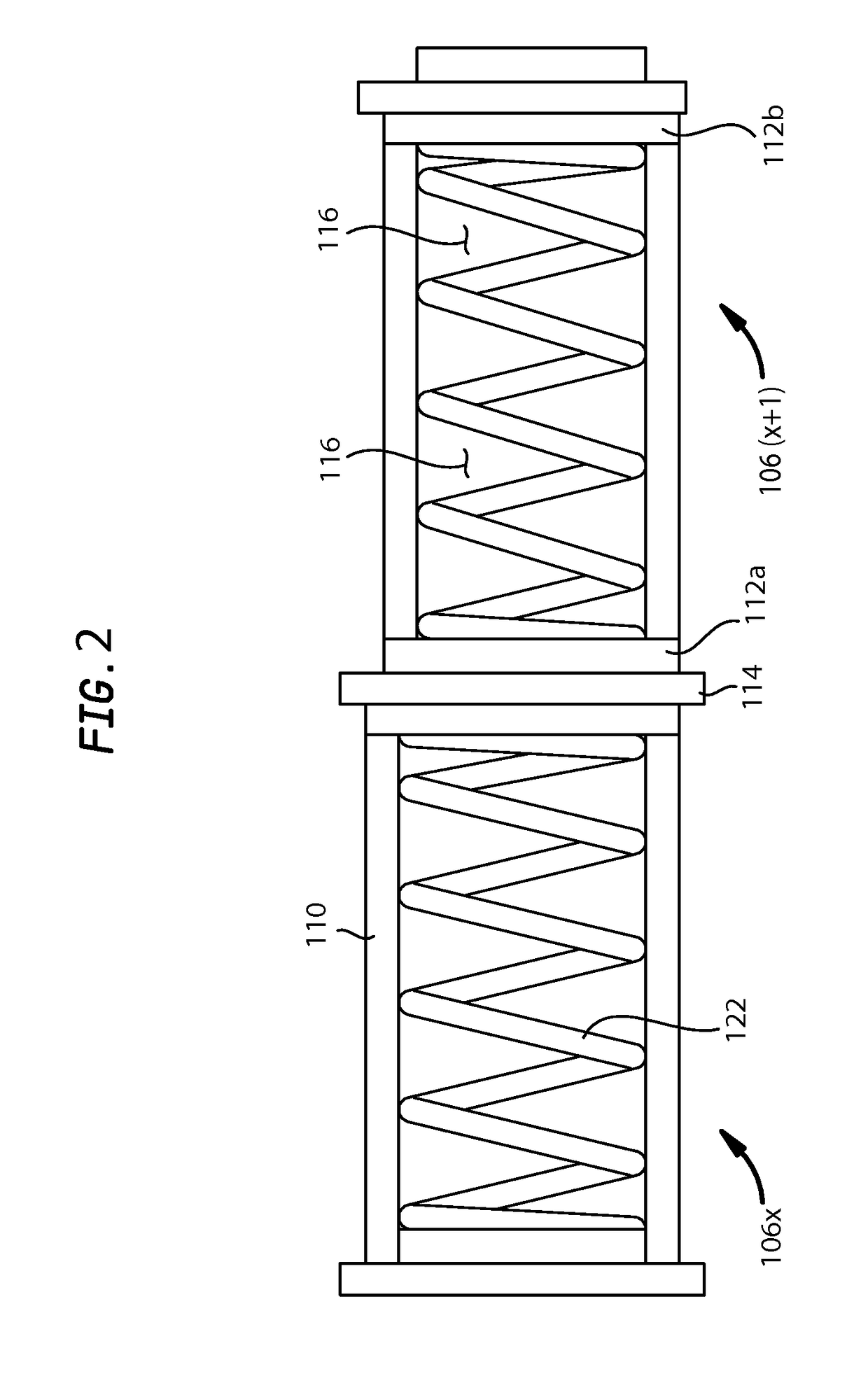

Continuum style manipulator actuated with phase change media

ActiveUS9713873B2Low costImprove clarityProgramme-controlled manipulatorMechanical apparatusEngineeringFriction angle

A continuum style manipulator is actuated by jammable media within an envelope of a module, which is also actuated by a tensile element, such as a cable and spooler motor. Multiple modules may be reversibly added. Two or more tensile elements may also be used. Three or more actuated tensile elements can actuate three DOFs of each module, and the terminal module, as well as the entire manipulator. Jammable media may be granular, actuated by a pressure change. Coarsely ground coffee works well. Rather than a jammable media, tensile elements may alternatively be used with other phase change media, such as magnetorheological and electrorheological media. A high friction angle of the granular media is desirable, and has been achieved with a particle size dispersion including both small and relatively larger particles. Applications include endoscopes, proctoscopes, laparoscopic instruments, manufacturing and medical manipulators. Methods of actuating include unjamming all modules, positioning the manipulator with tensile elements or otherwise, jamming the base-most module, and then repositioning remaining, not-jammed modules, followed by jamming the base-most not-jammed module, and so on, until all modules are positioned and jammed.

Owner:MASSACHUSETTS INST OF TECH

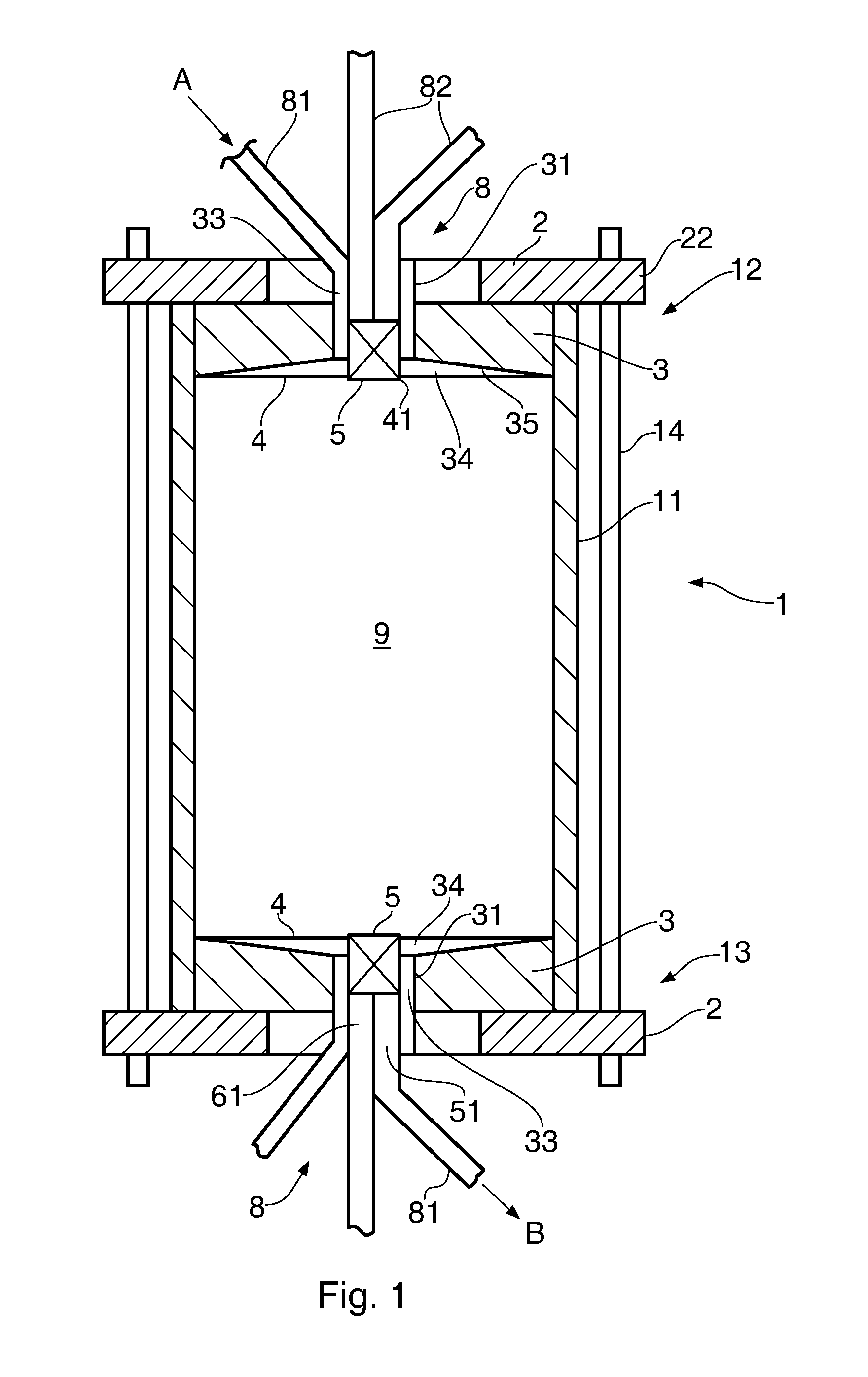

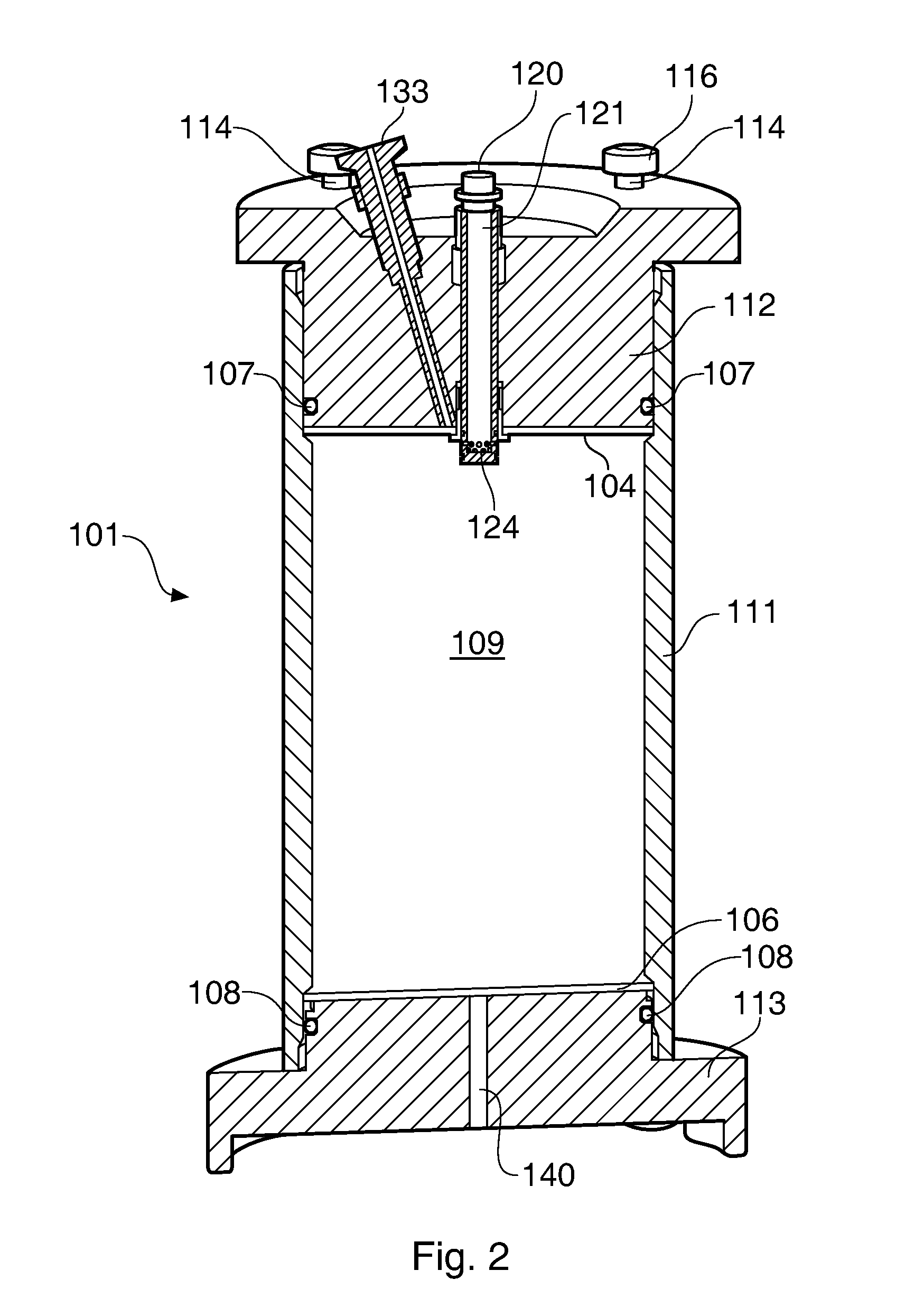

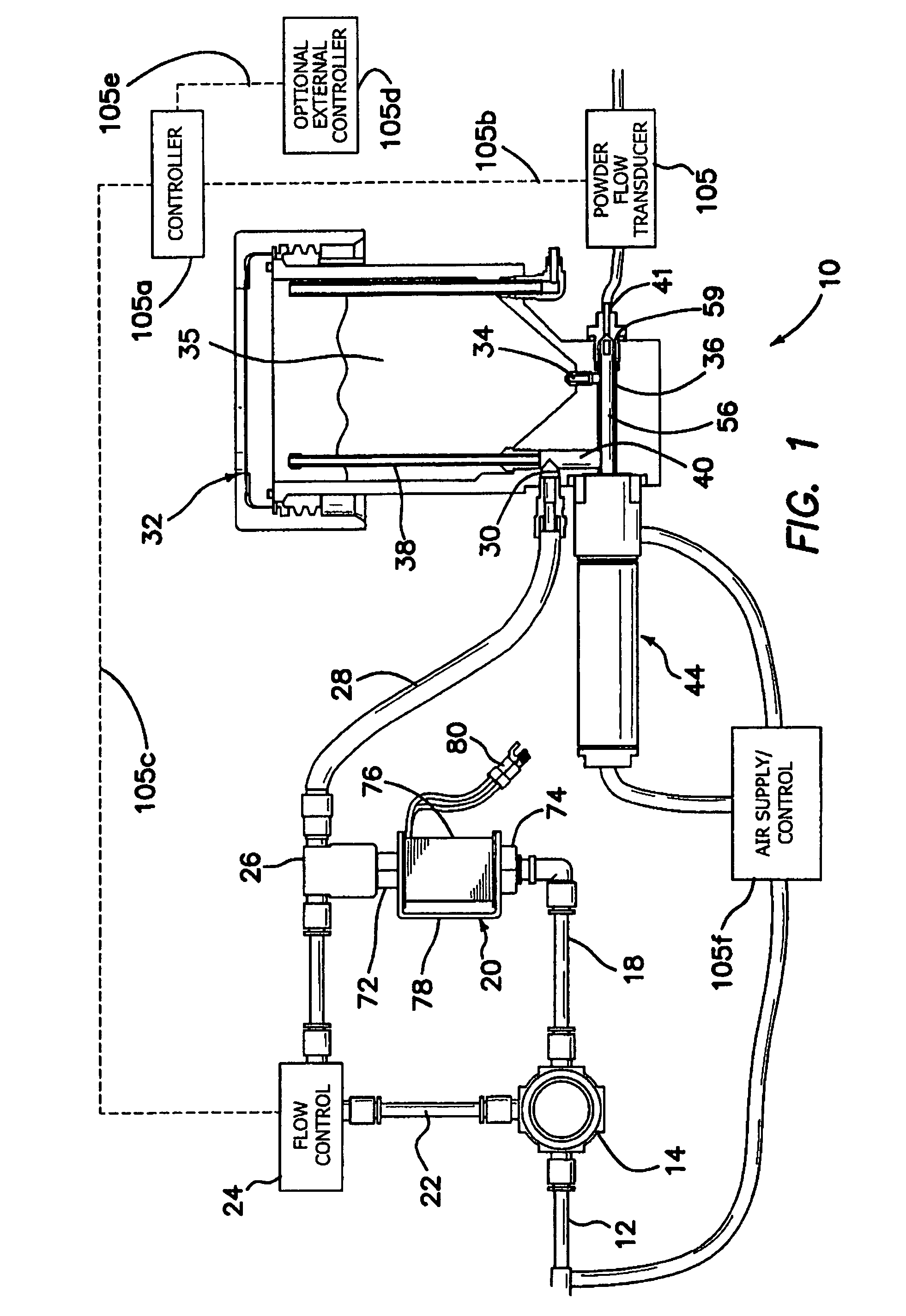

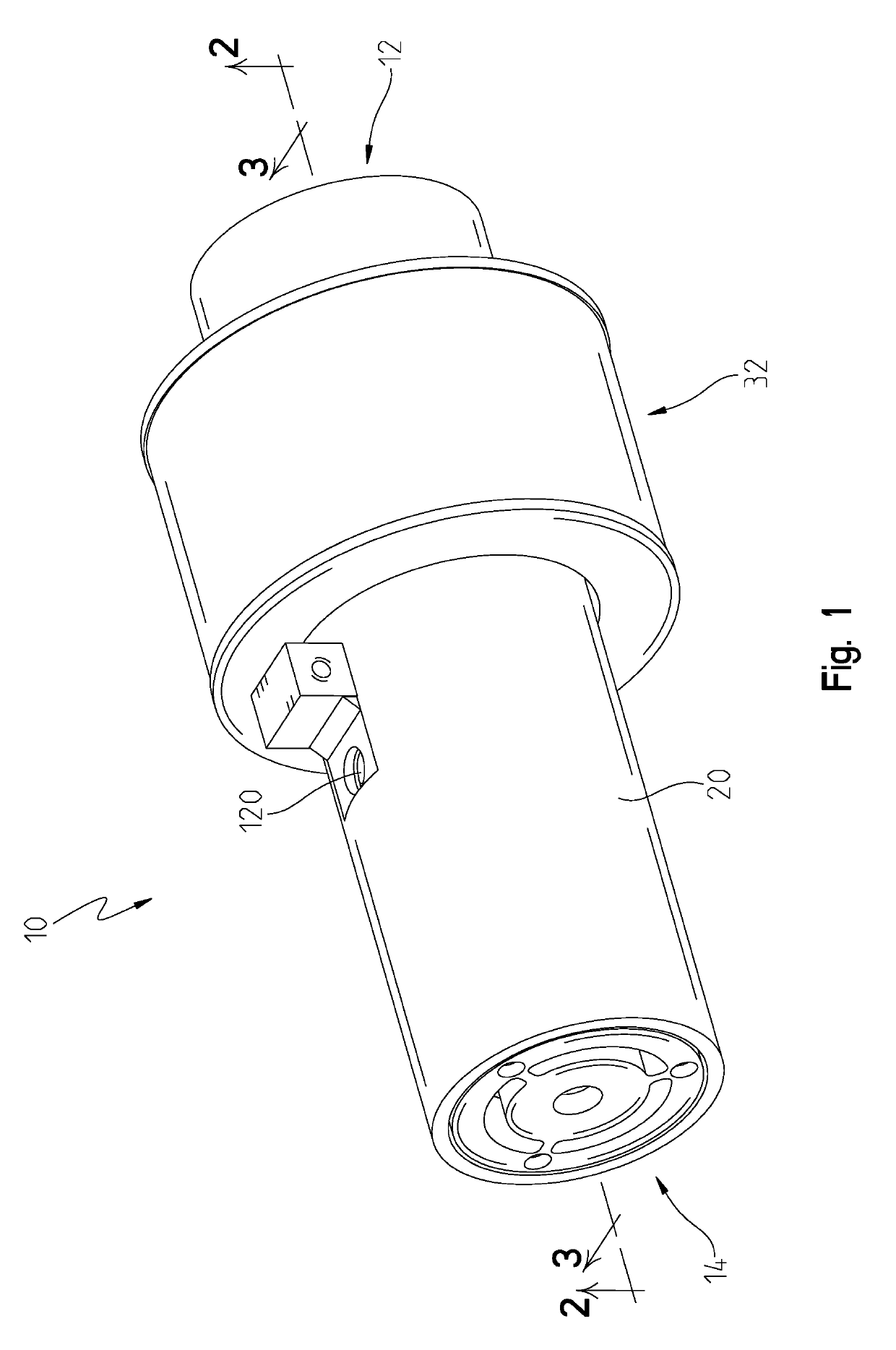

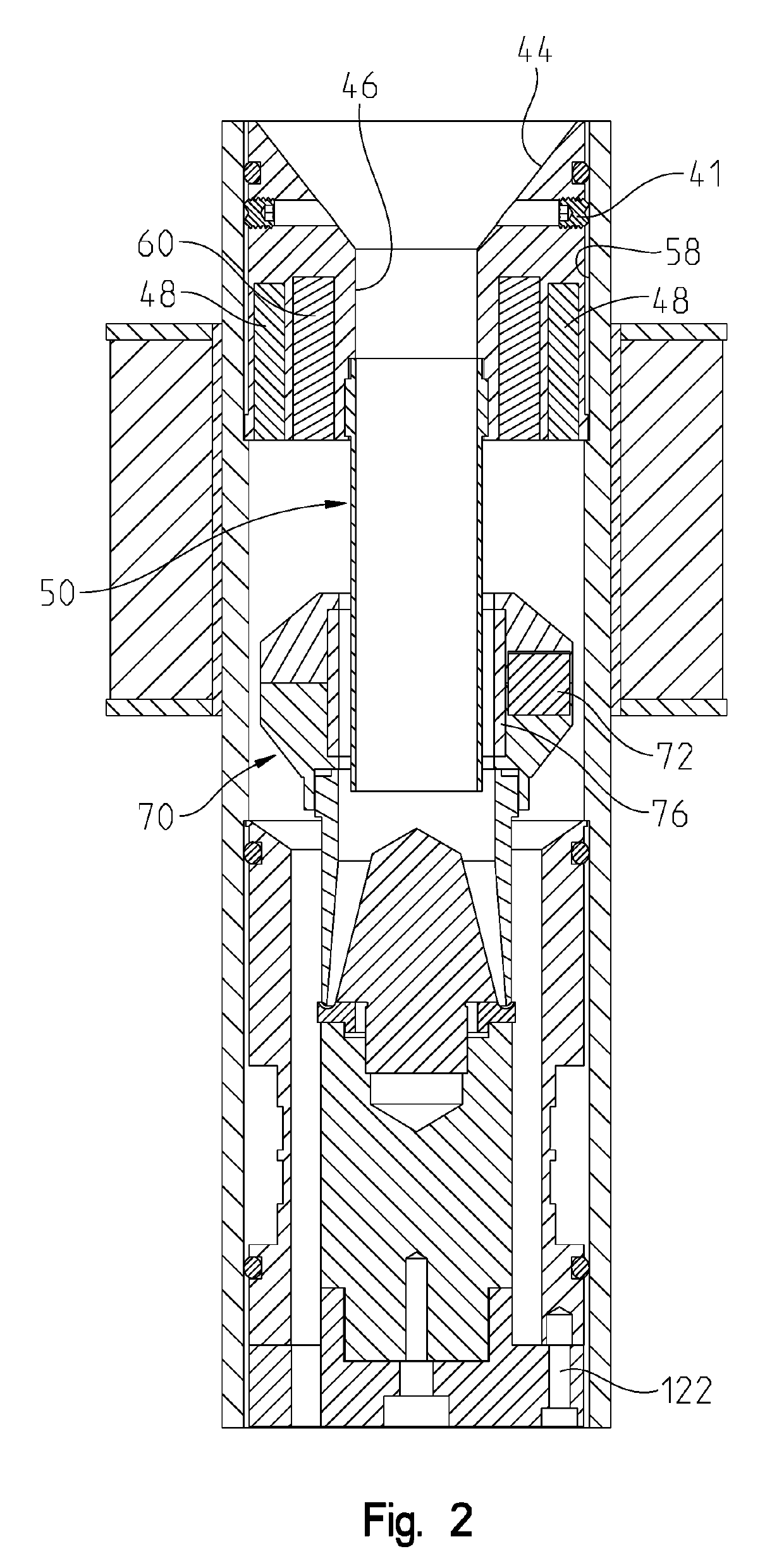

Apparatus and methods for dispensing particulate media

A particulate media / fluid delivery system comprises a tank for containing a supply of particulate media, preferably an abrasive powder. A modulator is disposed upstream of the tank for modulating the pressure of air flowing therethrough. A mixing chamber is adjacent to the tank, and an orifice is provided for delivering particulate media from the tank into the mixing chamber. A fluid inlet delivers fluid from the modulator to the tank, and a bypass tube is disposed adjacent to the fluid inlet for receiving fluid from the fluid inlet and delivering the fluid into the tank. A discharge port is provided for delivering a fluid / particulate media mixture to a tool. Control of the fluid / particulate is via differential modulation pressure. This differential modulation pressure is a function of two mechanisms, namely, the modulator in the system, including bypass (or blend) air around it that is metered, and the aforementioned bypass tube. Fine adjustment of the particulate media / fluid ratio is by a panel flow control valve, which may be either manually or automatically controlled, and coarse adjustment is via change-out of the bypass tube with another bypass tube having a different internal diameter.

Owner:COMCO

Packing system and method for chromatography columns

ActiveUS8778187B2Improve bed stabilityHigh column efficiencyIon-exchange process apparatusComponent separationChromatography columnParticulate media

The invention relates to a system for packing chromatography columns with a chromatography medium and packing method for use in such columns. In particular, the invention relates to a method and system for packing chromatography columns which utilizes an external drive means to compress a bed of particulate medium to a target bed height.

Owner:CYTIVA BIOPROCESS R&D AB

Tool for using a particulate media/fluid mixture

ActiveUS7524233B1Quick disassemblyLarge caliberBlast gunsAbrasive blasting machinesParticulatesEngineering

A nozzle assembly for a tool which utilizes a particulate / fluid mixture comprises a unique floating ferrule within a handpiece assembly, and eliminates the need, in the prior art, for a nose piece to attach a nozzle to the handpiece assembly. Rather, the nozzle and its integral holder are designed so that a hose may be slipped over its extended rear tube and then, when the handpiece with its floating ferrule is twisted on, the hose is captured and sealed. This is managed because the ferrule is unengaged when the handpiece tube is first started to be threaded onto the nozzle holder. After a few turns, the ferrule pushes against the hose and seals it against the rear extension of the nozzle holder. When the handpiece is unscrewed from the nozzle, because the nozzle must be replaced, the ferrule remains attached to the nozzle and hose, allowing for easy turning. Once the handpiece is unscrewed from the nozzle, the nozzle may be tipped slightly to disengage it from the hose very easily.

Owner:COMCO

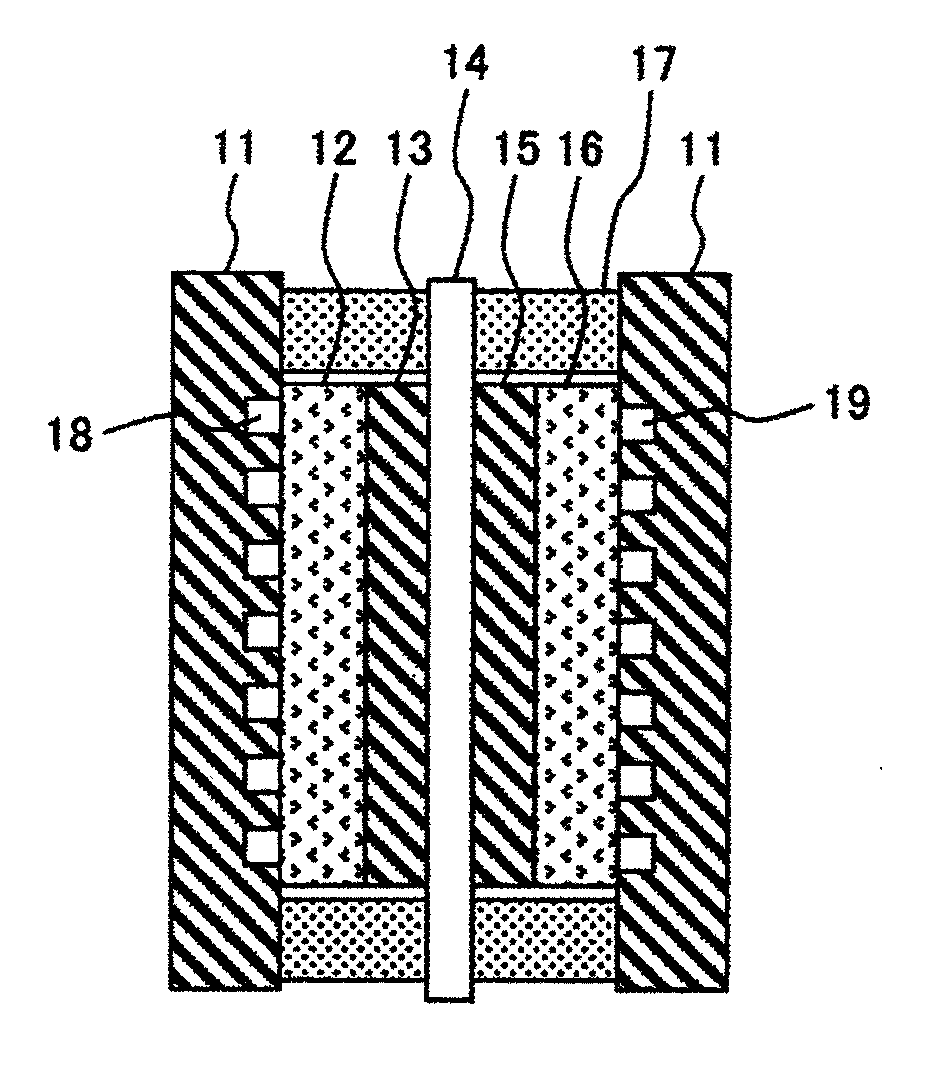

Membrane-electrode assembly and fuel cell using the same

InactiveUS20110123897A1High catalyst utilizationIncrease output powerFinal product manufactureCell electrodesPolymer electrolytesFuel cells

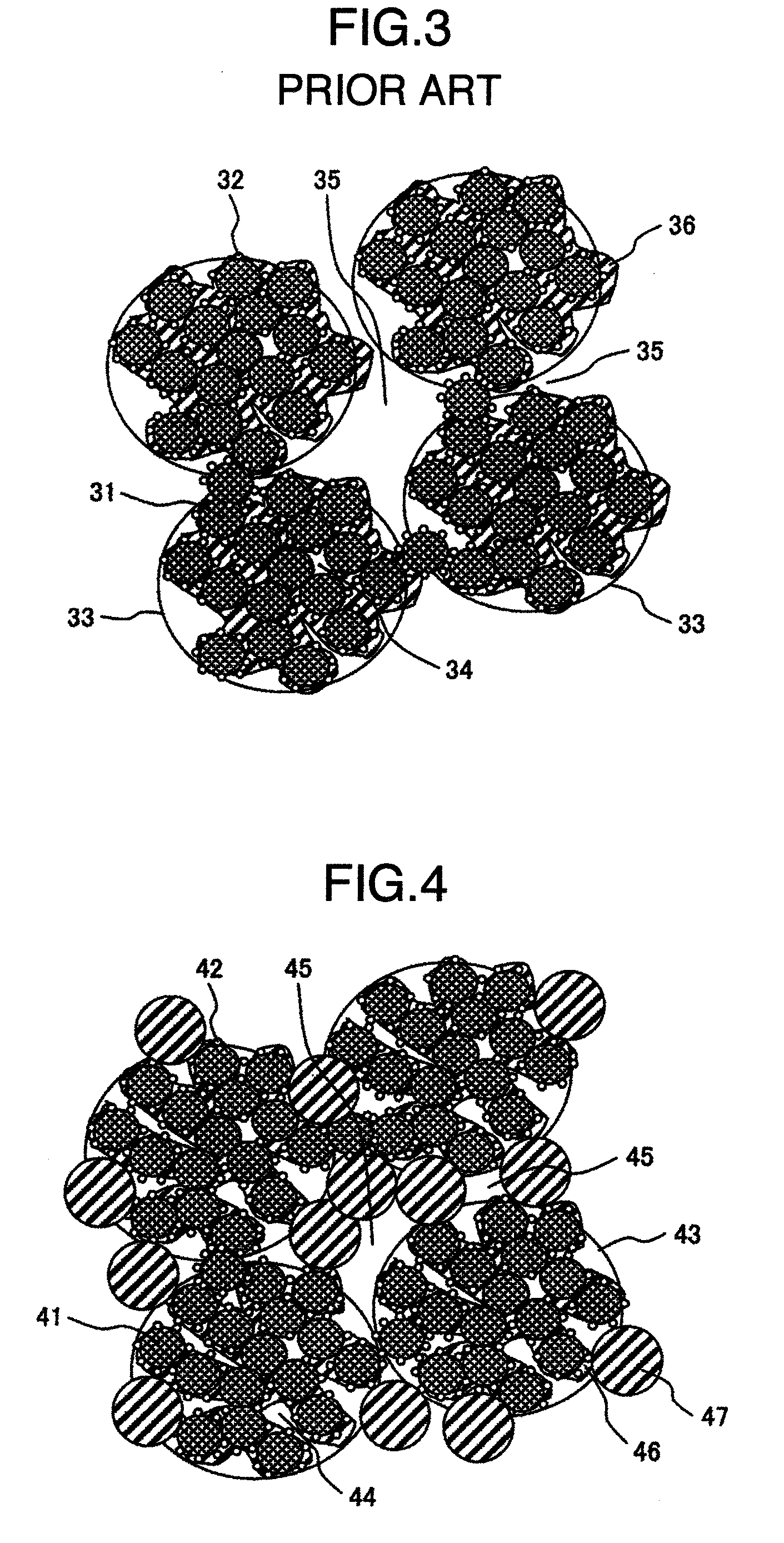

In a membrane-electrode assembly comprising an anode, a cathode and a polymer electrolyte membrane and having a constitution in which the polymer electrolyte membrane is interleaved between the anode and the cathode, an agglomerate structure of carbon support formed with a plurality of carbon primary particles supporting catalyst particles is contained in the anode and the cathode, and particulate media having polymer electrolyte on the surface thereof are contained between adjacent agglomerate structures of carbon supports.

Owner:HITACHI LTD

Magnetic recording particulate medium

InactiveUS6149989AMinimal in head wearRunning durability freeMaterials with cobaltSynthetic resin layered productsParticulatesPolyester

The present invention discloses a magnetic recording particulate mediumhaving amagnetic layer on anonmagnetic support, the magnetic layer containing a ferromagnetic metal powder and a binder and having a coercive force of 1,400 to 1,700 Oe, wherein the ferromagnetic metal powder is spindle-shaped particles consisting essentially of Fe and having a Co / Fe ratio of from 1 to 5 atomic %, an Al / Fe ratio of from 5 to 15 atomic %, an average major axis length of 0.1 to 0.2 mu m and a specific surface area of 40 to 50 m2 / g, and the binder contains a polyurethane consisting essentially of a diol component comprising a polyether polyol and a polyester polyol and a polyisocyanate component. This magnetic recording particulate medium is characterized by minimal head wear, freedom from head clogging, and satisfactory electromagnetic characteristics.

Owner:FUJIFILM CORP +1

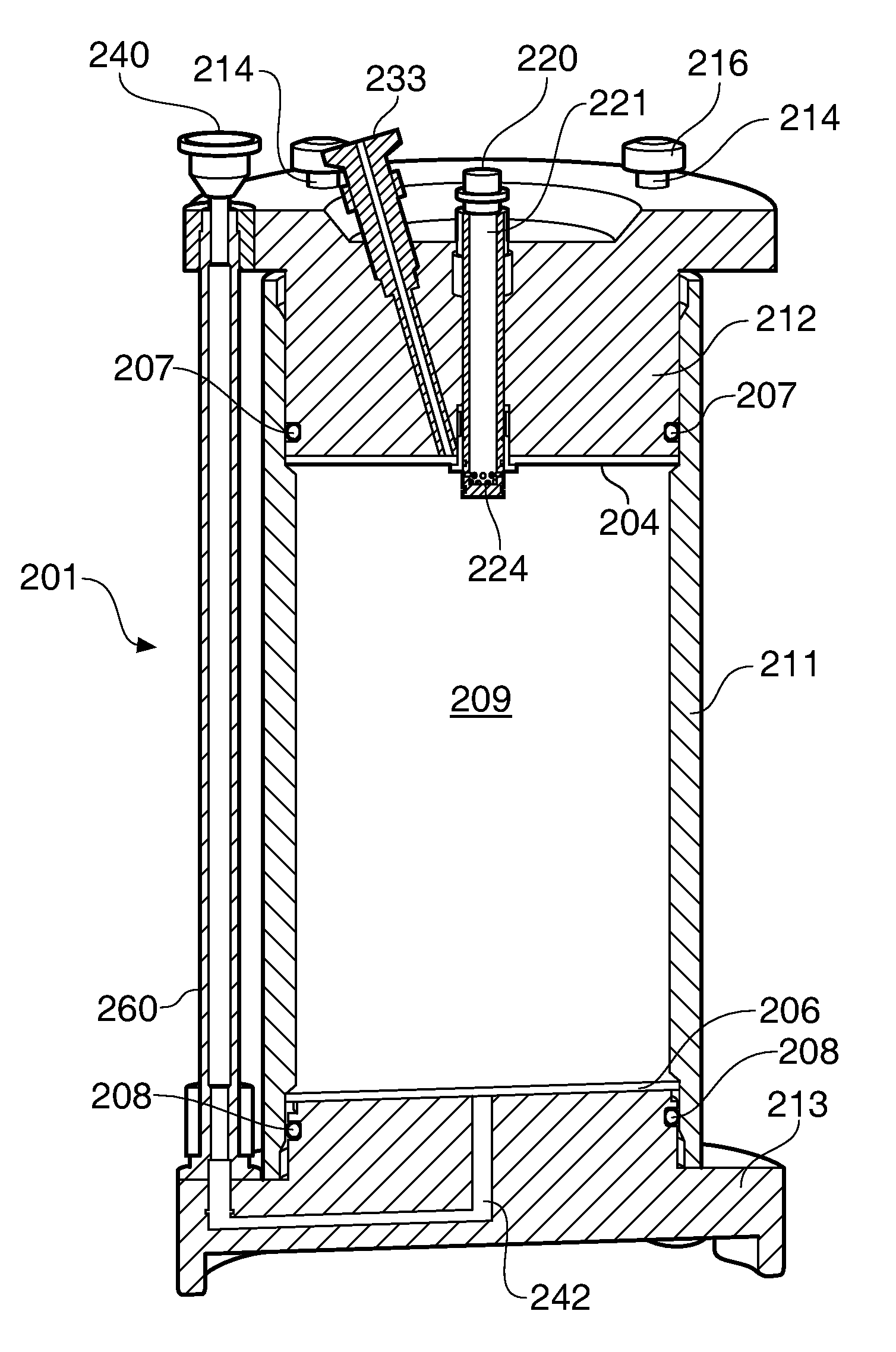

A blast attenuator

ActiveUS20160313094A1Weaken energyMaximizes friction capacityArmoured vehiclesBlastingEngineeringMechanical engineering

Methods and apparatus are provided for a blast attenuator having a container with an outer wall that defines a cavity in which a particulate media is disposed, and a stirring element disposed in and moveable relative to the container. At least a portion of the stirring element extends into the particulate media, wherein, in use, the particulate media provides resistance against movement of the stirring element relative to particulate media so as to attenuate the energy of a blast.

Owner:ARMORWORKS HLDG

High performance impregnant for braided packing and impregnation process thereof

ActiveCN101984183APrevent leakageImprove creep resistanceFibre typesLiquid/gas/vapor removalState of artWater leakage

The invention relates to a high performance impregnant for braided packing and impregnation process thereof. The invention mainly solves the technical problems of poor thermal conductivity of existing packings prepared by the prior art, so that creep deformation is formed under the condition of higher linear velocity and granular media existed and performance degradation of products in size stability, pliability and extrusion resistance property is generated due to the large amount of abrasion loss, as well as water leakage. The impregnant provided by the invention comprises, by mass, 15%-25% of distilled water, 65%-75% of graphite emulsion and 10%-20% of polyacrylate adhesive.

Owner:浙江国泰萧星密封材料股份有限公司

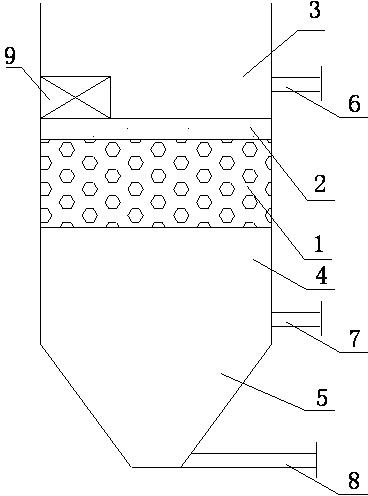

Efficient and energy-saving method for backflushing filter media

InactiveCN102698502ASmall footprintSave land resourcesLoose filtering material filtersGravity filtersLand resourcesFilter system

The invention relates to an efficient and energy-saving method for backflushing filter media. By the method, precipitation and filtering of sewage purification can be achieved in a system, size is reduced, high-quality water can be obtained, and the problems that water quality is poor in an existing precipitation system and high-turbidity sewage cannot be treated directly by a filter system are solved. Furthermore, the method has the advantages of high efficiency and economized land resources. In addition, since light granular media filter material is adopted, vibration energy or oscillation energy generated by an energy generator and clean water are utilized to flush floc heavier than water out from the filter material from top to bottom, and the floc accumulated in the filter material can be flushed. The vibration energy or oscillation energy is adopted to backflush the filter material from top to bottom mainly, so that on the one hand, the clean water to be consumed by backflushing the filter material can be economized greatly, on the other hand, no water is needed to be taken out of a device, energy saving is achieved, and water resources are economized.

Owner:徐宏康 +1

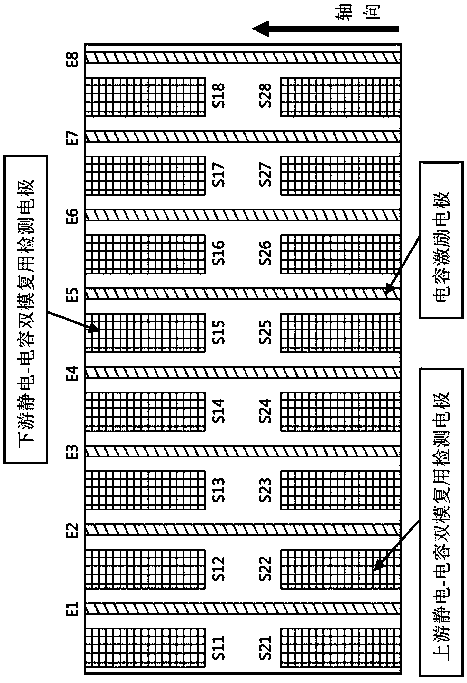

Method and apparatus for measuring charge distribution of pneumatic conveying two-phase flow particles

PendingCN108398606AResolve inconsistenciesEfficient measurementElectrical measurementsParticle suspension analysisGas solidPrior information

The invention belongs to the technical field of gas-solid two-phase flow detection. It is a method for measuring particle charge distribution in two-phase flow in pneumatic conveying. Combining the projection data from the electrostatic signal of the sensor, the prior information from the distribution of particle medium and velocity with the dynamic space charge sensitivity of the sensor, the particle charge distribution is retrieved by the image reconstruction algorithm. The invention also discloses a corresponding measuring apparatus. According to the particle charge distribution measurementmethod provided by the method, the problems existing in the current particle charge distribution measurement are effectively solved, and the effective measurement of the particle charge distributioncan be realized. The method and apparatus for measuring charge distribution of pneumatic conveying two-phase flow particles has the advantages that the charge distribution of the two-phase flow particle of the pneumatic conveying can be effectively measured in real time. The method and apparatus for measuring charge distribution of pneumatic conveying two-phase flow particles provides a basic measurement method and a method for exploring the basic flow characteristics of the gas-solid two-phase flow, monitoring the industrial production process and preventing the electrostatic hazards.

Owner:YANGZHOU UNIV

Process for removing thermal barrier coatings

InactiveCN1894071ASo as not to damageMolten spray coatingEfficient propulsion technologiesThermal barrier coatingMetallic substrate

Briefly, the present invention provides a process which uses an air jet containing non-abrasive particulate media at a low pressure which selectively removes thermal barrier coatings from components without damaging the metallic substrate. This process selectively removes thermal barrier coatings from the cooling holes of components.

Owner:TURBOCOMBUSTOR TECH

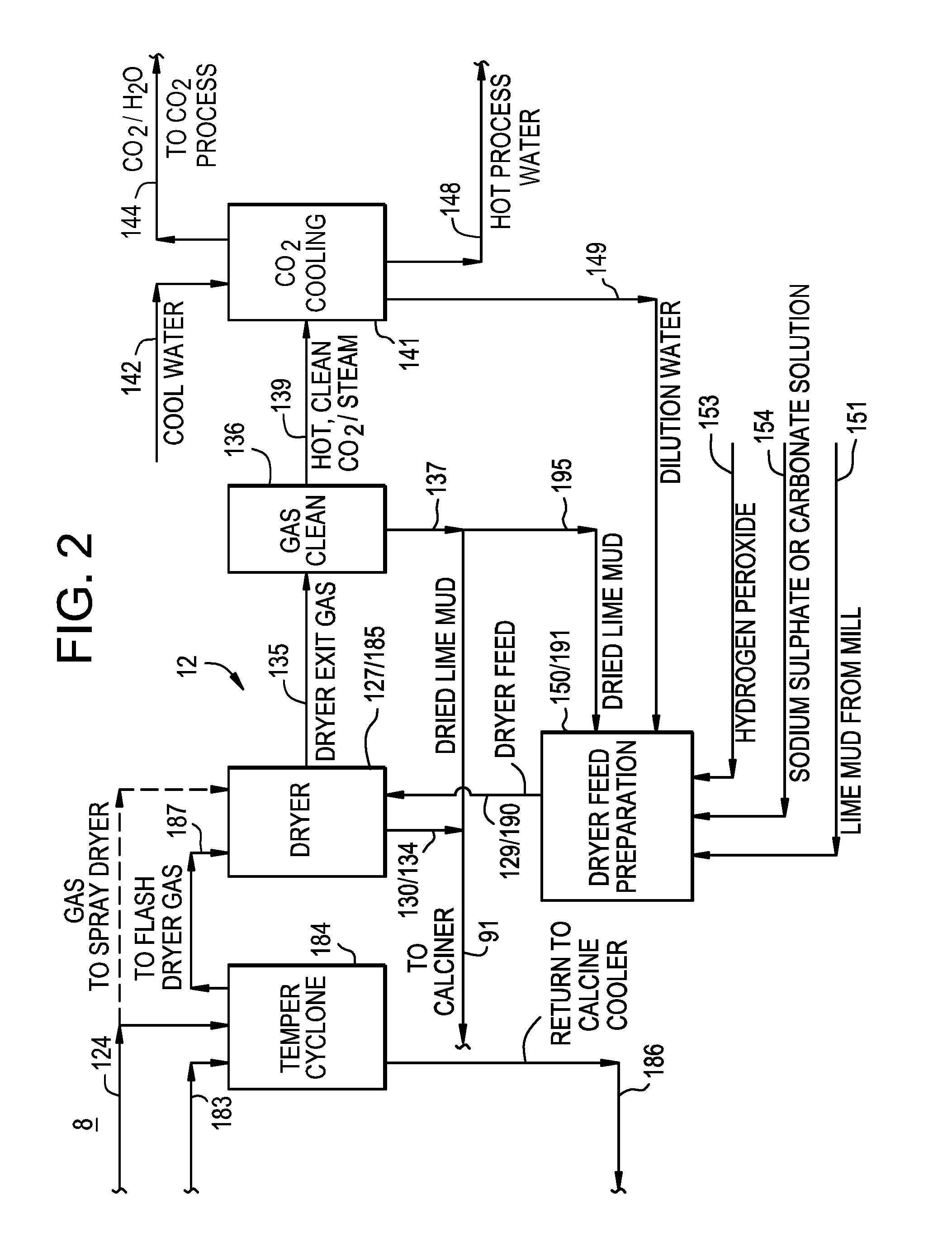

Process and system for producing commercial quality carbon dioxide from recausticizing process calcium carbonates

ActiveUS20150056125A1Maximize dry lime mud particle residence timeHigh melting pointOxide/hydroxide preparationCarbon compoundsSludgeSolid particle

The invention features methods and systems for recovering carbon dioxide, for producing commercial quality carbon dioxide (CO2) of 90% to +99% purity using, wet calcium carbonate lime mud produced in a recausticizing process that also produces caustic soda, for instance, Kraft paper pulp mill lime mud (a.k.a., “lime mud”) as a feedstock to a multi-stage lime mud calcination process. This process may be fueled with low, or negative cost “carbon-neutral” fuels such as waste water treatment plant (WWTP) sludge, biomass, precipitated lignins, coal, or other low cost solid fuels. High reactivity, high-quality calcined lime mud (a.k.a. re-burned lime, or calcine), required in the Kraft paper pulp mill's recausticizing process is also produced, and superheated high pressure steam and hot boiler feed-water is generated and exported to the mill's steam distribution and generation system as well as hot process water for use in the mill's manufacturing operation. The system for calcining calcium carbonate lime mud produced from a recausticizing manufacturing operation and converting it to calcined lime mud and CO2 comprises a calciner and a combustor linked by a moving media heat transfer (MMHT) system or apparatus. The MMHT system or apparatus thermally links separate fluid bed combustion (exothermic) and calcination (endothermic) stages with a solid particulate media. The system further comprises a flash dryer or spray dryer that utilizes exhausted enthalpy from the calcination stage.

Owner:ROSSI ROBERT A

Capacitive sensor for a flow control valve

ActiveUS10451464B1Reduces magnetic fieldPrevent movementOperating means/releasing devices for valvesIndividual particle analysisCapacitive sensingControl valves

A flow sensor for use downstream from a particulate media dispensing device is provided having an inlet to receive particulate media and an outlet to dispense the media. The flow sensor has an inlet portion with a funnel to direct particulate media towards a central axis. An axially mounted flow director is located downstream from the funnel to direct the media outwards towards a sensor portion. A capacitive sensor located in the sensor portion surrounds the flow director to create an annular flow path to measure the amount of media that passes through sensor rings in the sensor.

Owner:ELEKTRONIK

Novel high-efficient energy-saving precipitating and filtering method utilizing light particle medium filter materials

The invention relates to a novel high-efficient energy-saving precipitating and filtering method utilizing light particle medium filter materials. By the aid of the method, two processes including a precipitating process and a filtering process for sewage purification are completed in a system, occupied area is saved, purposes of not only directly treating sewage with higher turbidity but obtaining outflow water with better quality are realized, so that problems that at present, the quality of outflow water of a precipitating system is poorer and a filtering system cannot directly treat sewage with higher turbidity are resolved, and the novel high-efficient energy-saving precipitating and filtering method has the advantages that efficiency is high and occupied land resources are saved. In addition, as the light particle medium filter materials are utilized, floccules heavier than water in the filter materials are flushed out from the filter materials from top to bottom, the filtering materials enter a mixing precipitating region below a filter material layer, and the floccules heavier than water automatically sink to enter a sludge accumulation region. By the aid of a back flush mode, on the one hand, the quantity of needed clear water is much lower, water pressure is also much lower, and the purpose of saving energy is achieved, on the other hand, water does not need to be taken away from the system, and purposes of not only saving energy but saving water resources are achieved.

Owner:DONGGUAN HONGJIE ENVIRONMENTAL PROTECTION TECH

Process and system for producing commercial quality carbon dioxide from high solids lime mud

ActiveUS8865101B2High melting pointMitigate calciner scaling and fouling and unwanted gaseous emissionsCarbon compoundsEnergy inputSludgeChemical recovery

The invention features methods and systems for producing commercial quality carbon dioxide (CO2) of 90% to +99% purity using, wet calcium carbonate lime mud produced in a manufacturing operation, for instance, Kraft pulp mill lime mud (a.k.a., “lime mud”) as a feedstock to a multi-stage lime mud calcination process. This process may be fueled with waste water treatment plant (WWTP), sludge biomass, precipitated lignins, coal, or other low cost solid fuels. High reactivity “soft-burned” lime product (“calcine”) required in the mill's chemical recovery circuit is also produced, and steam and heated boiler feed-water is generated and exported to the mill's steam distribution and generation system as well as hot process water for use in the mill's boiler house and manufacturing operation. The system for calcining calcium carbonate lime mud produced from a re-causticizing manufacturing operation and converting it to re-burned lime and CO2 comprises a calciner and a combustor linked by a moving media heat transfer (MMHT) system or apparatus. The MMHT system or apparatus thermally links separate fluid bed combustion (exothermic) and calcination (endothermic) stages with a solid particulate media. The system further comprises a flash dryer or spray dryer that utilizes exhausted heat from the calcination stage.

Owner:ROSSI ROBERT A

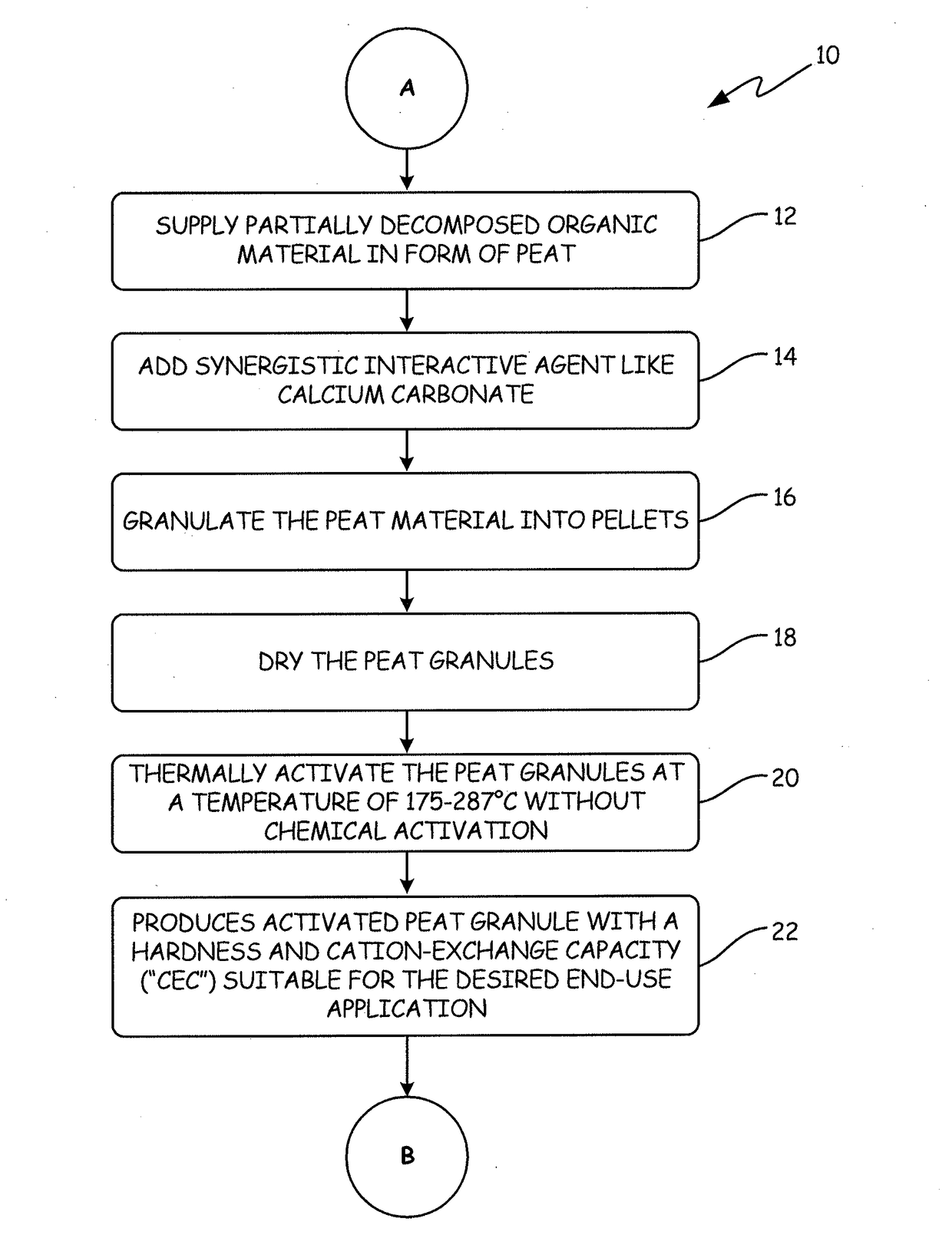

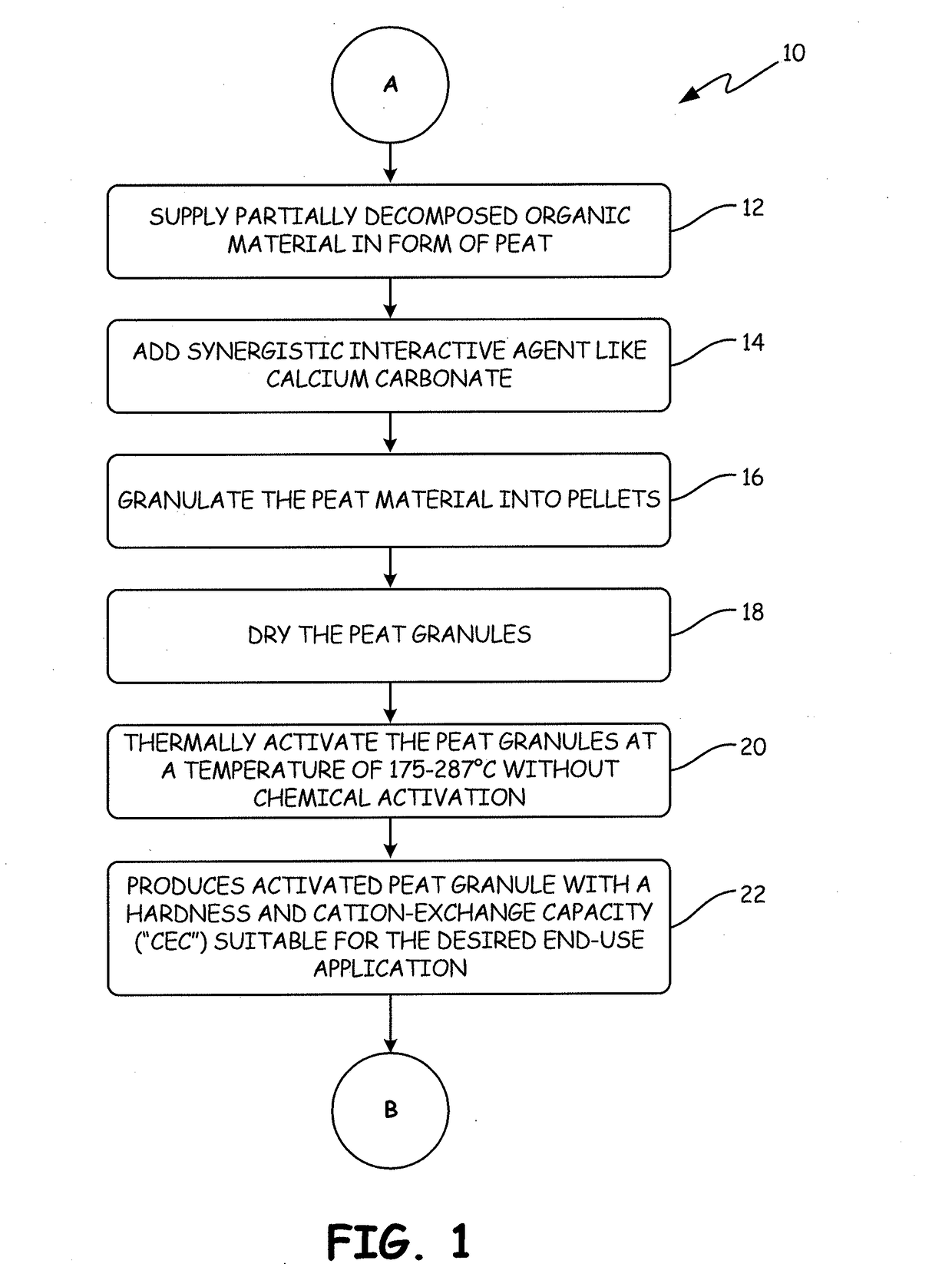

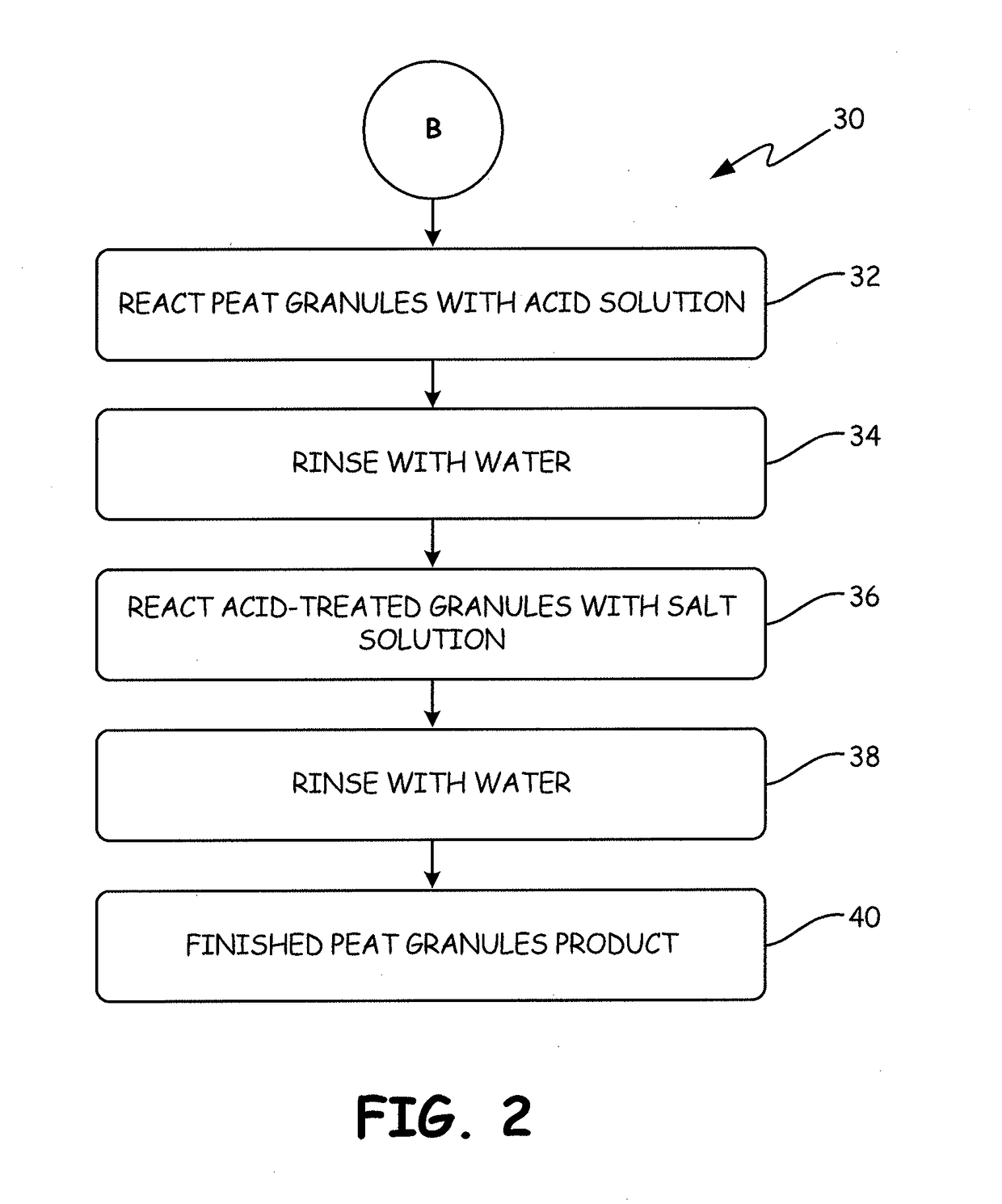

Particulate medium prepared from partially decomposed organic matter for selective sorption between competing metal ions in aqueous solutions

ActiveUS20170165659A1High of pellet hardnessImprove usabilityWater contaminantsAmphoteric ion-exchangersChemical treatmentHigh concentration

A process for the preparation of a granulated or pelletized sorption medium from a partially decomposed organic material like peat, followed by low-temperature thermal activation of the sorption medium to produce a high degree of granule or pellet hardness balanced against an efficacious level of ion-exchange and adsorption capacity, followed by chemical treatment of the sorption material via a preselected solution of soluble salts (called “APTsorb II*M”) for use in a wastewater treatment process where competing toxic metal cations are present in the wastewater is provided by this invention. Depending upon the M+ cations contributed to the peat granule sorption activity sites by the preselected salt used in the salt solution treatment step, the granules exhibit a selectivity α of a first type of more-toxic metal cations (such as cadmium, lead, copper, or other metals at high concentrations) over a second type of less-toxic metal cations of (such as zinc, aluminum, or iron) in the wastewater; greater adsorption activity for the first type of more-toxic metal cations; and greater breakthrough capacity for the first type of more-toxic metal cations. This allows the end user to target the more-toxic metals for adsorption by the sorption medium containing the cations contributed by the preselected solution of soluble salts.

Owner:RGT UNIV OF MINNESOTA +1

Chromatography columns and their operation

InactiveUS7972506B2Ion-exchange process apparatusComponent separationDriven elementChromatography column

A chromatography column (100) is disclosed comprising a housing (10) comprising a tubular side wall (1); opposed, axially spaced end units (2,3) which together with the side wall define an enclosed bed space to contain a bed of particulate medium, at least one of the end units being slidable in axial direction; an axial drive element (5) connected to the slidable end unit, said drive element extending internally in the column bed space; a drive (4) positioned on or beyond the opposite end unit and connected to the drive element.

Owner:PALL CORP

Novel method for the preparation of granulates of active constituents, and granulates as obtained

InactiveUS20110280945A1Avoid disadvantagesIncreasing apparent half-lifeBiocidePowder deliveryMedicineSolid particle

Owner:DEBREGEAS & ASSOCIES PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com