Efficient and energy-saving method for backflushing filter media

A technology of backwashing filtration, high efficiency and energy saving, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of large floor area, large amount of clean water, low efficiency, etc., to save land resources and efficiently occupy resources , the effect of saving floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

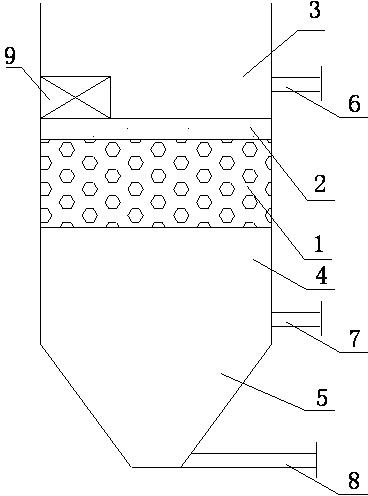

[0017] In this example, figure 1 As shown, the method is to fill the system with a light granular medium filter material, thereby forming a filter material layer, that is, a filter area 1, and an energy generating device 9 is arranged above the light granular medium filter material, between the filter material layer 1 and A perforated plate 2 is set between the energy generating devices 9, and of course it can also be a grid, and the system is divided from top to bottom into: a clear water area 3, a filtration area 1, a mixed sedimentation area 4 and a sludge accumulation area 5, and the filter material The clear water area 3 above the layer is equipped with a clear water discharge pipe 6, the mixed sedimentation area 4 below the filter material layer is equipped with a sewage inlet pipe 7, and the bottom of the system is equipped with a slag discharge pipe 8; Sewage enters the system from the water inlet pipe 7, and first further coagulates in the mixed sedimentation zone 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com