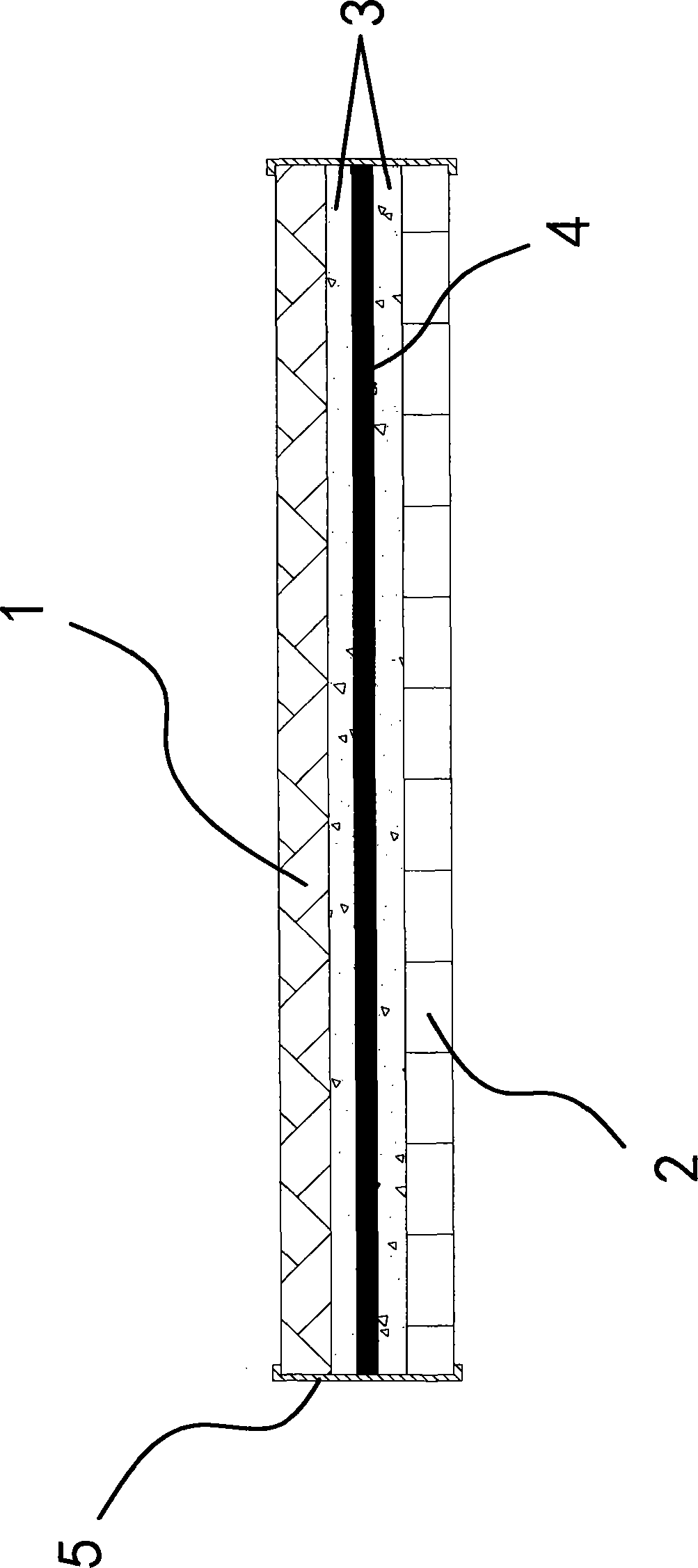

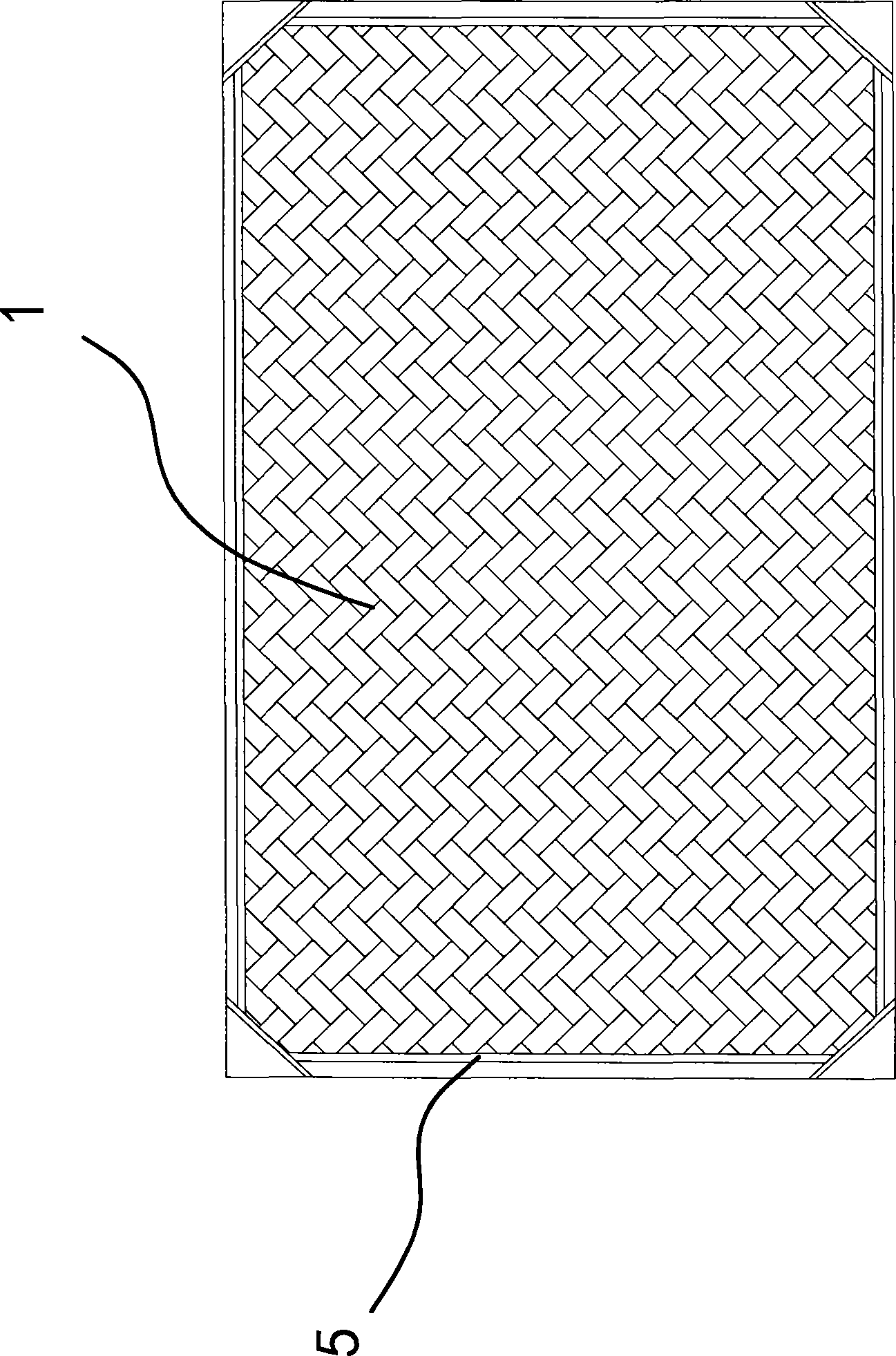

Processing technology and product of imitation vine and bamboo composite dual-purpose mat

A processing technology, the technology of imitating rattan mats, which is applied in the field of textile processing, can solve the problems that rattan mats have not been waterproofed, are inconvenient to store separately, and have complex processes, and achieve the effects of good hand feeling, long service life and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Select grass waste and add CMC for beating, the degree of substitution is 0.5, the viscosity is 800cp, the temperature is 25°C, the concentration is 2%, the amount of CMC is 0.48kg / t slurry, the pH value of the slurry is 7, the reaction time between CMC and slurry is 20 minutes, the CMC The adding point is selected at the outlet of good pulp of the concentrator before knocking, low-consistency beating; semi-finished paper is made through paper processing technology; the surface of the semi-finished paper is directly sprayed with polyethylene emulsion waterproofing agent for waterproof treatment, and then thoroughly dried by a dryer; according to the mat Specifications Cut the dried semi-finished paper into sheets, leaving margins; wrap the cotton yarn core into rope-shaped paper with sheet-shaped paper and roll it, and weave the rope-shaped paper into the main body of imitation rattan mat; The main body of the rattan mat is under a pressure of 150kgf / cm 2 , Calendering ...

Embodiment 2

[0047] Select grass waste and add CMC for beating, the degree of substitution is 0.4, the viscosity is 700cp, the temperature is 20°C, the concentration is 1%, the amount of CMC is 0.5kg / t slurry, the pH value of the slurry is 8, the reaction time between CMC and slurry is 15 minutes, and the CMC Adding points are selected in the unknocked pulp tank, and the pulp is medium-concentrated; semi-finished paper is made through paper processing technology; the surface of the semi-finished paper is directly sprayed with polyvinylidene chloride emulsion waterproofing agent for waterproof treatment, and then thoroughly dried by a dryer; according to the mat Specifications Cut the dried semi-finished paper into sheets, leaving margins; wrap the cotton yarn core into rope-shaped paper with sheet-shaped paper and roll it, and weave the rope-shaped paper into the main body of imitation rattan mat; The main body of the rattan mat is under a pressure of 180kgf / cm 2 , Calendering for 0.8min i...

Embodiment 3

[0052] Use waste wood raw materials, kraft chemical wood pulp and add modified cellulase for beating: the amount of modified cellulase is 0.47kg / t pulp, the reaction time is 40 minutes, the enzyme use temperature is 50°C, the pH value is 7, and the addition point is selected In the hydropulper, low-consistency beating; semi-finished paper is made through paper processing technology; polyorganosilicon waterproofing agent is directly sprayed on the surface of the semi-finished paper for waterproof treatment, and then thoroughly dried by a dryer; the dried paper is dried according to the specifications of the mat The semi-finished paper is cut into flakes, leaving a margin; the cotton yarn is wrapped into a rope-shaped paper with a sheet-shaped paper and rolled into a roll, and the rope-shaped paper is woven into the main body of the imitation rattan mat; 100kgf / cm 2 , Calendering for 0.2min in a special calender at a temperature of 120°C.

[0053] The bamboo stems are processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com