Surface flame retardation reinforced solid wood and manufacturing method thereof

A manufacturing method and technology for solid wood, which are applied in the fields of manufacturing tools, wood compression, and wood treatment, can solve the problems of high production cost, intolerant of decay, service life, and prone to mildew and blue stain, and achieve uniform moisture content distribution and moisture content. The effect of small rate deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

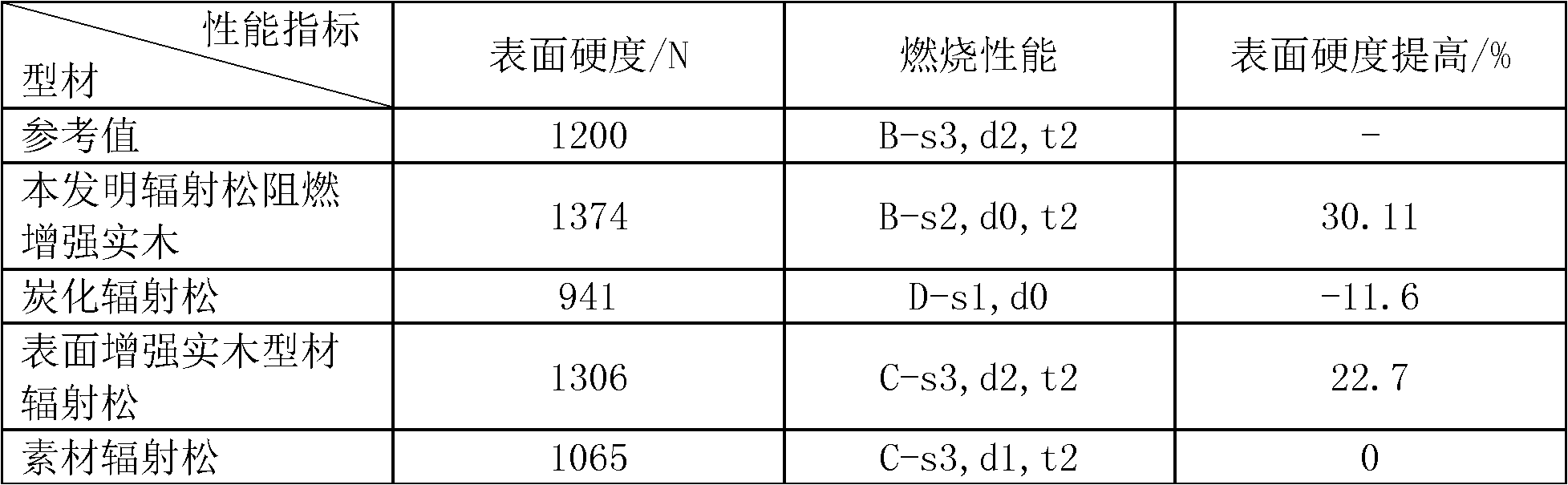

Examples

Embodiment 1

[0034] (1) The first high-temperature and high-humidity rapid drying step: stack the 24mm thick masson pine fast-growing timber in the drying kiln, first open the humidification valve to quickly humidify the drying kiln and directly humidify to a relative humidity of ≥98%, so that the drying kiln Fill with water vapor, then keep the humidification valve open, keep the relative humidity ≥ 98%, and open the heating valve for the first time to quickly heat until the dry bulb temperature is 1°C higher than the wet bulb temperature and keep it for 5 hours, and continue to humidify to control the relative humidity in the drying kiln to 99~ 100%, heat up the dry bulb temperature in the kiln from 103 to 135°C, and dry the masson pine with a thickness of 24mm at 2°C for 2 hours for 3 days to reduce the moisture content of the wood to 6%.

[0035] (2) Flame retardant treatment step: prepare a water-soluble inorganic phosphorus-nitrogen-boron flame retardant with a solution concentration ...

Embodiment 2

[0046] (1) The first high-temperature and high-humidity rapid drying step: stack the 100mm thick poplar fast-growing timber in the drying kiln, first open the humidification valve to quickly humidify the drying kiln and directly humidify to a relative humidity ≥ 98%, so that the drying kiln Fill the interior with water vapor, then keep the humidification valve open, keep the relative humidity ≥ 98%, and open the heating valve for the first time to quickly heat until the dry bulb temperature is greater than the wet bulb temperature by 2°C and keep it for 25 hours. Continuous humidification controls the relative humidity in the drying kiln to 99 ~100%, heat up the dry bulb temperature in the kiln from 103 to 135°C, and dry the poplar wood at a thickness of 100mm at 2°C for 10.5h for 15 days to reduce the moisture content of the wood to 12%.

[0047] (2) Flame retardant treatment step: prepare ammonium polyphosphate (APP) flame retardant with a solution concentration of 25% in the...

Embodiment 3

[0057] (1) The first high-temperature and high-humidity rapid drying step: stack the radiata pine fast-growing wood with a thickness of 50mm in the drying kiln, first open the humidification valve to quickly humidify in the drying kiln and directly humidify to a relative humidity ≥ 98%, so that the drying Fill the kiln with water vapor, then keep the humidification valve open, keep the relative humidity ≥ 98%, and open the heating valve for the first time to quickly heat until the dry bulb temperature is greater than the wet bulb temperature 1.8°C and keep it for 20h, and continue to humidify to control the relative humidity in the drying kiln. 99-100%, heat the dry bulb temperature in the kiln from 103 to 135°C, and dry the radiata pine wood at a thickness of 50mm at 1.5°C for 6 hours for 8 days to reduce the moisture content of the wood to 8%.

[0058] (2) Flame retardant treatment step: it is to prepare the phosphorus-nitrogen-boron flame retardant of 25% flame retardant eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com