Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

142results about How to "Eliminate formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

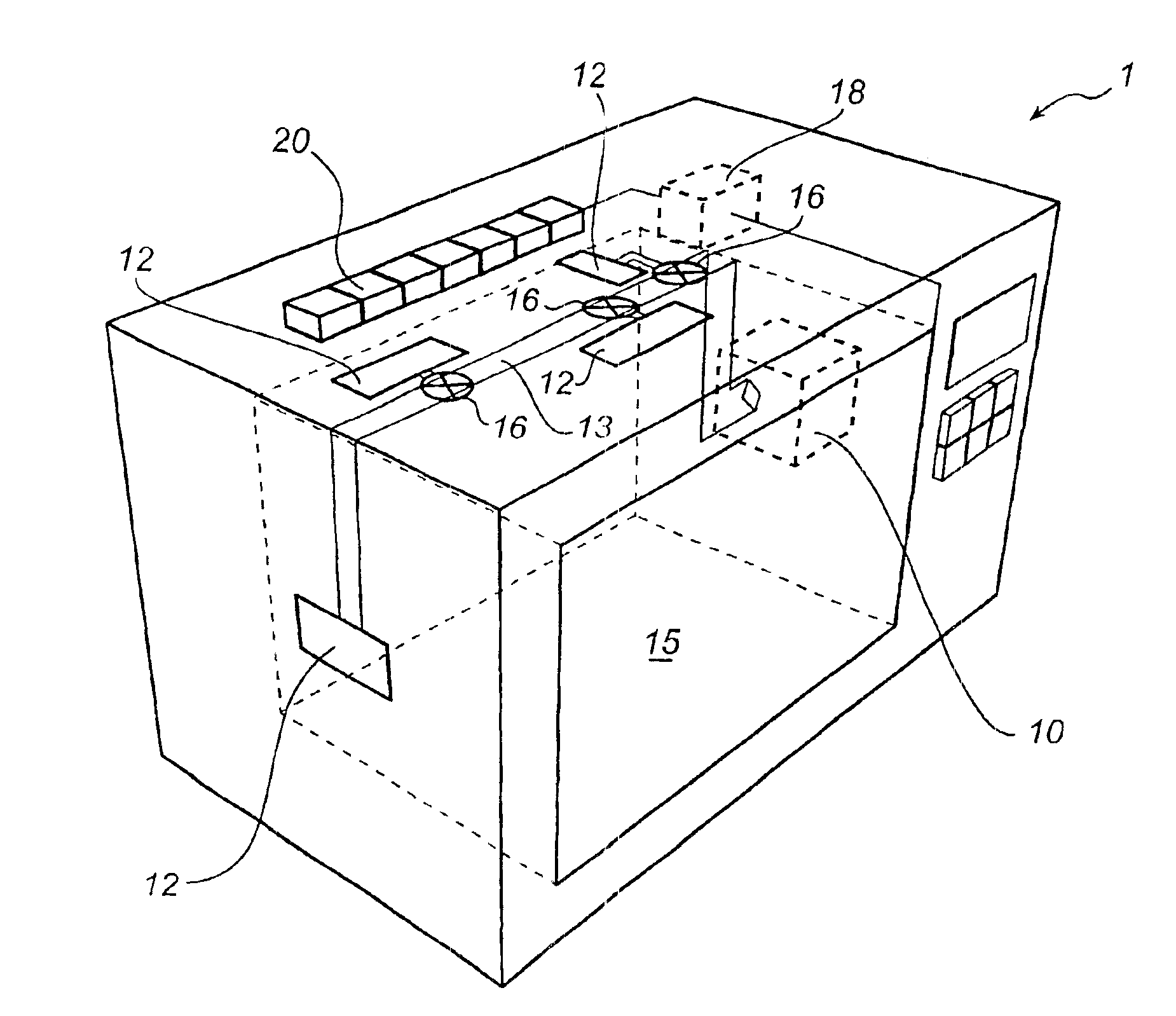

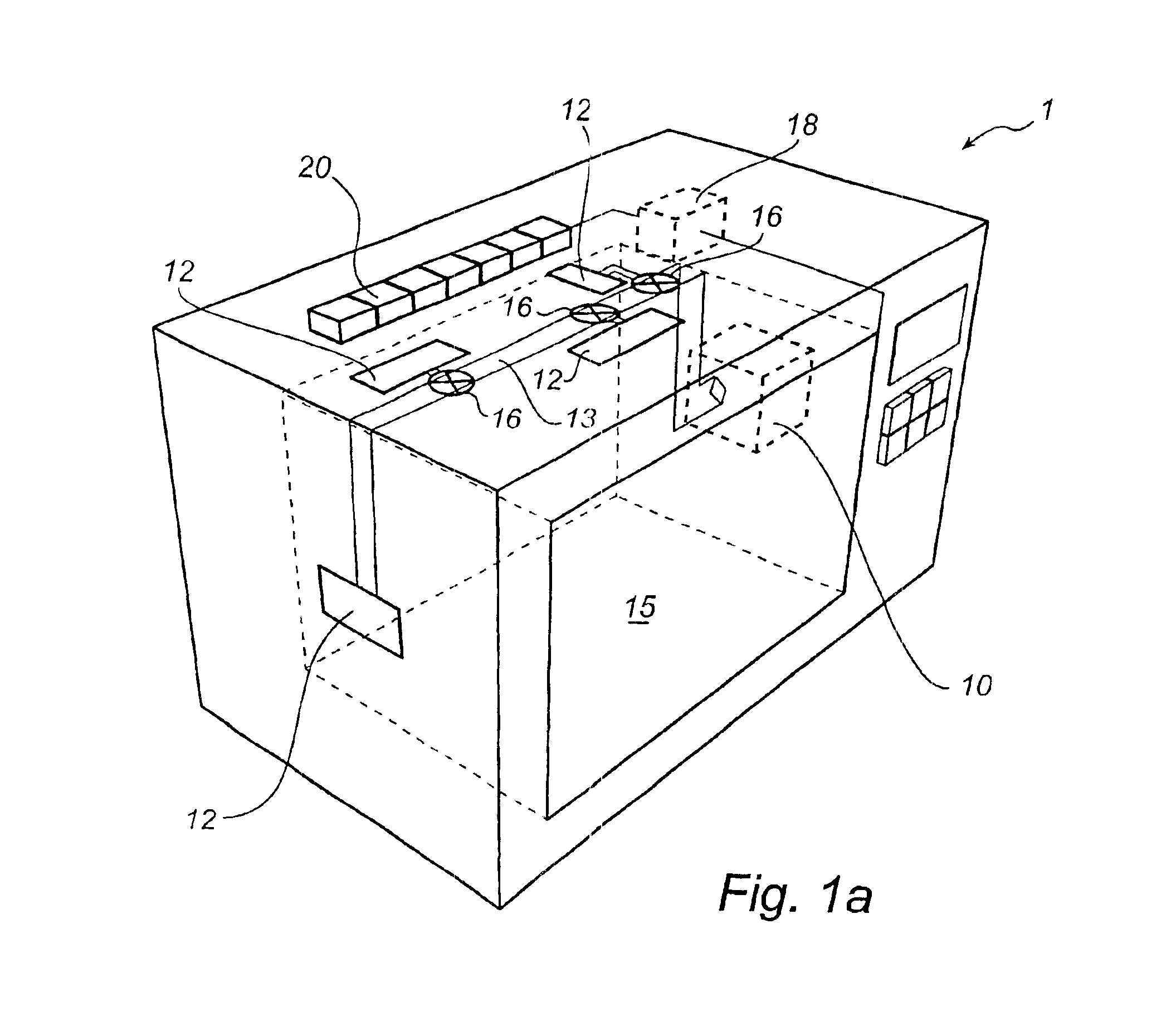

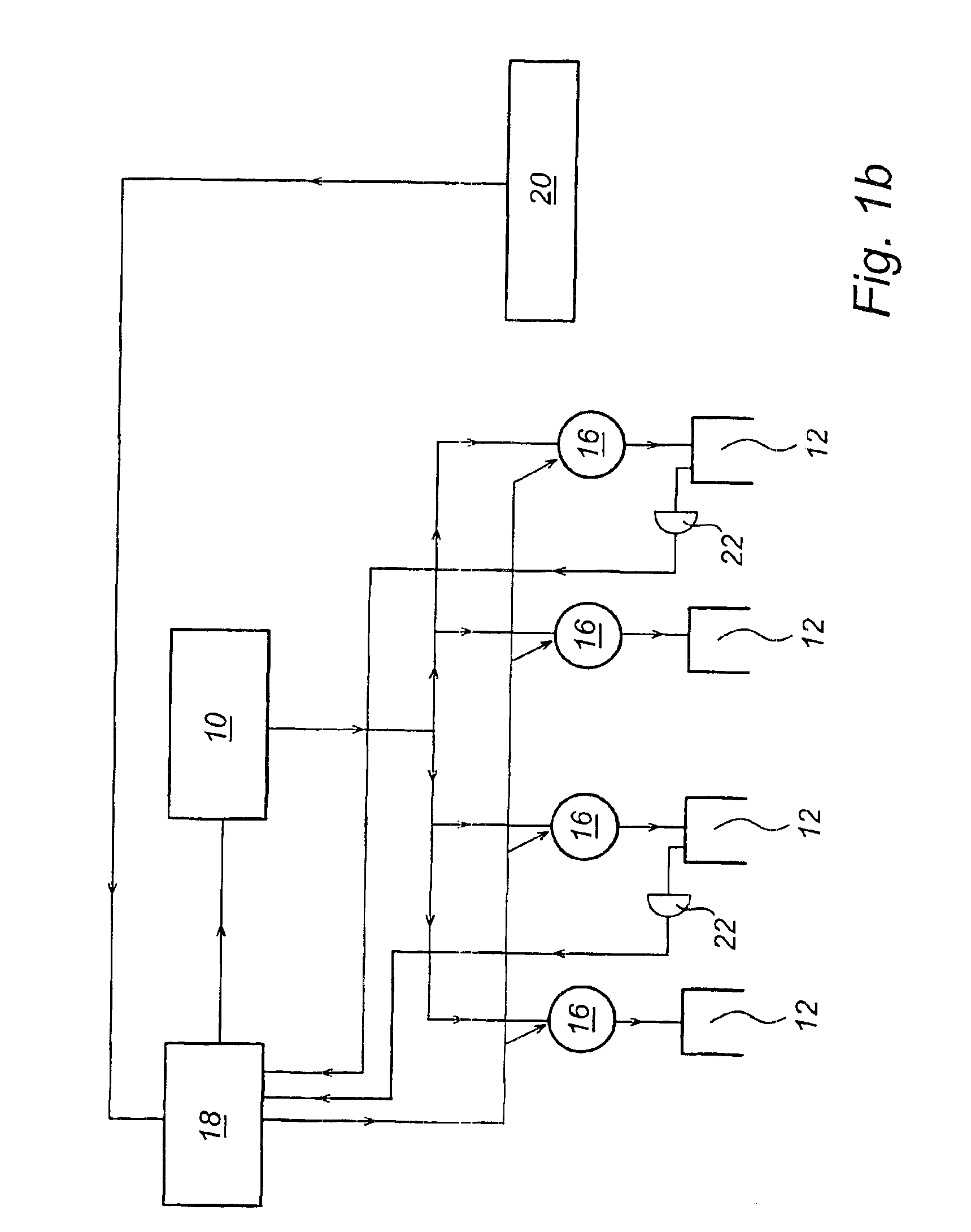

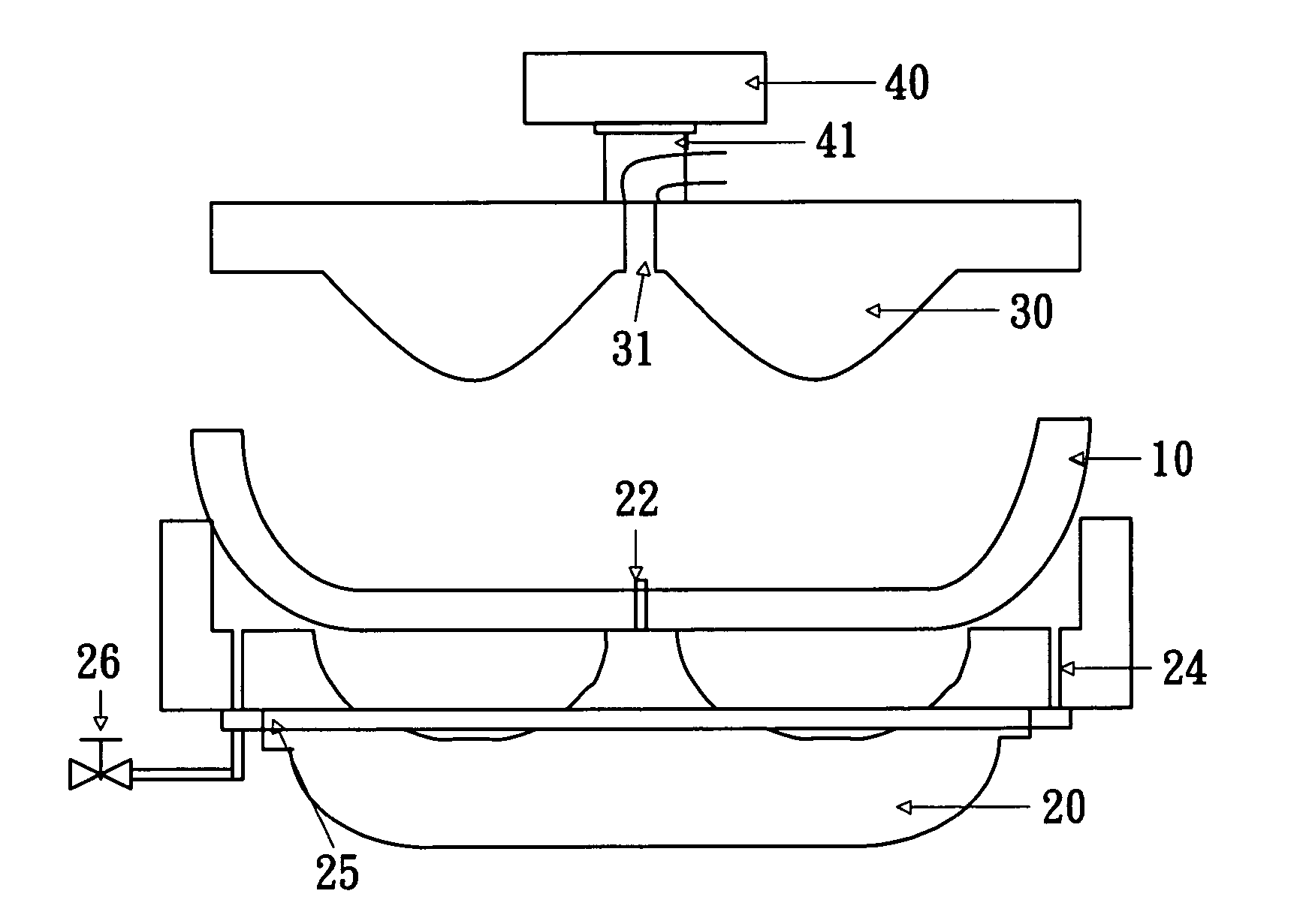

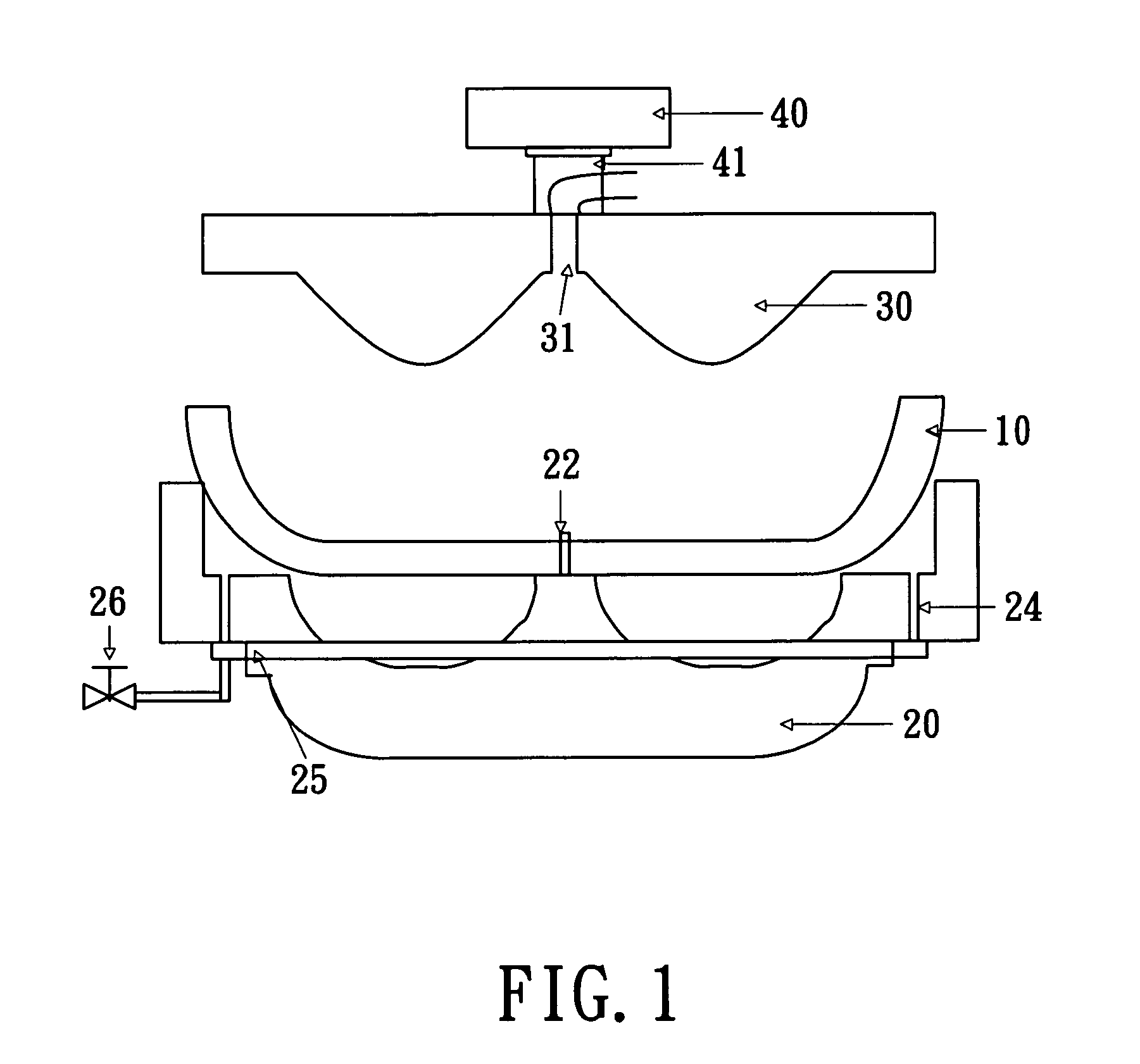

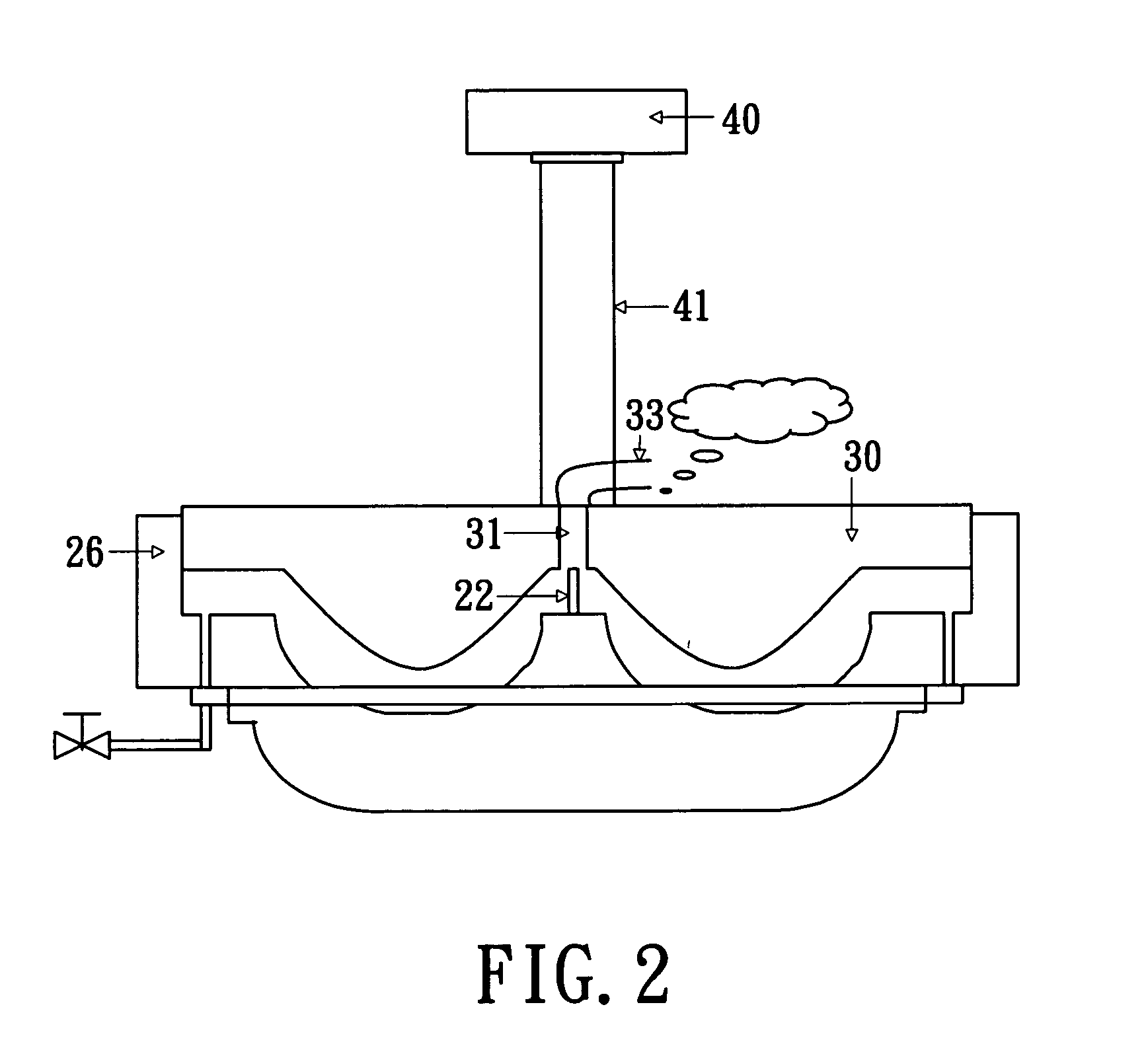

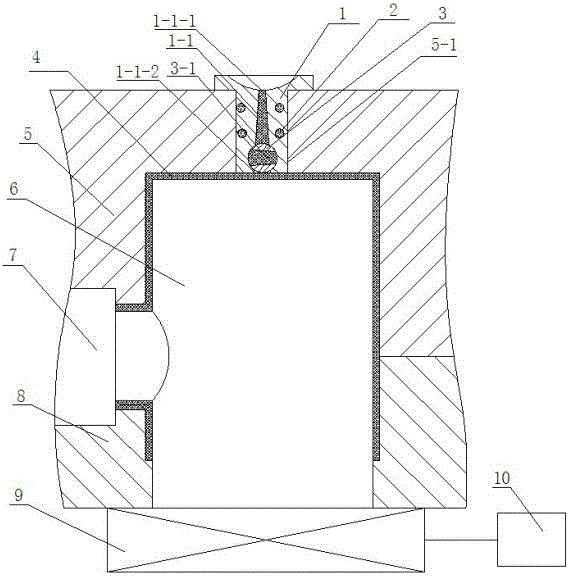

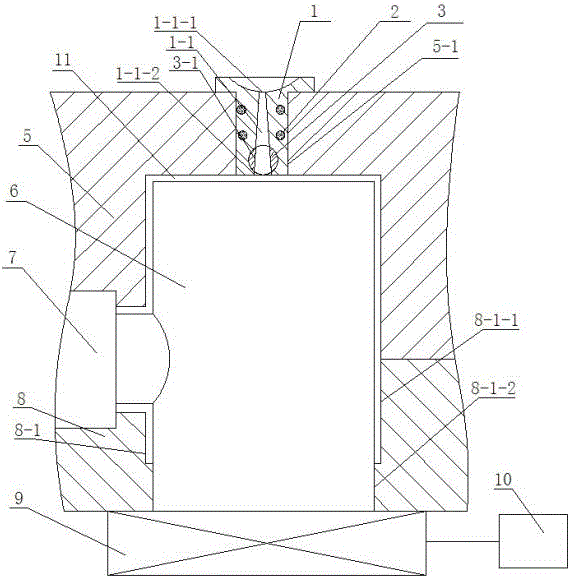

Method and apparatus for uniform heating in a microwave oven

InactiveUS6884979B1Heating evenlyEliminate formationDielectric heating circuitsMicrowave heatingMicrowave ovenElectrical and Electronics engineering

A microwave oven and a method for heating a load which is placed therein. According to the invention a predetermined mode in the cavity of a microwave oven is fed by means of an associated feeding port which is arranged to feed essentially the intended mode only, the feeding of a mode other than the intended, predetermined mode being essentially prevented.

Owner:WHIRLPOOL CORP

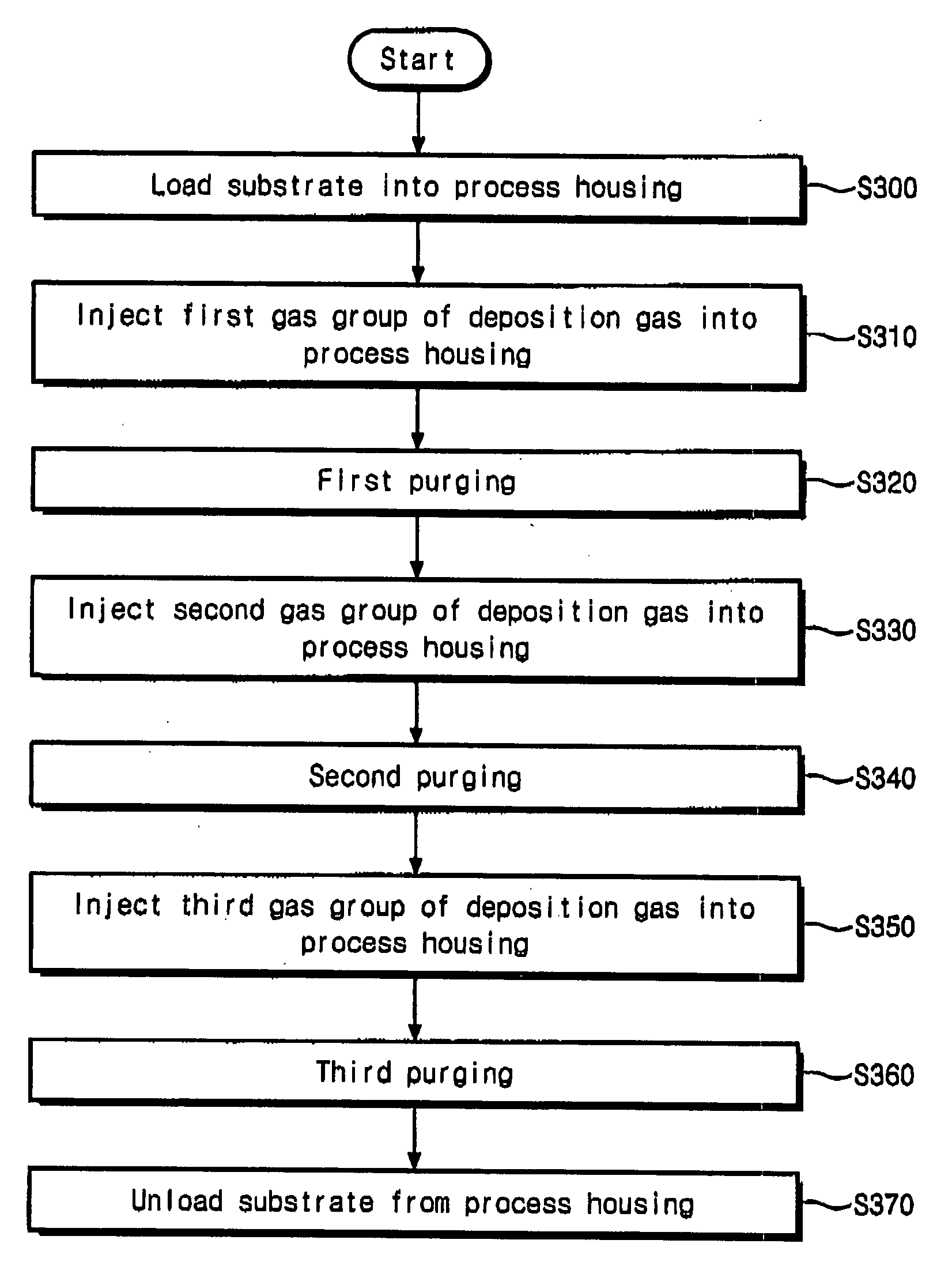

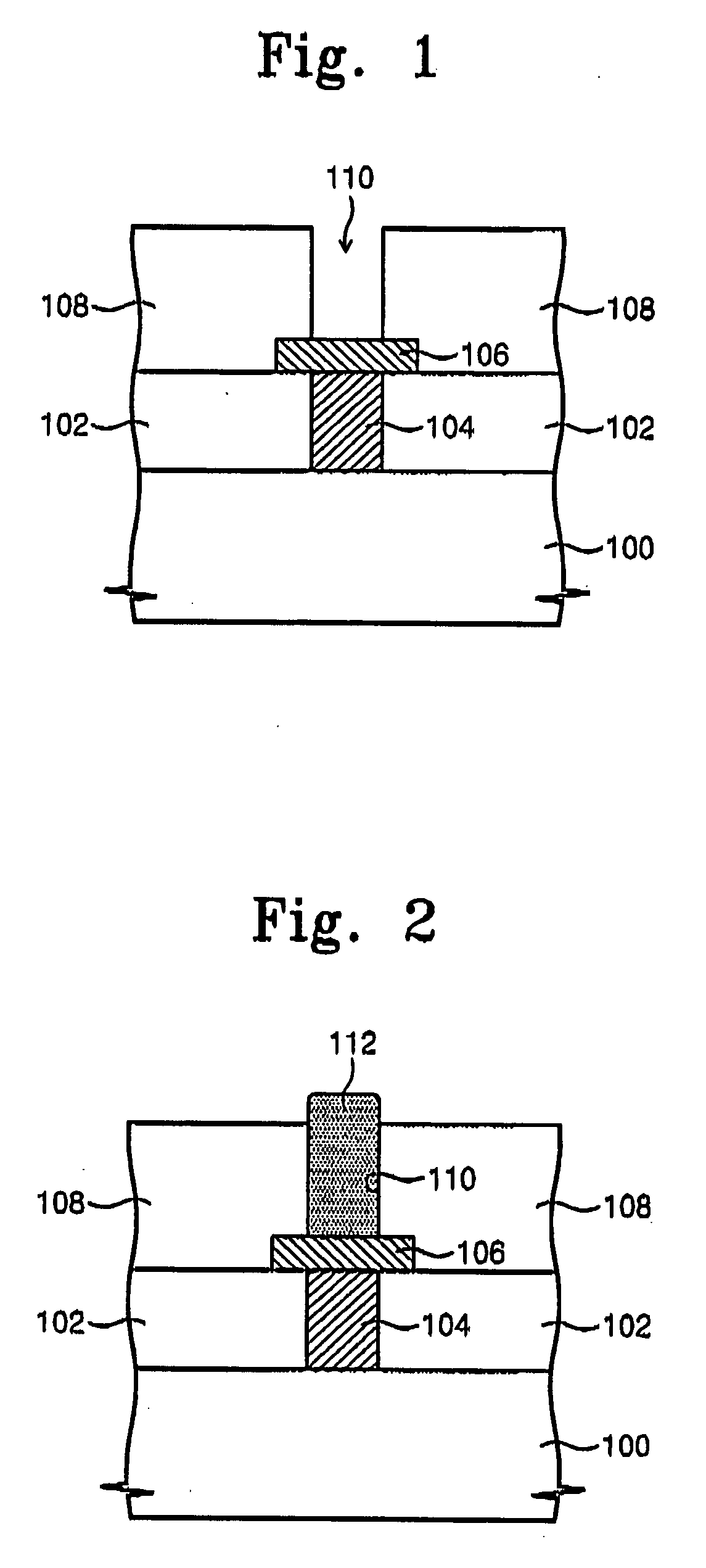

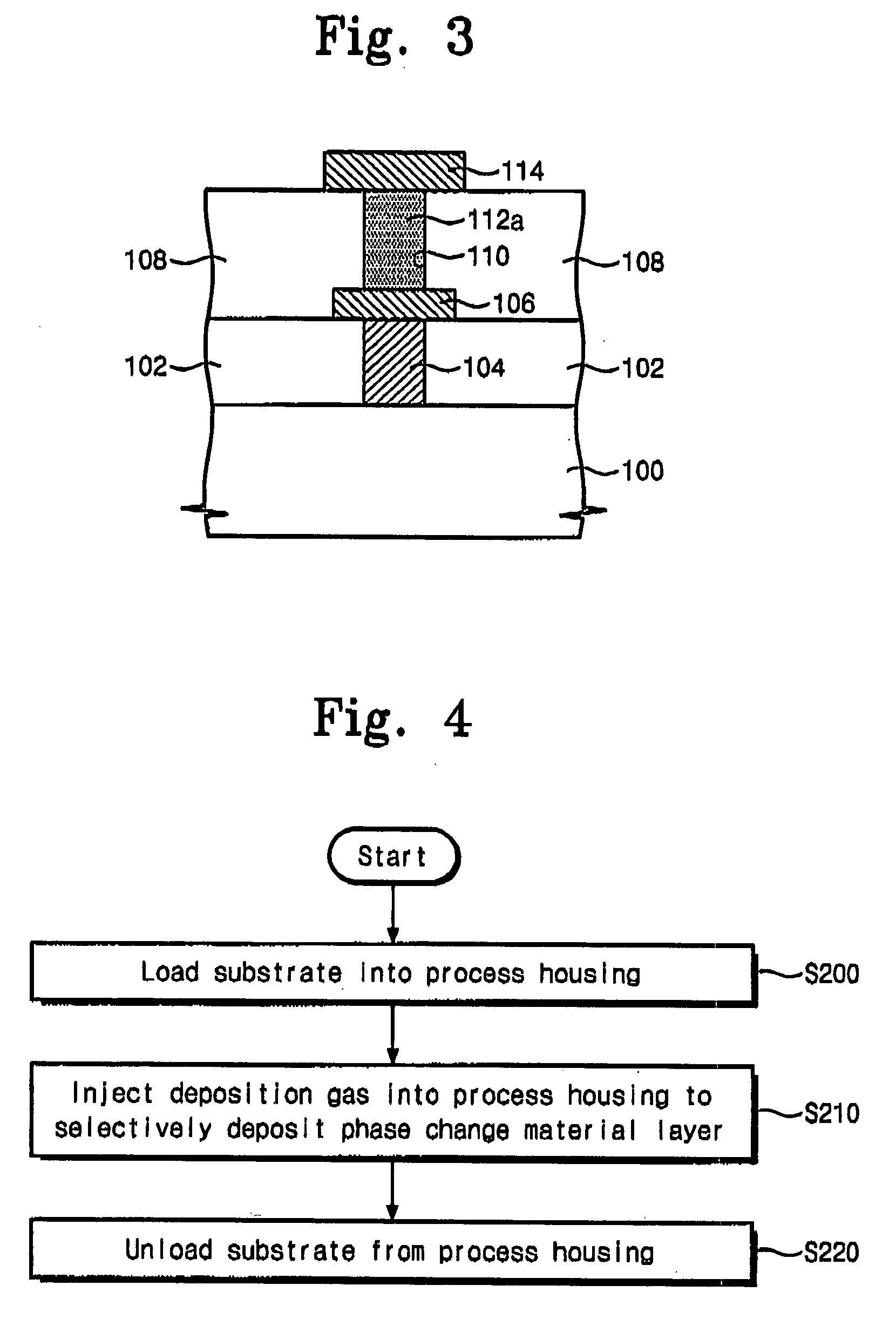

Method of forming a phase change material layer, method of forming a phase change memory device using the same, and a phase change memory device so formed

ActiveUS20070246743A1Easy to integrateReduce power consumptionSolid-state devicesChemical vapor deposition coatingThermal energyElectrical conductor

A method of forming a phase change material layer includes preparing a substrate having an insulator and a conductor, loading the substrate into a process housing, injecting a deposition gas into the process housing to selectively form a phase change material layer on an exposed surface of the conductor, and unloading the substrate from the process housing, wherein a lifetime of the deposition gas in the process housing is shorter than a time the deposition gas takes to react by thermal energy.

Owner:SAMSUNG ELECTRONICS CO LTD

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

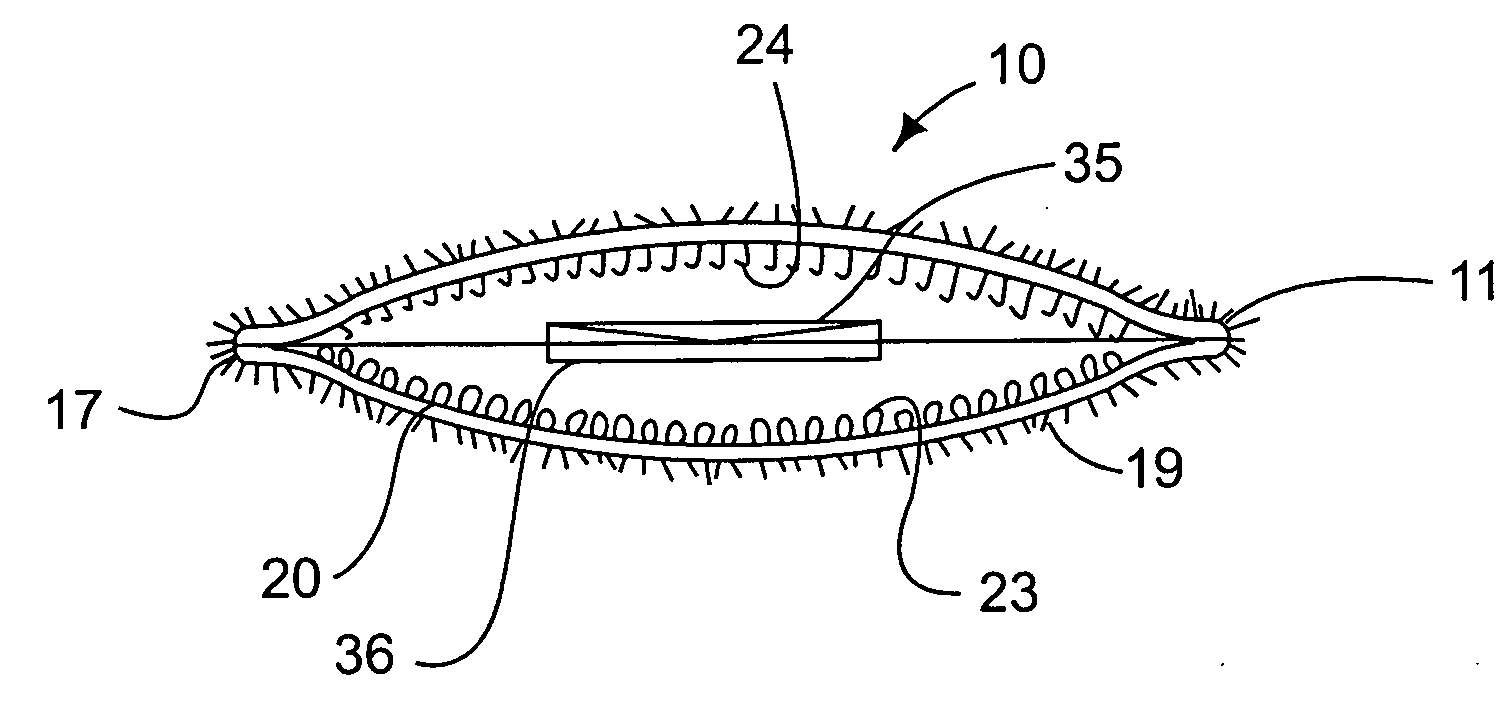

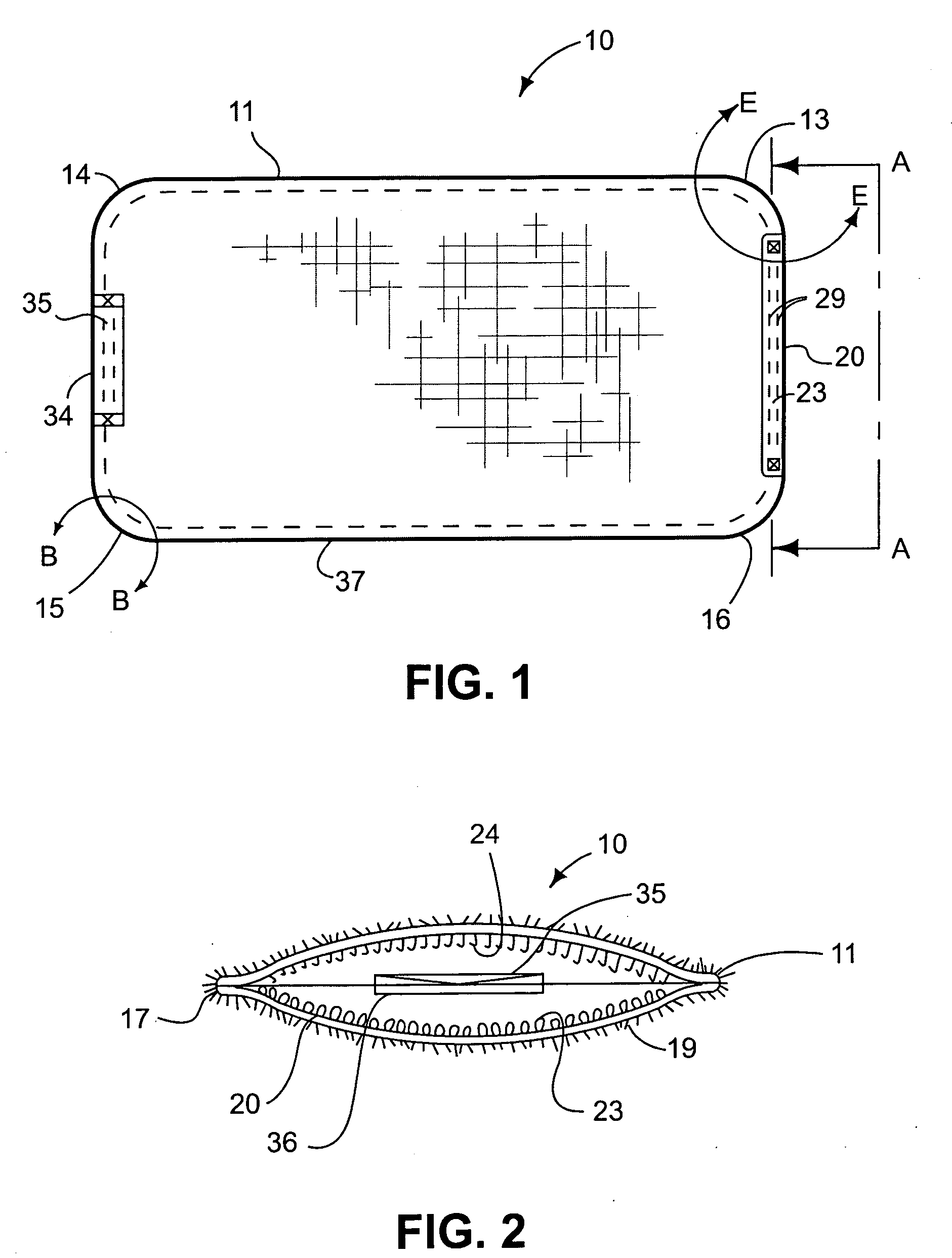

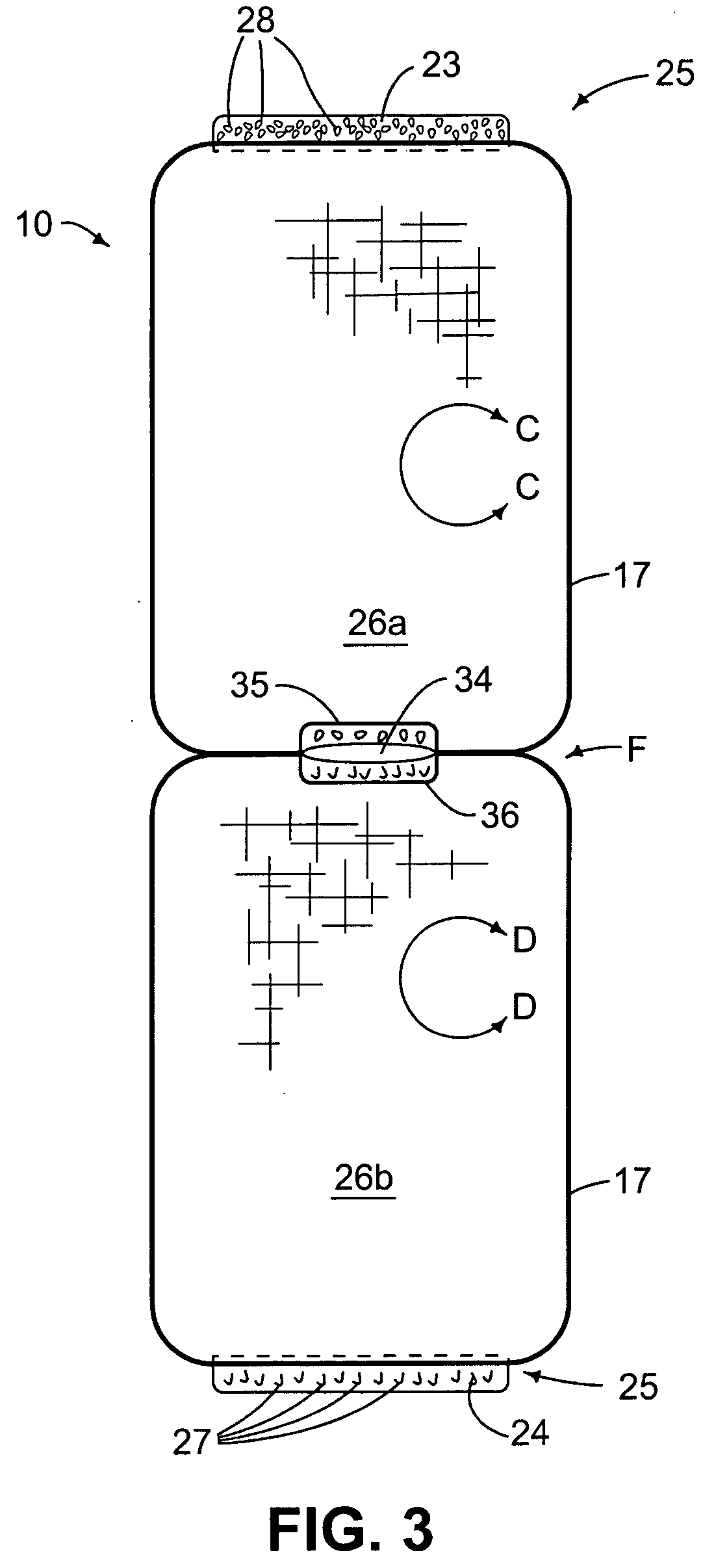

Removable moisture-wicking pillow case covering with Velcro(R) fastened oppositely-disposed, different sized openning thereinto

A removable moisture-wicking pillow case covering for a pillow for absorbing moisture and for maintaining the loft of the pillow upon which a person's places his or her sweat or perspiration on the head, neck and hair when in bed, or when laying down to rest, comprising a rectangularly-shaped sack having a volume which is slightly smaller than the volume of the pillow inserted and housed therein, the sack having four corners thereof rounded to eliminate the formation of sharp corners on the outside of the sack and for providing a means for registration of the pillow therein, the sack being made of a cloth base having a plurality of threads anchored therein and extending outwardly therefrom from about 3 / 16 to ⅜ of an inch and continuing through to the opposite side of the cloth base to form a plurality of relatively short loops extending therefrom, and having a pair of oppositely disposed openings into the sack along the seams thereof, one of the oppositely disposed openings being smaller than the other one, the peripheral lips of each of the openings having a pair of lipped portions having a Velcro® fastening system secured thereto so that when the lips are folded over 180 degrees and directed into the inside of the opening to the sack, the hook portion of the Velcro® fastening system when pressed together is operatively fastened to the oppositely-disposed loop portion of the Velcro® fastening system.

Owner:TAYLOR MICHAEL STEVEN

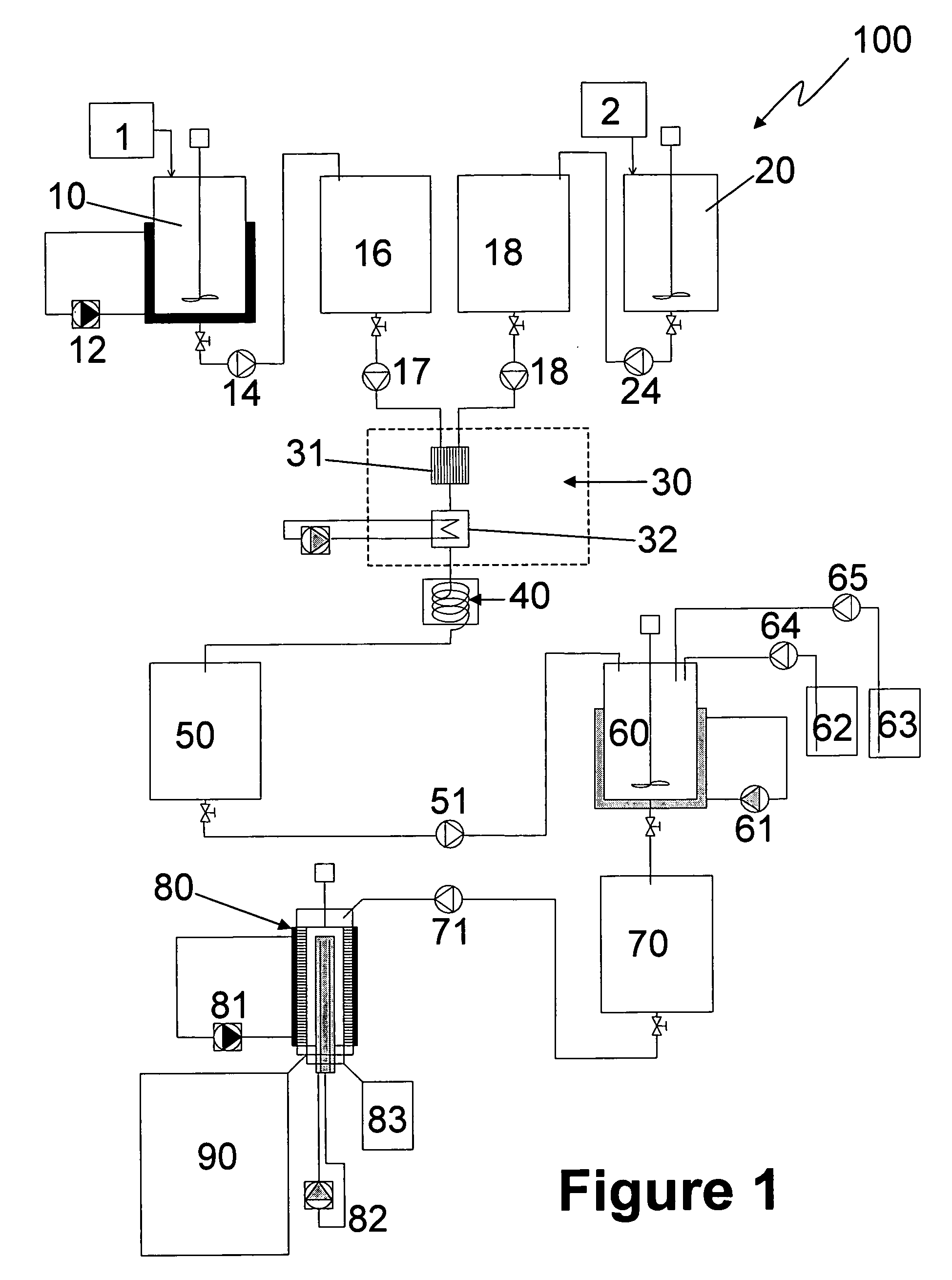

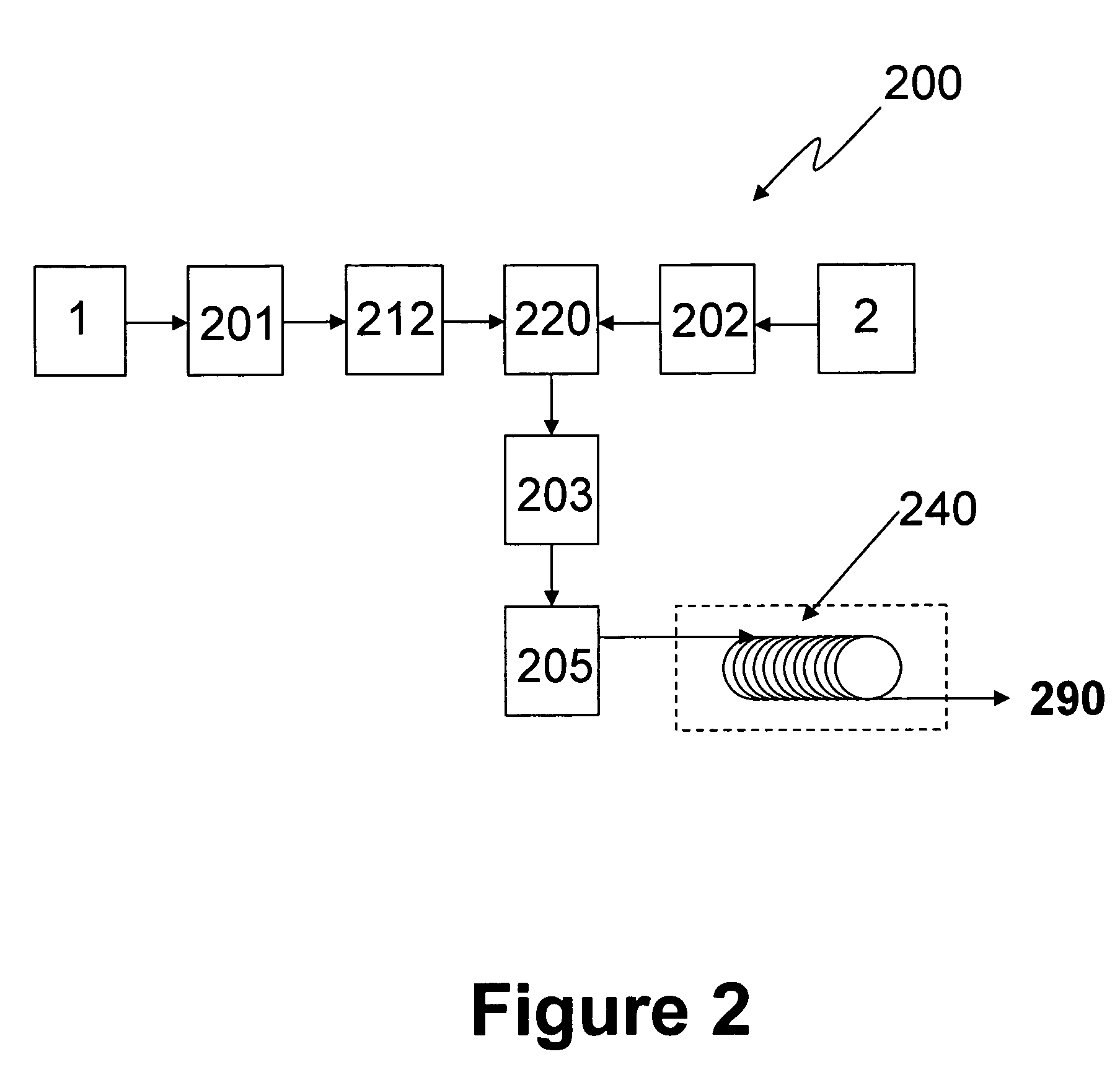

Continuous process for production of polymeric materials

ActiveUS20060241242A1Minimize and substantially eliminate unwanted high-molecular-weight fractionDisturbing flow of solutionChemical/physical/physico-chemical microreactorsMicroreactorContinuous flow

The invention provides a continuous-flow process for producing a polymeric material. The process of the invention comprises the steps of: introducing at least two solutions, each comprising one or more reactants, into a microreactor to mix the two solutions to form a reacting solution, wherein the one or more reactants are selected from the group consisting of a monomer, an initiator, a coupling agent, a prepolymer, a macromer, and mixtures thereof; feeding continuously the reacting solution into a flow-through polymerization reactor in a coil form, wherein the flow-through polymerization reactor is capable of providing a residence time sufficient for (co)polymerizing the reactants to form a polymer with a desired polydispersity, wherein the flow-through polymerization reactor is immersed in an ultrasonic bath to minimize or substantially eliminate unwanted high-molecular-weight fractions of the polymer.

Owner:ALCON INC

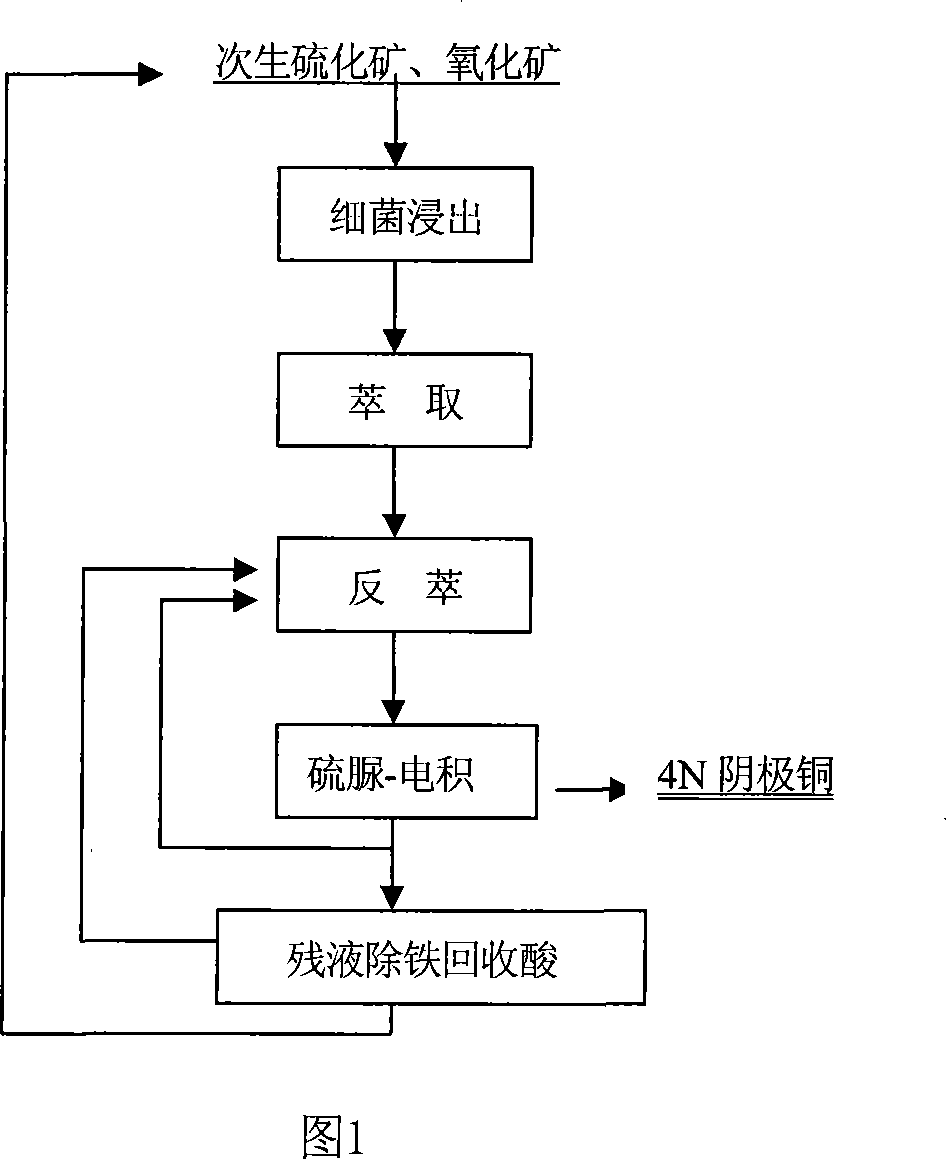

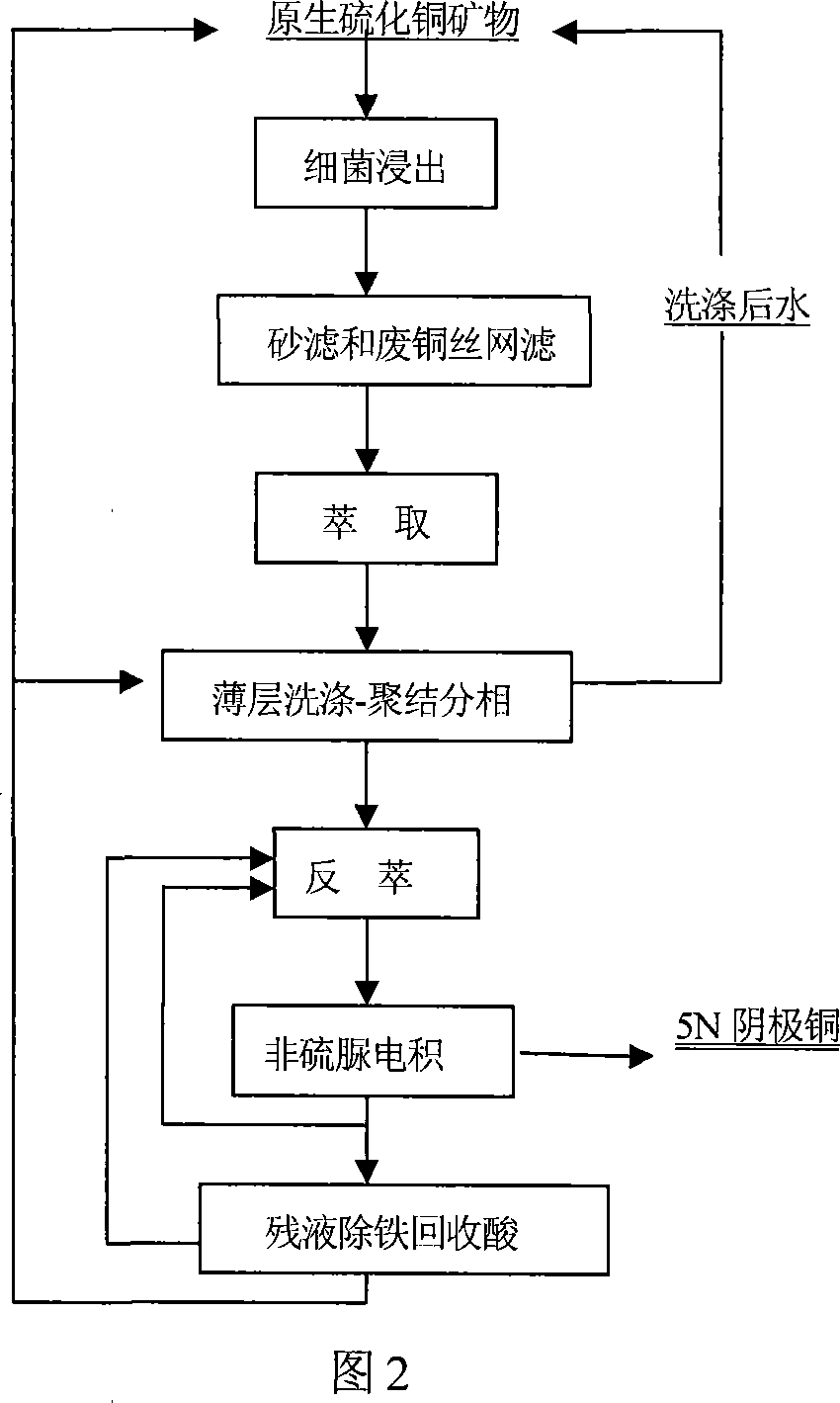

Method of preparing high purity copper by bacteria leaching primary sulfide ore

InactiveCN101033508AEnhanced synergistic leachingIncrease leaching ratePhotography auxillary processesProcess efficiency improvementSulfurThin layer

The invention relates to a method of preparing high pure copper from the leachate of primary sulfide ore bacteria, including: it leaches the primary sulfide ores and its mixture by using the mixture of middle and mesophilic bacterias. It filters and extracts the bacterial leaching solution, and conducts thin-layer wash-condensate, coalescence phase, and back-extraction electrowinning for the organic phase load. The invention uses hybrid strains of bacteria and sub-culture techniques to enhance the synergy of the bacterial leaching role and the minerals leaching rate, uses gelatin and other additives without sulfur element to reduce the sulfur impurities.

Owner:CENT SOUTH UNIV

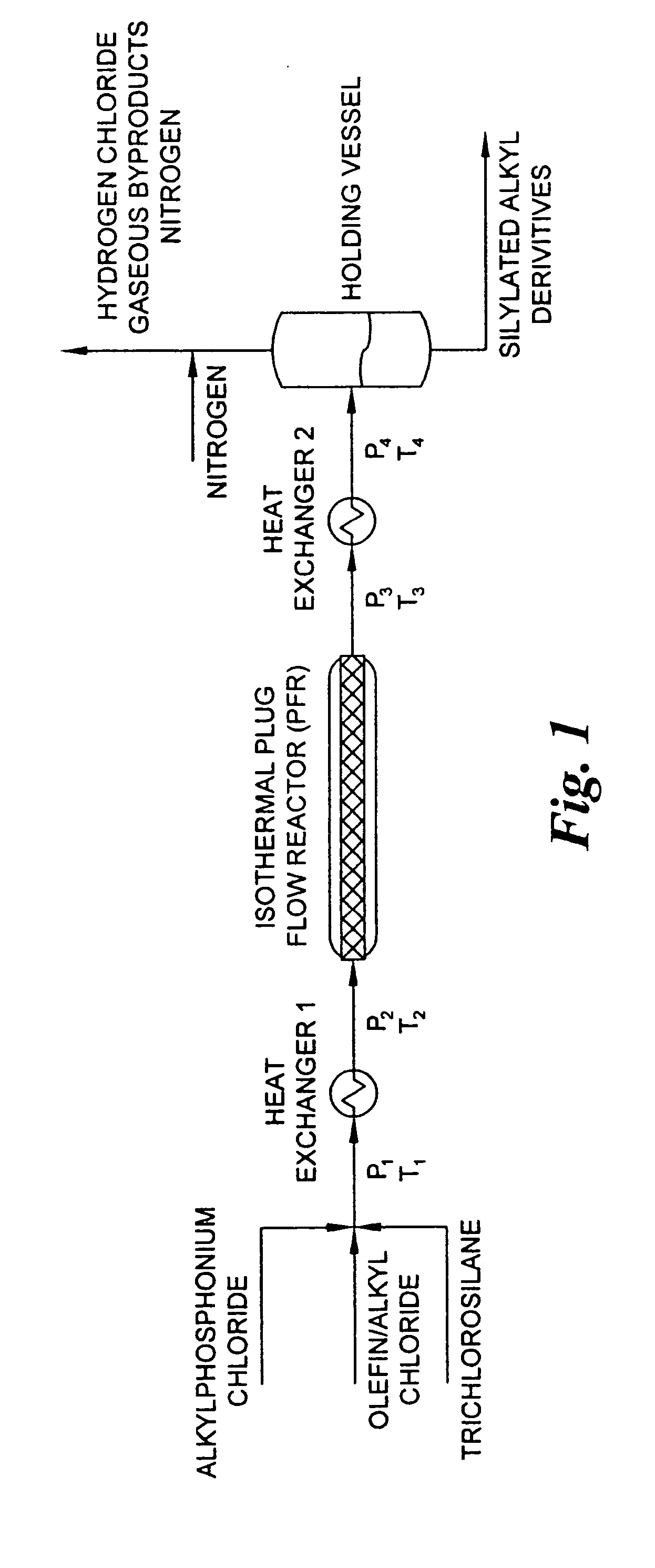

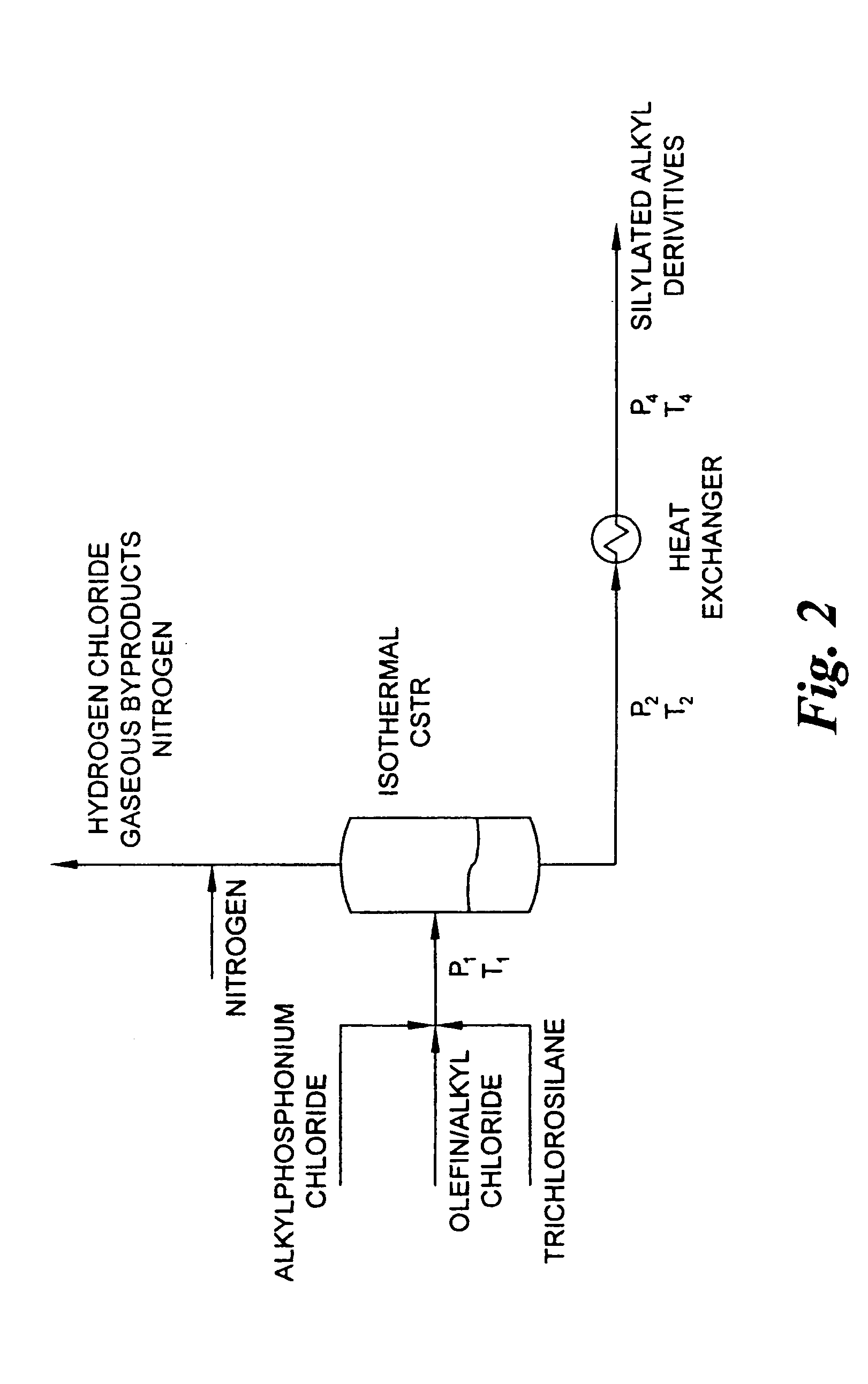

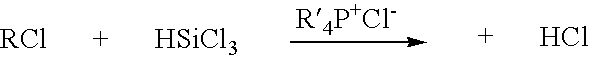

Processes for manufacturing organochlorosilanes and dipodal silanes and silanes made thereby

ActiveUS20050027138A1Continuous processEliminate formationSilicon organic compoundsContinuous useChemistry

Processes are provided for producing organchlorosilanes and dipodal silanes in which an organic halide or alkene or chloralkene is reacted with a hydridochlorosilane in the presence of a quarternary phosphonium salt catalyst by providing sufficient heat to effect a dehydrohalogenative coupling reaction and / or a hydrosilylation reaction and venting the reaction to control reaction pressure and to remove gaseous byproducts from the reaction. The processes are preferably continuous using a catalyst in fluid form at reaction pressures not exceeding about 600 psi. The reactions may be carried out substantially isothermally and / or isobarically, for example in a plug flow reactor or continuous stirred tank reactor. The processes may produce novel silylated compounds including 1,2-bis(trichlorosilyl)decane or 1,2-bis(trimethoxysilyl)decane.

Owner:GELEST

Iron and aluminum intermetallic compound and steel impulse fusion welding method

InactiveCN101195187AImprove welding efficiencyLow costArc welding apparatusWelding/soldering/cutting articlesArgon flowPulse duration

The invention discloses a method for fusion-welding iron-aluminum inter-metallic compounds and steel through pulses. The invention adopts Cr25Ni13Mo2Nb austenite steel welding wires as filling materials and inertia gas protection. The invention takes argon tungsten pulsed arc welding to weld the iron-aluminum inter-metallic compounds and carbon steel or stainless steel. The diameter of the austenite steel welding wires is 1.6-3.0 mm, the inertia gas protection is argon, the processing parameters of the argon tungsten pulsed arc welding are that base current is 70A-180A, pulse current is 100A-250A, pulse duration is 0.15s-0.60s, welding voltage is 12V-18V, argon flow is 10L / min-16L / min, the argon flow of back protecting gas is 2L / min-5L / min, and distance between a jet of a welding torch and a component is 6mm-12mm. The invention can weld the iron-aluminum inter-metallic compounds and the dissimilar materials of the steel to obtain welding connectors with non-cracks and non brittle phases under the condition of non-heating. The invention has the advantages of strong applicability, convenient operation, the invention is convenient for popularization and application, the invention is in particular suitable for welding the iron-aluminum inter-metallic compounds and the carbon steel or the stainless steel, and applied to weld the iron-aluminum inter-metallic compounds and other low-alloy structural steel and heat resistant steel.

Owner:SHANDONG UNIV

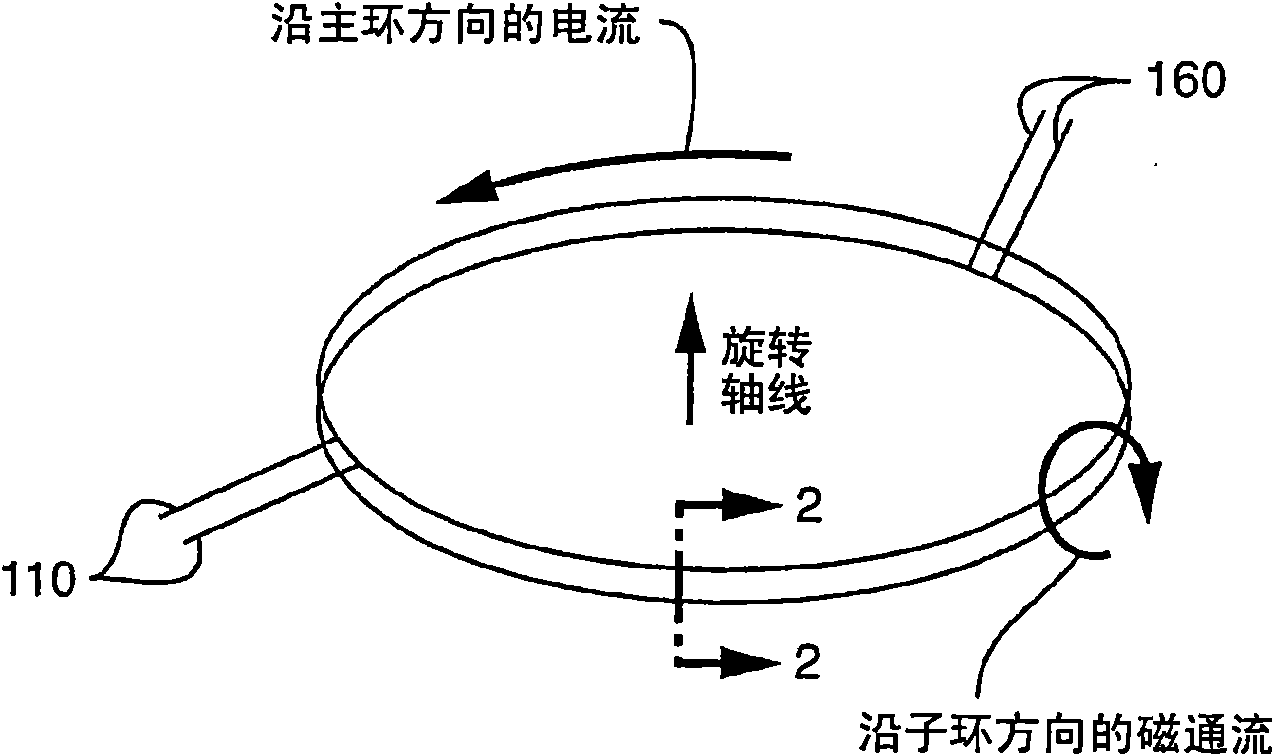

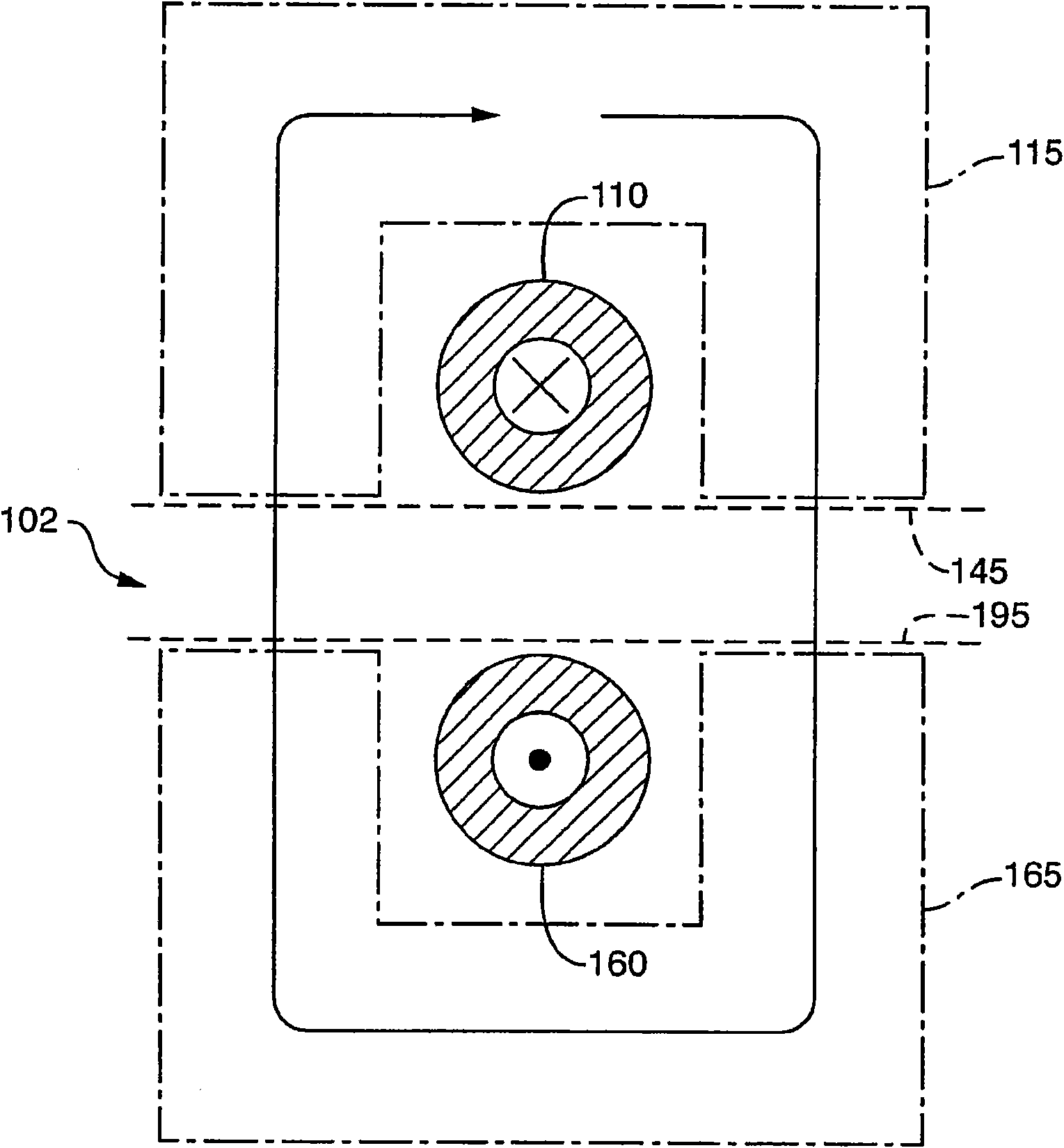

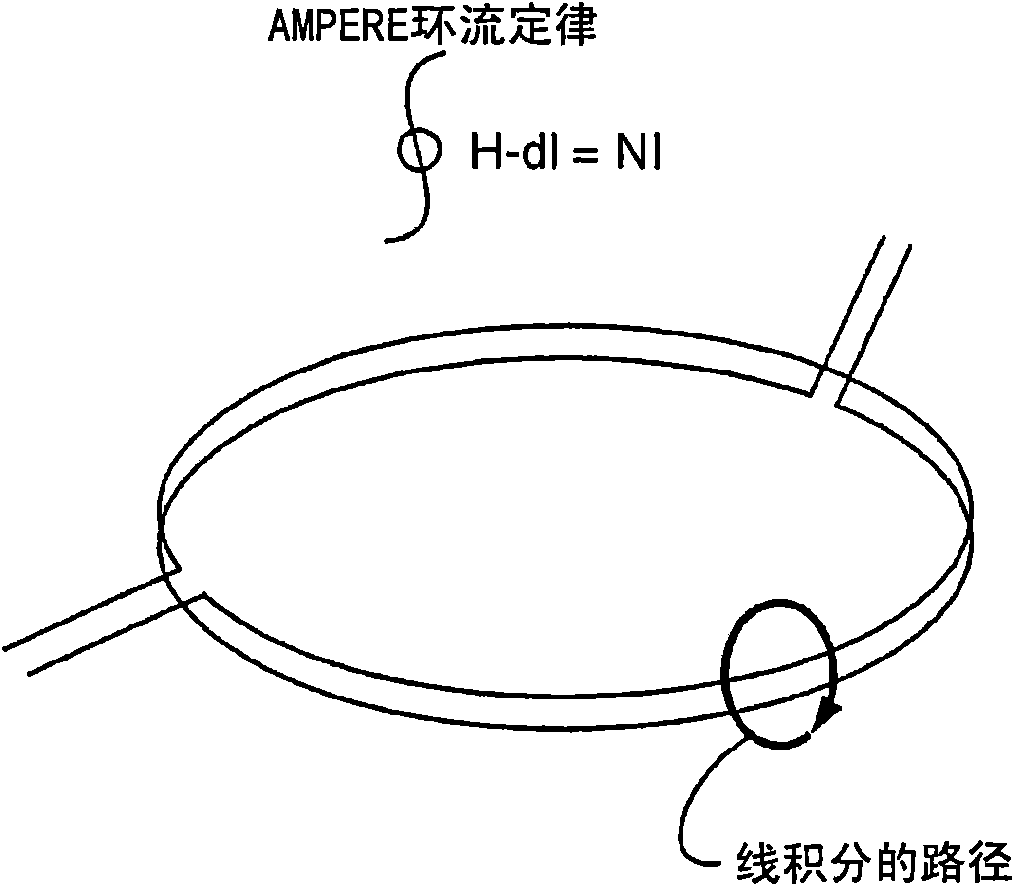

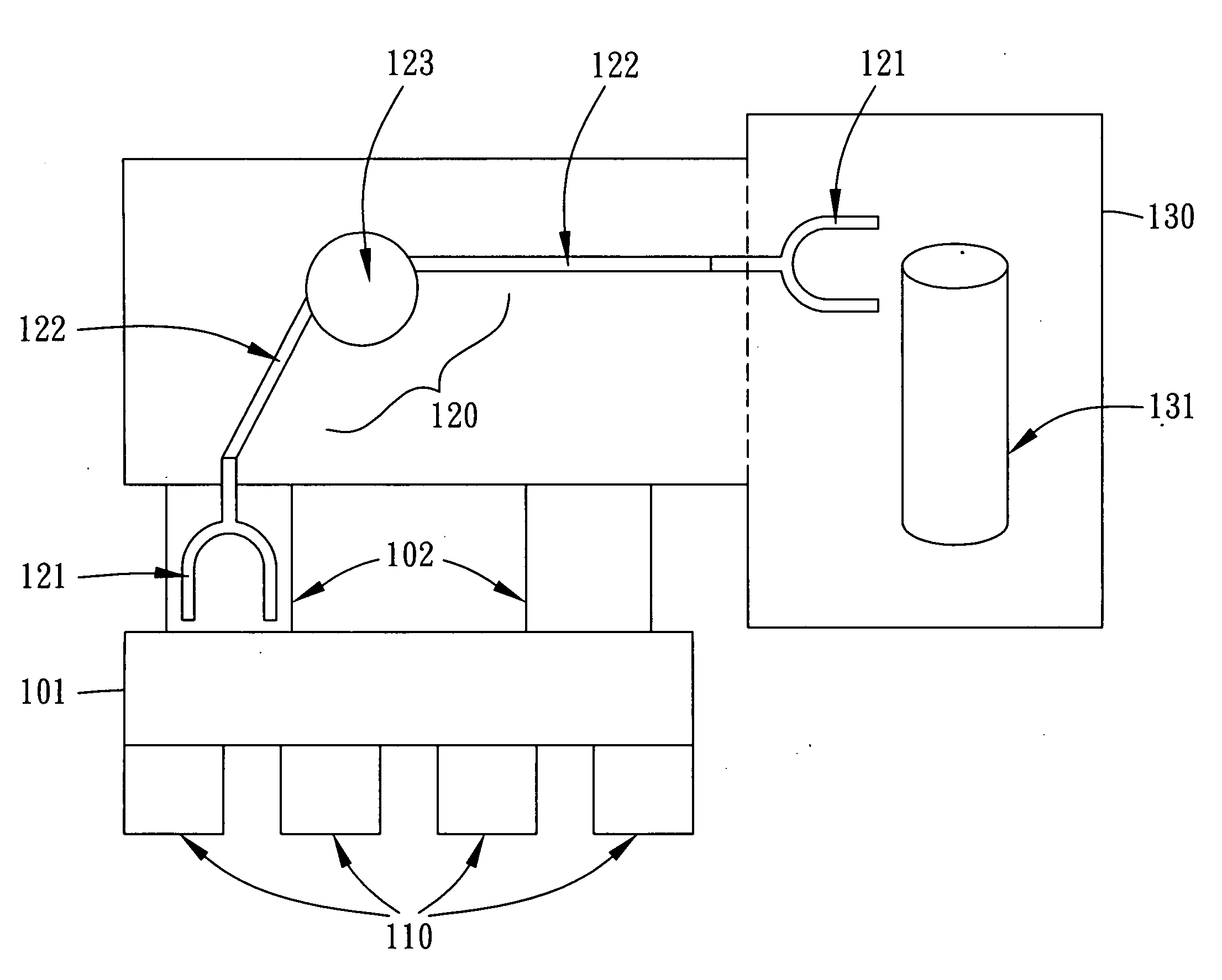

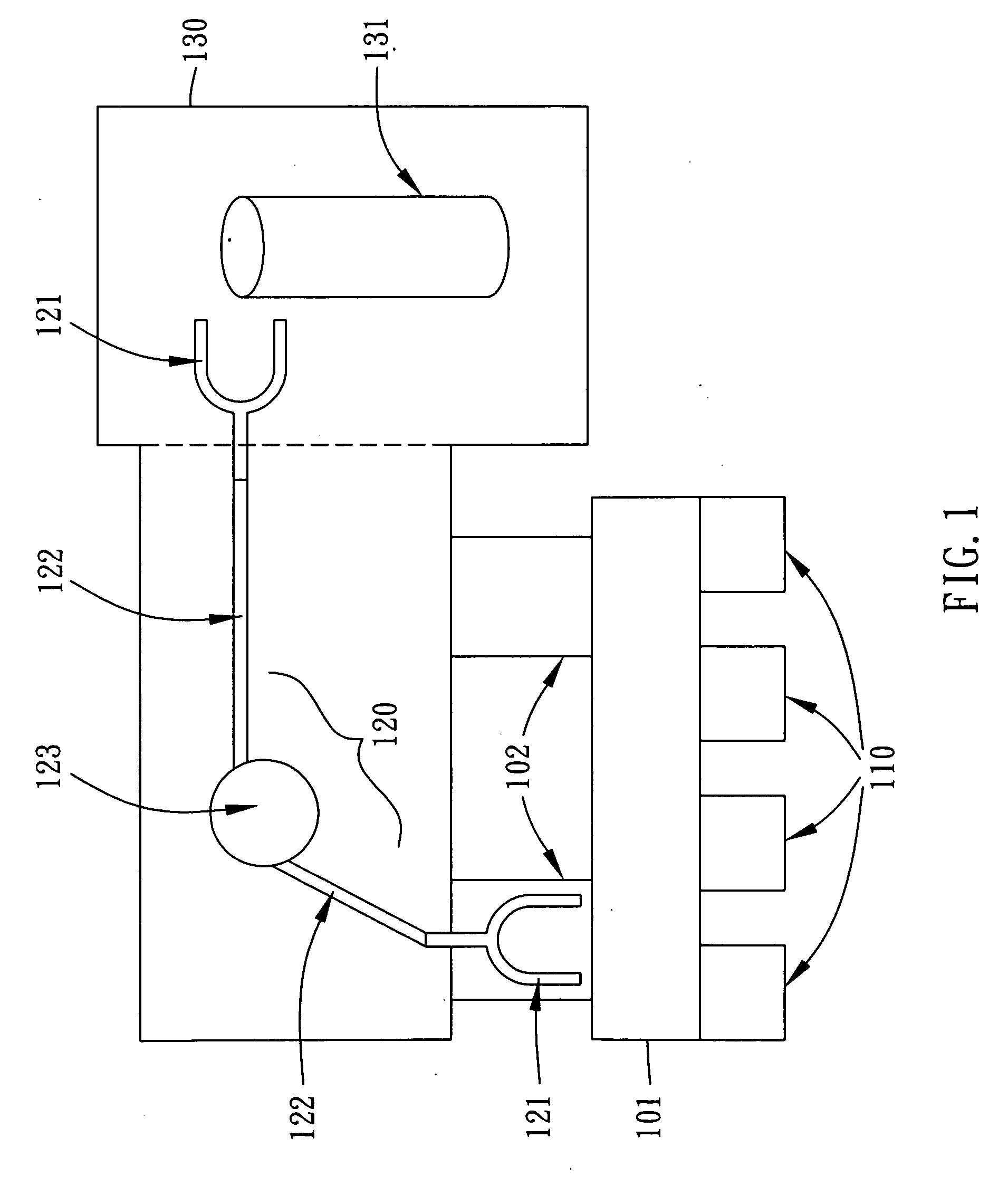

Shielded power coupling device

ActiveCN101636800AReduce distributionEliminate formationRadiation diagnosis data transmissionTransformersMagnetic coreElectrically conductive

Axisymmetric solid of revolution derivable from section at figure 5 is generally toroidal with electric current(s) in windings (110, 160) preferably flowing circumferentially along major circle(s) during power coupling device operation. Current(s) in windings (110, 160); current(s) in half-shields (120, 170); and the volume of space swept out by shield airgap(s) (101) emerge from plane of paper perpendicularly at figure 5 but as these emerge therefrom they curve to follow toroidal major circle(s). Cores (115, 165) preferably shunt and align magnetic flux such that magnetic field lines escape therefrom primarily only in region(s) of core airgap(s) and such that magnetic flux loops lie in planes of toroidal minor circle(s). Half-shield(s) (120, 170) preferably have electrically conductive material(s) distributed therein as is sufficient to substantially cancel magnetic flux lines impinging thereon before effects of such impinging magnetic flux lines would reach shield airgap(s) (101) and / or outer surface(s) of half-shields (120, 170).

Owner:ANLOGIC CORP (US)

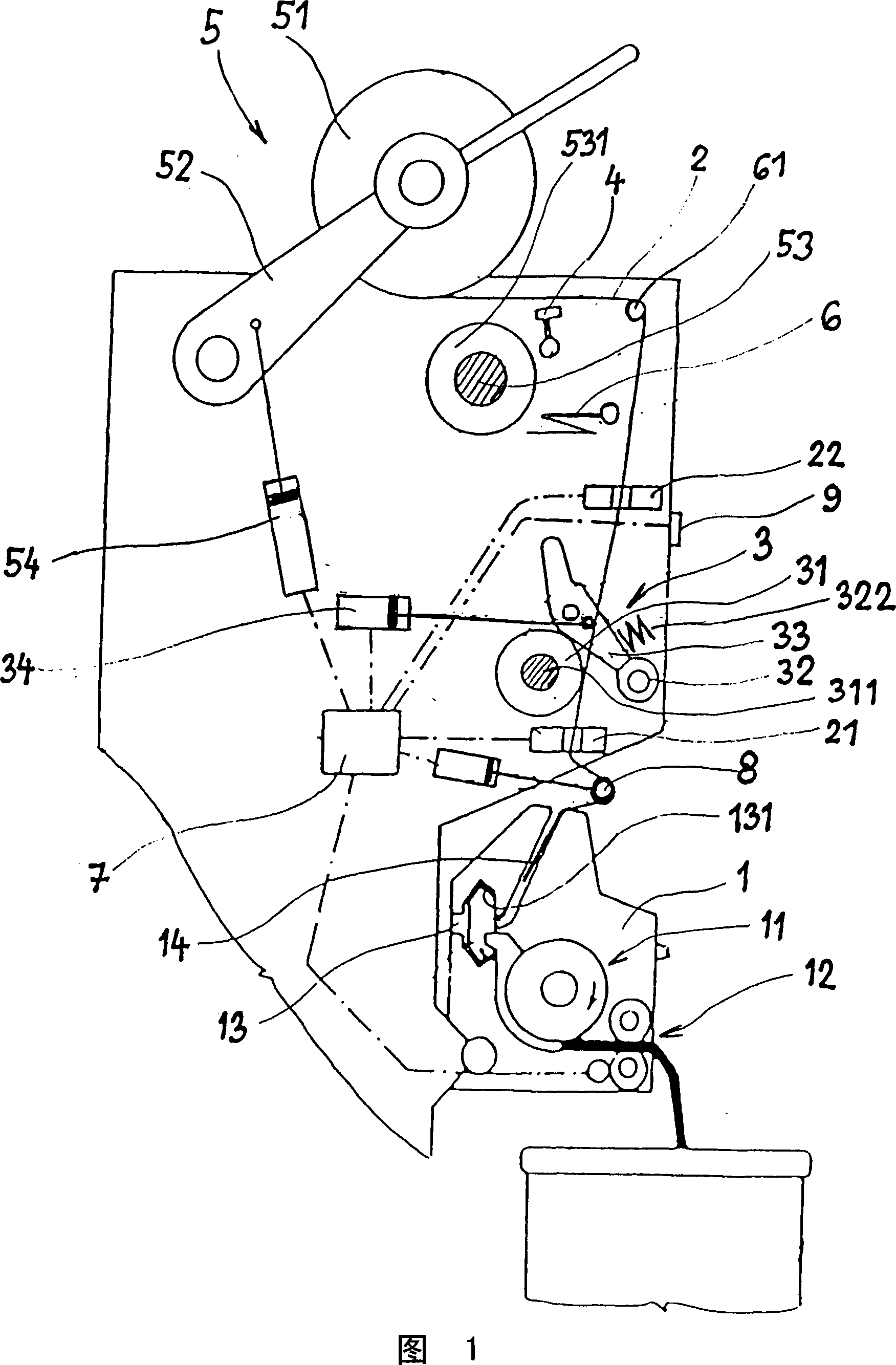

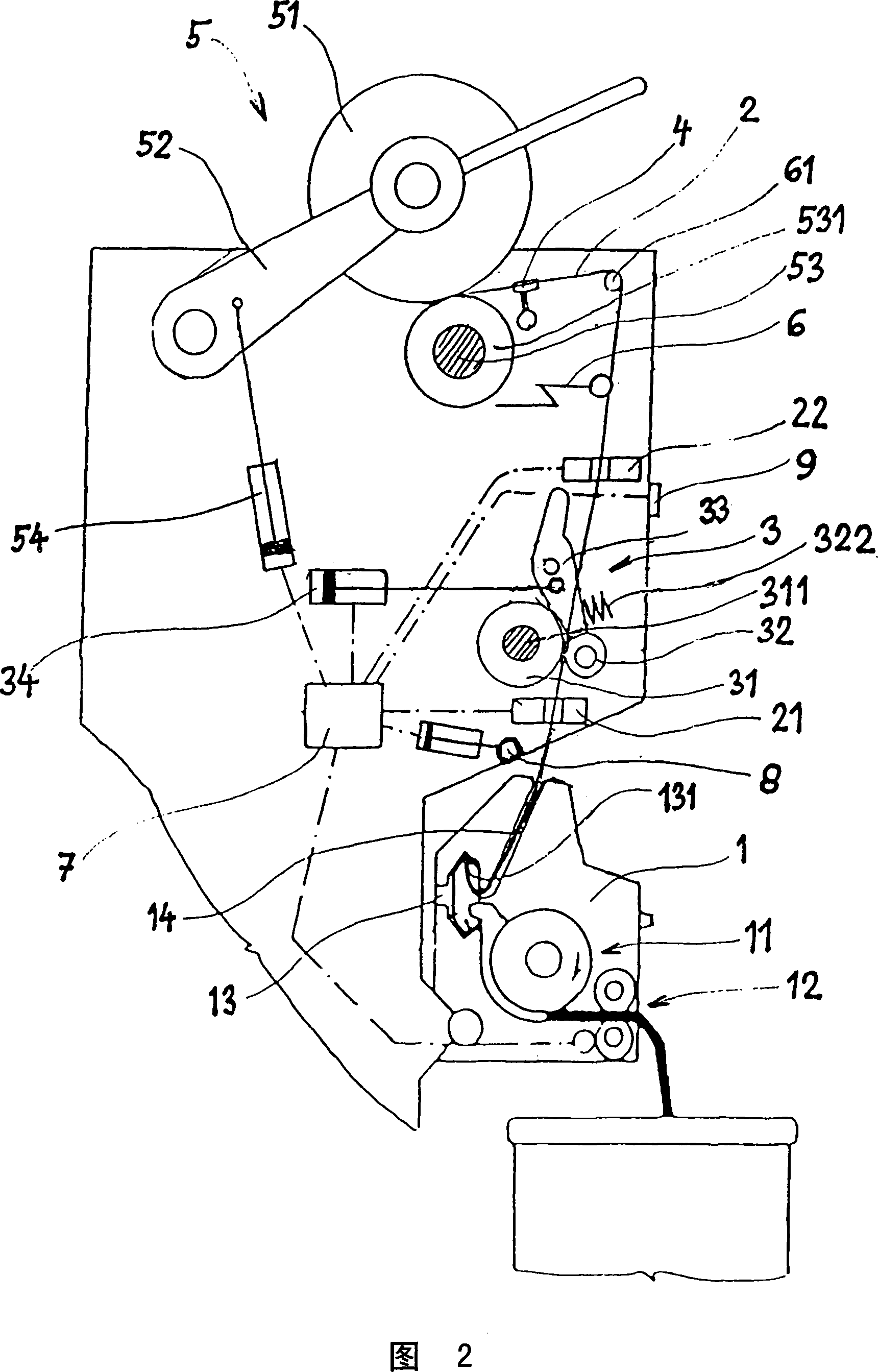

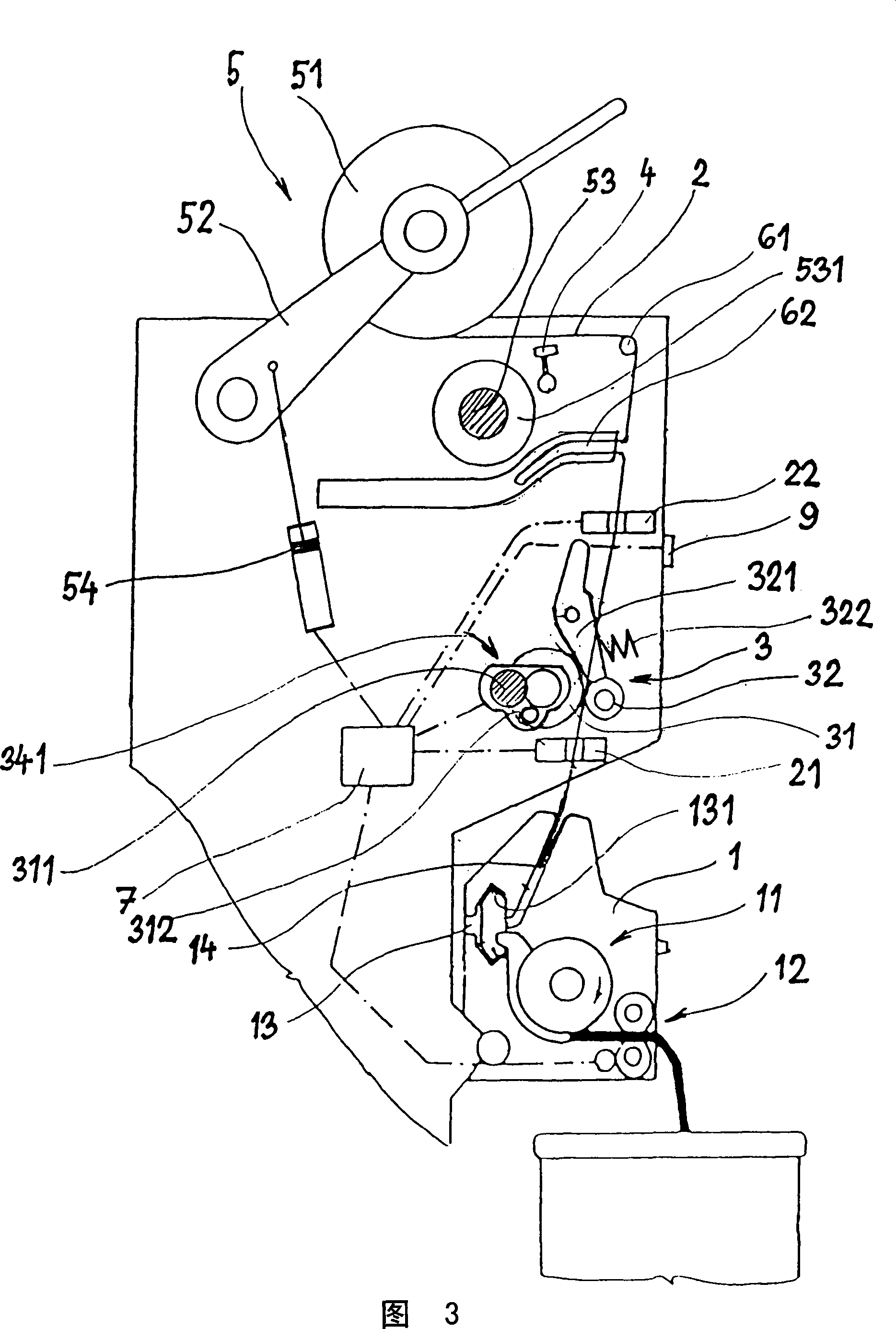

Method and device for producing single yarn on operation unit of rotor spinning machine

InactiveCN101078140ASmall difference in qualityImprove synchronicityContinuous wound-up machinesOpen-end spinning machinesYarnProcess engineering

The invention provides a method and device for individual yarn spinning at spinning station of a rotor spinning machine. During the process of spinning, the yarn is effected in turn by a drafting device (3) independently controlling the yarn and a takeup device (5) independently controlling the yarn.

Owner:RIETER CZ AS

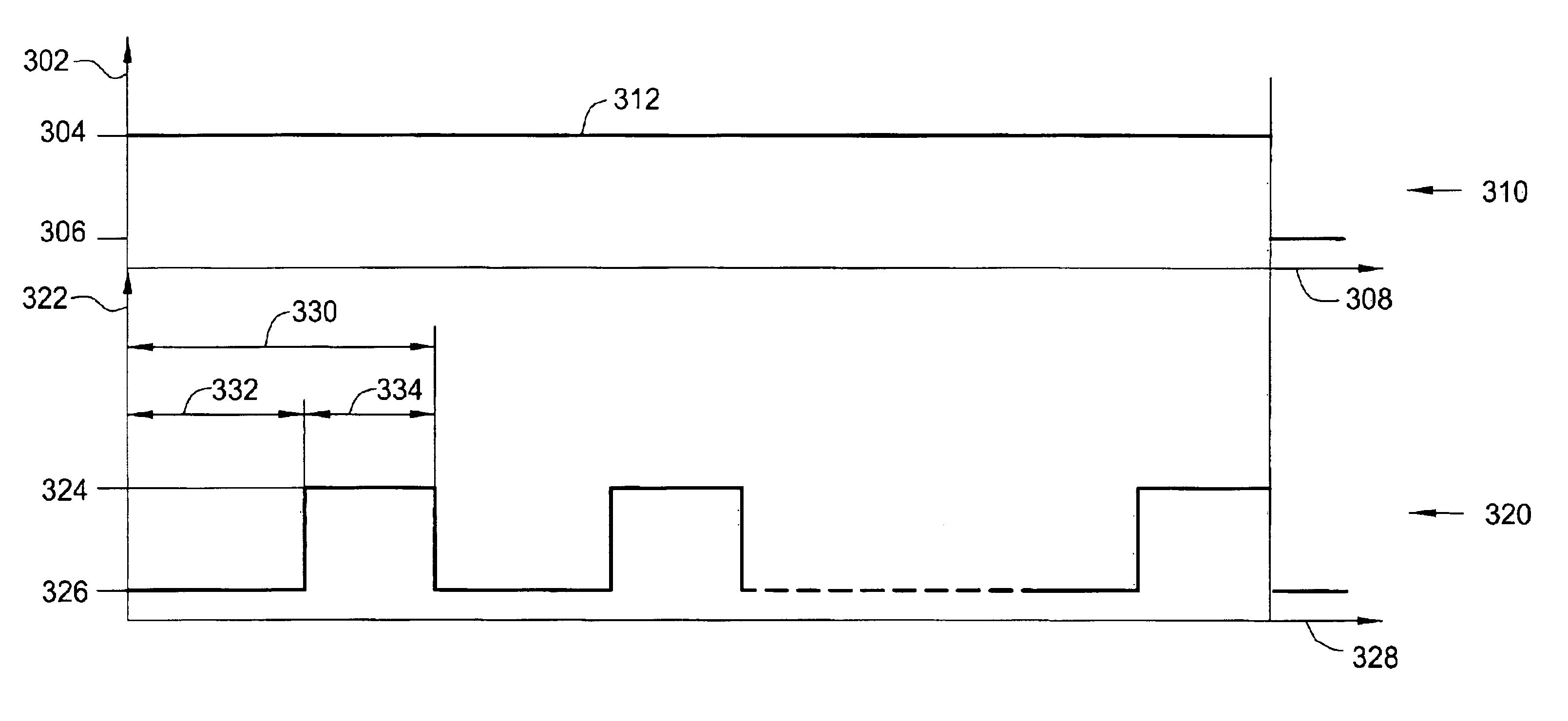

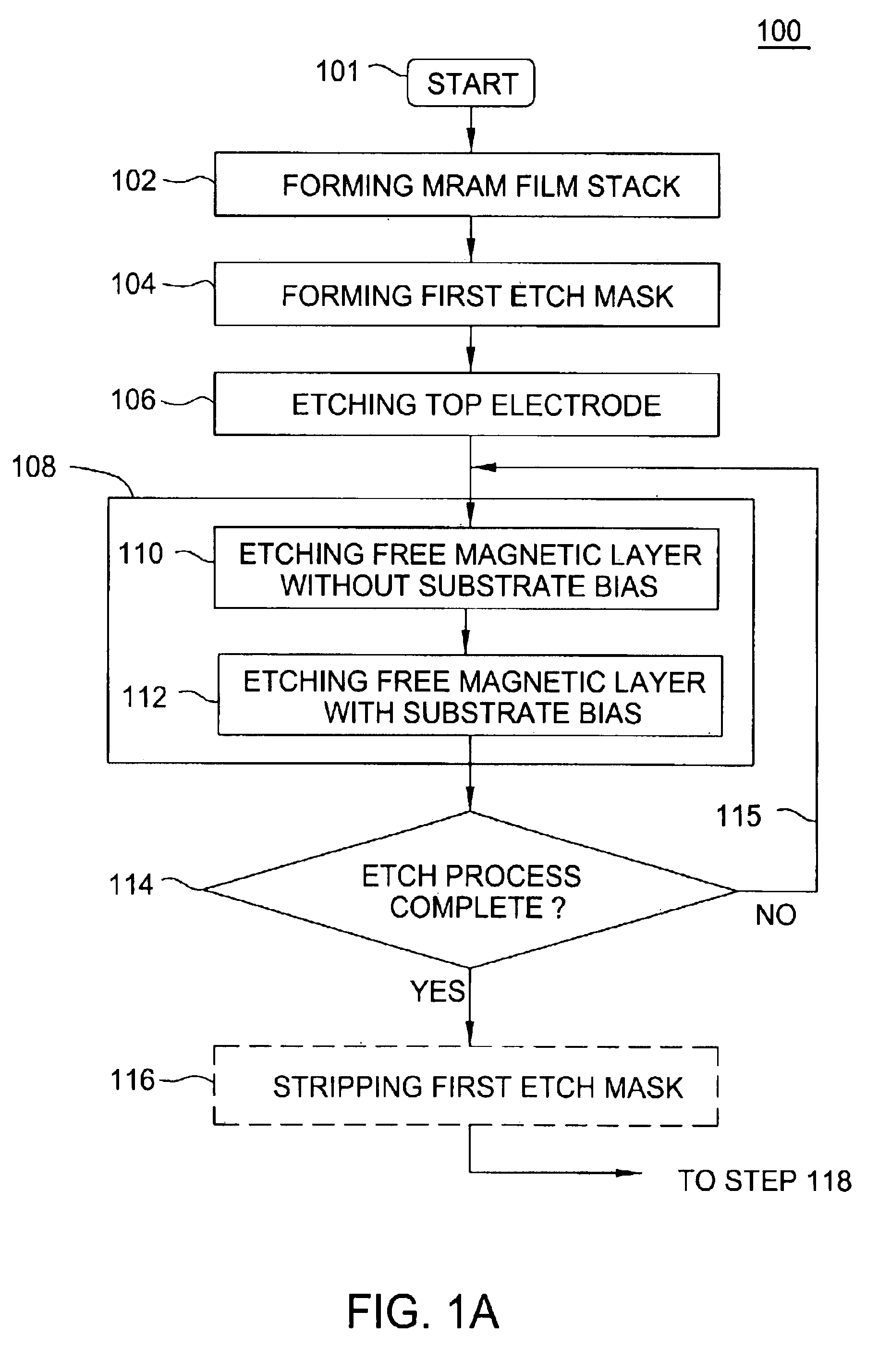

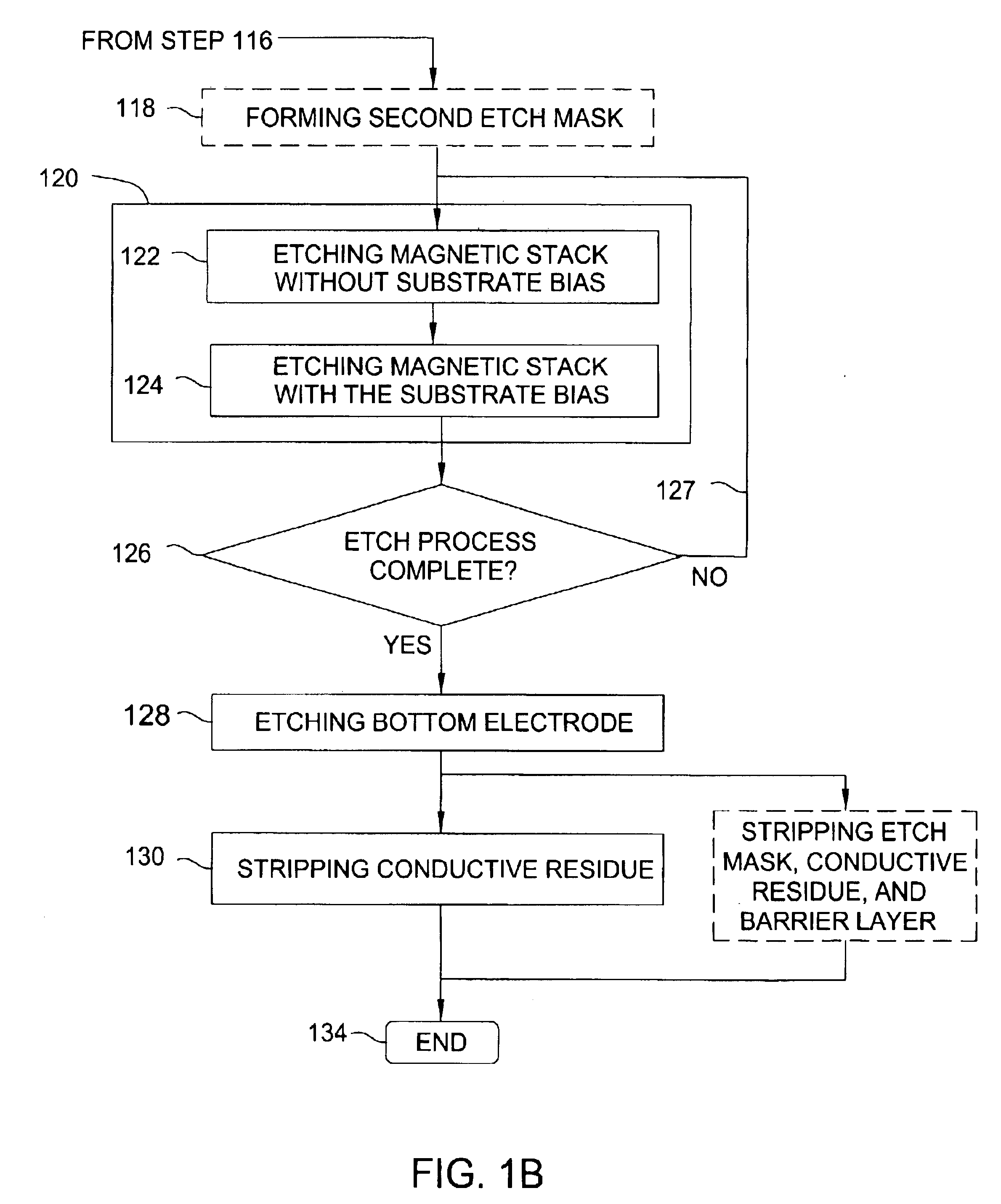

Method of etching magnetic and ferroelectric materials using a pulsed bias source

InactiveUS6942813B2Eliminate formationReduce harmNanostructure applicationNanomagnetismStatic random-access memoryRandom access memory

A method for etching magnetic and ferroelectric materials using a pulsed substrate biasing technique (PSBT) that applies a plurality of processing cycles to the substrate, where each cycle comprises a period of plasma etching without substrate bias and a period of plasma etching with the substrate bias. In exemplary applications, the method is used for fabricating magneto-resistive random access memory (MRAM) and ferroelectric random access memory (FeRAM) devices.

Owner:APPLIED MATERIALS INC

Fusion welding method for magnesium and aluminium dissimilar metals

InactiveCN1663727ANo crackMeet the use requirementsArc welding apparatusWelding/cutting media/materialsImpulse frequencyElectromagnetic pulse

The invention discloses a fusion welding of magnesium and Al heterogeneous metals, which adopts low magnesium Al alloy weld stick as the filling materials, the indifferent gas to protect, the electromagnetic pulse AC tungsten Ar arc to weld magnesium and Al. there into, the mass percentages of the weld stick are: magnesium is 0.5-3.0% with 2.0-3.0mm diameter; the said indifferent gas is Ar gas with purity more than 99.9%; the parameter of the tungsten Ar arc welding is: the basic current is 50-130A, the impulse current is 200-350A, the impulse time is 5-10s, the impulse frequency is 35-75Hz, the welding voltage is 24-26V, the welding speed is 1.0mm / s-1.8mm / s, the Ar gas flux is 10-18L / min, the extension length of the tungsten polar is 5-6mm, the distance between the welding torch jet and the working piece is 6mm-10mm, the thickness of the working piece is 1.5mm-14mm. the invention has high welding efficiency, low cost, convenient operation, and is suitable for the manufacturing of magnesium-Al heterogeneous compound structure.

Owner:SHANDONG UNIV

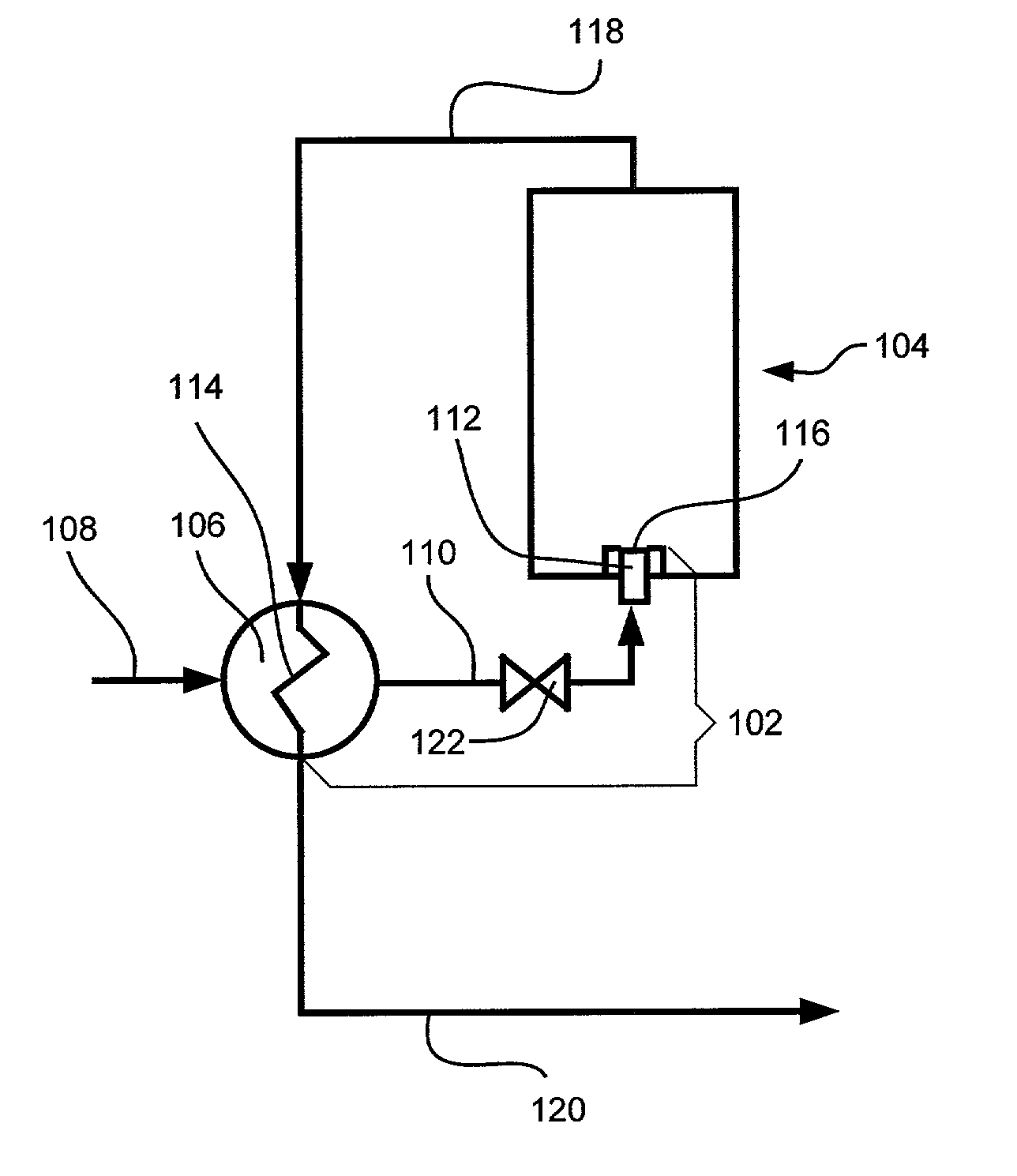

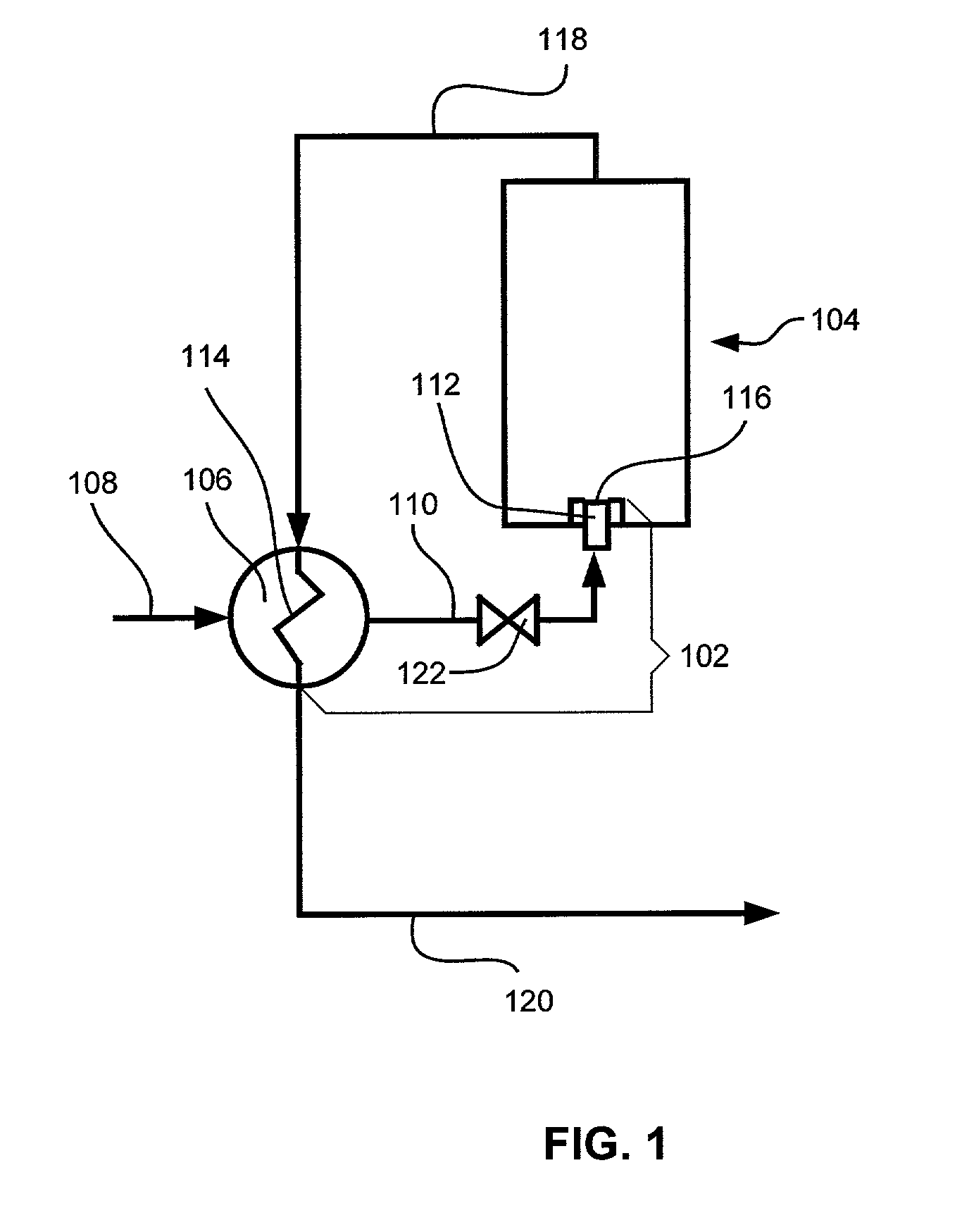

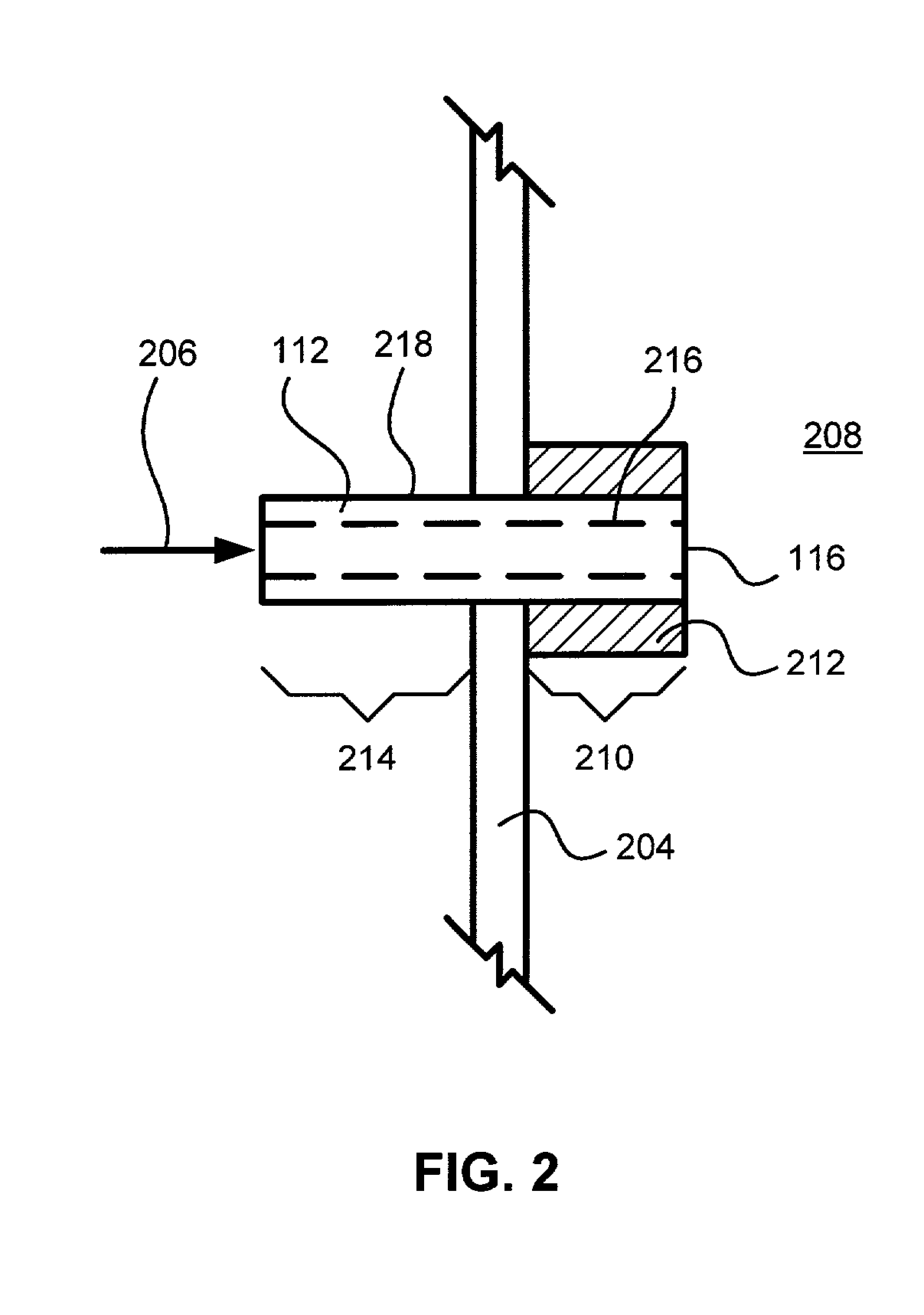

Shorten Temperature Recovery Time of Low Temperature Ion Implantation

InactiveUS20100301236A1Shorten recovery timeEliminate formationElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMoisture

The present invention discloses a low temperature ion implantation by performing a heating process after the end of an implanting process and before the wafer is moved into the external environment. This invention actively raises wafer temperature at a time no later than implementation of the vacuum venting process, such that the condensed moisture induced by the temperature difference between a vacuum environment inside ion implanter and an external environment outside ion implanter is effectively minimized. The wafer can be heated at a loadlock, a robot for transferring wafer and / or an implantation chamber. The wafer can be heated by a gas, a liquid, a light and / or a heater embedded in a holder for holding the wafer.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

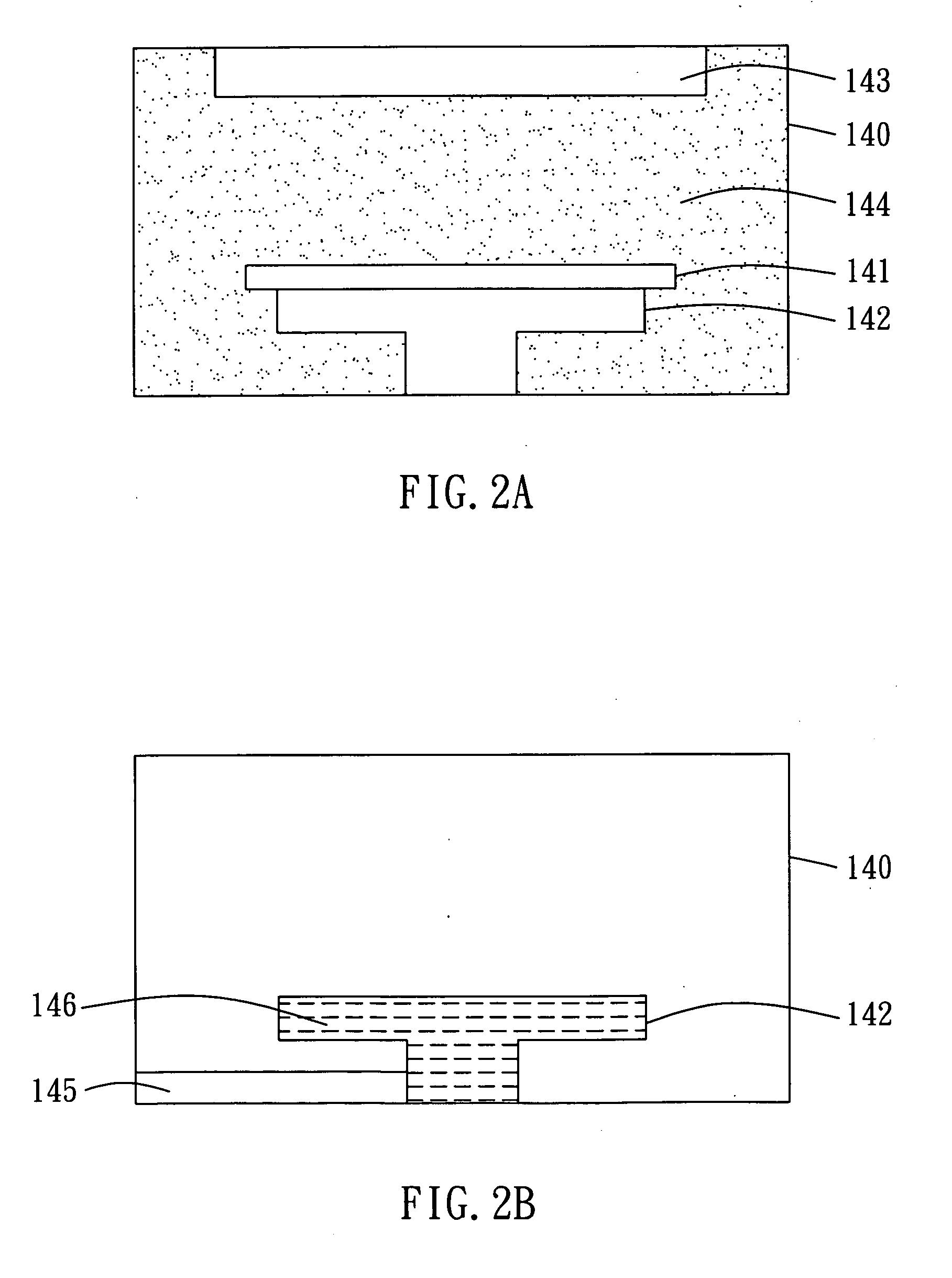

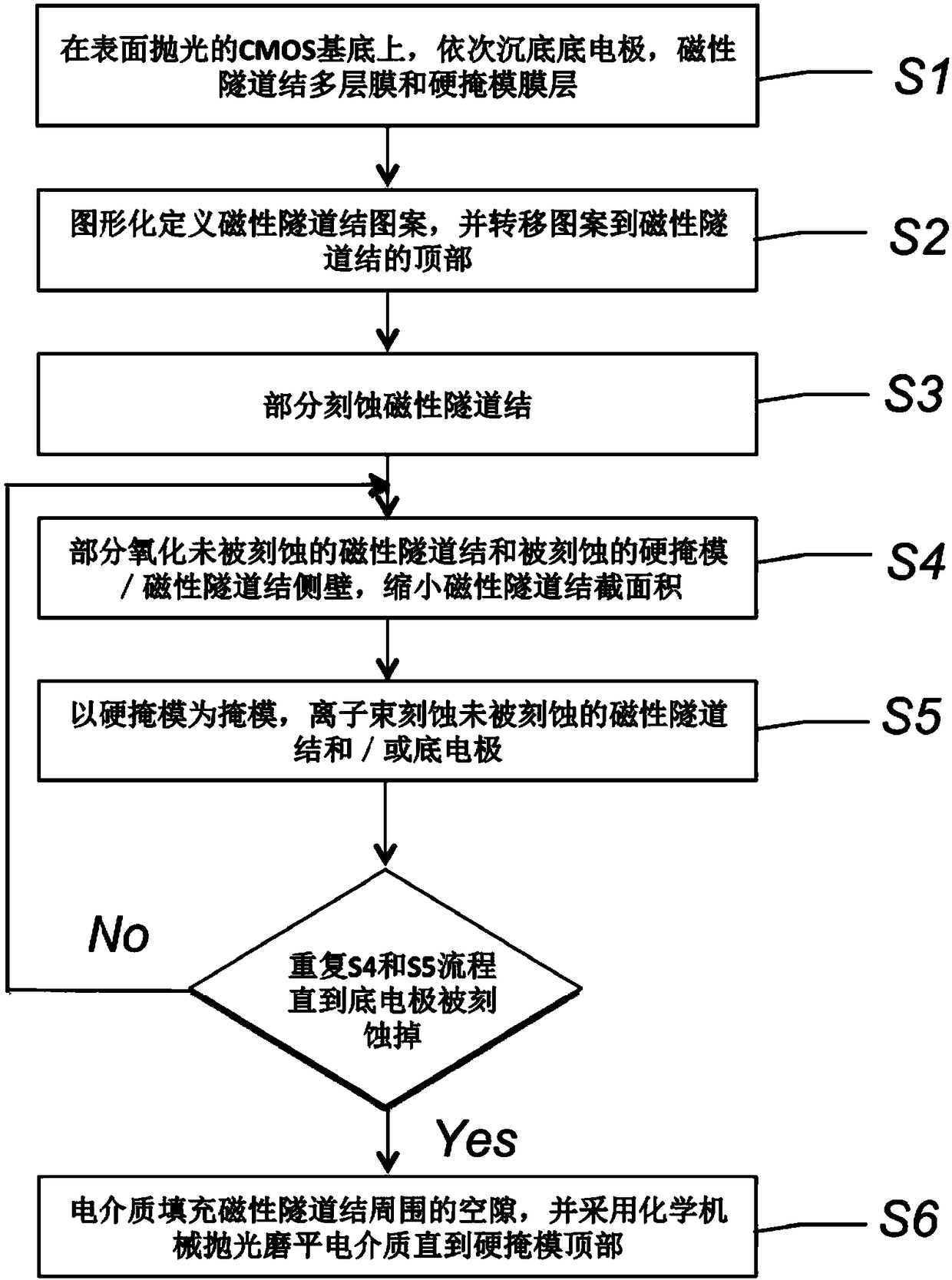

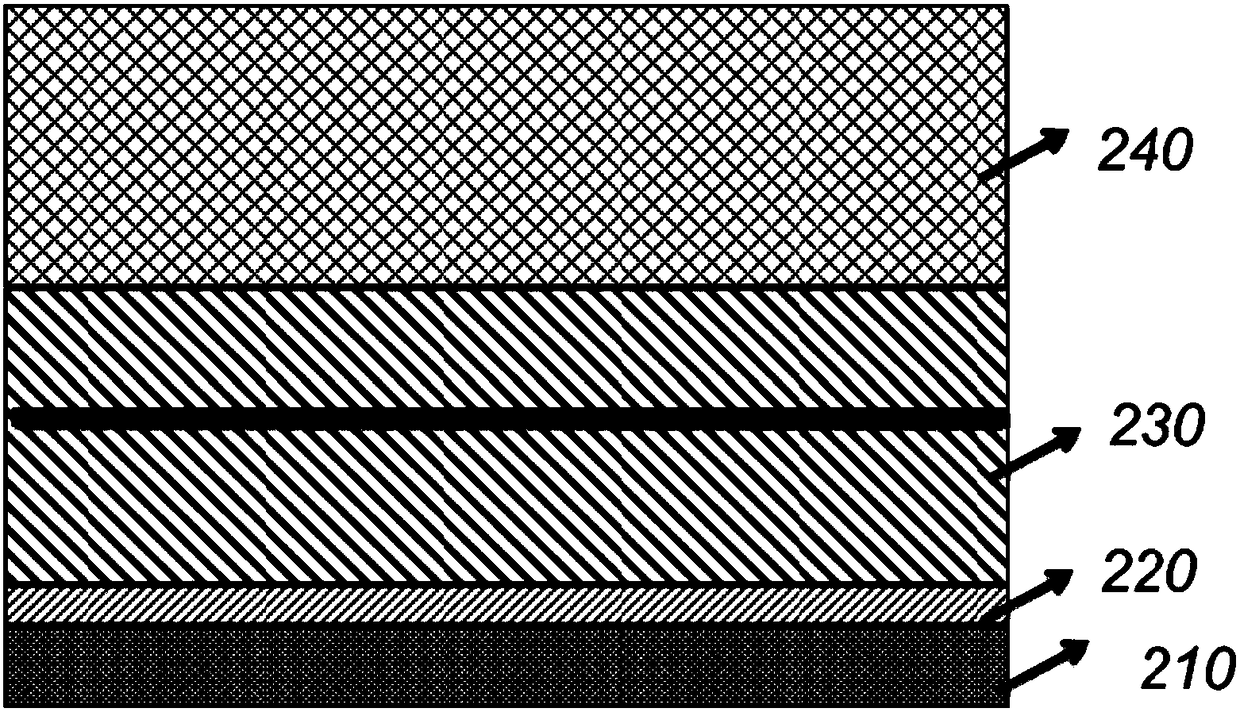

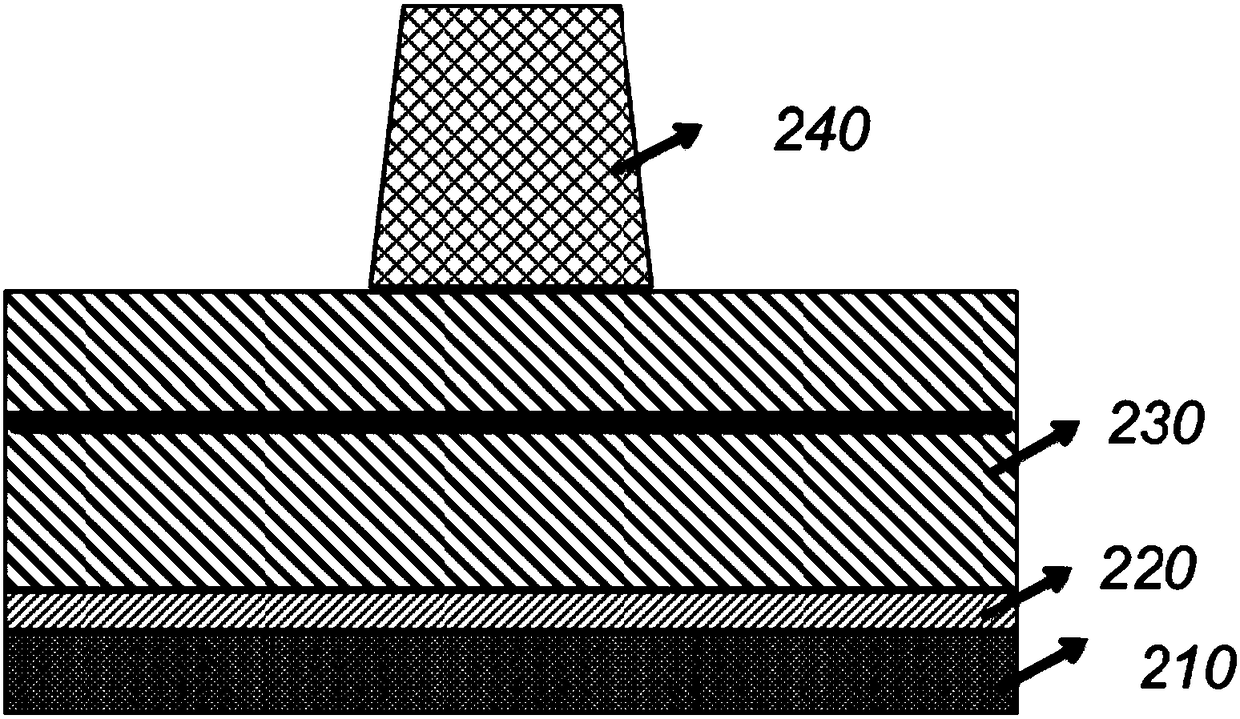

Method of manufacturing magnetic tunnel junction

ActiveCN108242502AImprove electrical performanceImprove product yieldGalvano-magnetic device manufacture/treatmentIon beam etchingStructural unit

The invention provides a method of manufacturing a magnetic tunnel junction. A multiple oxidation and ion beam etching process is adopted, formation of a short circuit passage between a memory layer and a reference layer of a magnetic random access memory (MRAM) is completely eliminated, enhancement of the magnetic properties, the electrical properties and the product yield of the MRAM loop is facilitated, and the method can be used for manufacturing a structural unit of a super small magnetic random access memory.

Owner:SHANGHAI CIYU INFORMATION TECH

Method for preparing brassiere cup

An improved method of preparing molded seamless breast pads, cups, fronts and the like for use in brassieres and other garments is described. Polyurethane foam sheet, which still contains free isocyanates in its urethane matrix, is sliced from a freshly made foam bun, and placed between the mold parts. The mold parts are then closed by a hydraulic press. Steam is injected through holes in one mold part, and flows throughout the compressed polyurethane foam. Exhaust steam is emitted from holes in the other mold part. Moisture and heat from the steam then accelerate reactions with the free isocyanates and further cure the polyurethane foam material. The polyurethane foam material is therefore molded into the shape of mold parts cavity.

Owner:HSUEH PAN TING

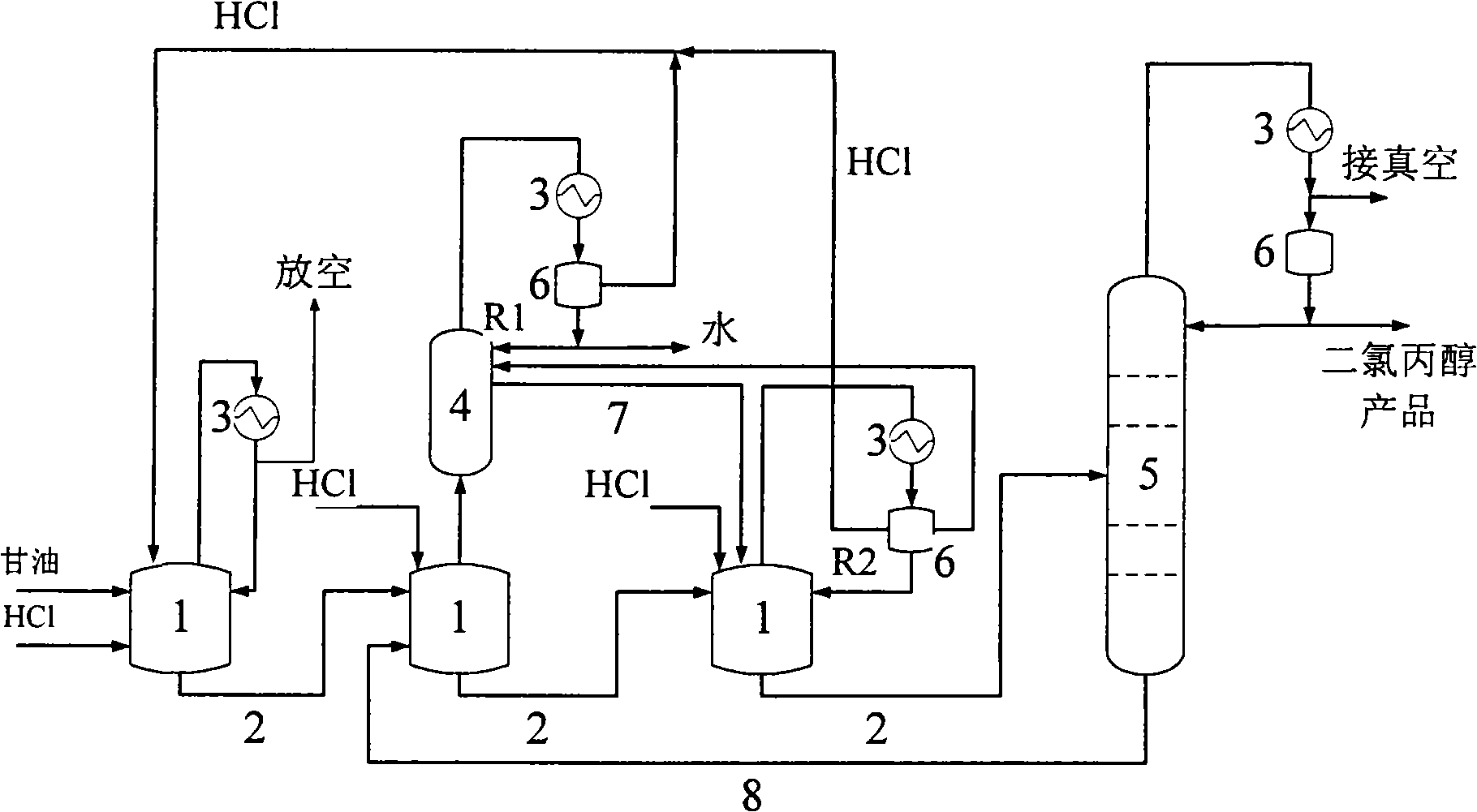

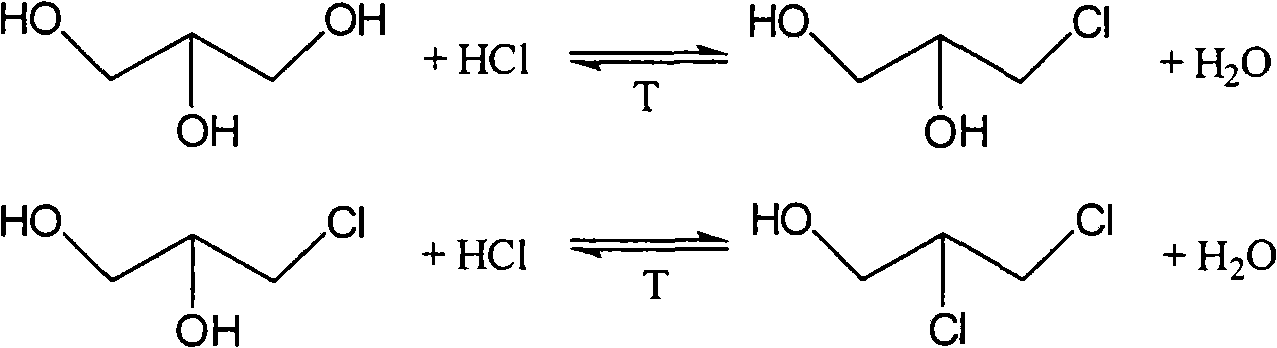

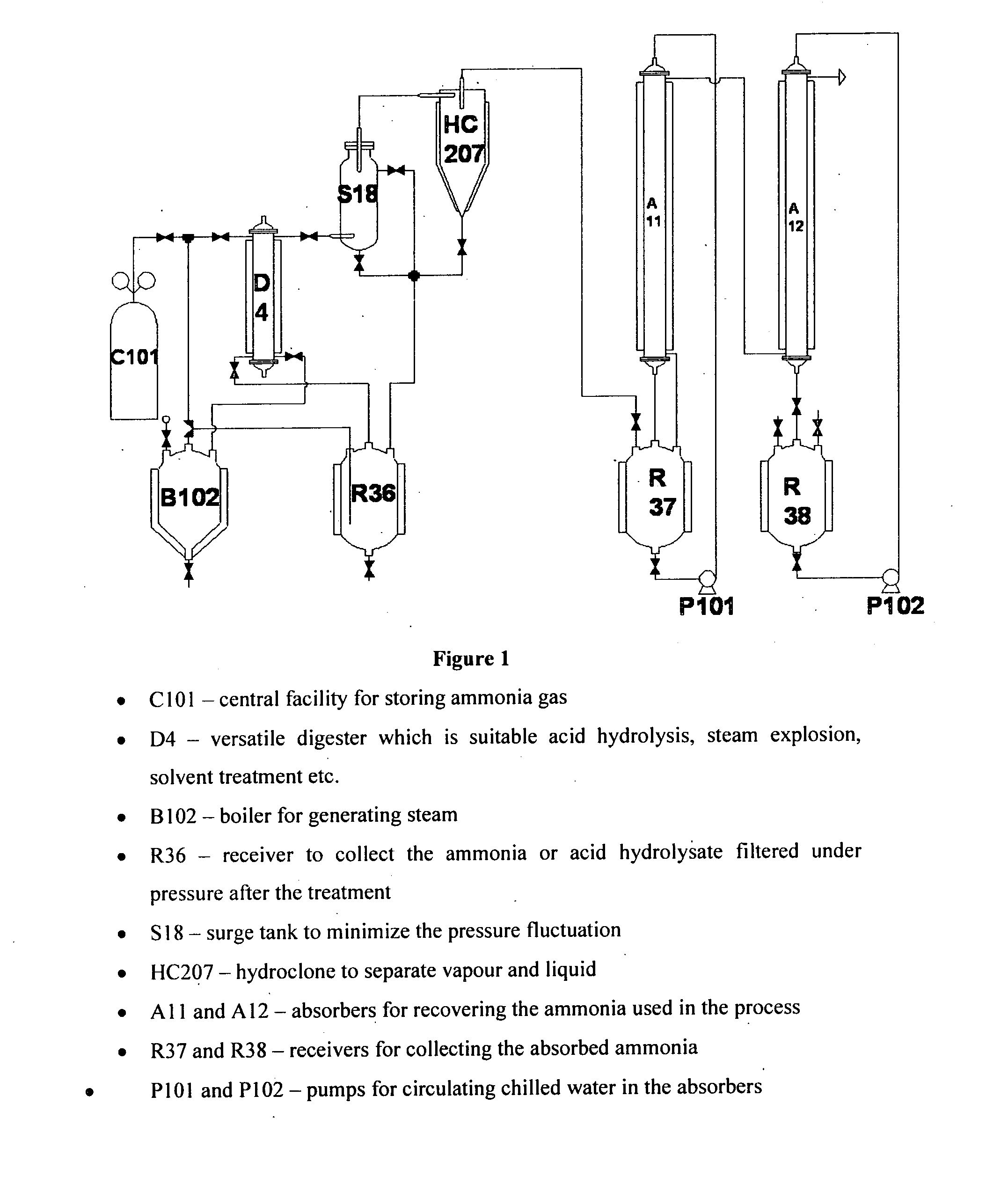

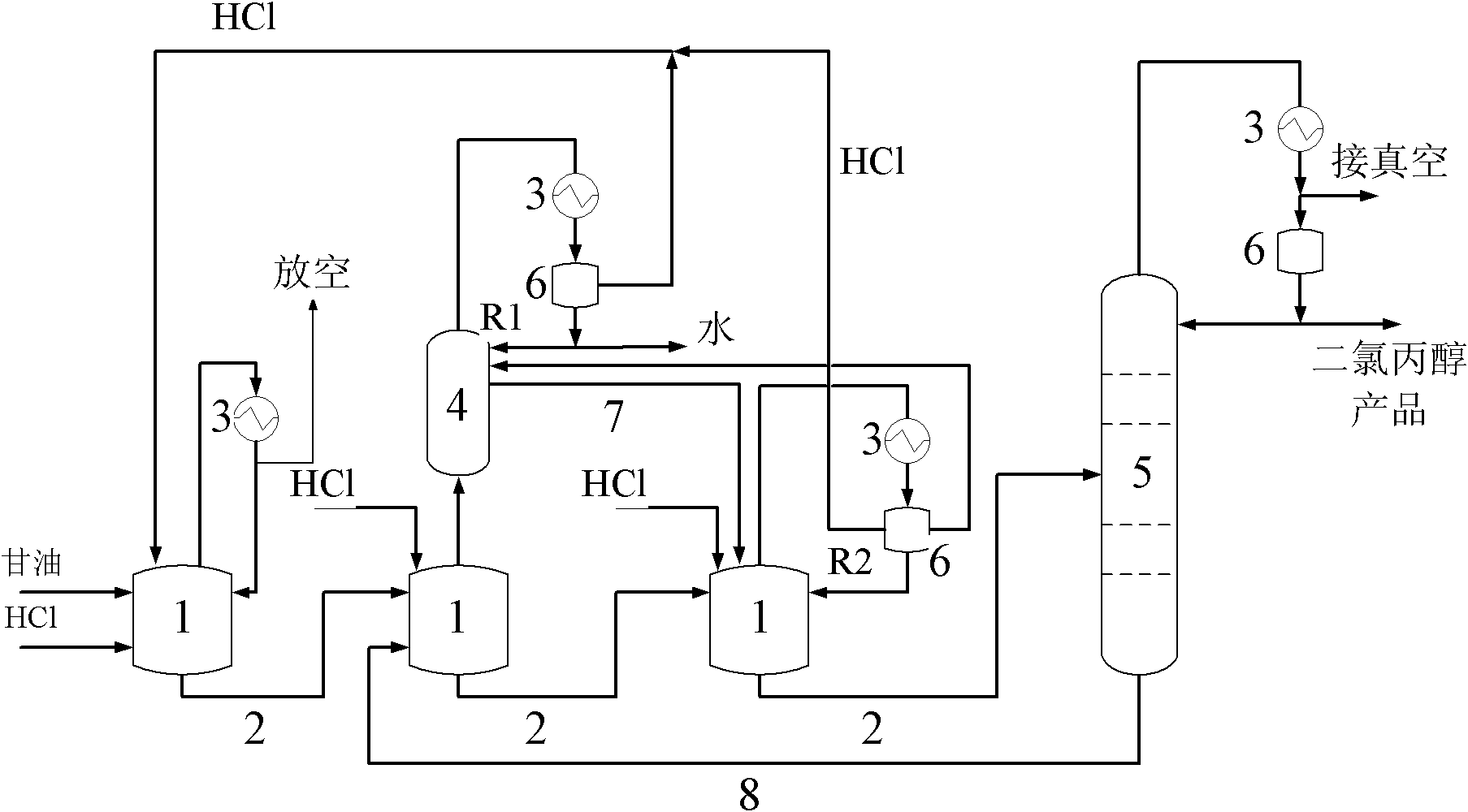

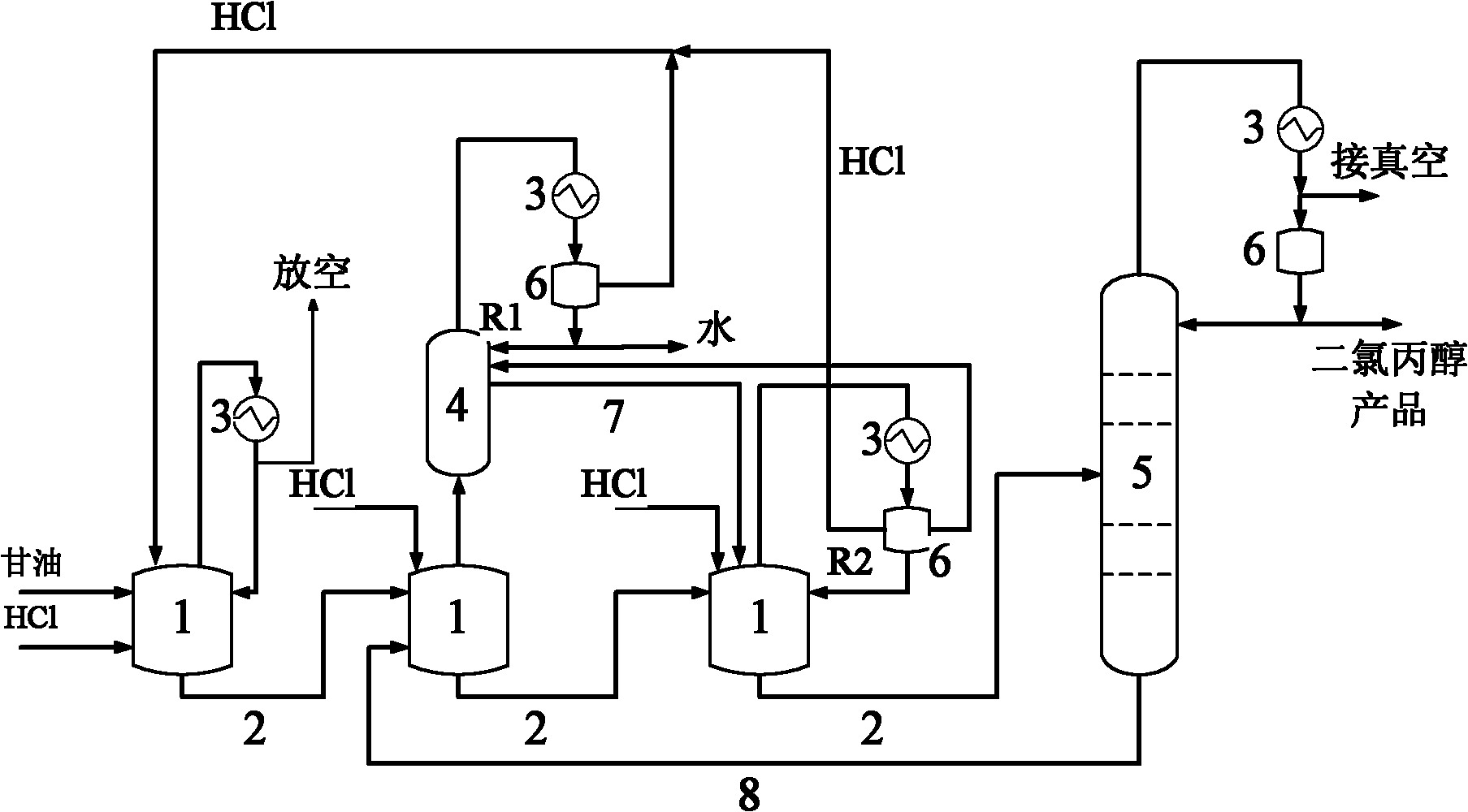

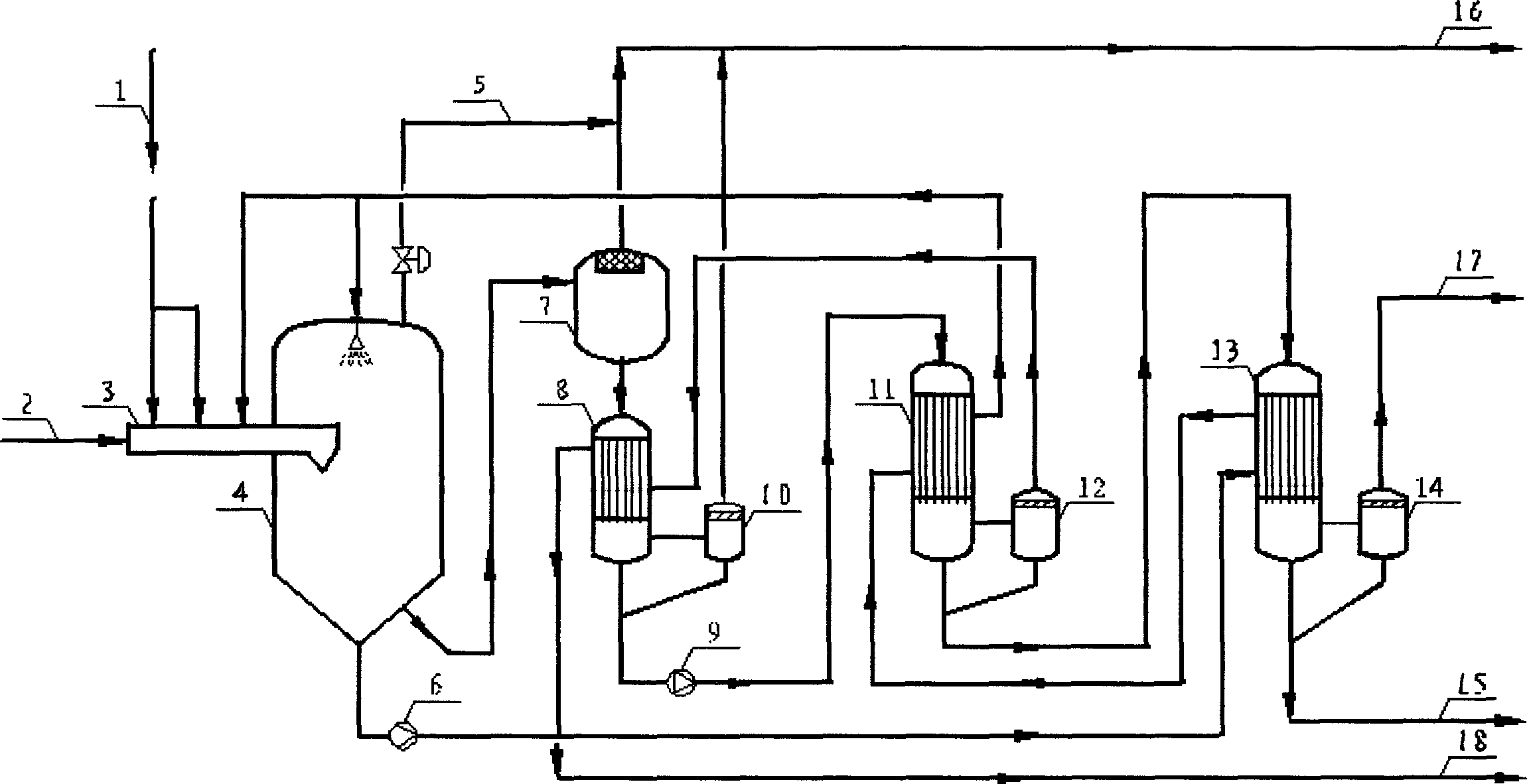

Technique and system for preparing dichloropropanol by autocatalysis reaction of glycerine and hydrogen chloride

ActiveCN101357880AReduce usageEliminate formationPreparation by halogen introductionAutocatalysisBoiling point

The invention discloses a technique for preparing dichloropropanol by the autocatalytic reaction of glycerol and hydrogen chloride. Glycerol and hydrogen chloride carry out autocatalytic reaction at the temperature of 105 to 160 DEG C and the pressure of 0.05 to 0.5Mpa, and the water generated in the reaction is distilled and removed. The invention also discloses a system for preparing dichloropropanol by the autocatalytic reaction of glycerol and hydrogen chloride gas. By adopting the technique of autocatalytic reaction of glycerol and hydrogen chloride, the invention avoids the using of catalyst, lowers production cost obviously, eliminates the formation of by-products with high boiling point, improves reaction selectivity and has the advantages of simple technique and low production cost. The system can transform glycerol fully and greatly improves the selectivity of dichloropropanol; the purity of the dichloropropanol obtained finally is more than 99.5 percent.

Owner:NANTONG TIANSHI CHEM

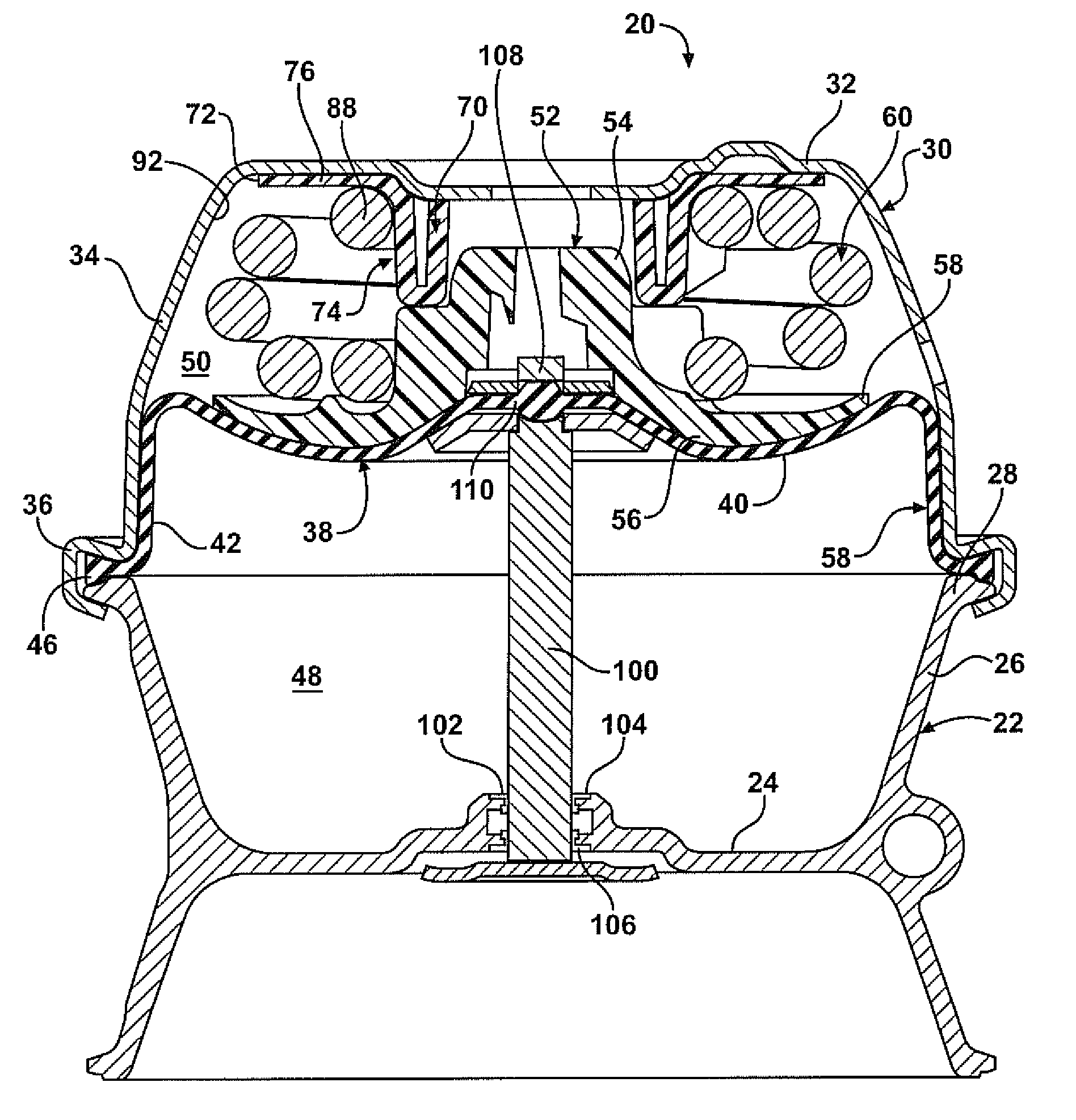

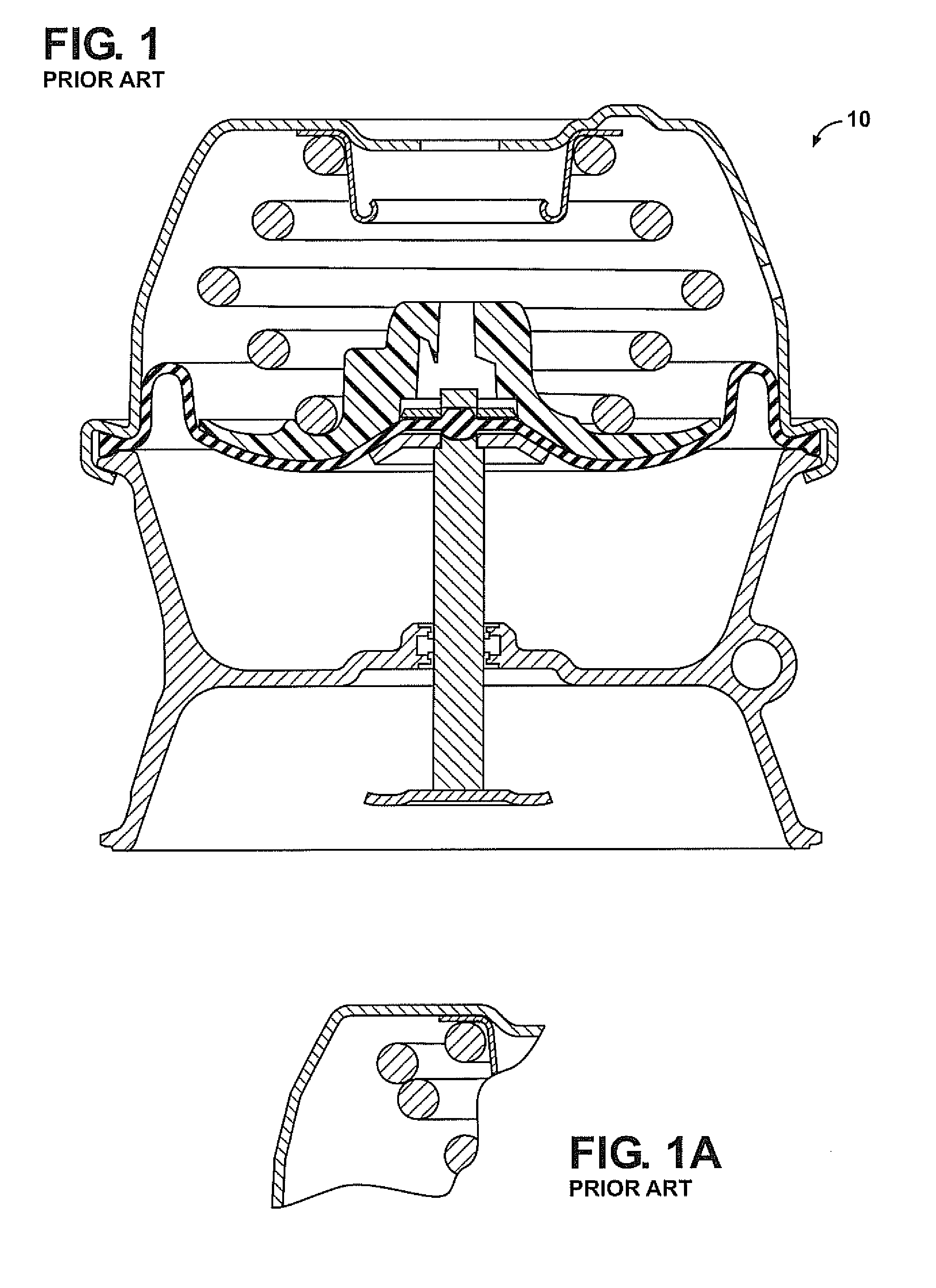

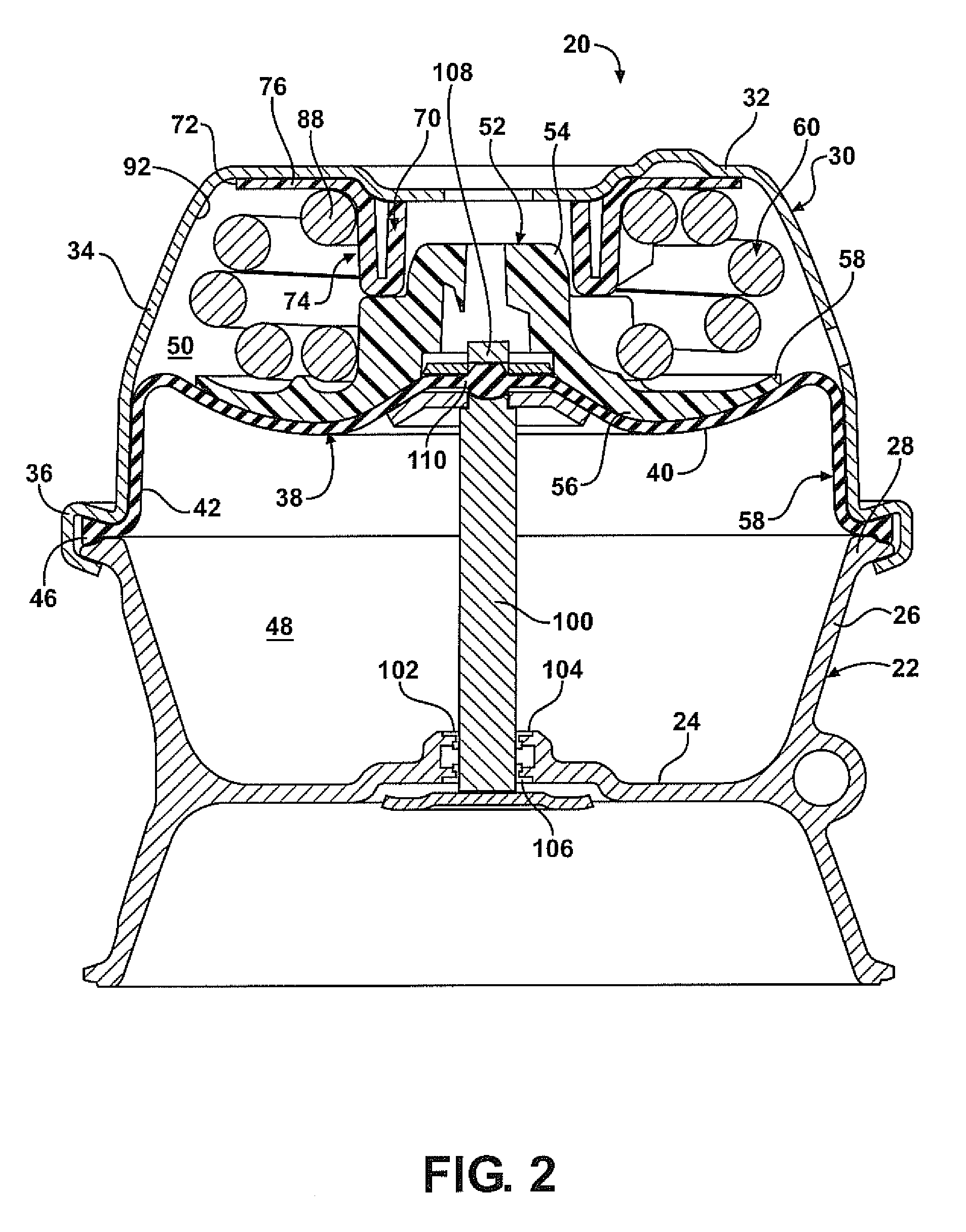

Brake actuator and method of forming the same

ActiveUS20100154627A1Reduce frictional contactEliminate formationReciprocating piston enginesBrake cylindersActuatorPiston

An improved diaphragm-type pneumatic brake actuator includes a flange case, a cover cooperable with the flange case, a flexible diaphragm extending between the flange case and the cover forming a lower pneumatic chamber and an upper pneumatic chamber on opposed sides of the diaphragm. A piston assembly is disposed in the cover for moving a spring between compressed and decompressed positions. A spring guide is disposed between the cover and the piston assembly in the upper chamber. The spring guide prevents direct contact of the spring with the cover to prevent formation of a corrosion cell.

Owner:INDIAN HEAD INDUSTRIES INC

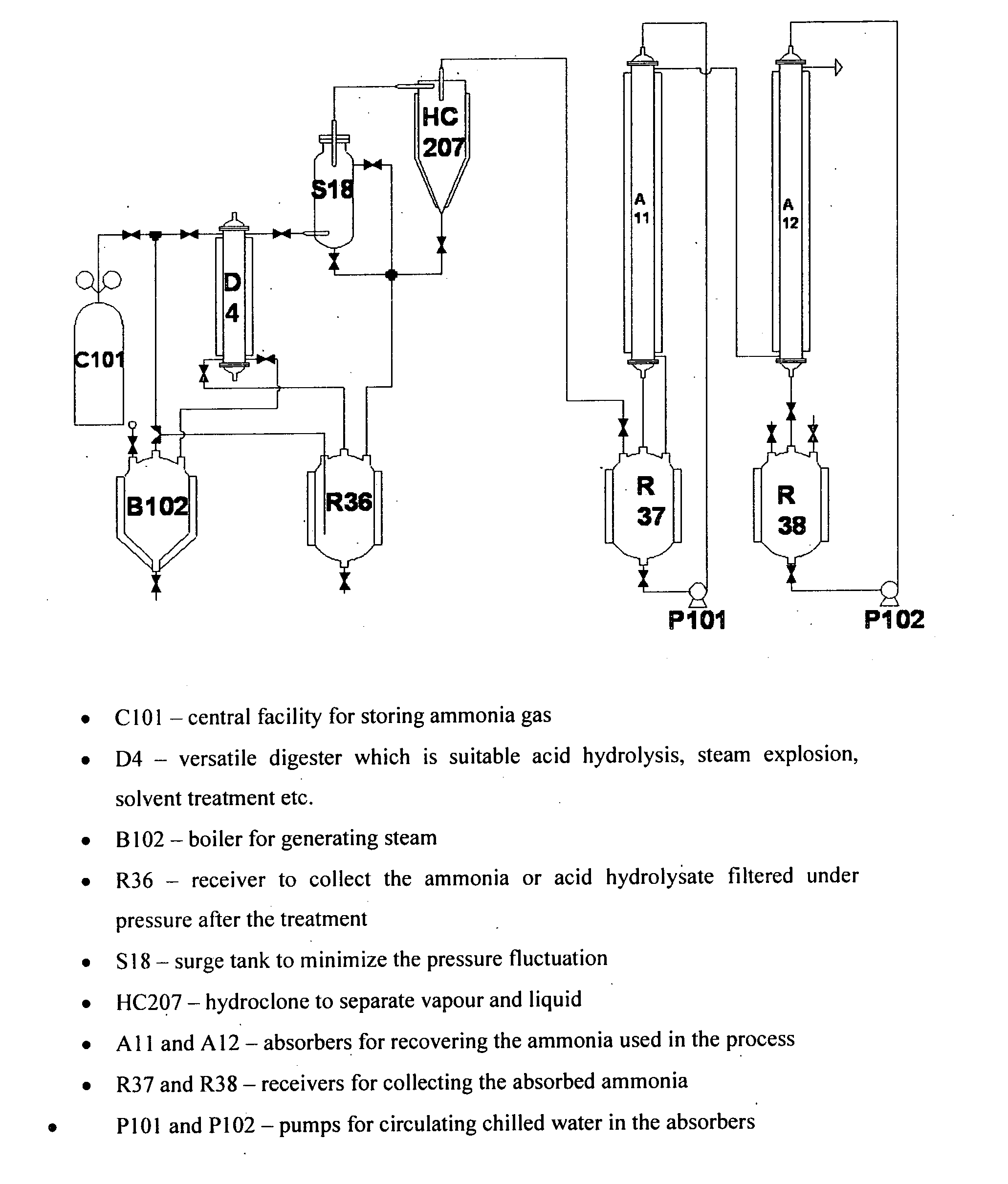

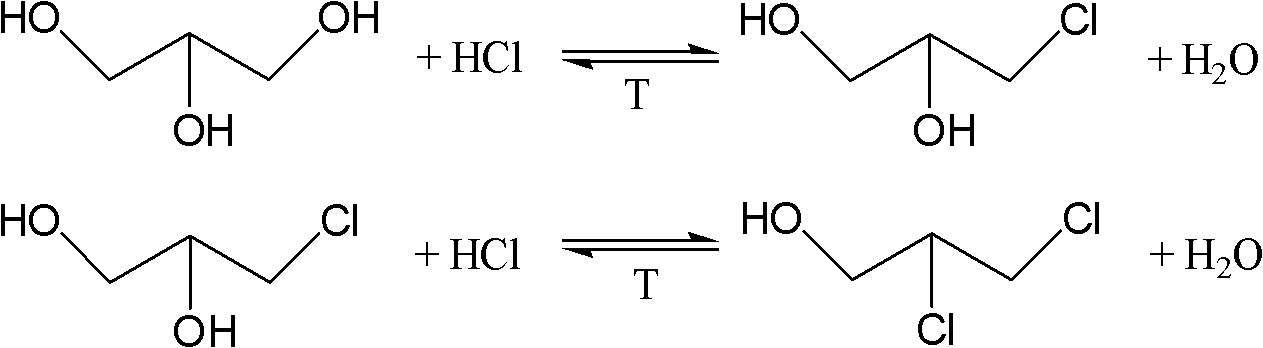

Process for separating biomass components

InactiveUS20100317843A1Eliminate formationShorten treatment timePulping with acid salts/anhydridesLignin derivativesChemistryHemicellulose

The present invention provides a process and System for Separation of biomass components into individual components such as cellulose, hemicellulose and lignin. The present invention provides a process for separating lignin in its native form. The cellulose obtained by the process of the present invention is highly reactive for saccharification.

Owner:NAGARJUNA ENERGY

System for preparing dichloropropanol by autocatalytic reaction of glycerol and hydrogen chloride

ActiveCN102040479AReduce usageEliminate formationPreparation by halogen introductionBoiling pointGlycerol

The invention discloses a process for preparing dichloropropanol by an autocatalytic reaction of glycerol and hydrogen chloride. The process comprises the following steps: the glycerol and the hydrogen chloride gas perform the autocatalytic reaction at the temperature of between 105 and 160 DEG C and pressure of between 0.05 and 0.5MPa, and generated water is distilled and removed during the reaction. The invention also discloses a system for preparing the dichloropropanol by the autocatalytic reaction of the glycerol and the hydrogen chloride. The invention adopts the technology of the autocatalytic reaction of the glycerol and the hydrogen chloride without using a catalyst, so that the production cost is remarkably reduced, formation of high boiling side products is eliminated, and the reaction selectivity is improved. The invention has the advantages of simple process and low production cost. The system can ensure that the glycerol is completely converted and greatly improves the selectivity of the dichloropropanol, so that the purity of the finally prepared dichloropropanol is more than 99.5 percent.

Owner:NANTONG TIANSHI CHEM

Method and apparatus for reducing decomposition byproducts in a methanol to olefin reactor system

InactiveUS7034196B2Reduce eliminateSuitable for usePhysical/chemical process catalystsHydrocarbon from oxygen organic compoundsReactor systemDecomposition

Disclosed is a method and apparatus for reducing the amount of metal catalyzed side-reaction byproducts formed in the feed vaporization and introduction system of a methanol to olefin reactor system by monitoring and / or maintaining the temperature of at least a portion of the feed vaporization and introduction system and / or of the feedstock contained therein below about 400° C., 350° C., 300° C., 250° C., 200° C. or below about 150° C. The temperature can be maintained in the desired range by jacketing at least a portion of the feed vaporization and introduction system, such as at least a portion of the feed introduction nozzle, with a thermally insulating material or by implementing a cooling system.

Owner:EXXONMOBIL CHEM PAT INC

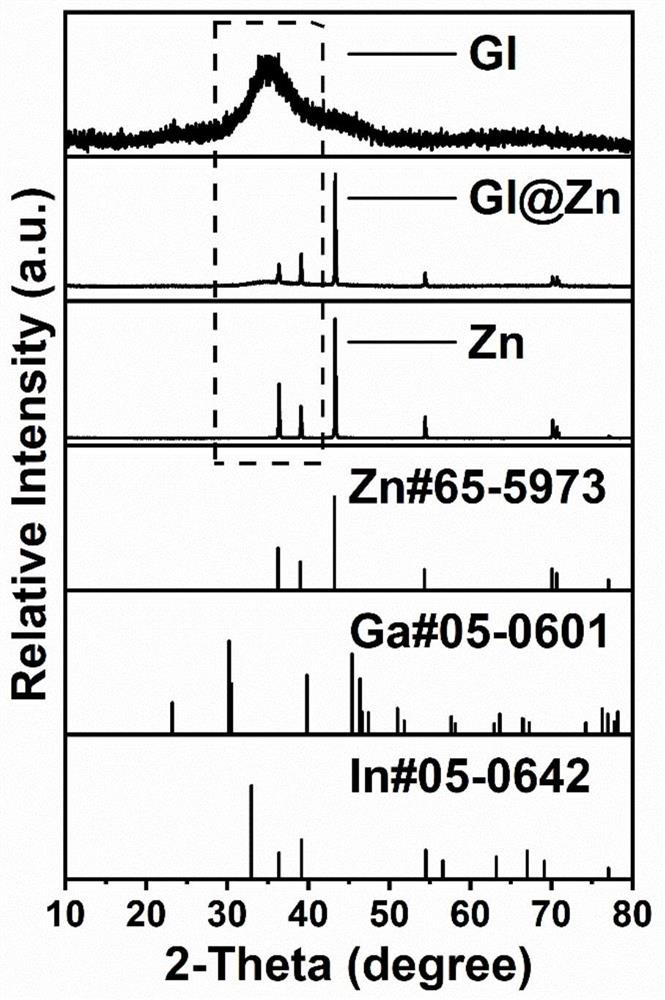

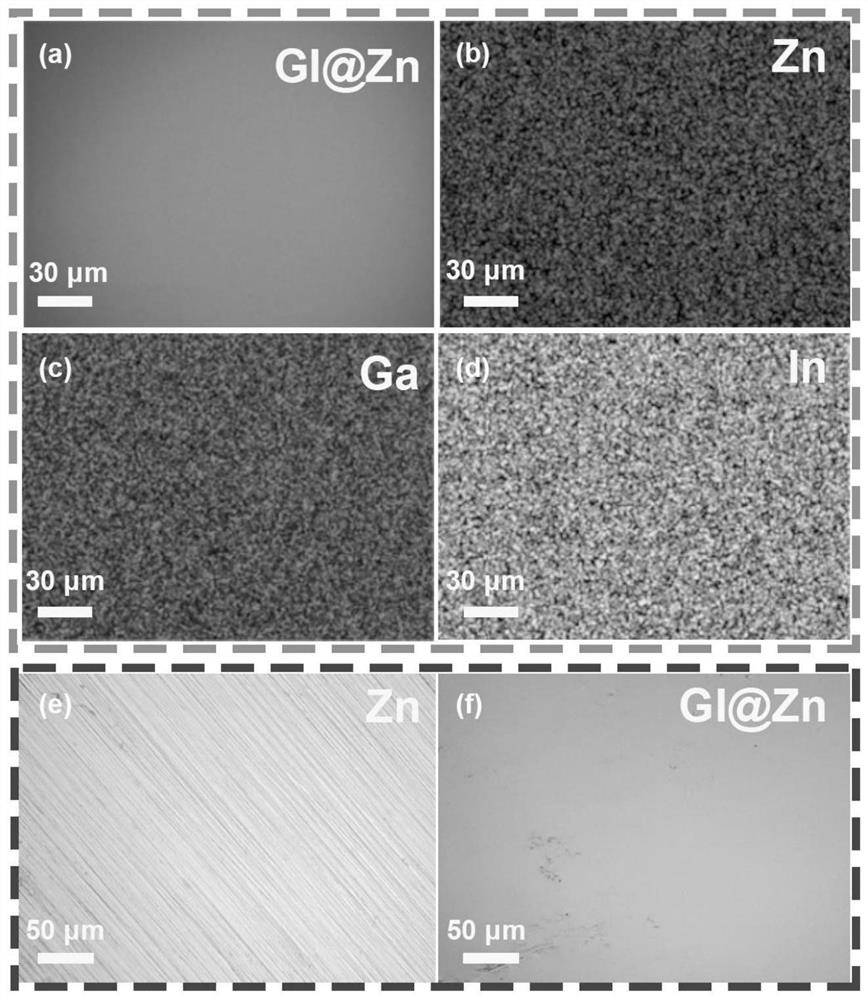

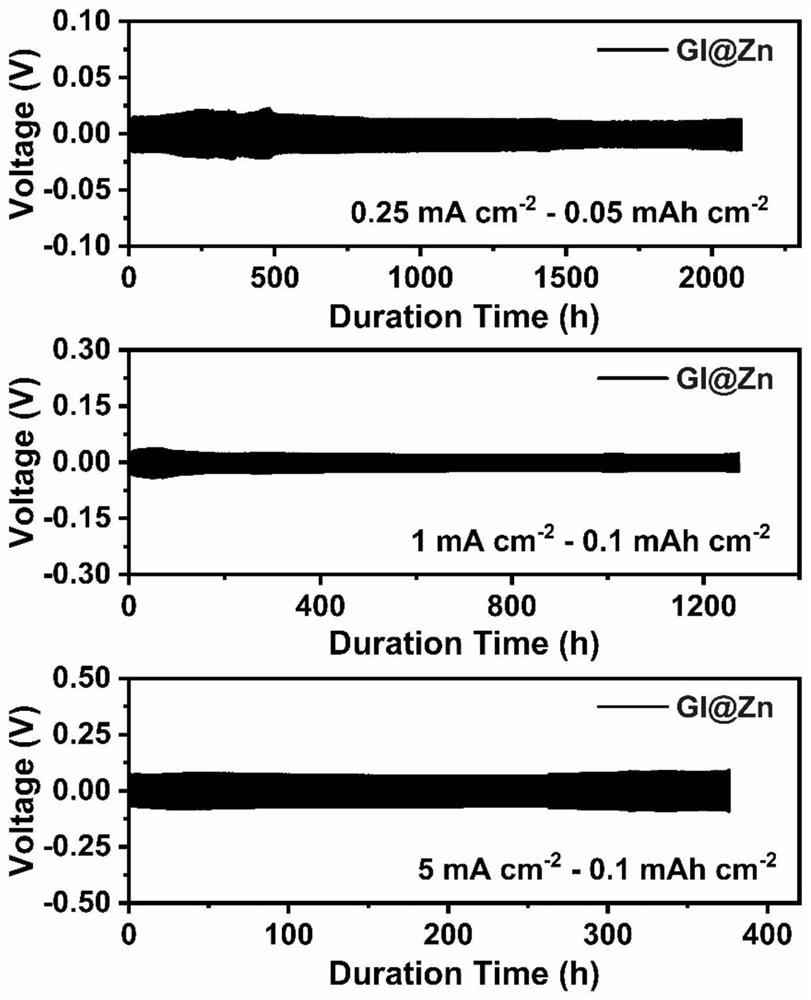

Zinc ion battery liquid metal composite negative electrode and preparation method and application thereof

ActiveCN111916744AImprove corrosion resistanceAvoid corrosionFinal product manufactureCell electrodesElectrolytic agentIndium

The invention discloses a zinc ion battery liquid metal composite negative electrode and a preparation method and application thereof. The composite negative electrode comprises a zinc metal matrix and a liquid alloy layer, and the liquid alloy layer is arranged on the surface of the zinc metal matrix. The characteristic of low solubility of zinc metal in the liquid gallium-based alloy is utilized, the zinc metal can be used as an electrochemically inert liquid coating material, the liquid alloy layer is formed by coating the surface of the zinc metal matrix with the liquid gallium-based alloy, and zinc ion flow, close to the surface of the negative electrode, of electrolyte can be well homogenized. Meanwhile, zinc is in a saturated state in the liquid gallium-based alloy, so zinc in the circulation process finally uniformly nucleates and grows on the surface of the zinc metal matrix, and dendrites are prevented from being formed on the surface of the composite negative electrode. Meanwhile, by compounding with gallium and indium with high hydrogen evolution overpotential, the corrosion resistance of the composite zinc negative electrode can be improved, the problem of side reactions such as negative electrode corrosion hydrogen production in the zinc ion battery is relieved, the cycle life of the zinc ion battery is prolonged, and the use stability and safety of the battery are improved.

Owner:CENT SOUTH UNIV

Method for preparing concentration liquid of ammonium nitrate

InactiveCN1907856AHigh final ammonium nitrate concentrationSave on investment costsAmmonium nitratesEvaporationHigh concentrationReaction rate

This invention discloses a preparation method for concentrated ammonium nitrate solution, which is characterized by (1) enhancing atomization at the nitric acid inlet by tubular reactor and increasing reaction rate and efficiency, (2) controlling reactor pressure higher than saturated vapor pressure according to different water conternt in nitric acid, therefore producing no secondary steam, avoiding drop formation from flash separation after reaction, and reducing investment cost markedly, and (3) totally taking advantage of reaction heat to prepare 96-99.7% ammonium nitrate according different requirements under different reaction temperature and different cycle temperature differences of ammonium nitrate and different vacuum degree, wherein the reaction heat is from vacuum-flash ammonium nitrate solution heated by 180-185DEG C ammonium nitrate with lower concentration. The invention is specifically applicable for high concentration nitric acid as raw material and preparation of high density ammonium nitrate.

Owner:太原海力丰科技发展有限公司

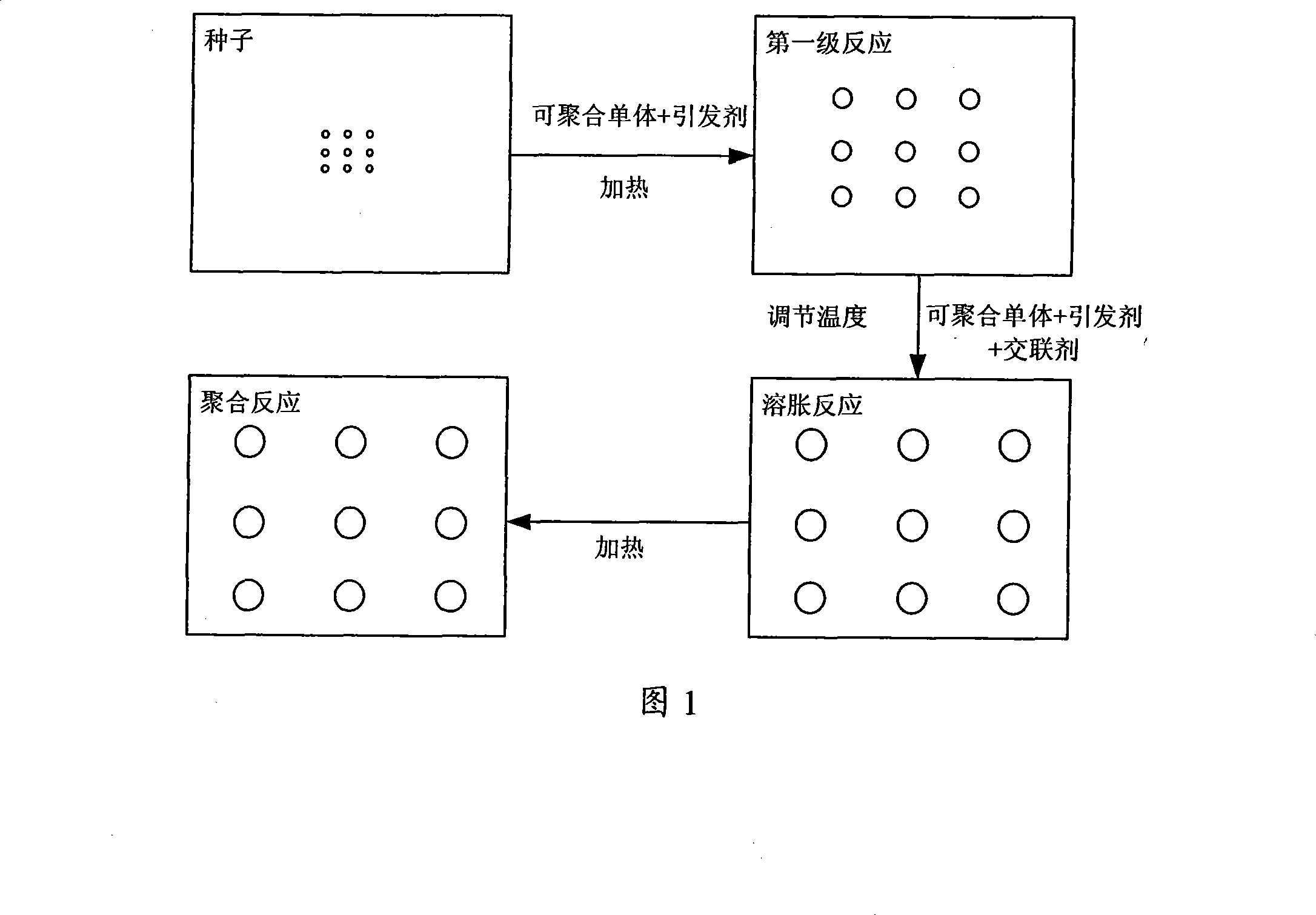

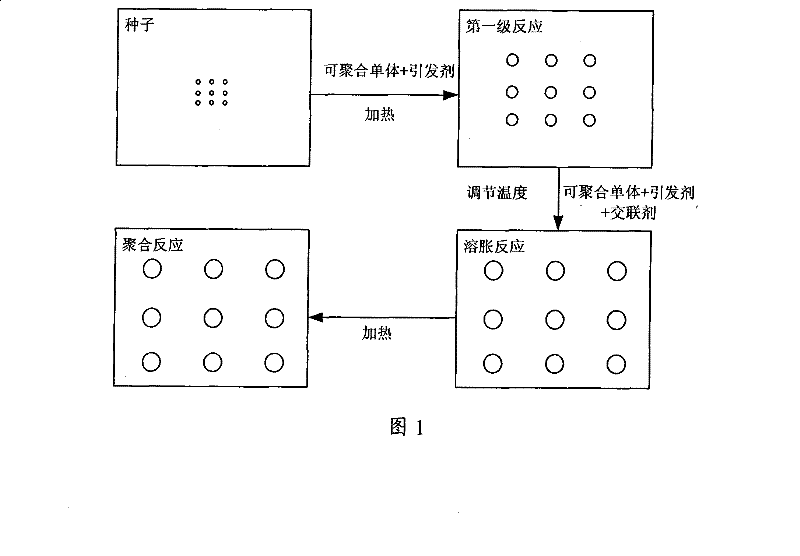

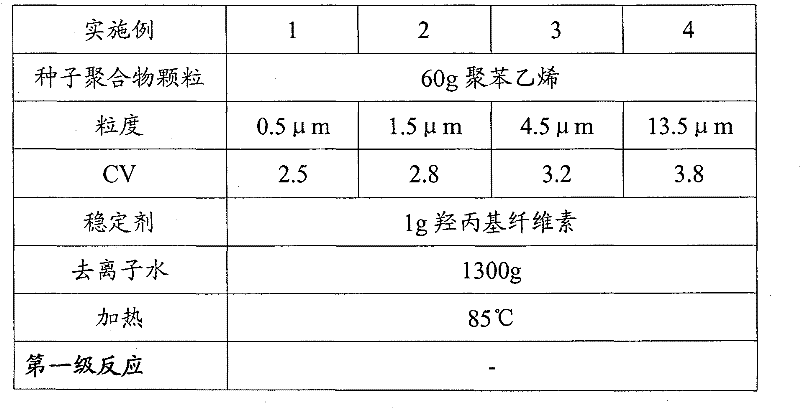

Method for preparing polymer particle

The invention discloses a preparation method of polymer particle, which comprises that suspends monodisperse and swelling seed polymer particles with a first preset value of mass into a water solution containing stabilizer and surface activator, mixes polymerisable monomer with mass of second preset value and initiator with mass as third preset value, to be added into monomer solution at polymerisable temperature, to process reaction, while the reaction degree is controlled at 30-98%, adjusts temperature, adds reactant, swells, while the reactant contains a polymerisable monomer with mass of fourth preset value or a second crosslinkable monomer with mass of fifth preset value, and an initiator with mass of sixth preset value, heats to polymerisable temperature, to process polymerization. The inventive microballoon has better monodispersity, high yield, reaction reproduction support, reduced production cost, and controllable product shape and property, while the invention can prepare porous monodisperse microballoon product.

Owner:深圳市纳微科技有限公司

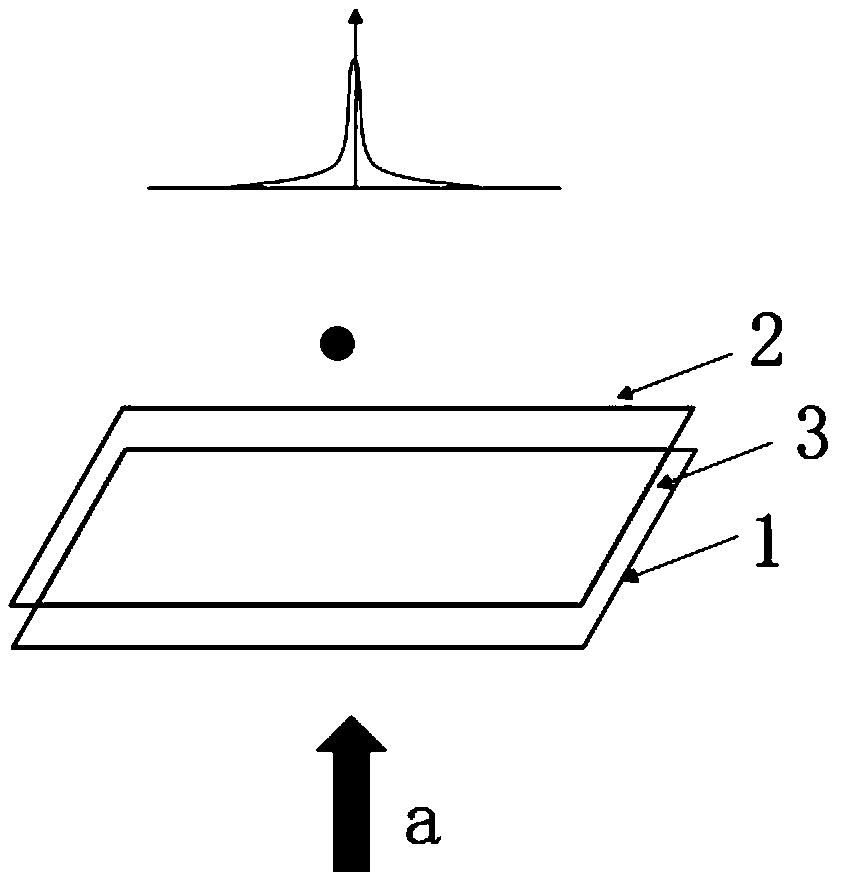

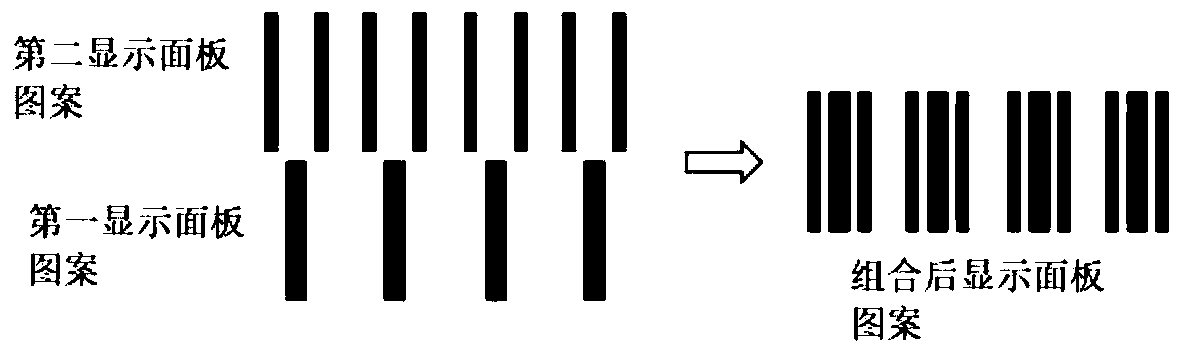

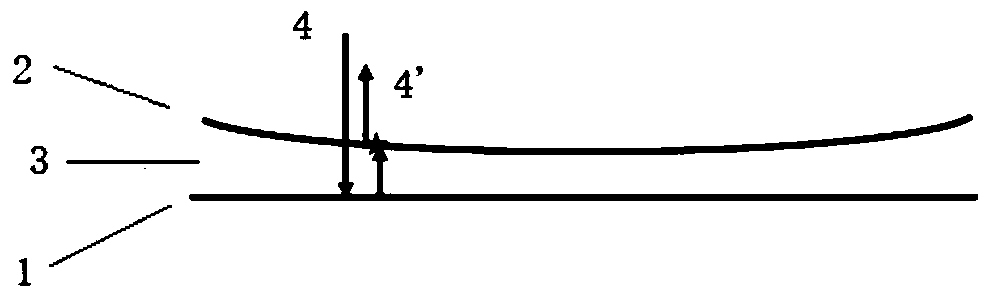

Display panel and manufacturing method and display device thereof

ActiveCN109491155AImprove the display effectEliminate formationNon-linear opticsDispersion curveBand shape

An embodiment of the invention provides a display panel. The display panel comprises a first display panel and a second display panel arranged above the first display panel, and further comprises a plurality of optical anisotropic array structures; and the array structures are positioned between the first display panel and the second display panel, and are used for supporting the first display panel and the second display panel. The embodiment of the invention further discloses a manufacturing method and a display device of the display panel. The array structures are arranged between the firstdisplay panel and the second display panel of the embodiment of the invention, and have optical anisotropy, a dispersion curve of light wave which spreads in the array structures becomes band-shapedstructures, photonic band gaps which are similar to semiconductor band gaps will exist among the band-shaped structures, frequency drops in photons in the photonic band gaps and cannot spread in the array structures, then interference ripples are scattered, moire is eliminated, and the display effect of the display panel is improved.

Owner:BOE TECH GRP CO LTD +1

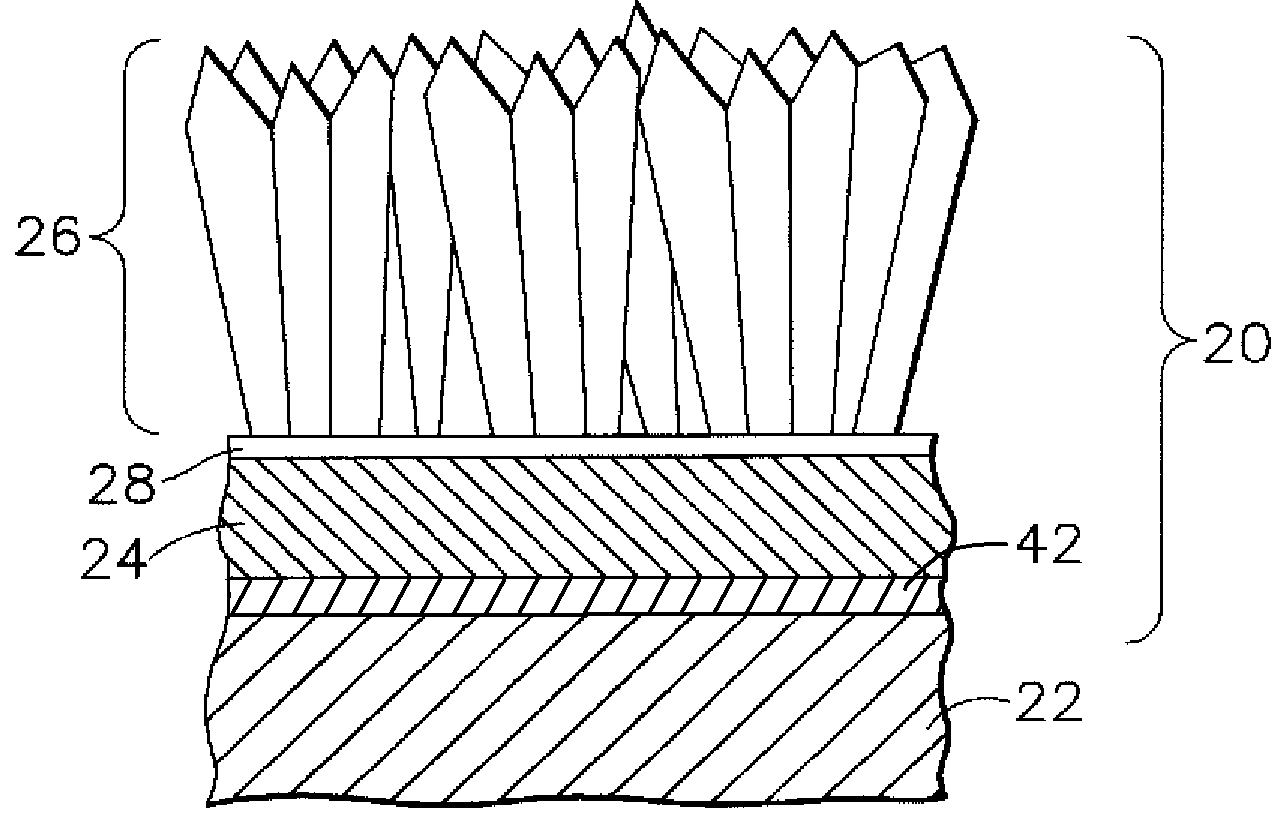

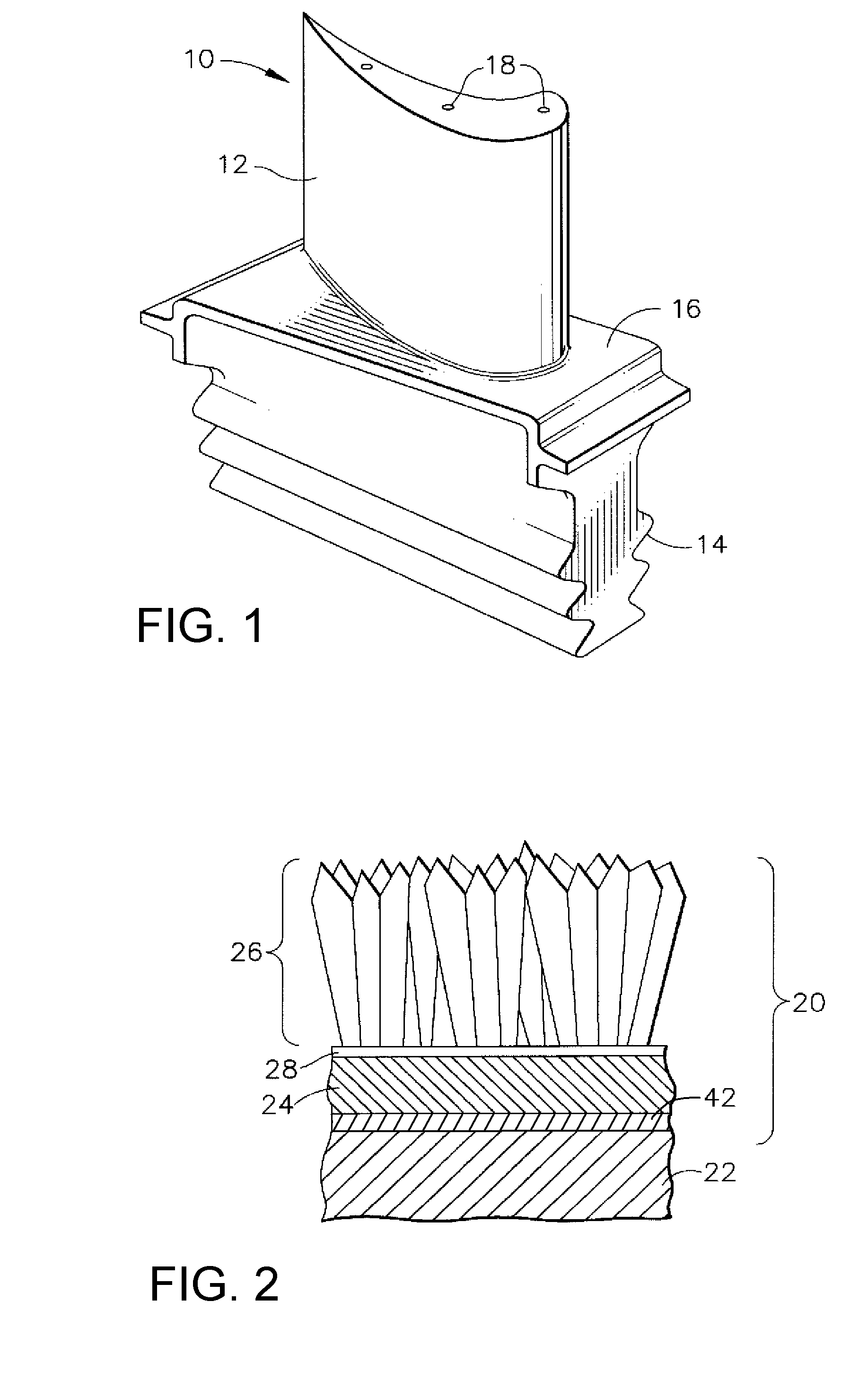

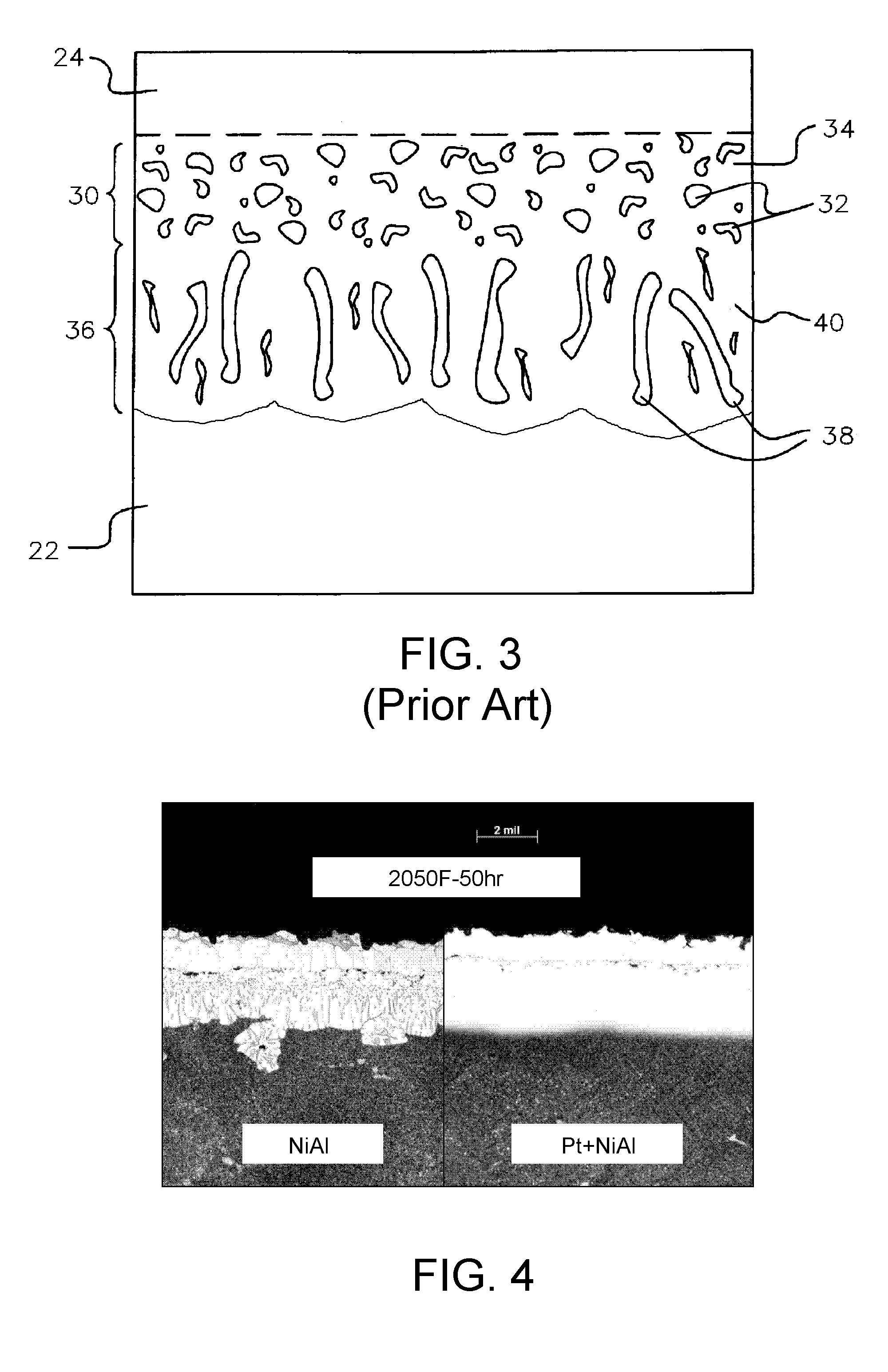

Ni-base superalloy having a coating system containing a stabilizing layer

InactiveUS7544424B2Controlled diffusionImprove performancePropellersRecord information storageIridiumCoating system

A coating process and system for an article having a substrate formed of a metal alloy that is prone to the formation of a secondary reaction zone (SRZ). The coating system includes an aluminum-containing overlay coating and a stabilizing layer between the overlay coating and the substrate. The overlay coating contains aluminum in an amount greater by atomic percent than the metal alloy of the substrate, such that there is a tendency for aluminum to diffuse from the overlay coating into the substrate. The stabilizing layer is predominantly or entirely formed of at least one platinum group metal (PGM), namely, platinum, rhodium, iridium, and / or palladium. The stabilizing layer is sufficient to inhibit diffusion of aluminum from the overlay coating into the substrate so that the substrate remains essentially free of an SRZ that would be deleterious to the mechanical properties of the alloy.

Owner:GENERAL ELECTRIC CO

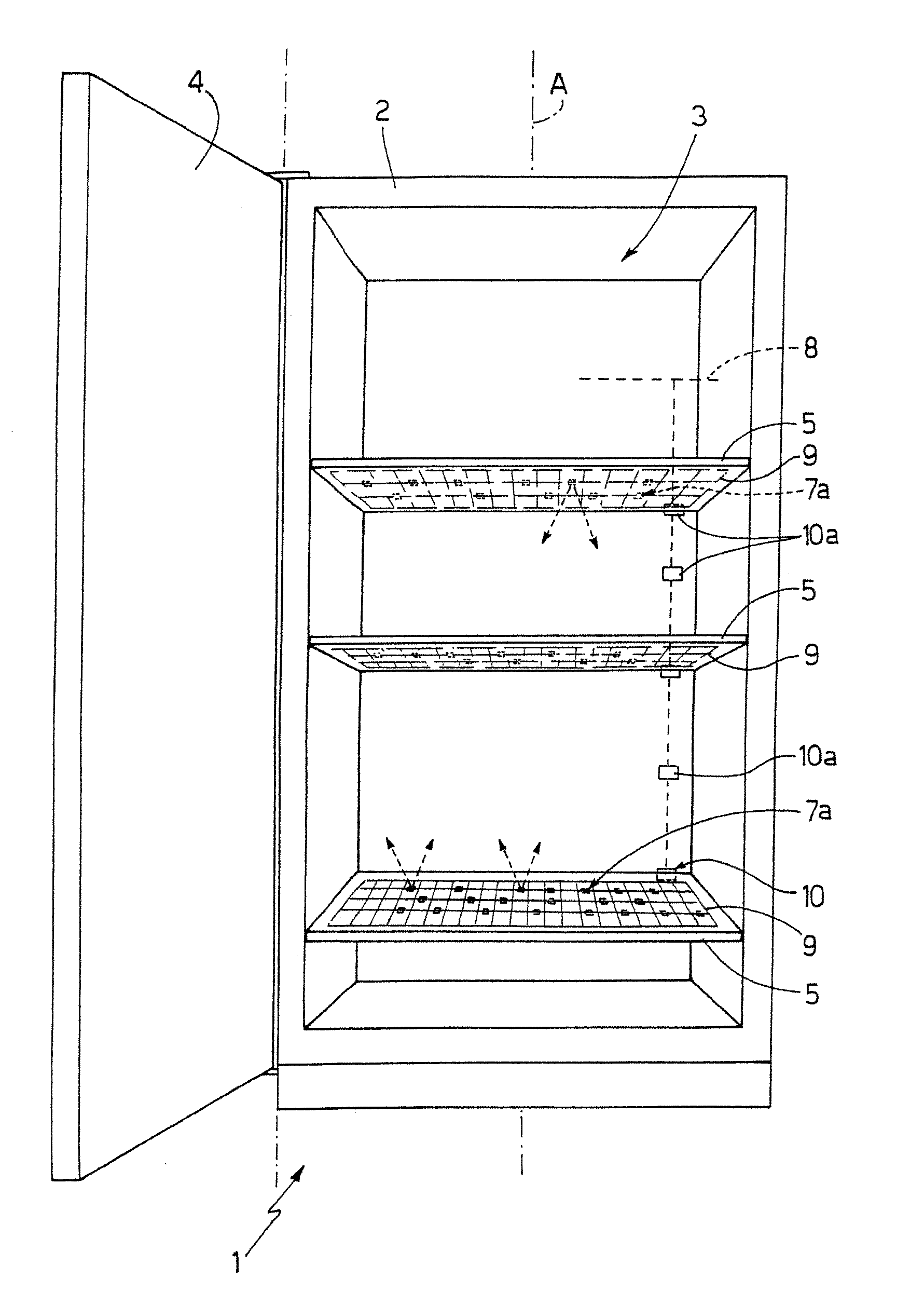

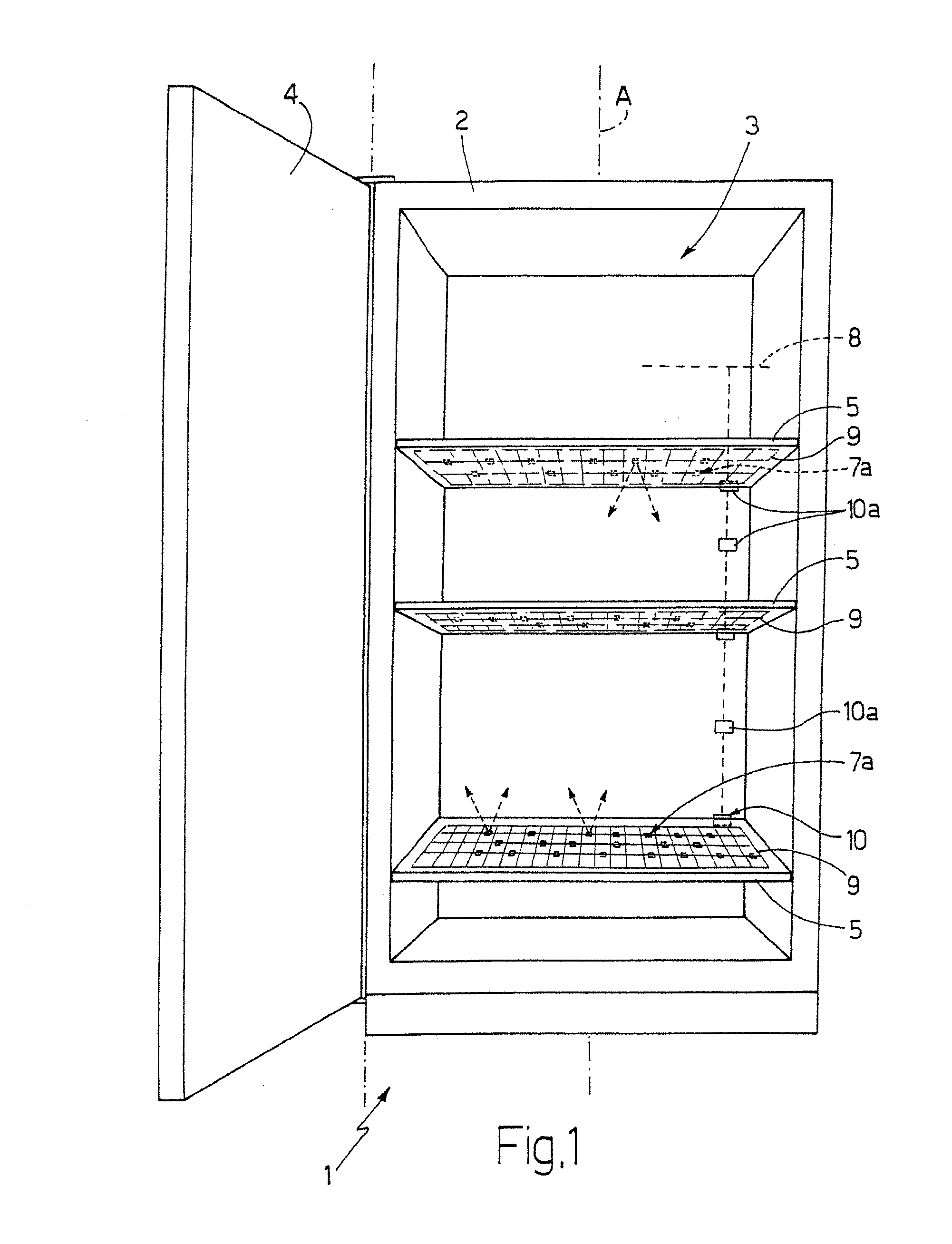

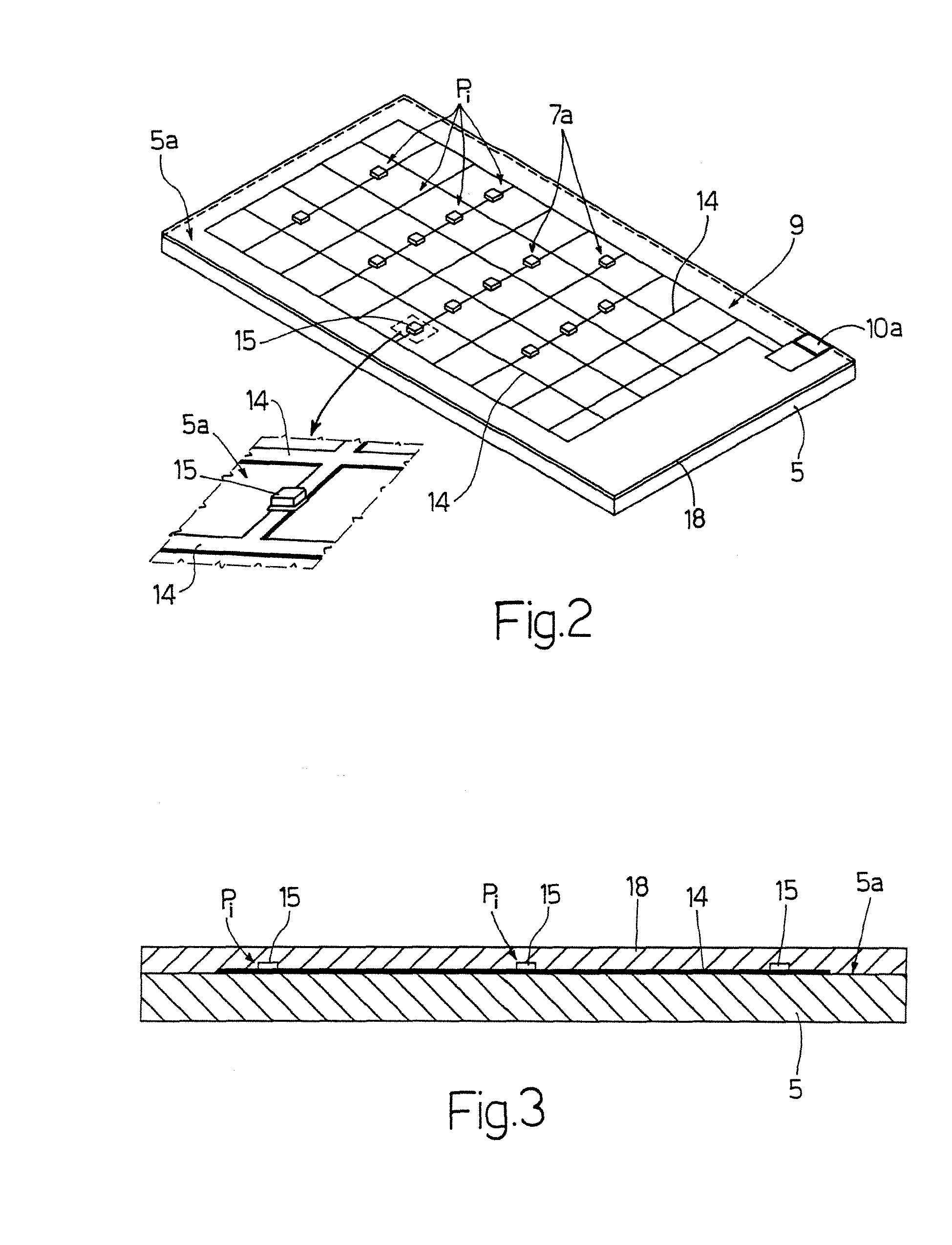

Food refrigeration appliance with illuminated shelves, and method of producing the illuminated shelves

ActiveUS8459817B2Eliminate formationSimplify cleaningMechanical apparatusFurnace componentsLighting systemLight source

There is described a food refrigeration appliance (1) having a casing (2); a food refrigeration chamber (3) housed inside the casing (2); a food-supporting shelf (5) located inside the refrigeration chamber (3); and a lighting system (7), in turn having a number of spot light sources (7a) fixed stably to the shelf (5), and a power line (8) for electrically powering the spot light sources (7a); the lighting system (7) having a number of straight tracks (14) made of electrically conducting material and fixed stably to the shelf (5) to define an electric circuit (9) connecting the spot light sources (7a) to the power line (8).

Owner:ELECTROLUX HOME PROD CORP NV

Method for preparing manganese-stabilized zirconia film

InactiveCN101580391AEliminates the formation of amorphous layers and second phase oxidesFast preparationIonYttrium

The invention discloses a method for preparing a manganese-stabilized zirconia film, which comprises the following steps: using metal oxide ZrO2 powder and MnO2 powder as raw materials, weighing the raw materials according to a molar ratio of positive ions in Zr0.75Mn0.25O2 of 3:1, and mixing, grinding and sintering the raw materials; and after he raw materials are grinded and pressed again, repeatedly sintering the raw materials, again, polishing a sintered sample into a target material, corroding a target body by pulse laser projected onto the surface of the target material at certain substrate temperature, argon partial pressure and target-substrate distance, and depositing the doped zirconia onto a yttrium-stabilized zirconia single crystal substrate after a plume is formed to obtain the manganese-stabilized zirconia film. The method has the advantages that: the process is simple; the prepared manganese-stabilized zirconia film has good c-axis texture and smooth and compact surface; and an atomic-scale sharp interface is formed between the manganese-stabilized zirconia film and the single crystal substrate.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Ultrasonic vibration micro-foaming injection moulding device and ultrasonic vibration micro-foaming injection moulding method for plastic inspection well

The invention relates to an ultrasonic vibration micro-foaming injection moulding device and an ultrasonic vibration micro-foaming injection moulding method for a plastic inspection well, and relates to the field of injection moulding machining for plastic inspection wells. The ultrasonic vibration micro-foaming injection moulding device comprises a fixed die plate, a movable die plate, a die core and hot runner system, an ultrasonic vibration device and a control system, wherein die cores comprise a main die core and a side pulling core, and a die cavity is arranged among the die cores, the fixed die plate and the movable die plate. According to the invention, a cavitation foaming effect of ultrasonic vibration on plastic is utilized, the die cavity is filled with a plastic melt through injection moulding to reach 85-90% of the volume of the die cavity at first, and then the plastic melt in the die cavity is subjected to overall ultrasonic vibration and cavitation micro-foaming through the main die core provided with an ultrasonic vibration mechanism, thus micro-foaming injection moulding machining for the plastic inspection well is realized. The ultrasonic vibration micro-foaming injection moulding device disclosed by the invention is simple to operate, high in moulding accuracy, and capable of saving plastic raw materials by 10-15%, reducing an injection moulding pressure by 60-80%, saving energy, avoiding or reducing generation of weld marks, enhancing the product strength and prolonging the service life.

Owner:江苏正林环保科技有限公司

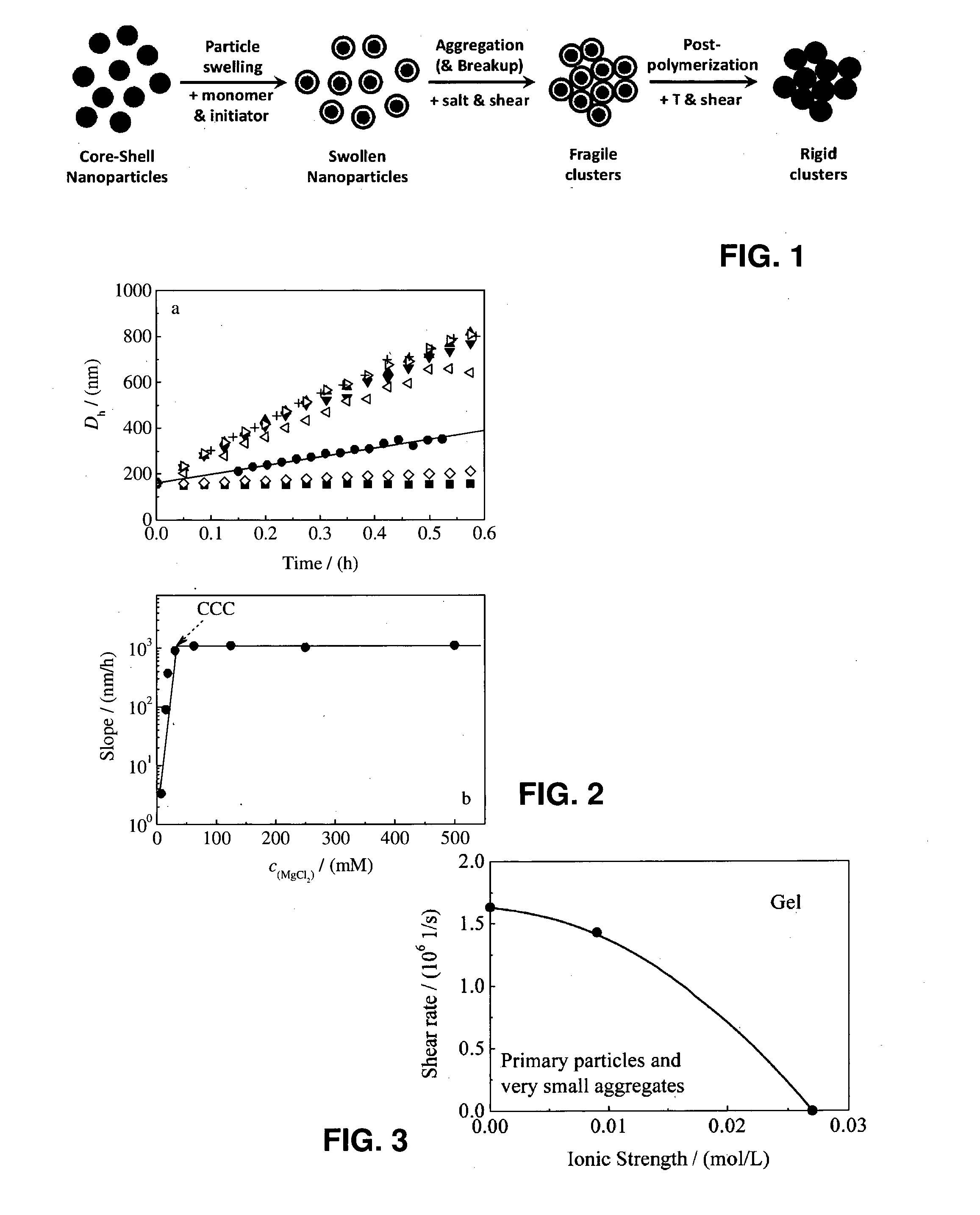

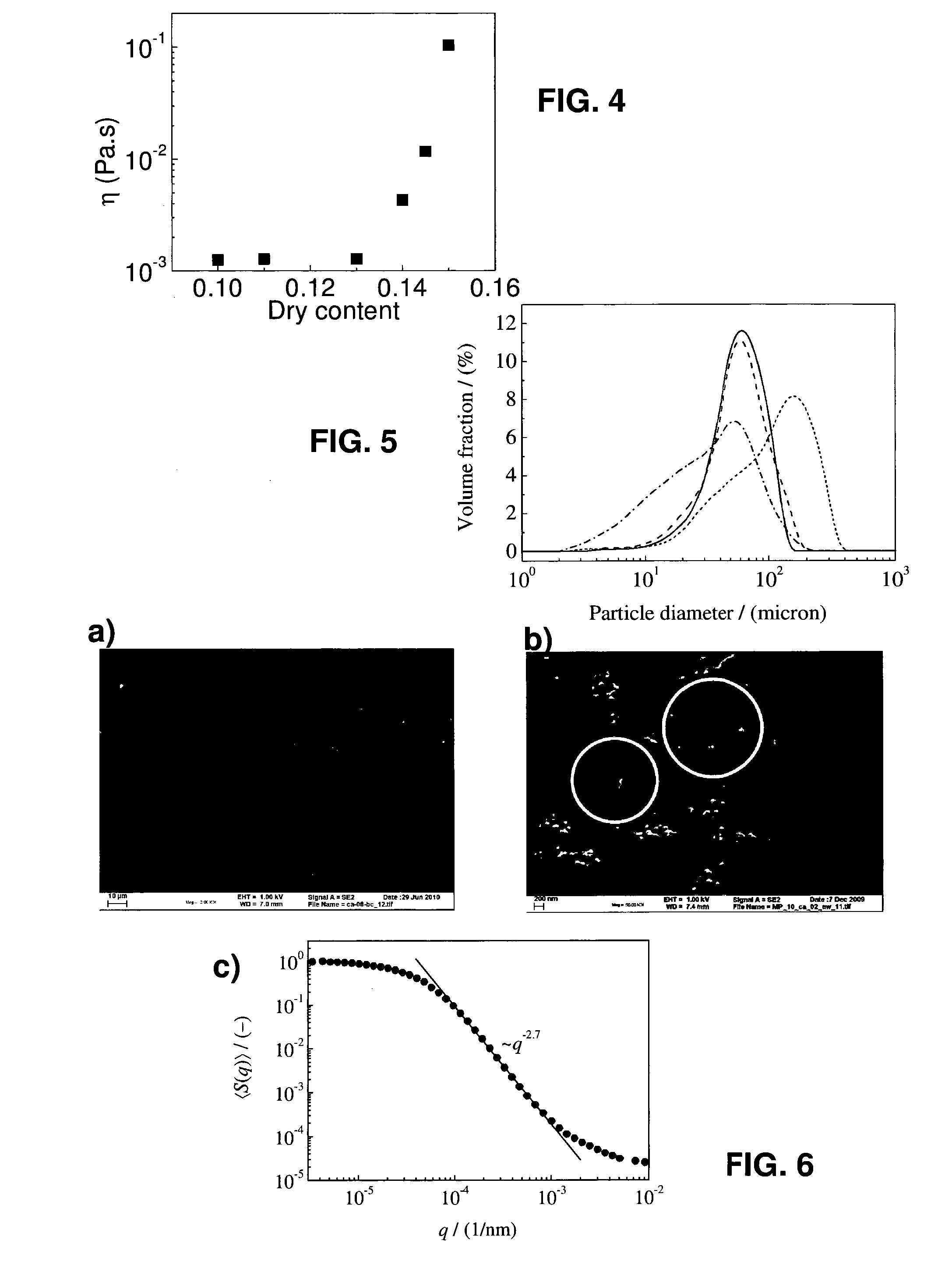

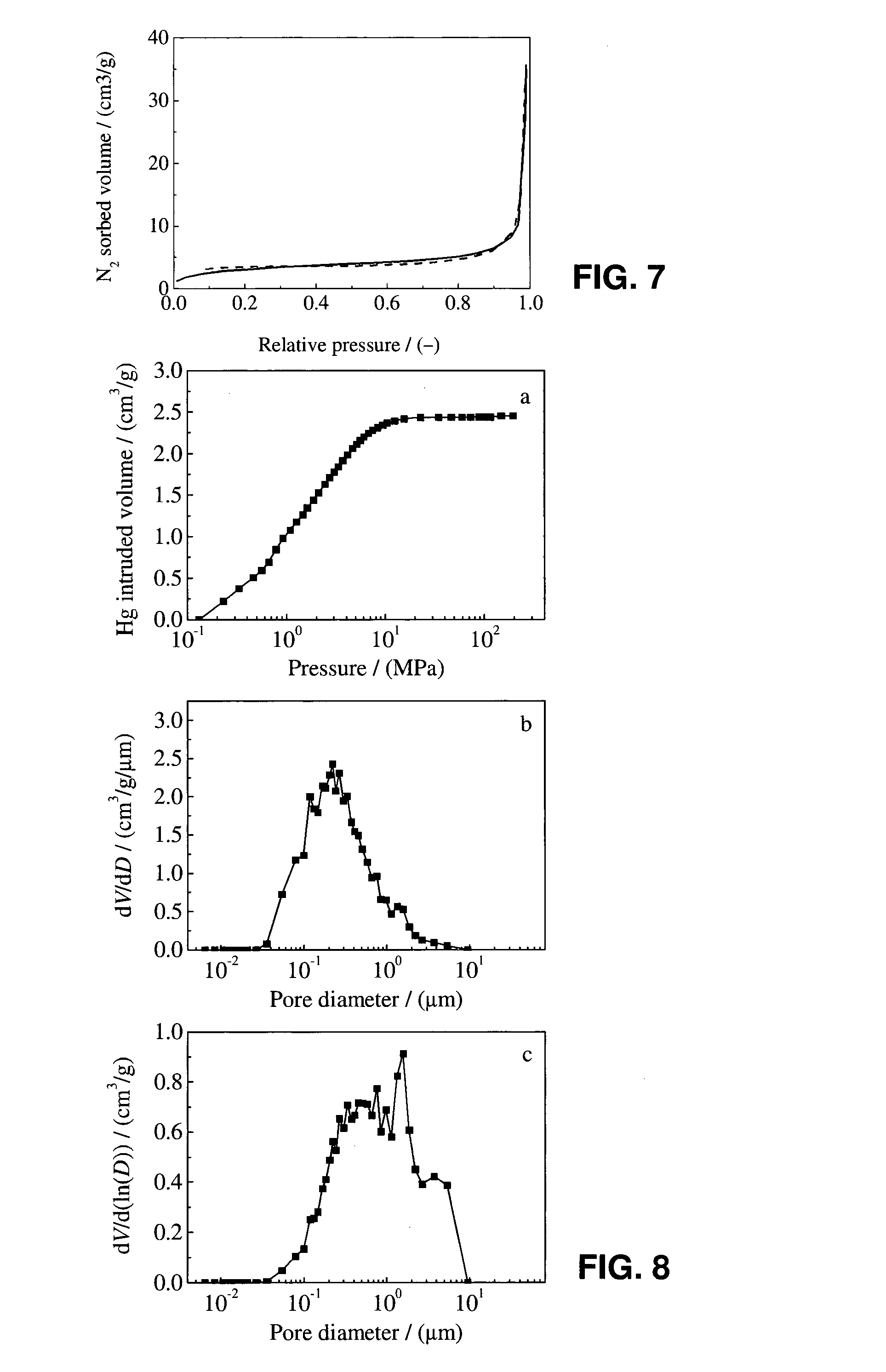

Method for the preparation of macroporous particles and macroporous

InactiveUS20150291760A1Eliminate formationFirmly connectedCation exchanger materialsOrganic anion exchangersIonChemistry

A method for producing macro porous micro-clusters is proposed comprising at least the following individual steps in given order: a) synthesis of dispersed cross-linked polymeric latex primary particles starting from at least one monomer or oligomer using emulsion polymerization; b) swelling of the primary particles with a liquid comprising at least an additional charge of monomer and / or oligomer and a cross-linker, optionally further comprising functionalization agents; c) destabilization by increase of ionic strength (by adding a salt and / or acid and / or base) in a combination with application of shear, both being above the gel formation boundary of the phase diagram, until agglomerates composed of primary particles of the desired size are formed; d) polymerization of the agglomerates to form the macro porous micro-clusters. Furthermore the invention to relates to correspondingly produced micro-clusters and uses of such micro-clusters in particular for chromatographic purposes.

Owner:ETH ZZURICH

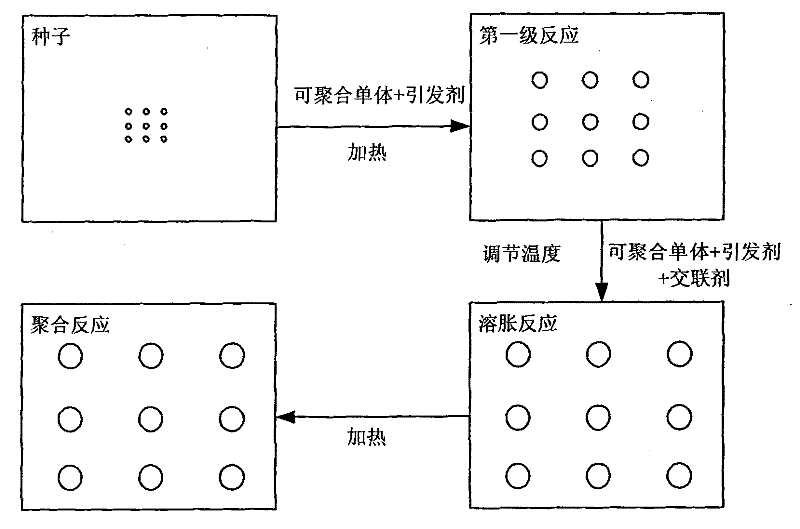

Method for preparing polymer particle

The invention discloses a preparation method of polymer particle, which comprises suspending monodisperse and swelling seed polymer particles with a first preset value of mass into a water solution containing stabilizer and surface activator, mixing polymerisable monomer with mass of second preset value and initiator with mass as third preset value, be added into a monomer solution at polymerisable temperature to process reaction while the reaction degree is controlled at 30-98%, adjusting temperature, adding reactant, swelling, while the reactant contains a polymerisable monomer with mass offourth preset value or a second crosslinkable monomer with mass of fifth preset value, and an initiator with mass of sixth preset value, and heating to polymerisable temperature to process polymerization reaction. The inventive microballoon has better monodispersity, high yield, reaction reproduction support, reduced production cost and controllable product shape and property, while the inventioncan prepare porous monodisperse microballoon product.

Owner:深圳市纳微科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com