Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Eliminate weld lines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

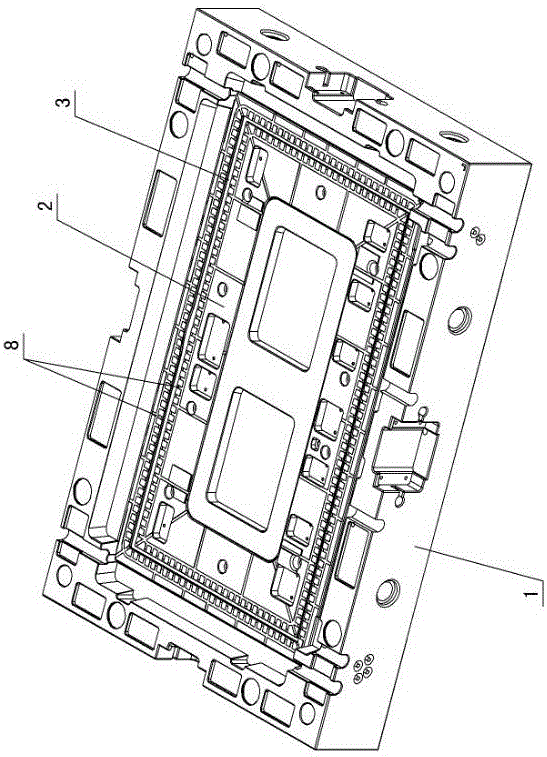

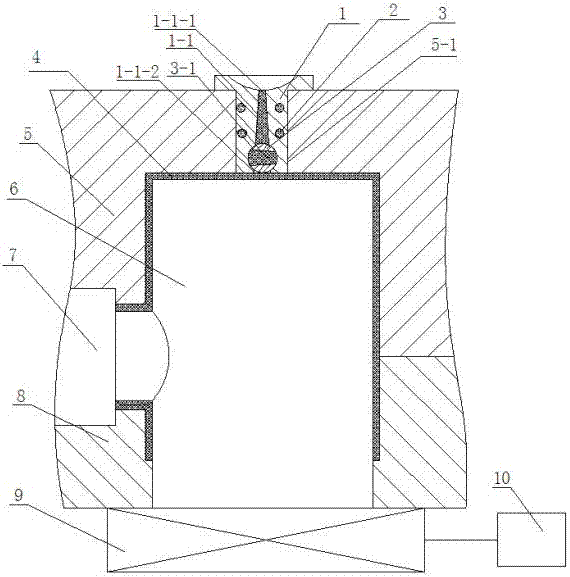

High-brightness non-melted mark steam injection mold and using method thereof

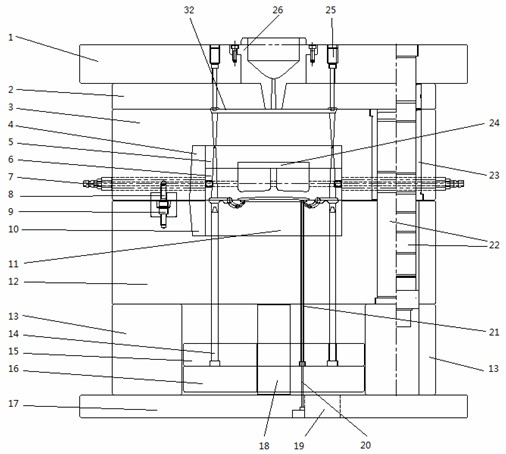

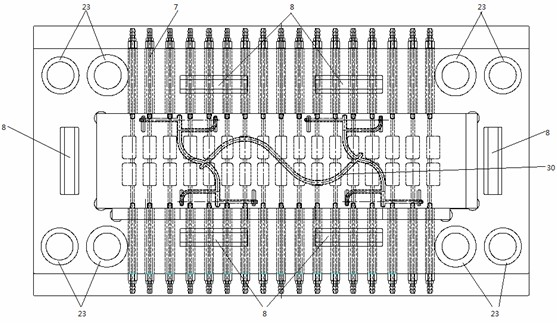

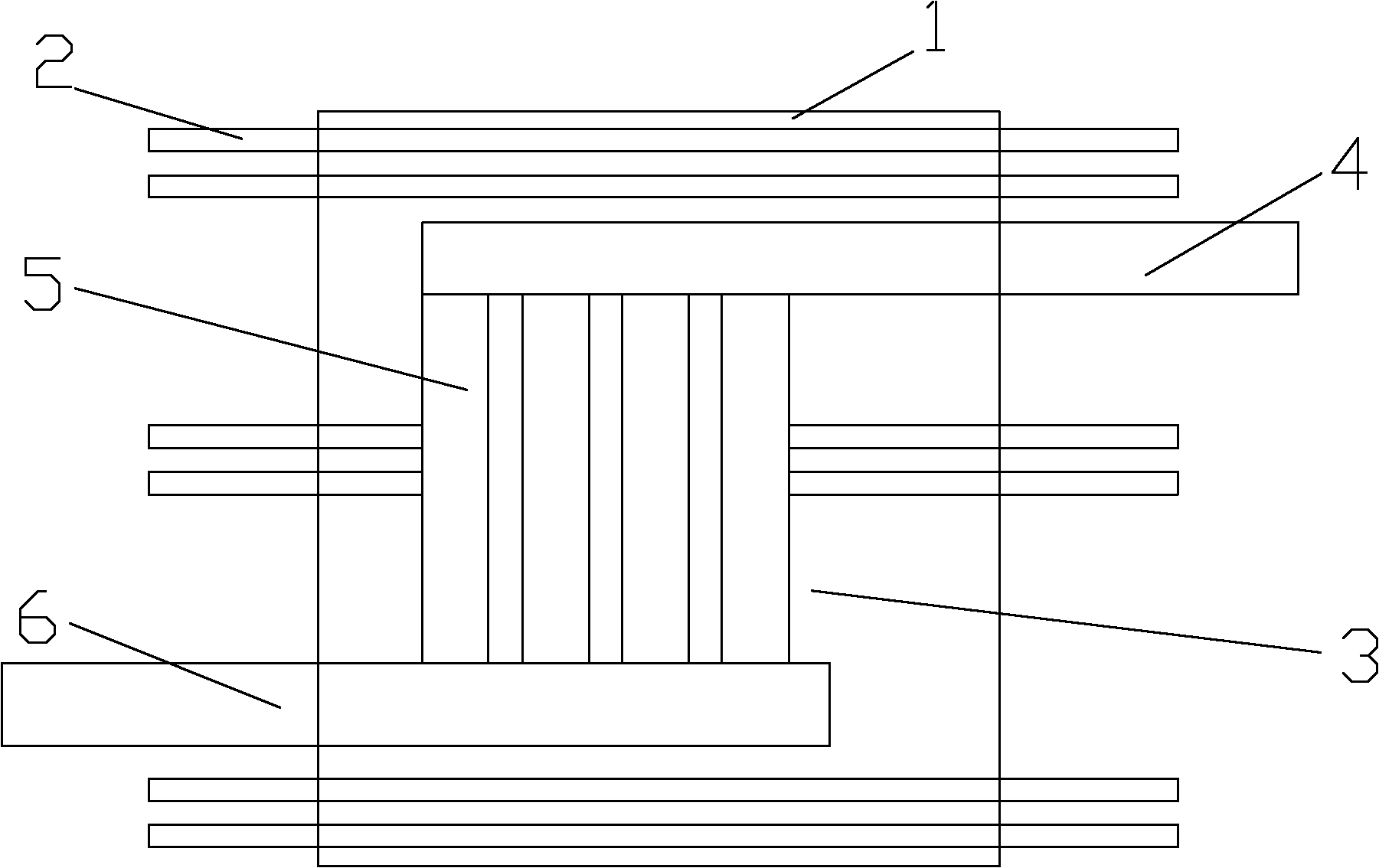

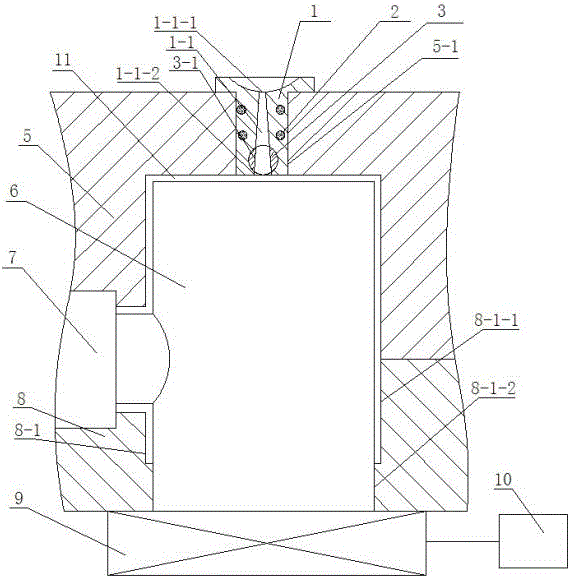

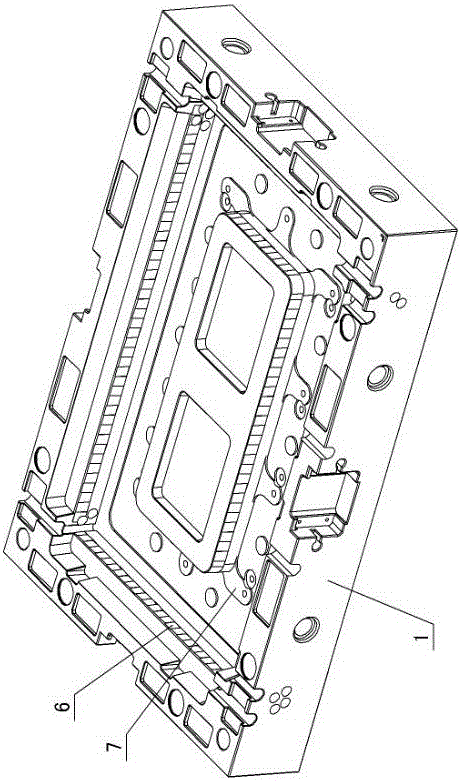

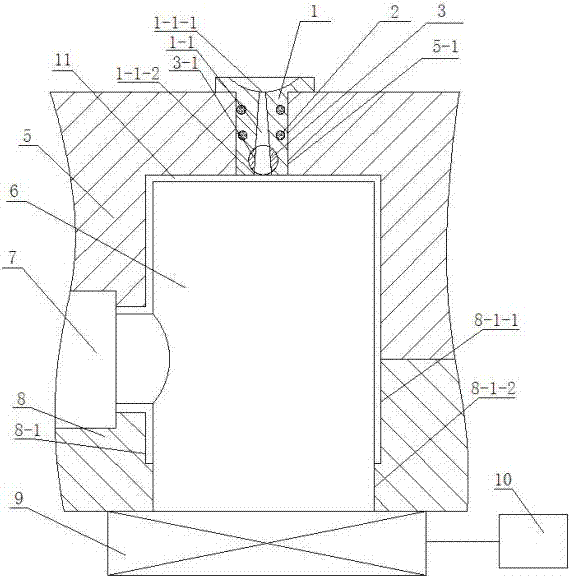

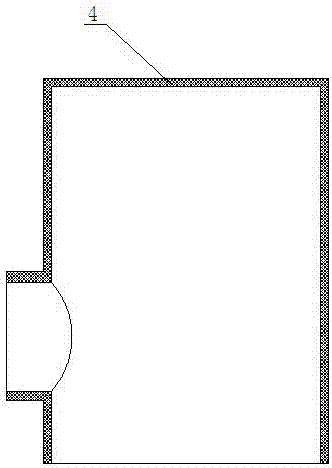

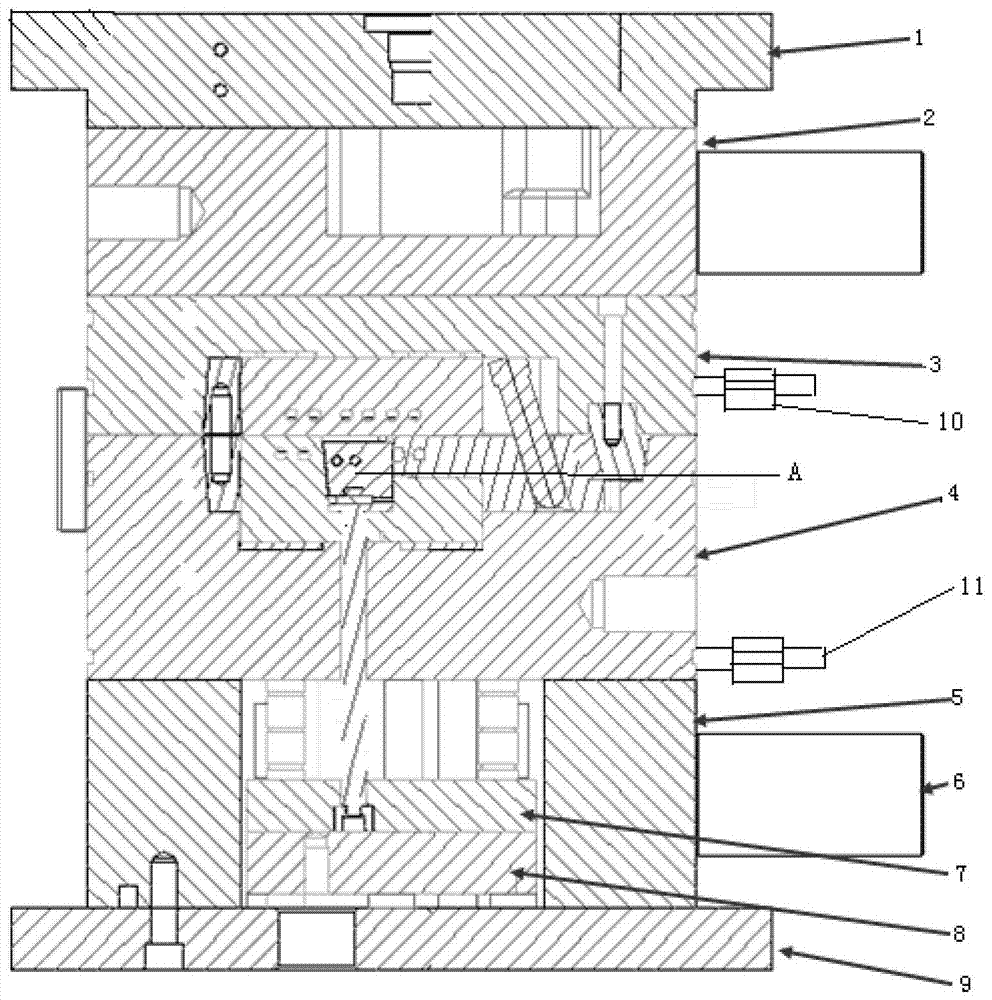

The invention discloses a high-brightness non-melted mark steam injection mold and a using method thereof. The high-brightness non-melted mark steam injection mold consists of an upper mold, a lower mold, a pouring system, a cooling water channel and an ejecting mechanism; the upper mold has an inlaying structure and consists of an upper mold inlaying plate, an upper-layer insert and a lower-layer insert, the upper-layer insert and the lower-layer insert are fixed in the upper mold inlaying plate, and the lower-layer insert is provided with a steam channel; the lower mold has an inlaying structure and comprises a lower mold inlaying plate and a lower mold insert, the lower-layer insert of the upper mold and the lower mold insert form a cavity, and the lower mold is internally provided with the cooling water channel; the pouring system is connected with the cavity by the upper mold inlaying plate, the upper-layer insert, the lower-layer insert and the lower mold insert; and the ejecting mechanism consists of an ejector rod, an ejector sleeve and a top plate. In the invention, a heat-insulating plate is arranged for heat insulation so as to deform the upper mold, improve the productquality and prolong the service life of the mold; the inlaying structure is adopted to effectively utilize the materials; and feeding is carried out from the inside of the product so as to have markson the surface after a sprue is removed, and ensure the outer surface quality of the product.

Owner:CIXI SHENGYI MOLD

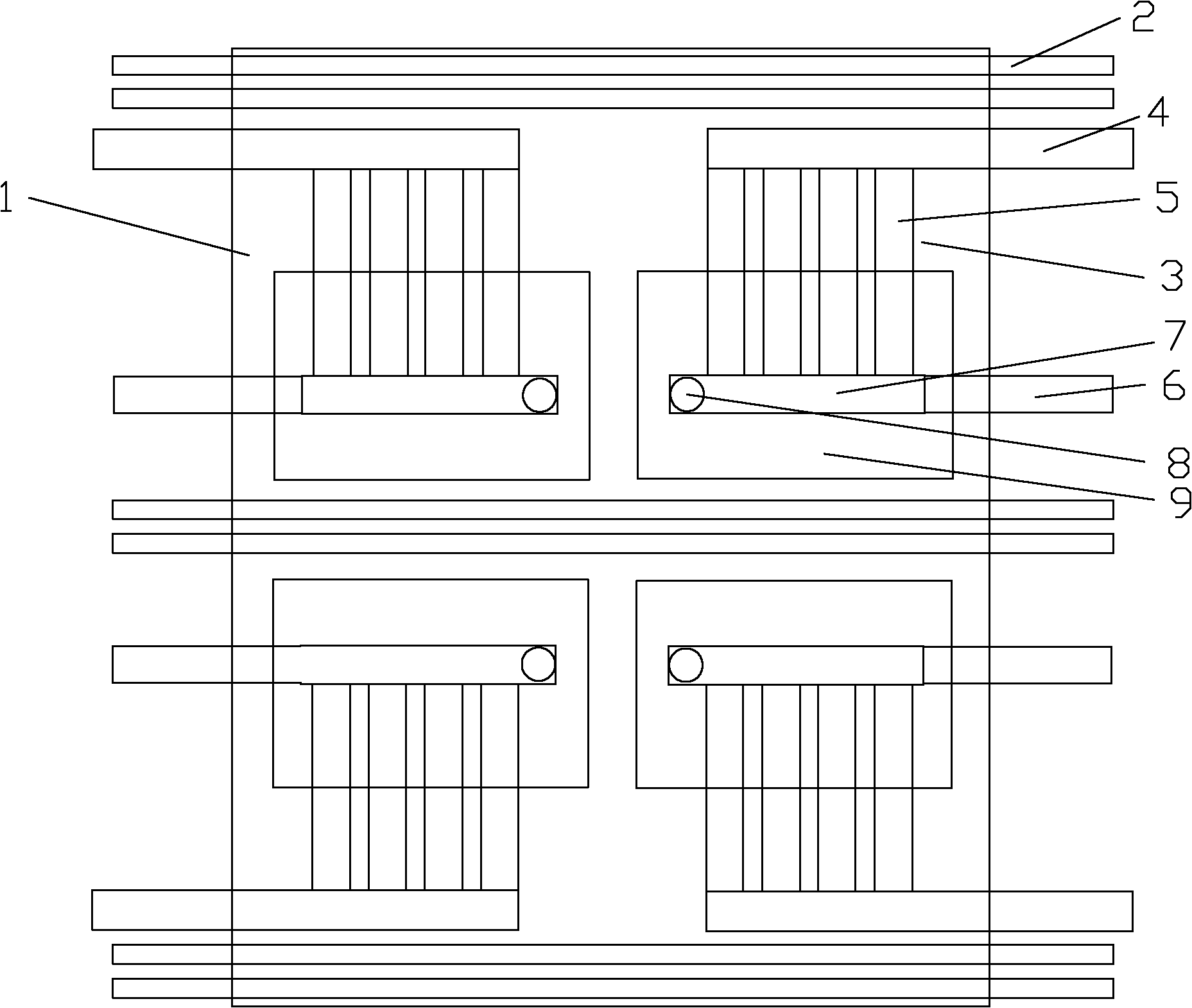

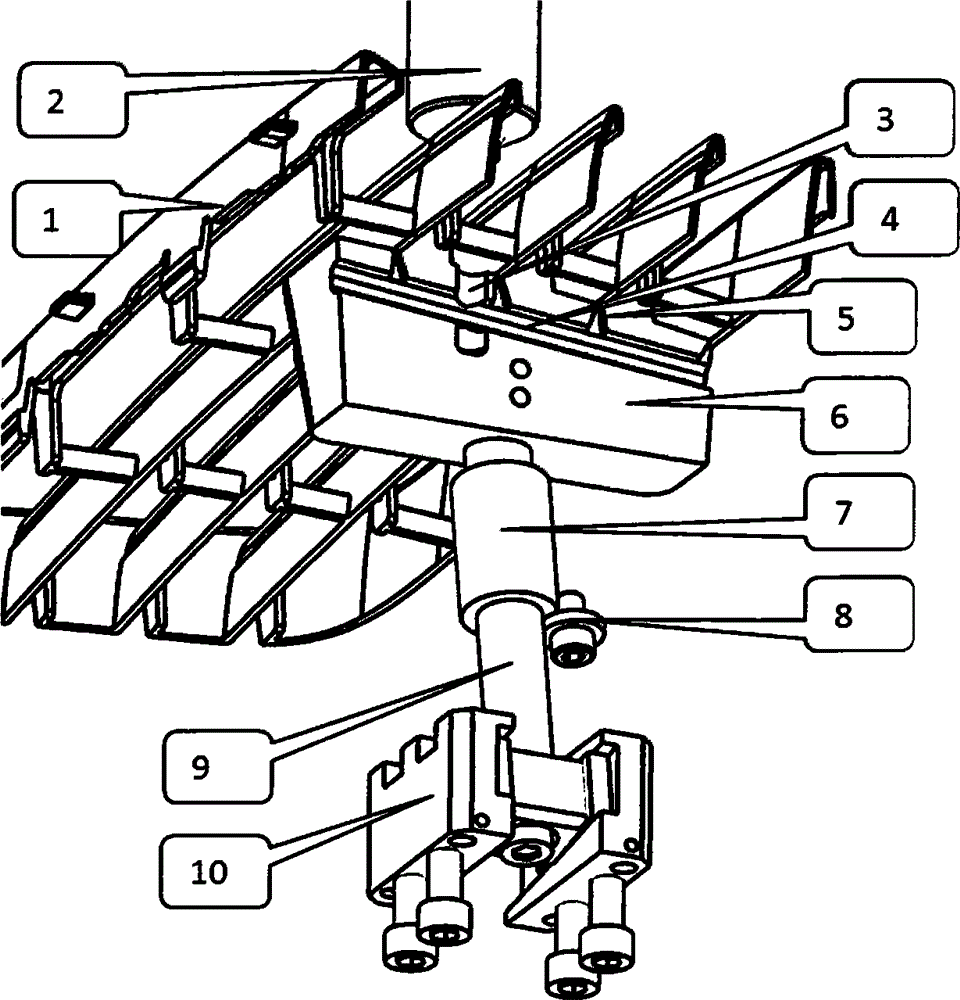

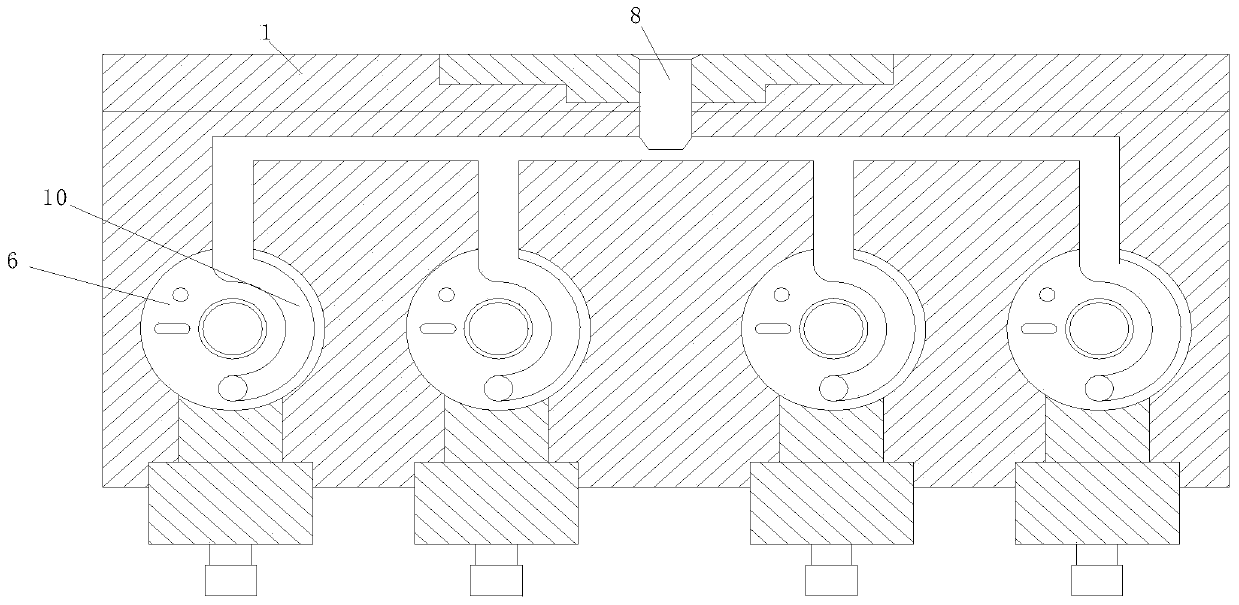

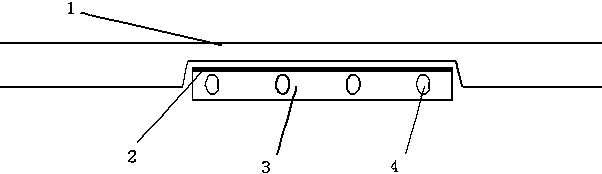

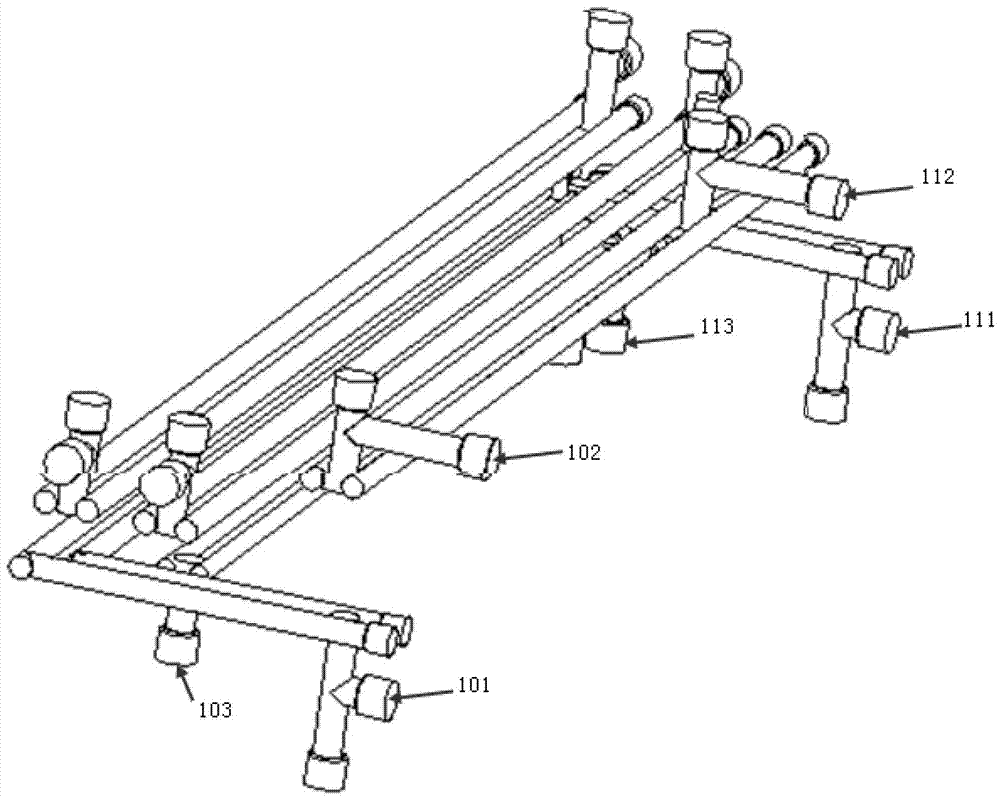

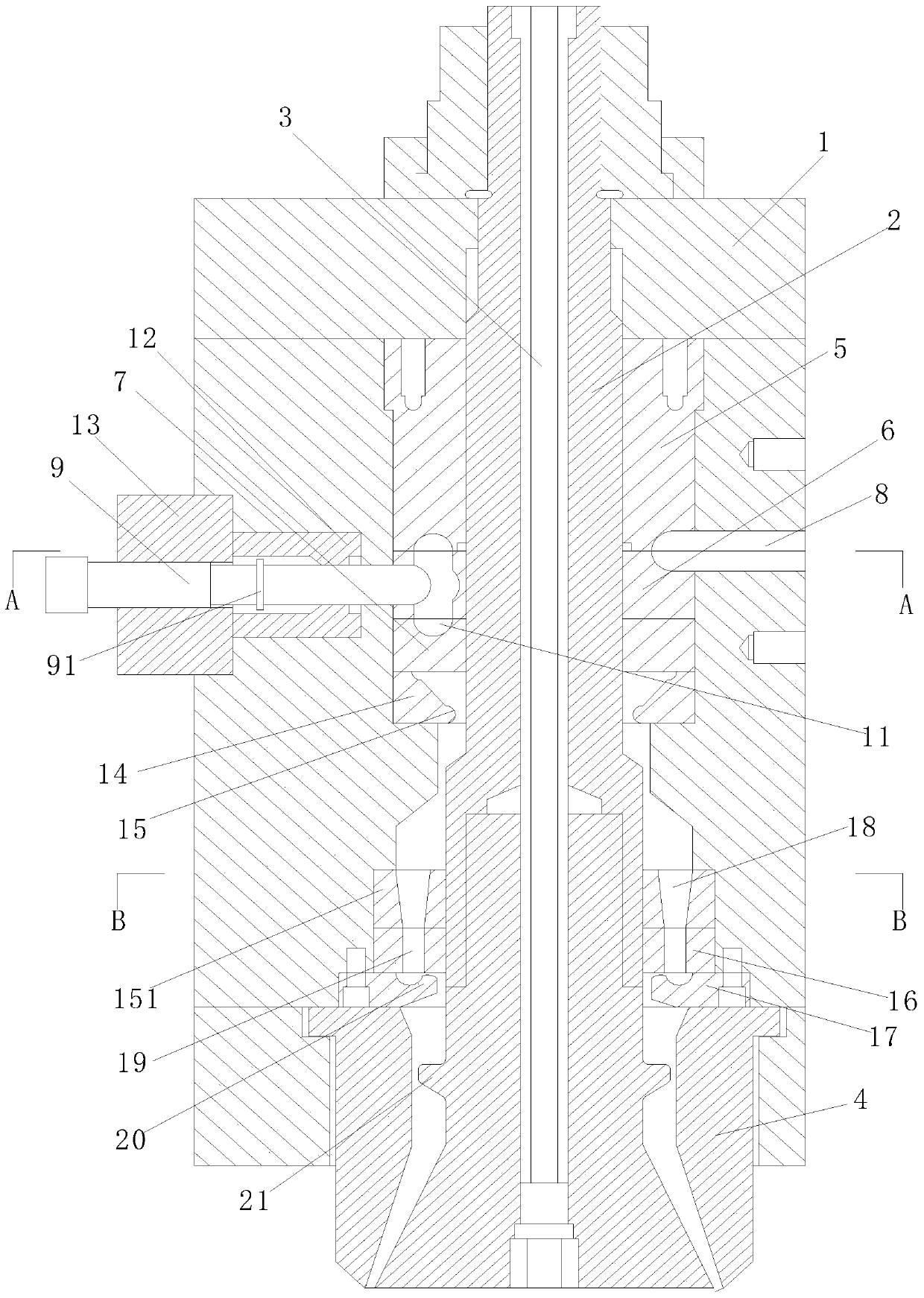

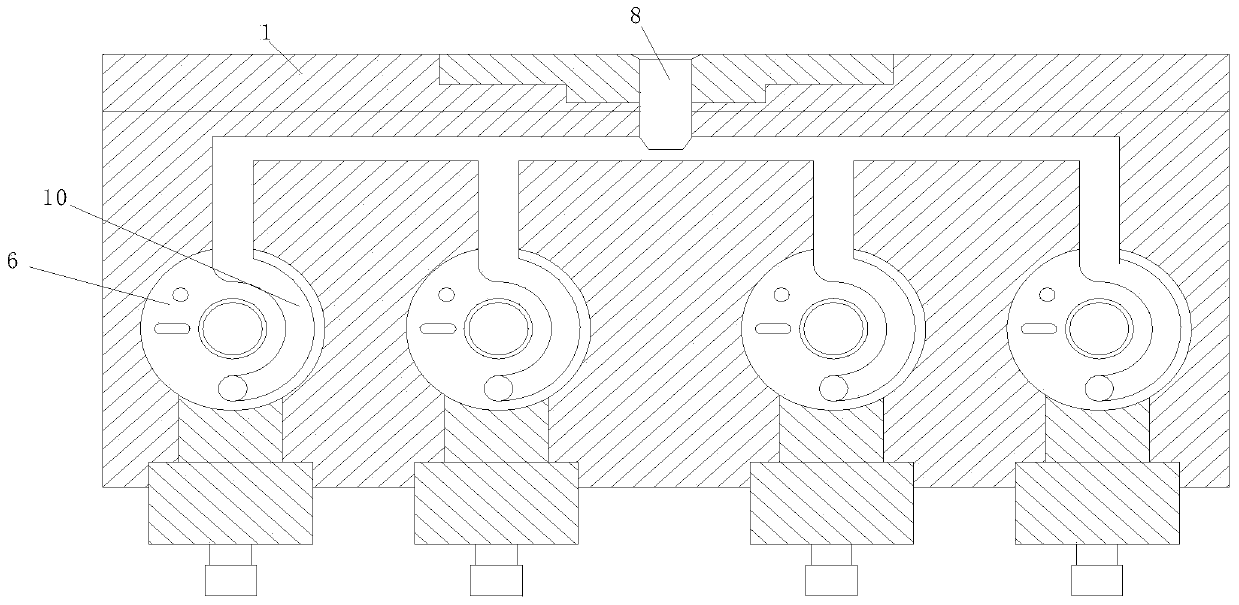

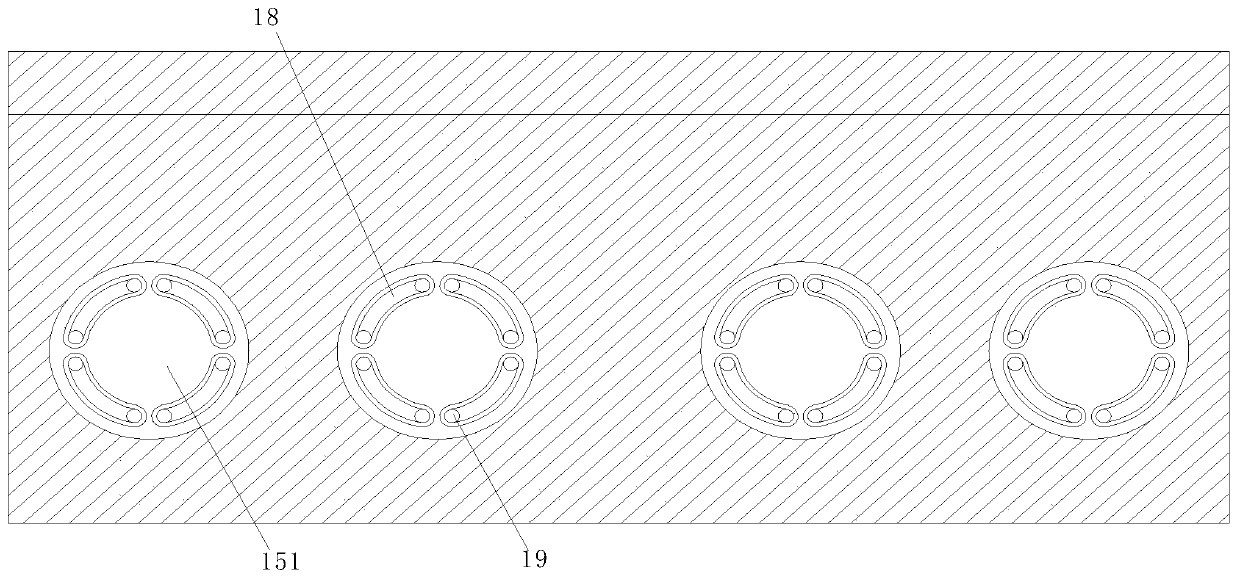

Sharp cooling and sharp heating highlight forming die

The invention discloses a sharp cooling and sharp heating highlight forming die, belonging to the technical field of injection moulding. The invention comprises a cavity insert and is characterized in that the inside of the cavity insert is provided with a plurality of cooling water channels transversely and a steam line; the steam line contains a main gas inlet pipe, shunts and a main gas outletpipe; the main gas inlet pipe extends in the upper right of the cavity insert and extends to the middle part of the cavity insert; four shunts are connected on the main gas inlet pipe side by side and extend downwards; the tail parts of the four shunts are connected with the main gas outlet pipe; and the main gas outlet pipe is arranged transversely and extends out of the lower left of the cavityinsert. The invention solves the problem of the prior art that the injection moulding equipment can not realize the fast heating and fast cooling of the mould, thus the product has the appearance quality defects such as weld marks and flow marks, and provides the sharp cooling and sharp heating highlight forming die which has simple structure and can realize fast heating and fast cooling and achieve better injection moulding effect.

Owner:KUNSHAN ESON PRECISION ENGINEERING CO LTD

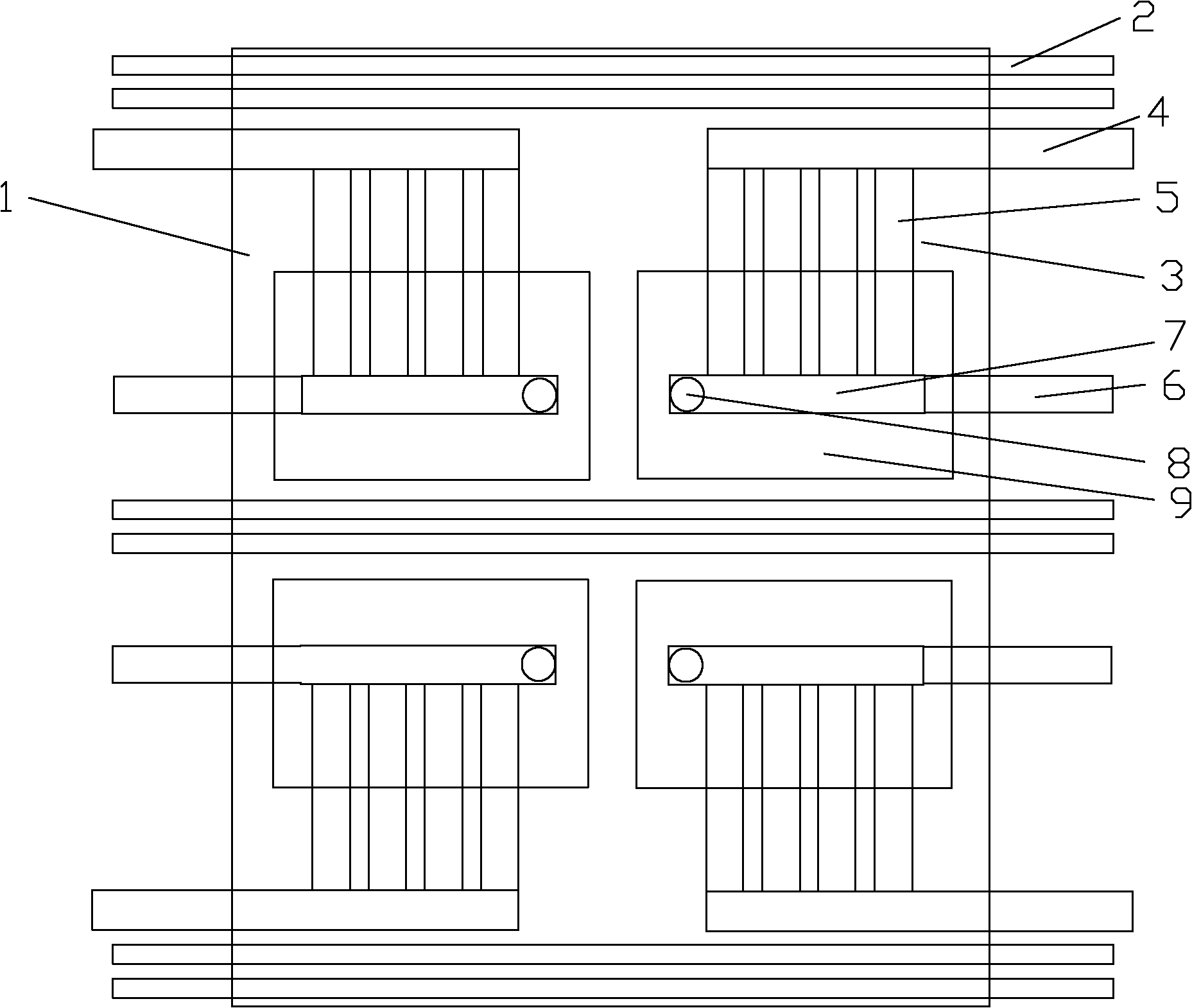

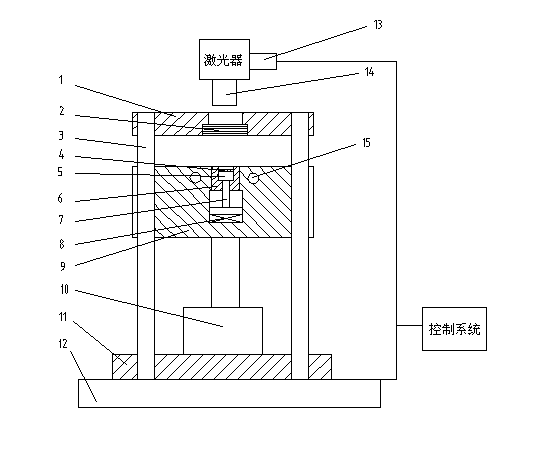

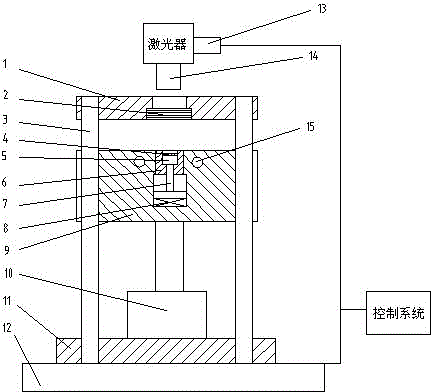

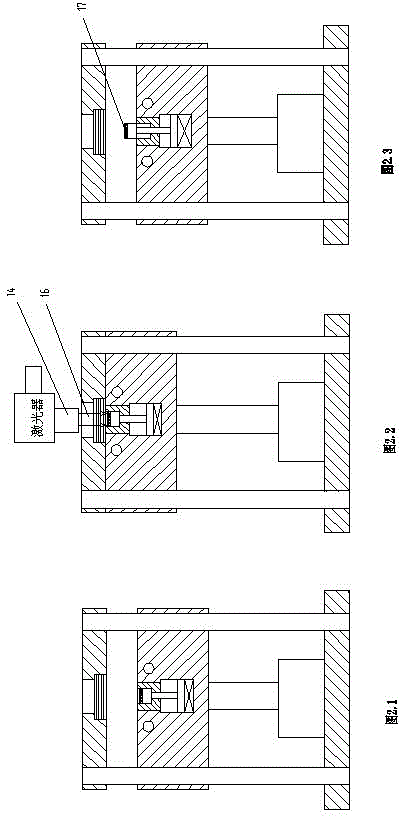

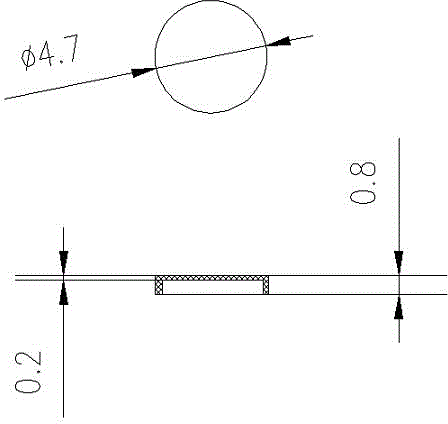

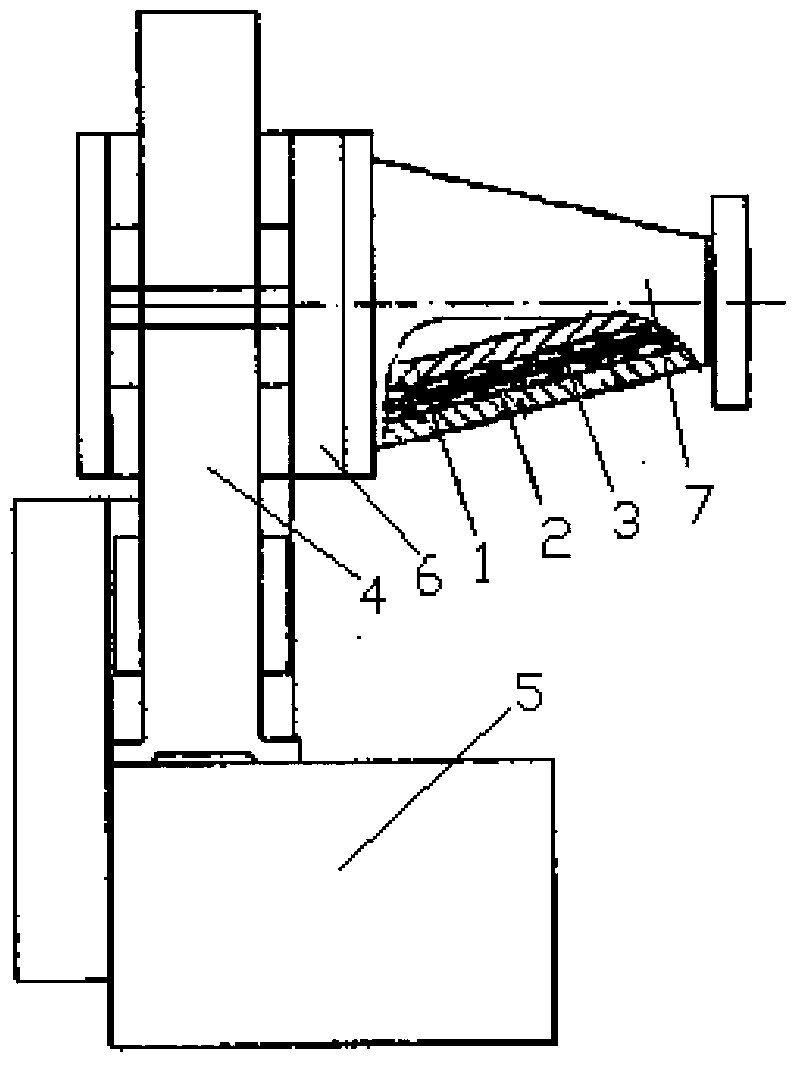

Small plastic part laser melting extrusion molding method and apparatus thereof

The invention discloses a small plastic part laser melting extrusion molding method and an apparatus thereof, relates to the high-precision small plastic part molding processing field, and especially relates to an infrared laser melting and die extrusion molding based small plastic part molding method and an apparatus thereof. Traditional high-precision small plastic parts have the disadvantages of high injection molding processing cost, difficult control of the quality of the an injection part, and severe wastes of plastic raw materials and energy. In the invention, infrared laser rapid heating melting and molding die extrusion molding processing technologies are adopted for the high-precision thermoplastic small plastic part. The small plastic part laser melting extrusion molding method and the apparatus thereof have the advantages of high molding precision, good molding quality, high efficiency and low cost, are suitable for the batch automatic molding processing of high-precision small plastic parts, and have high application values.

Owner:盐城动益汽车配件有限公司

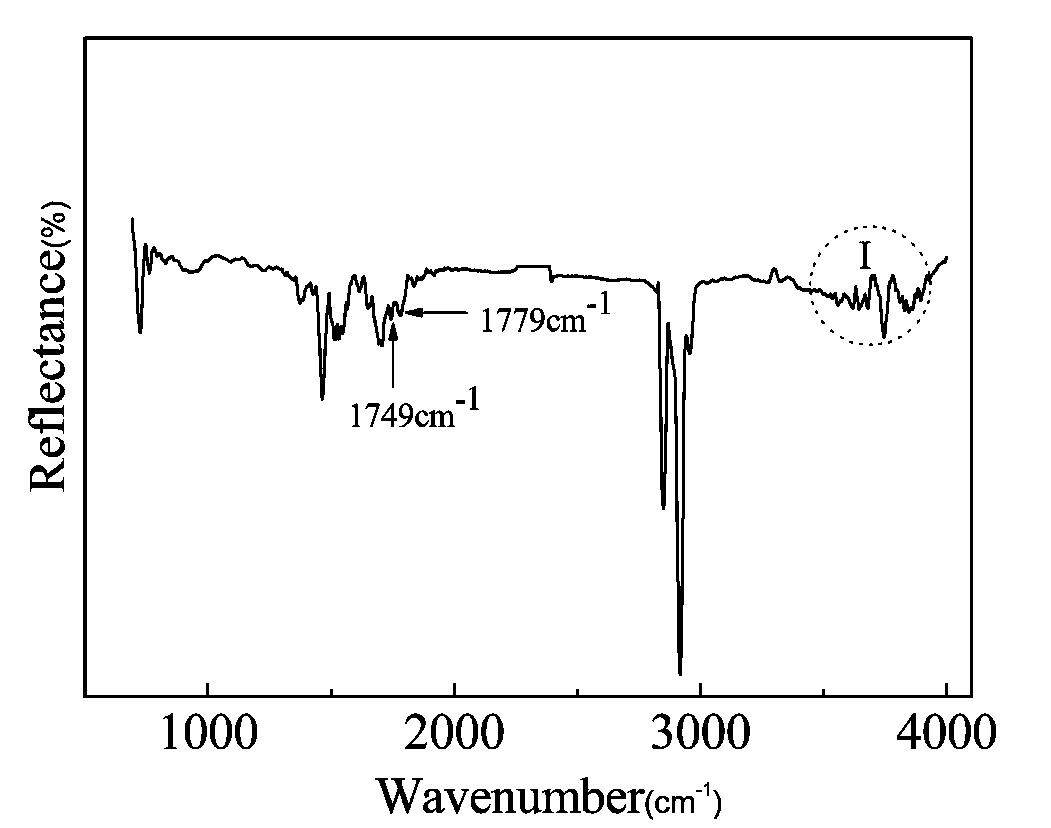

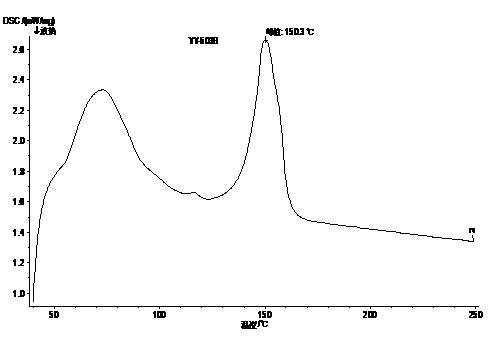

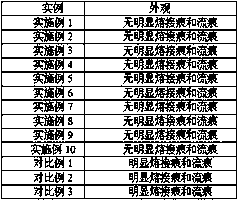

Metal-imitating ABS modified material and preparation method thereof

The invention relates to a metal-imitating ABS modified material. The metal-imitating ABS modified material consists of the following components: 70-95 parts of ABS, 0.5-10 parts of pigments, 1-5 parts of a coupling-lubricating composite modifier, 5-10 parts of a tackifier, 0-10 parts of filler and 0.1-1 part of an antioxidant, wherein the trademark of the coupling-lubricating composite modifier is YY-503, and the number-average molecular weight of the coupling-lubricating composite modifier is 3000-5000; a low melting point of the coupling-lubricating composite modifier is 75 + / - 5 DEG C, and a high melting point of the coupling-lubricating composite modifier is 150 + / - 10 DEG C; the tackifier is C5 petroleum resin with average molecular weight of 1000-2500. The metal-imitating ABS modified material can be used for overcoming the problems that weld marks are severe, the metal effects are not good and the impact strength is declined in the prior art, and has a wide application prospect in the industry of plastic products.

Owner:广东波斯科技股份有限公司

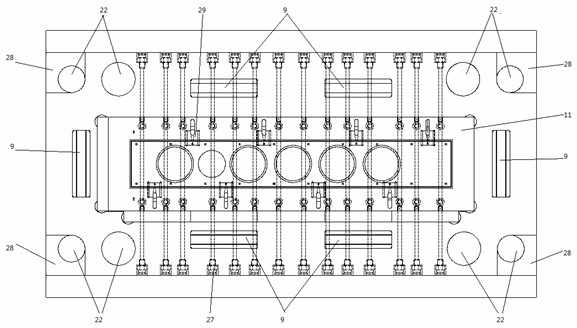

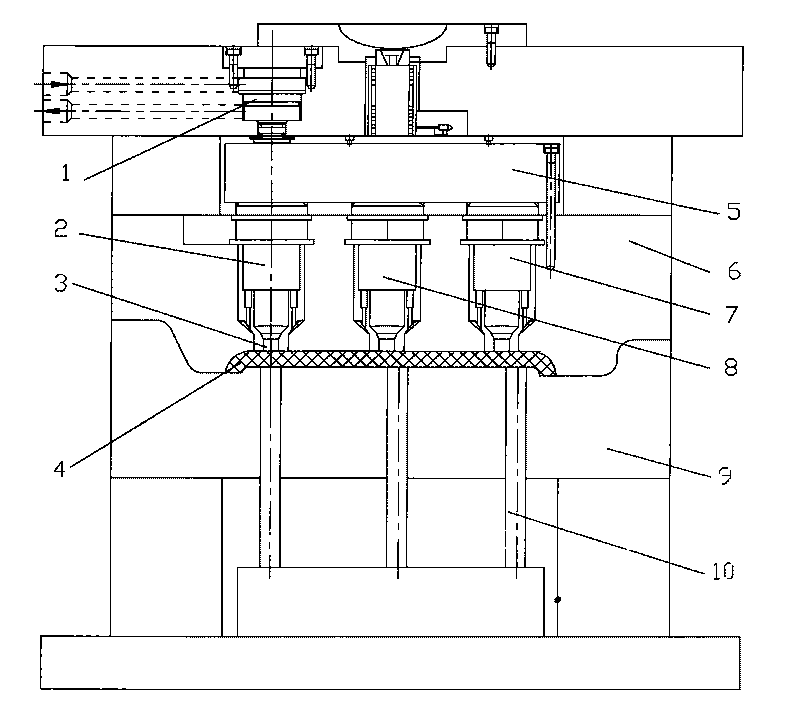

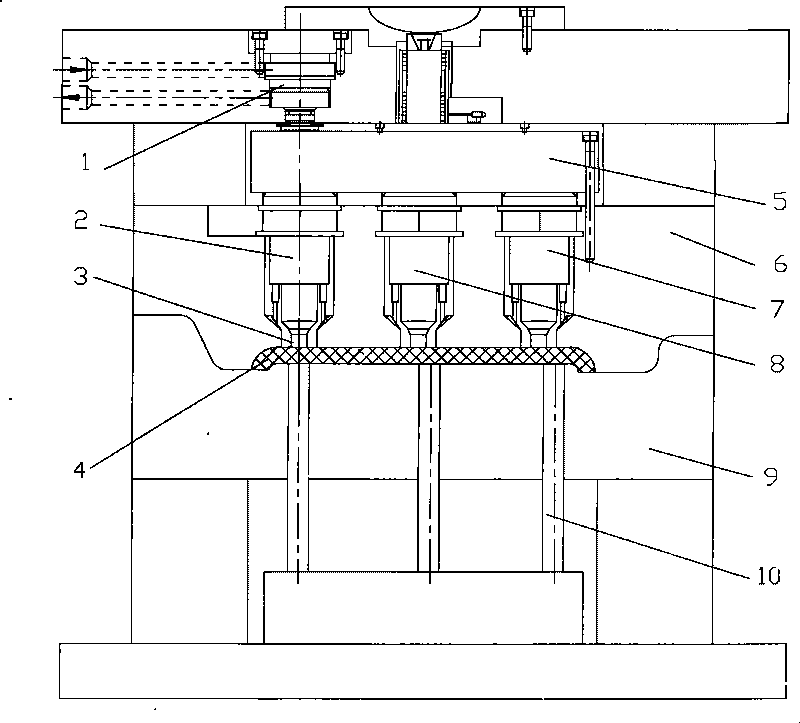

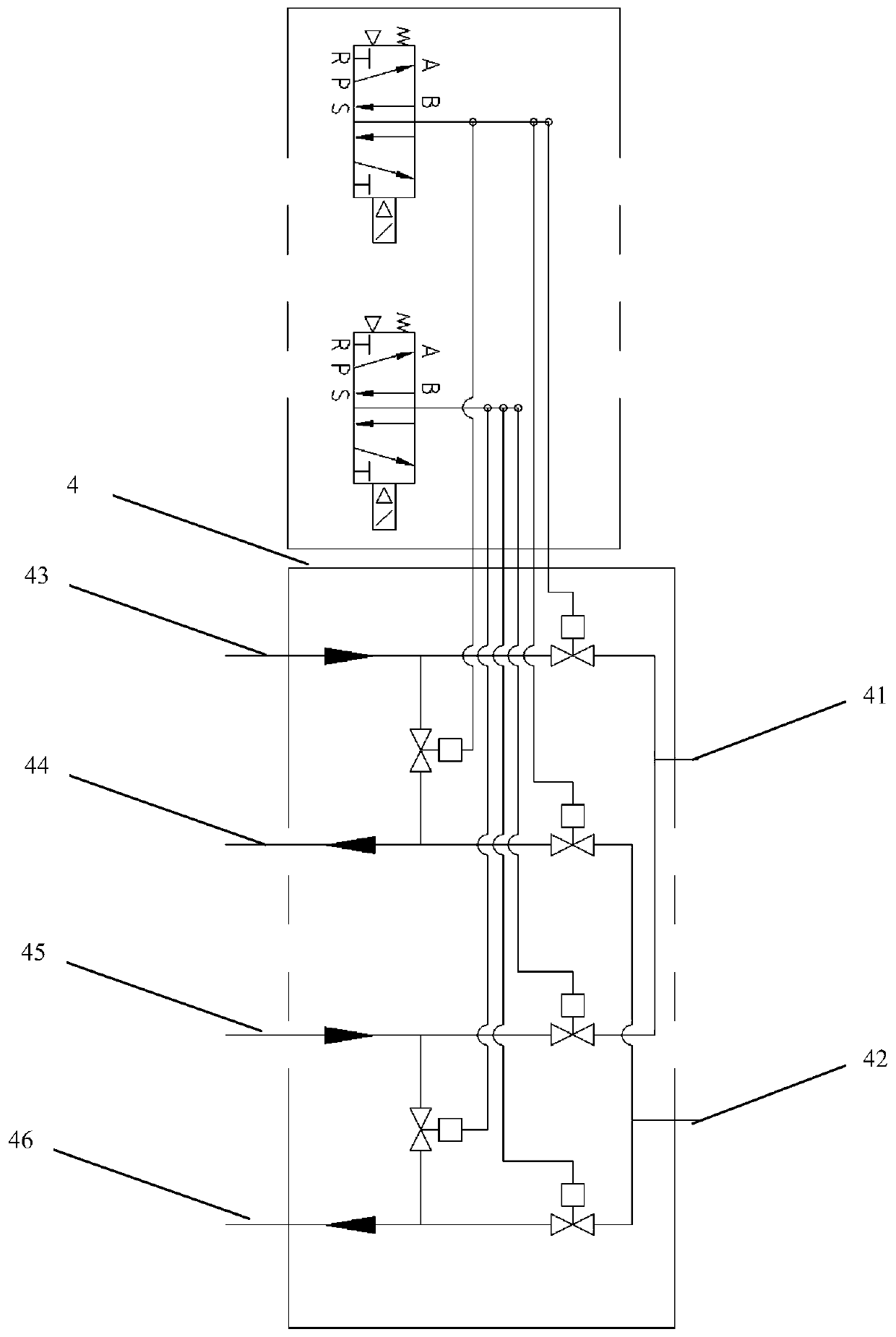

Ultrasonic vibration micro-foaming injection moulding device and ultrasonic vibration micro-foaming injection moulding method for plastic inspection well

The invention relates to an ultrasonic vibration micro-foaming injection moulding device and an ultrasonic vibration micro-foaming injection moulding method for a plastic inspection well, and relates to the field of injection moulding machining for plastic inspection wells. The ultrasonic vibration micro-foaming injection moulding device comprises a fixed die plate, a movable die plate, a die core and hot runner system, an ultrasonic vibration device and a control system, wherein die cores comprise a main die core and a side pulling core, and a die cavity is arranged among the die cores, the fixed die plate and the movable die plate. According to the invention, a cavitation foaming effect of ultrasonic vibration on plastic is utilized, the die cavity is filled with a plastic melt through injection moulding to reach 85-90% of the volume of the die cavity at first, and then the plastic melt in the die cavity is subjected to overall ultrasonic vibration and cavitation micro-foaming through the main die core provided with an ultrasonic vibration mechanism, thus micro-foaming injection moulding machining for the plastic inspection well is realized. The ultrasonic vibration micro-foaming injection moulding device disclosed by the invention is simple to operate, high in moulding accuracy, and capable of saving plastic raw materials by 10-15%, reducing an injection moulding pressure by 60-80%, saving energy, avoiding or reducing generation of weld marks, enhancing the product strength and prolonging the service life.

Owner:江苏正林环保科技有限公司

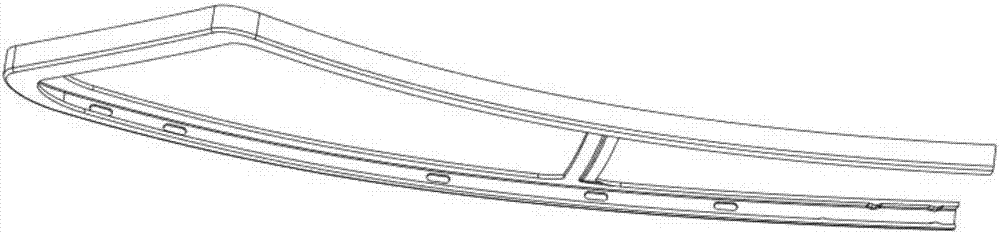

Molding method for thin-wall plastic product

InactiveCN104029330AEasy to glue and fillEliminate weld linesCoatingsManufacturing engineeringMachine tool

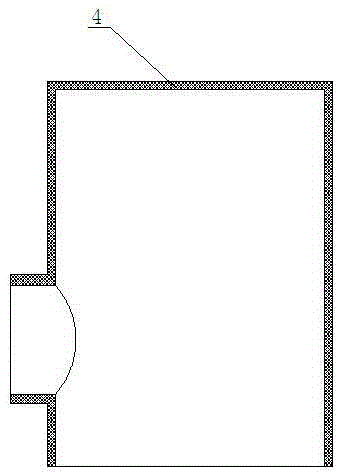

The invention provides a molding method for a thin-wall plastic product. The molding method comprises the following steps: injection molding of the thin-wall product, wherein a side gate type glue feeding point is used for feeding glue, the glue feeding point is a single glue feeding point, the glue feeding point is arranged inside a functional hole of the product, and a melt inside the functional hole of the thin-wall product forms a glue feeding position integrally with the thin-wall product after melt injection; and cutting of the glue feeding point, wherein the molded thin-wall product is fixedly arranged on a positioning jig; the glue feeding position inside the functional hole is removed by using a numerically-controlled machine tool. The molding method provided by the invention is convenient in sufficient glue-flowing and filling of the melt; weld marks generated on the surface of the product due to arrangement of the plurality of glue feeding points can be removed; the pressure of the injection molding can be prevented from being too large; meanwhile, the waste of materials and the design difficulty of the die can be reduced; the cost is reduced. Furthermore, a cutter controlled by the numerically-controlled machine tool can be used for cutting the glue feeding position positioned on the positioning jig from the functional hole rapidly and accurately, so that a qualified product can be obtained.

Owner:DONGGUAN GOOD MARK NEW PRECISION TECH CO LTD

Needle-valve order hot runner injection molding device

The invention relates to a needle-valve order hot runner injection molding device, which is composed of a conventional injection molding die part and a needle-valve order hot runner pouring system part, wherein the conventional injection molding die part consists of a die carrier, a die plate, a cavity, an ejection mechanism, and the like; and the needle-valve order hot runner pouring system part consists of control cylinder, a hot runner plate, a needle valve, gates, a sensor, and the like. The needle-valve order hot runner injection molding device can effectively improve and eliminate welding marks and sink marks of injection molding products, effectively improve the internal stress of the injection molding products, and increase the performance quality of the injection molding products. The needle-valve order hot runner injection molding device is especially suitable for producing large injection molding products.

Owner:CHONGQING TECH & BUSINESS UNIV

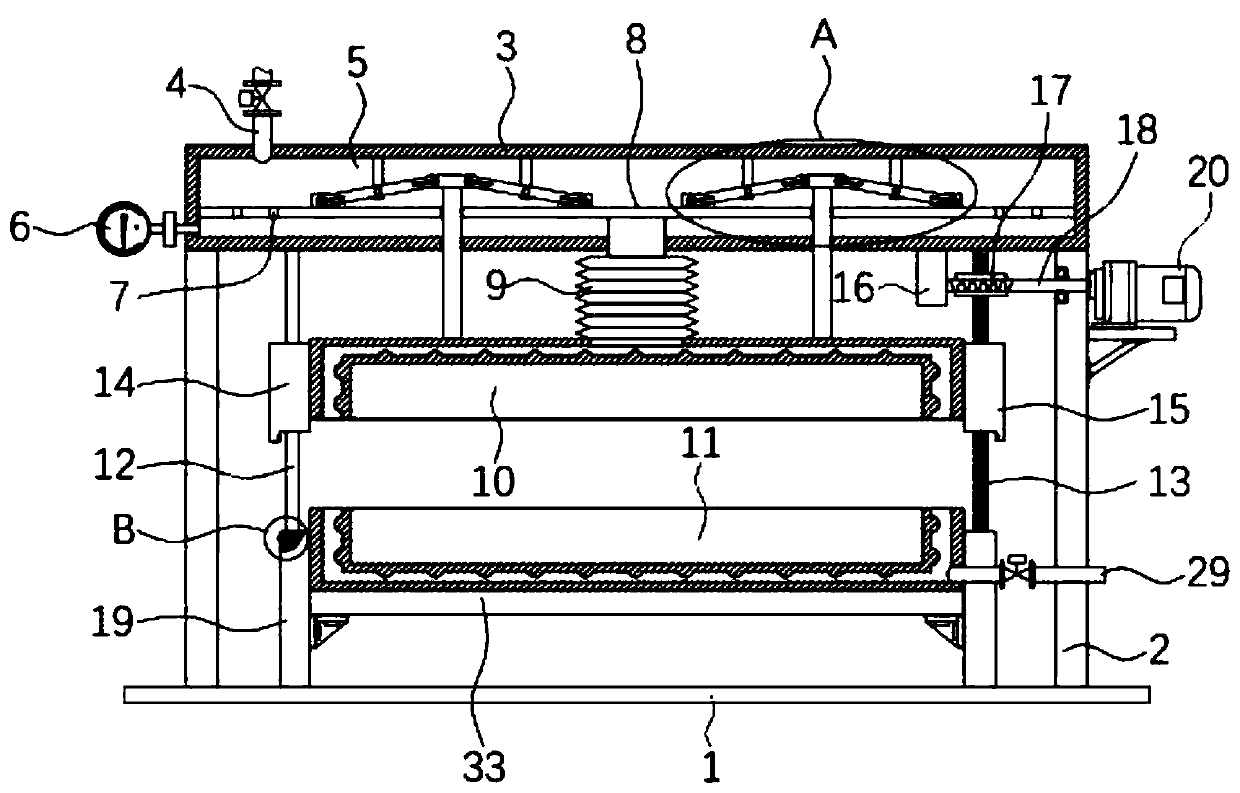

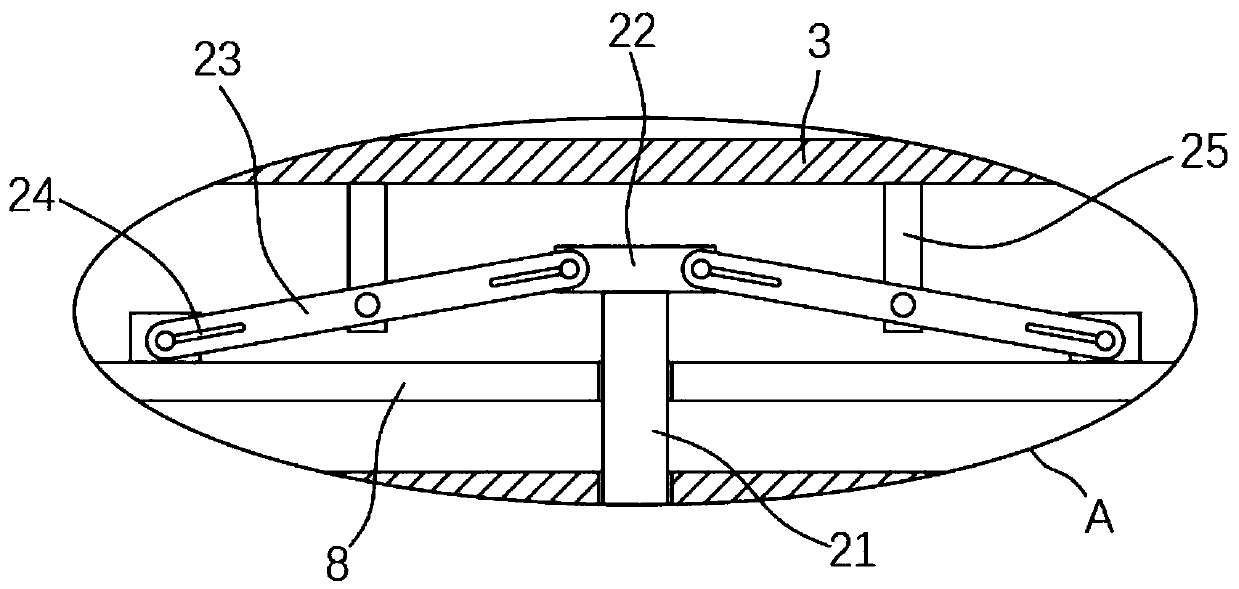

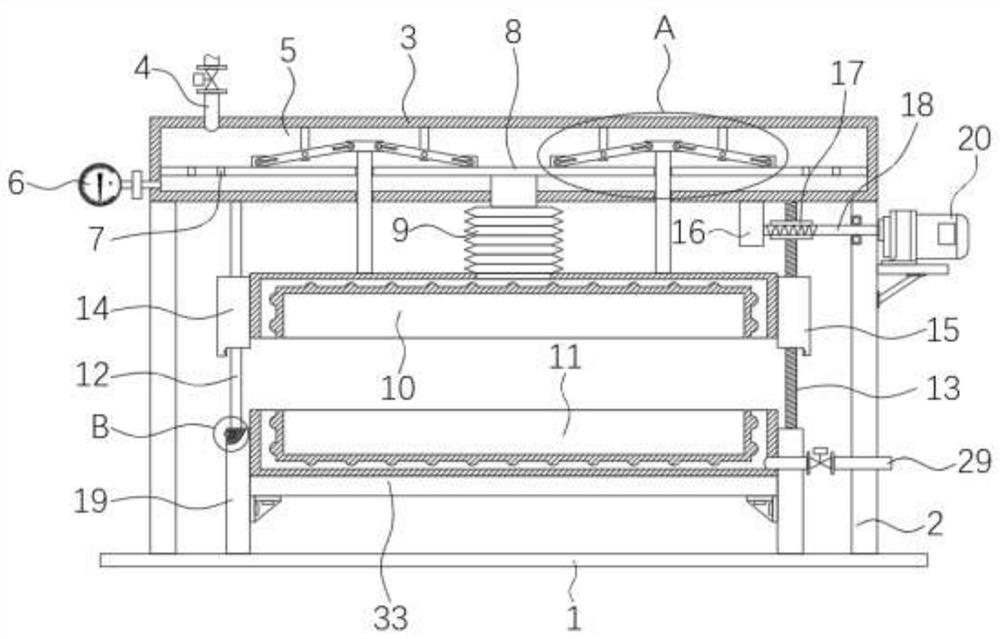

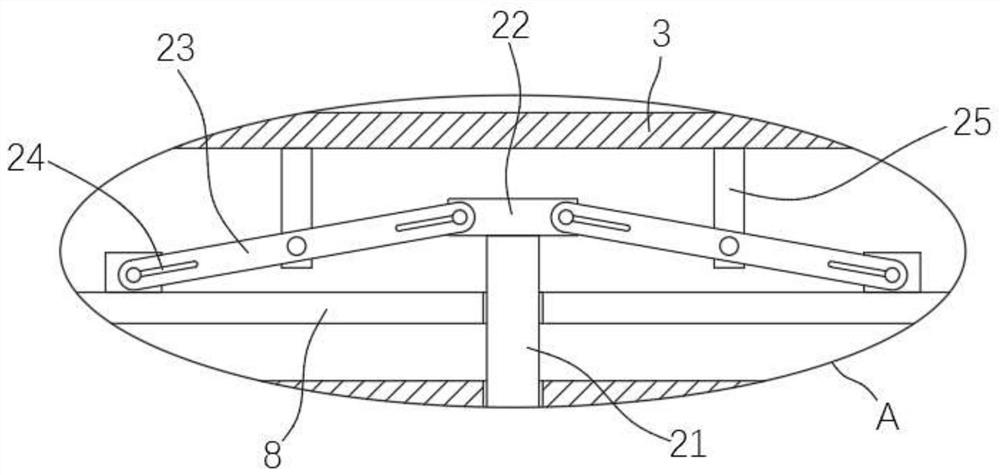

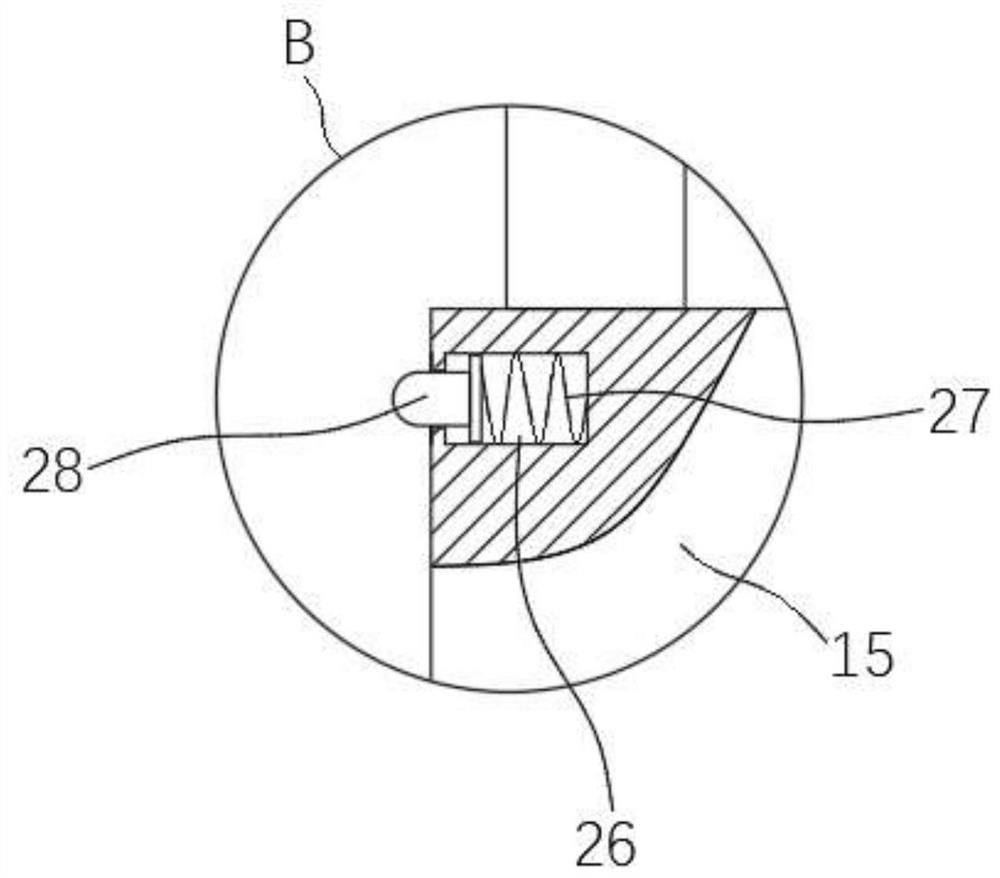

Injection mold structure of highlight traceless automobile plastic product

ActiveCN110406056AEliminate weld linesPlay the role of high gloss without traceDomestic articlesEngineeringExhaust pipe

The invention discloses an injection mold structure of a highlight traceless automobile plastic product. The injection mold structure of the highlight traceless automobile plastic product comprises abottom plate, wherein two vertically arranged supports are symmetrically fixedly connected to the upper end of the bottom plate; a tank is fixedly connected to the top ends of the two supports; and acavity is arranged in the tank. According to the injection mold structure of the highlight traceless automobile plastic product provided by the invention, an open-close linkage design of an upper moldand the tank is adopted, when the upper mold moves downwards, an ejector rod drives a support block fixedly connected with the ejector rod to move, the support block moves to further drive a connecting rod to move according to a lever, the connecting rod moves according to the lever so as to drive a baffle plate rotatably connected with the connecting rod to move upwards, a corrugated pipe and abaffle plate are separated at the moment, an air inlet pipe is connected with the steam output end of an external boiler, steam enters the cavity, the corrugated pipe, the upper mold and a lower moldat the moment to accomplish one cycle so as to be discharged from an exhaust pipe, and due to cooling and heating functions of high-temperature stem, welding marks on an injection mold can be eliminated, so that an injection mold product achieves a highlight traceless effect.

Owner:乐星汽车电子(青岛)有限公司

Gas auxiliary injection molding method of car roof handle

ActiveCN109624202APrevent warpageImprove injection molding efficiencyVehicle arrangementsInjection molding machineInjection moulding

The invention belongs to the technical field of car parts and particularly relates to a gas auxiliary injection molding method of a car roof handle. The method comprises the following steps that 1, molten plastic is injected into a die cavity through two or more pouring gates, and after injection of a die is full, pressure is maintained; 2, inert gas is injected into the molten plastic in the diecavity through two or more gas inlets, pressure of the injected inert gas is larger than storing pressure of injection molding, a part of the molten plastic in the die cavity returns to the pouring gates, and the hollow state is formed; and 3, the pressure is maintained, cooling is carried out, the die is opened, and a product is taken out.

Owner:NINGBO SHUAITELONG GRP CO LTD

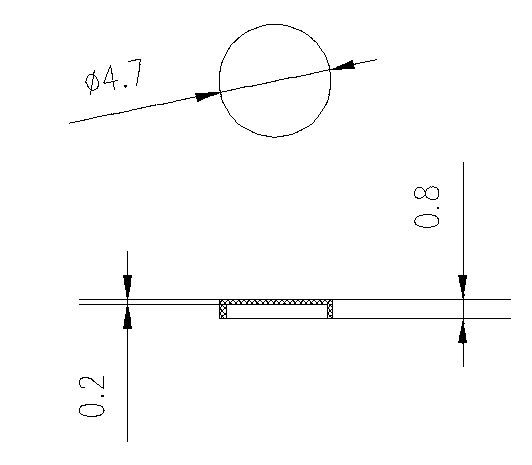

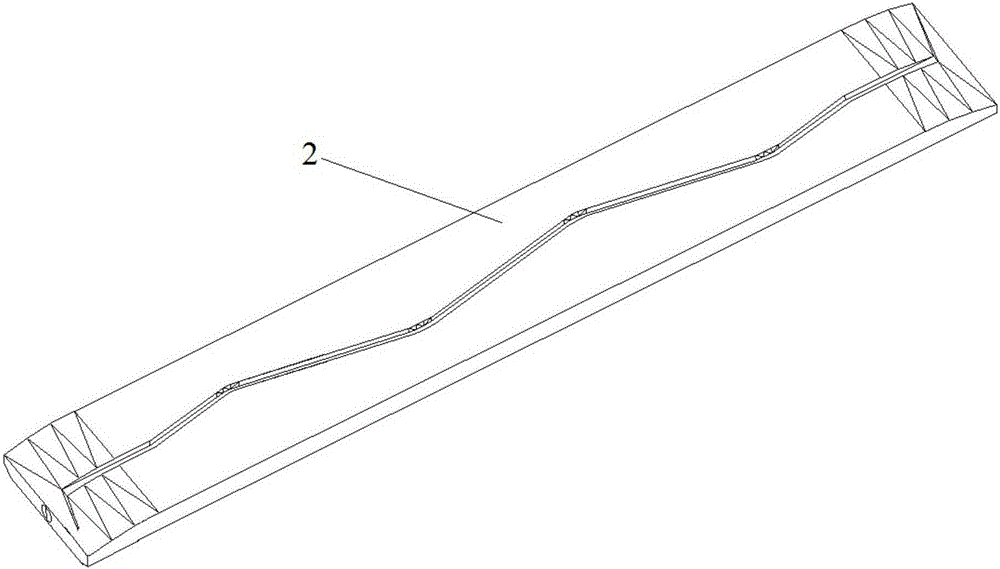

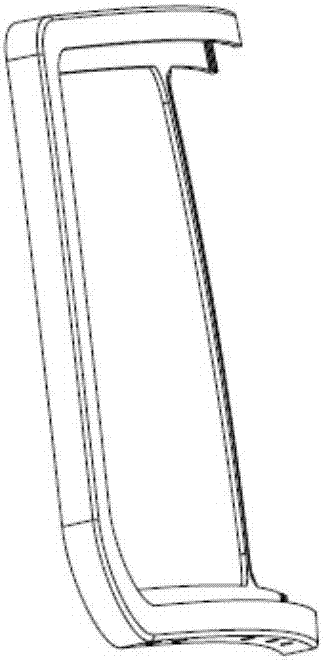

Elevator sliding guide shoe liner made of ultra-high molecular weight polyethylene and preparation method for elevator sliding guide shoe liner

The invention relates to an elevator sliding guide shoe liner made of ultra-high molecular weight polyethylene and a preparation method for the elevator sliding guide shoe liner. The shoe liner comprises a product B and two products A oppositely arranged on the product B in the length direction of the product B, and the product B and the two products A are combined to form a structure adaptive to an elevator sliding guide shoe in shape. The products A and the product B are prepared from ultra-high molecular weight polyethylene resin or composite materials with ultra-high molecular weight polyethylene resin as the base body through the injection molding process, the mass fraction of the ultra-high molecular weight polyethylene resin in the composite materials is 45%-75%, and the rest is low molecular weight polyolefine resin. Compared with the prior art, the elevator sliding guide shoe liner is made of the ultra-high molecular weight polyethylene composite materials for the first time, and the application of the ultra-high molecular weight polyethylene composite materials to special-shaped products is achieved through the characteristics of superior mechanical properties of high strength and wear resistance, superior chemical corrosion resistance and superior ageing resistance of the ultra-high molecular weight polyethylene.

Owner:SHANGHAI RES INST OF CHEM IND +1

Mold sudden cooling and sudden heating device adopting semiconductor refrigerator and phase change material

The invention provides a mold sudden cooling and sudden heating device adopting a semiconductor refrigerator and a phase change material. The device comprises a control module, a mold heater, a cooling liquid mold channel, a phase change cold storer, a cooling liquid cooling pipe and the semiconductor refrigerator; a phase change part is stored in the phase change cold storer; the cooling liquid mold channel is formed in a mold; the cooling liquid cooling pipe is arranged on the phase change cold storer, and communicates with the cooling liquid mold channel by a controllable valve; a heat endof the semiconductor refrigerator is connected with the mold, and a cold end is connected with the phase change cold storer; when the sudden heating operation is performed on the mold, the heat end ofthe semiconductor refrigerator heats the mold, and the cold end cools the phase change cold storer; and when the sudden cooling operation is performed on the mold, cooling liquid flows in the coolingliquid cooling pipe and the cooling liquid mold channel to quickly cool the mold. Through combination with the advantages of the semiconductor refrigerator and the phase change material, and introduction of a closed-loop feedback control circuit, the device can realize efficient energy-saved sudden cooling and sudden heating adjustment of the mold.

Owner:FUZHOU UNIV

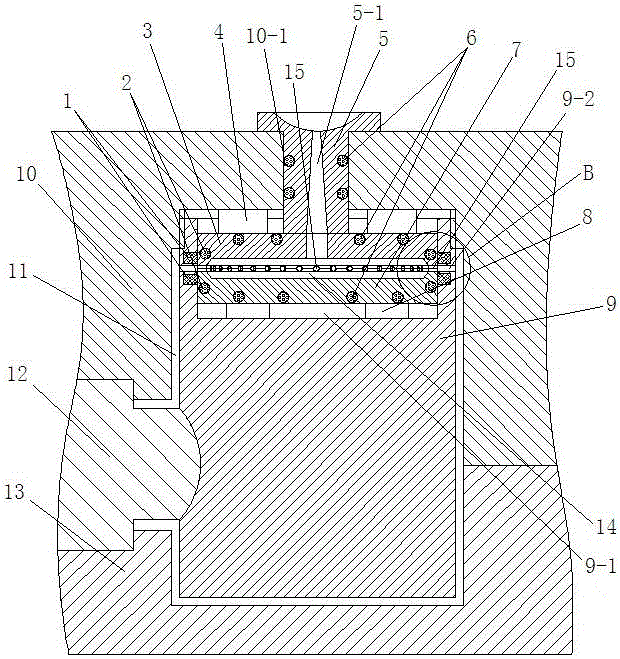

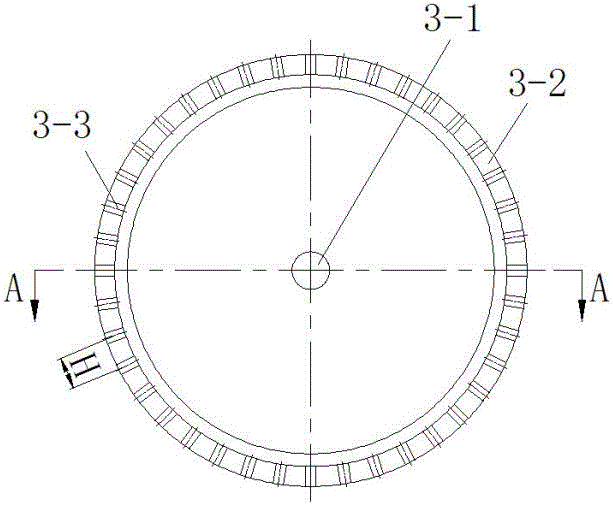

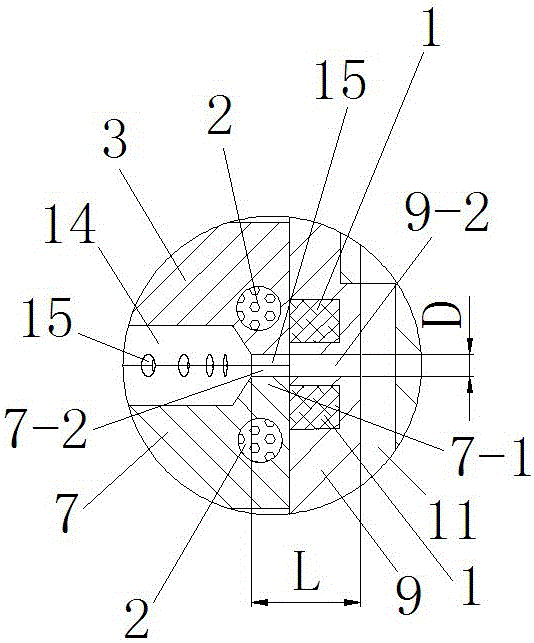

Injection mould and machining method for high-glossiness plastic part

InactiveCN106313436AImprove exhaust efficiencyAvoid rippleDomestic articlesMachiningMaterials science

The invention discloses an injection mould and a machining method for a high-glossiness plastic part. The injection mould comprises a cavity and a core, wherein a cavity insert is arranged in the cavity, a core insert is arranged in the core, and a mould cavity is formed between the cavity insert and the core insert. The injection mould is characterized in that a water path hole and a steam path hole are formed in the cavity and the cavity insert; the distance H between the steam path hole and the surface of the mould cavity is 10-12mm; an empty wall groove is formed in and a heat-isolation convex plate is arranged on the inner wall of the cavity; the heat-isolation convex plate contacts with the bottom surface of the cavity insert; exhaust grooves are uniformly distributed in the upper end surface of the cavity insert and located at the outer side and the inner side of the mould cavity; and the distance of each exhaust groove is 20-25mm.

Owner:TAIZHOU HUANGYAN KUNTAI MOLD CO LTD

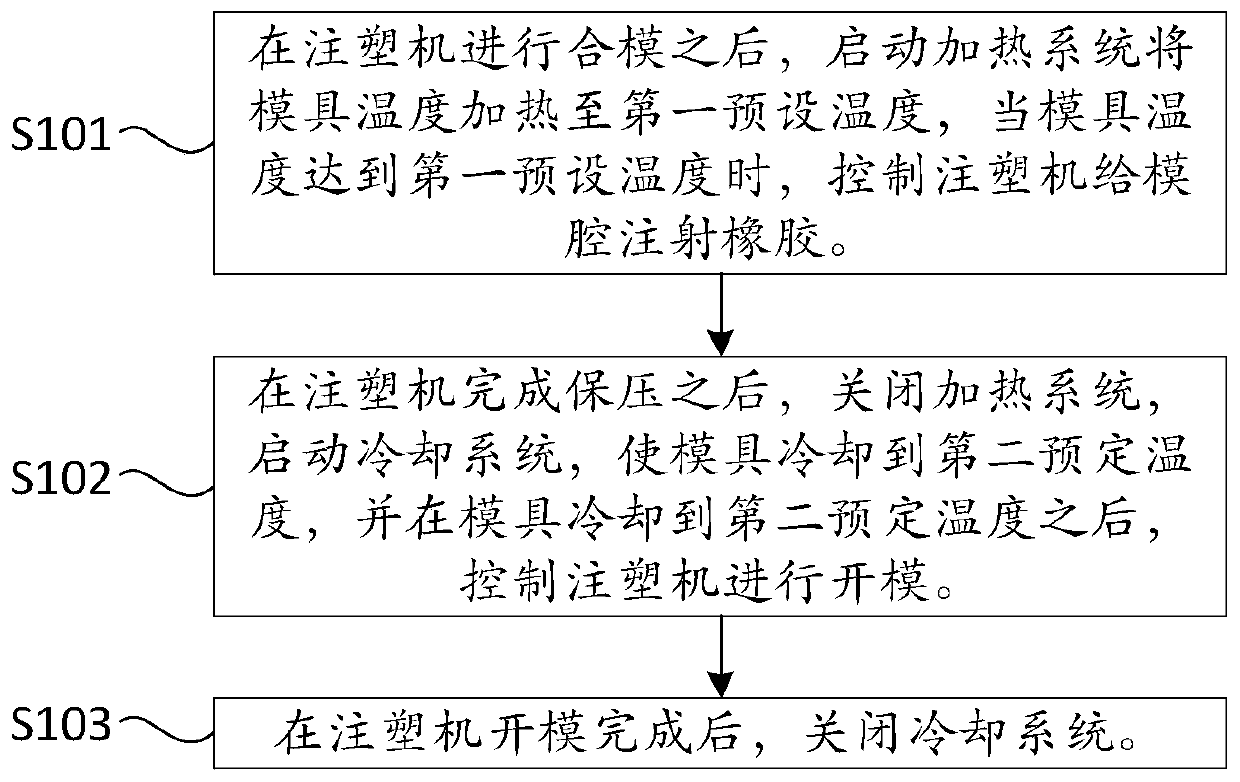

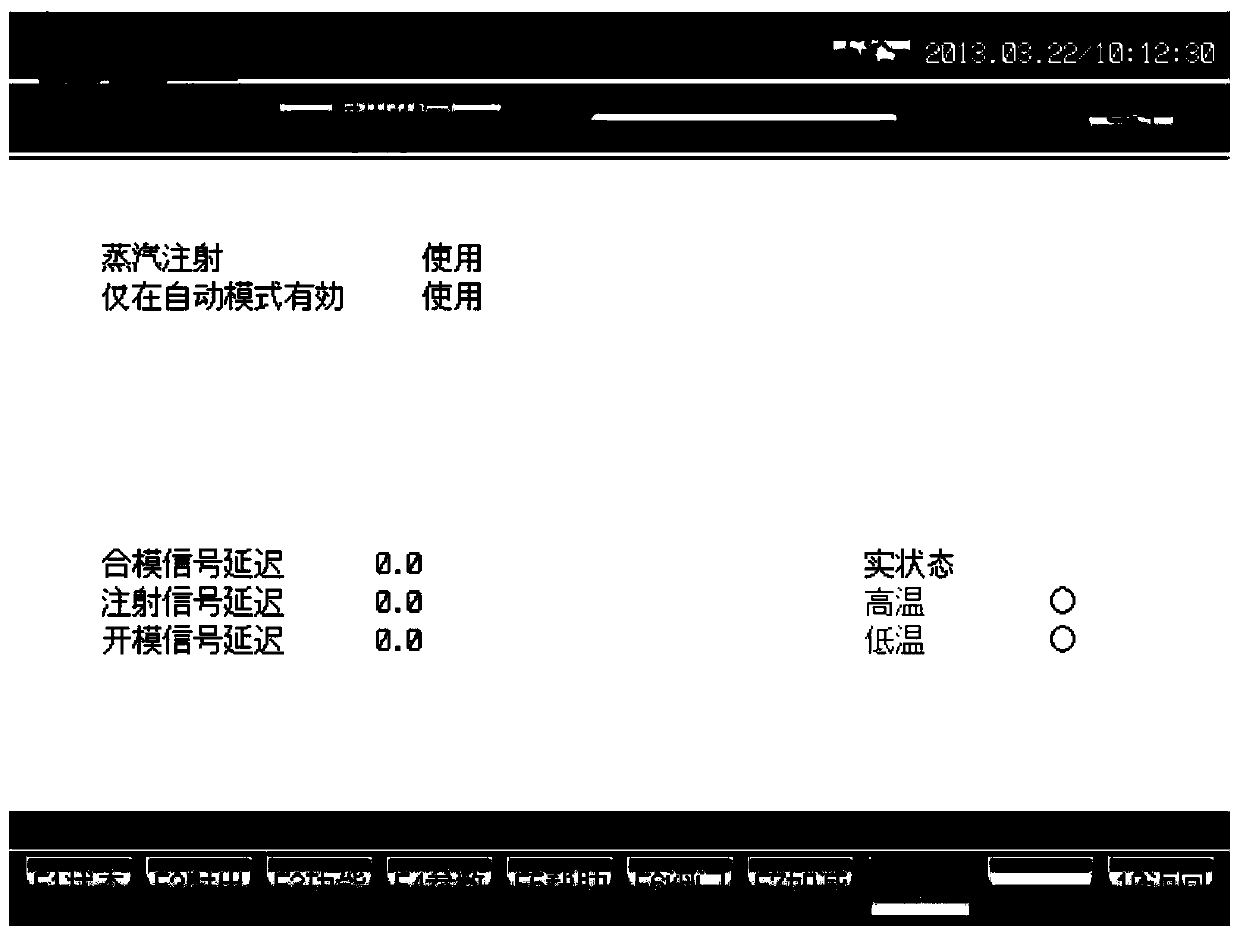

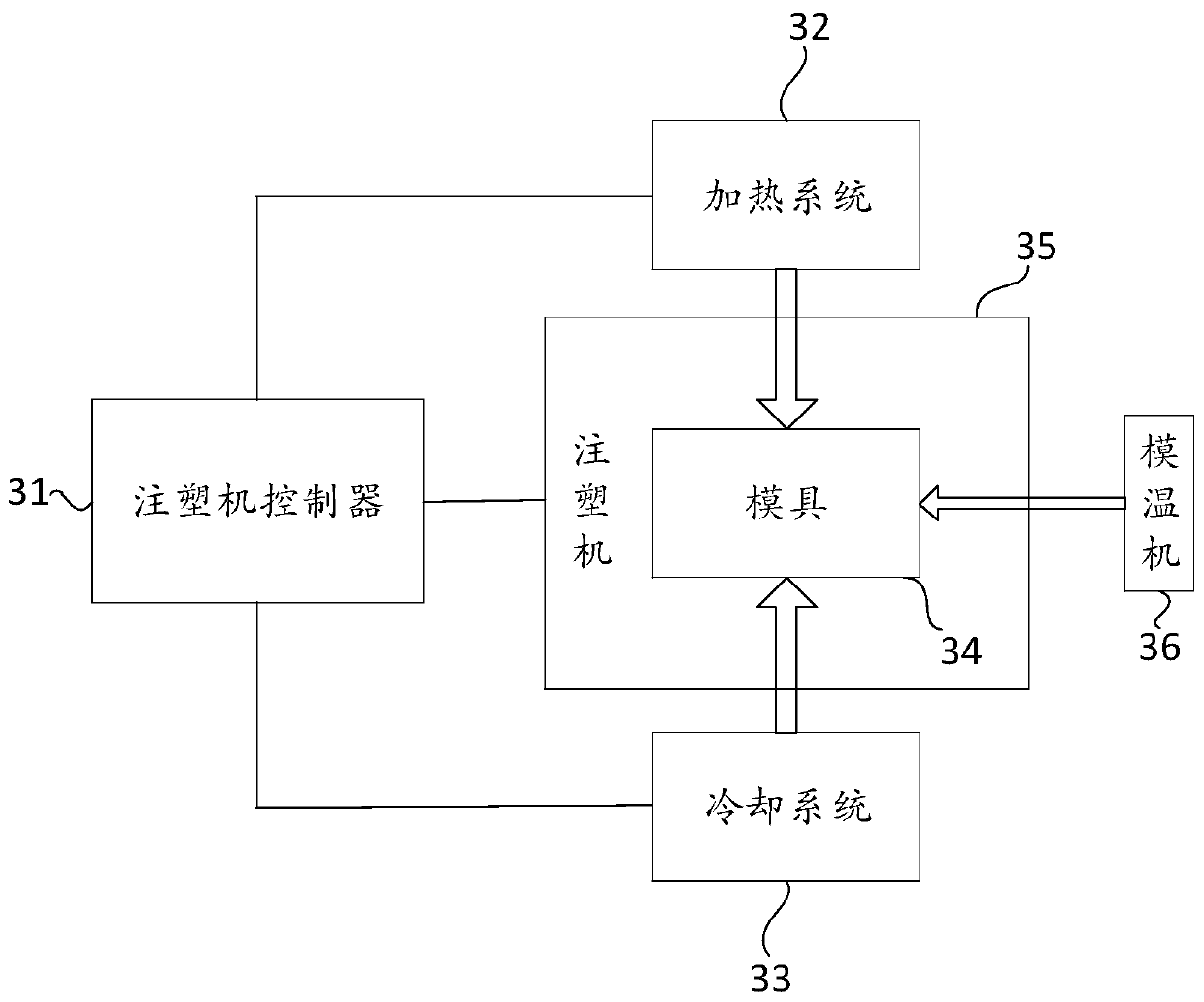

Mold temperature control method and system of injection molding machine

The application provides a mold temperature control method and system of an injection molding machine. The mold temperature control method of the injection molding machine comprises the following steps that after the injection molding machine is closed, a heating system is started to heat a mold temperature to a first preset temperature, and the injection molding machine is controlled to inject rubber into a mold cavity when the mold temperature reaches the first preset temperature; after the pressure maintaining of the injection molding machine is completed, the heating system is closed, a cooling system is started, a mold is cooled to a second predetermined temperature, and after the mold is cooled to the second predetermined temperature, the injection molding machine is controlled to open the mold; and after the injection molding machine opens the mold, the cooling system is turned off. The mold temperature control method can be applied to forming optical products with high transparency, plastic parts with microstructures on the surface, high-strength composite parts, long thin-wall parts and the like. By heating the mold to a higher set temperature, premature cooling of a polymer solution is prevented, and formed injection plastic parts have good surface quality.

Owner:HAITIAN PLASTICS MACHINERY GRP

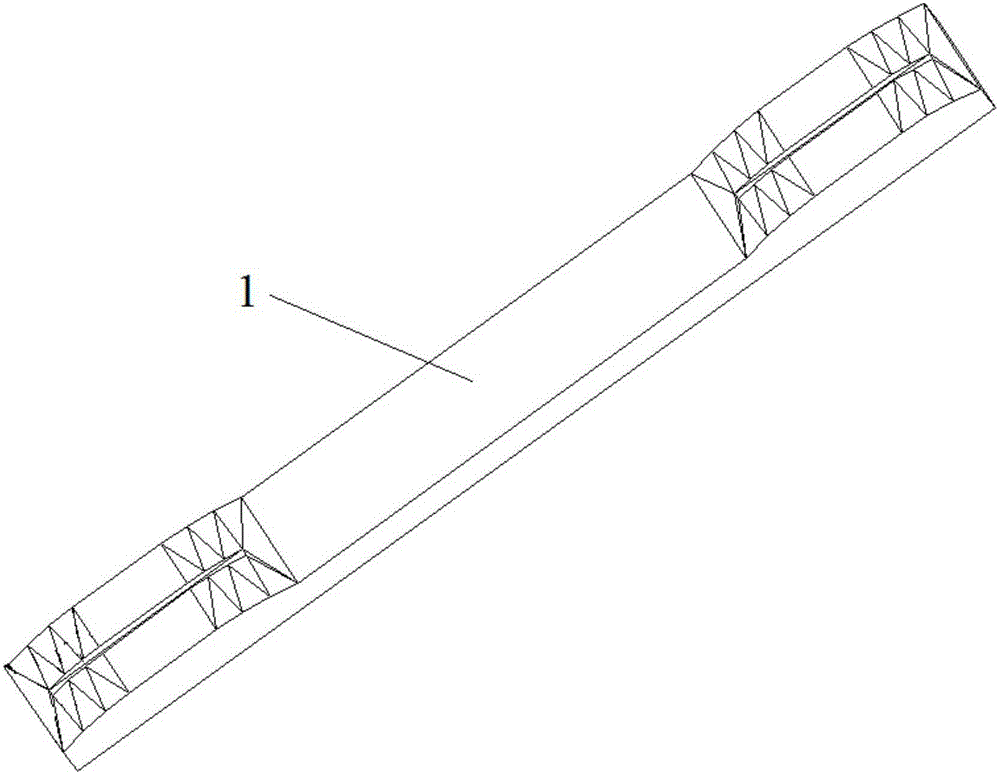

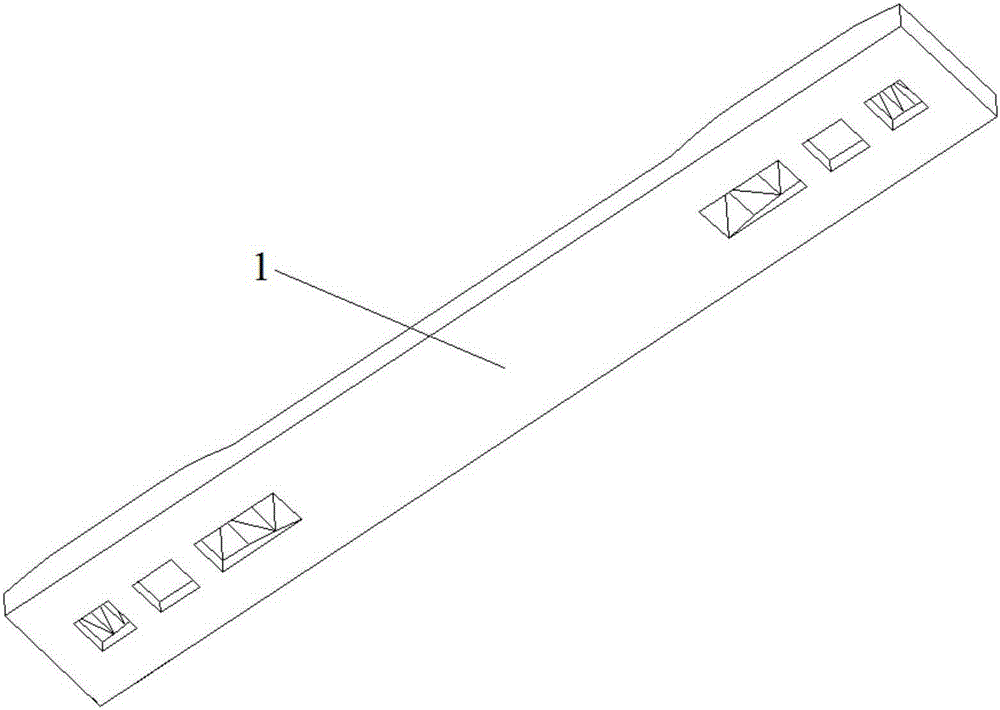

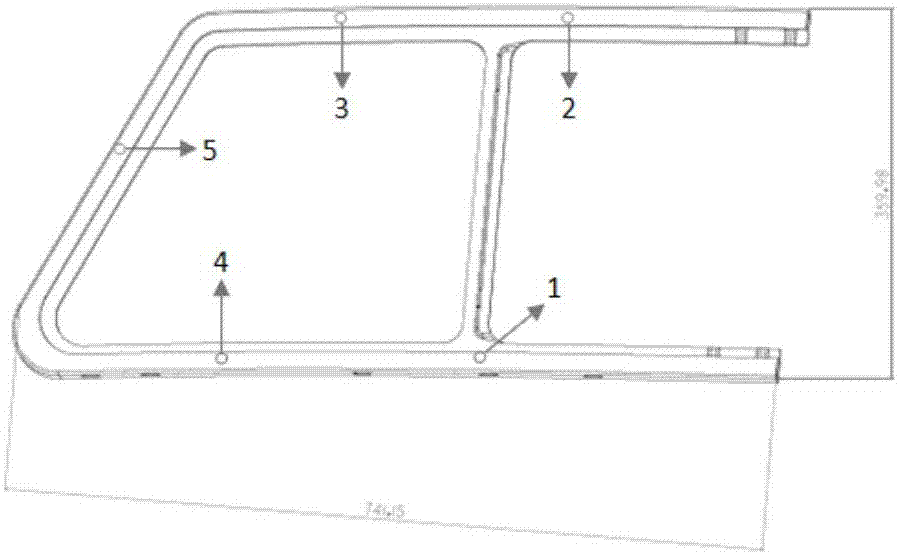

Molding method for helicopter cockpit door sliding window U-shaped guide rail

InactiveCN107351341AEliminate Weld LinesInvolves less processing stepsDomestic articlesSlide windowPass rate

The invention belongs to the technical field of injection molding and relates to a molding method for a helicopter cockpit door sliding window U-shaped guide rail. Moldflow is utilized for mold flow analysis to optimize the number and distribution of glue feeding points, a multi-point sequential glue feeding manner is adopted, a guide rail weld line is eliminated, the method that a temperature difference exists between the die temperature on the moving die side and the die temperature on the fixed die side is utilized, and buckling deformation of the guide rail is controlled. The molding method relates to less machining processes, production efficiency is greatly improved, time is saved, the cost is saved, product quality is greatly improved, and the appearance size and precision of a product are guaranteed. The appearance deviation of the product is less than or equal to + / -0.1 mm, the film pasting degree is less than or equal to 0.1 mm, and the opening deviation is less than or equal to 0.4 mm. The injection molding one-time integral forming technology for a complex structural component is utilized, the U-shaped guide rail high-precision molding method is high in efficiency, low in cost and high in qualified rate, the product molded by the method has the characteristics of being high in appearance quality and high in size precision and can meet the use requirements of a whole helicopter.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

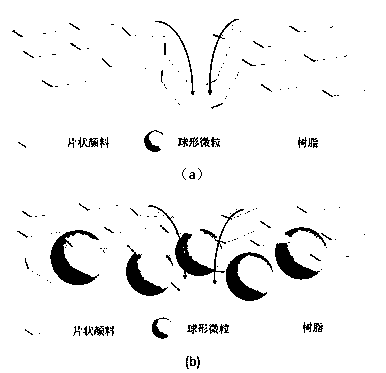

Polyolefin material with spray-free metal effect and preparation method and application thereof

The invention relates to a polyolefin material with a spray-free metal effect and a preparation method and an application thereof. The polyolefin material with the spray-free metal effect comprises the following components in part by weight: 5-30 parts of modified spherical micro-particles, 50-80 parts of polyolefin polymer, 0.5-10 parts of sheet metal-effect pigment and 0.1-10 parts of auxiliaryagent; the modified spherical micro-particles are spherical micro-particles modified with a surfactant. According to the polyolefin material with the spray-free metal effect and the preparation methodand the application thereof, the spherical micro-particles are modified by using the surfactant to greatly improve the dispersibility of the spherical micro-particles; the modified spherical micro-particles are good in dispersibility; the sheet metal-effect pigment at the melt junction can be inhibited to deflect with the melt flow direction through the steric hindrance effect to achieve the purpose of eliminating the welding mark of the polyolefin material with the spray-free metal effect; the existing process and equipment do not need to be improved, thus the cost is low.

Owner:广东波斯科技股份有限公司

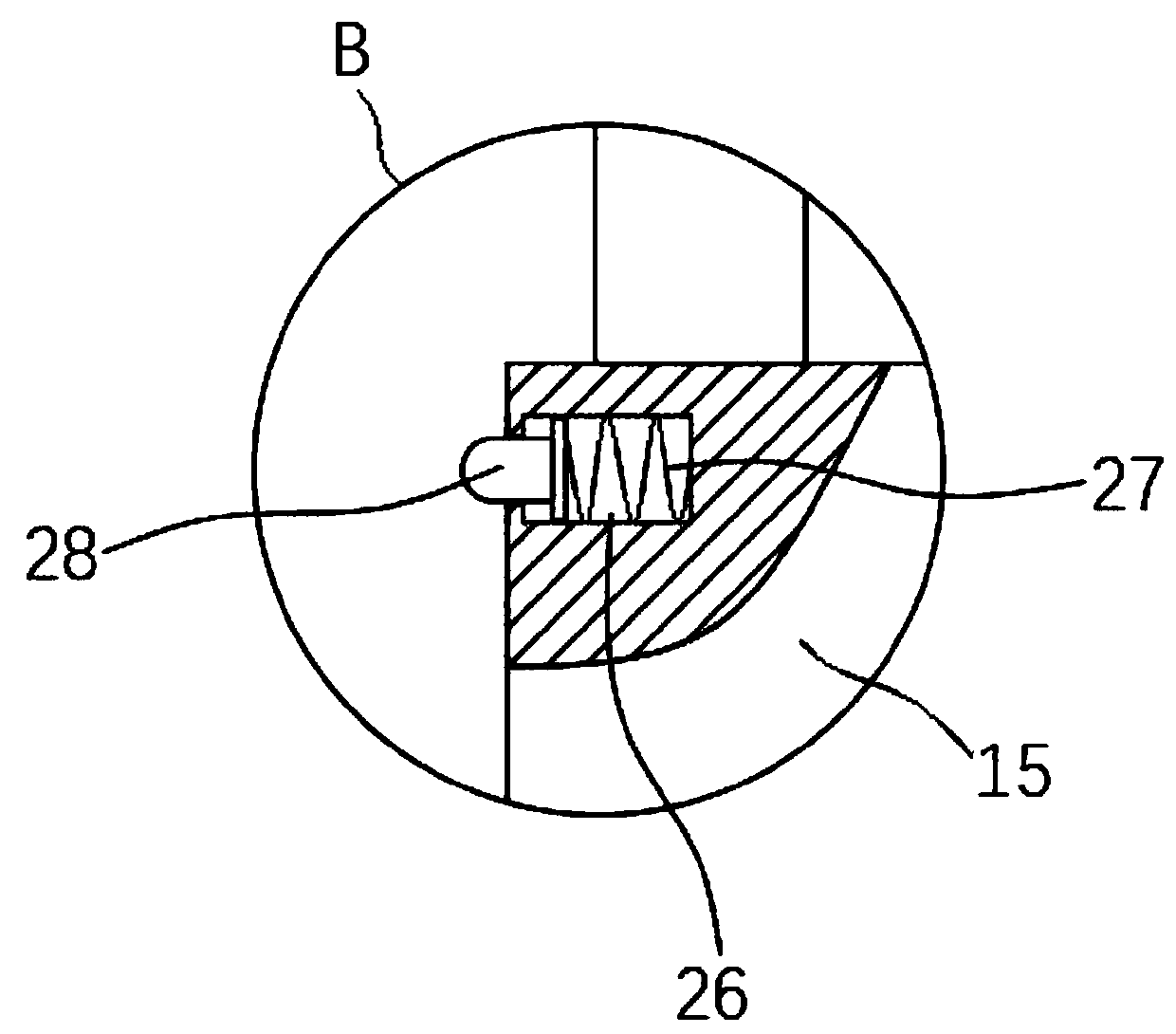

Pitched roof shunt mechanism

The invention discloses a pitched roof shunt mechanism. The pitched roof shunt mechanism mainly comprises a hot runner nozzle, a main sprue, a shunt channel, glue inlets, a pitched roof block, a pitched roof copper sleeve, a pitched roof rod, a pressing block and a pitched roof base, wherein the top of the main sprue is connected with the hot runner nozzle, and the root of the main sprue is connected with the shunt channel; the tops of the glue inlets are connected with a product; the main sprue, the shunt channel and the glue inlets are all arranged inside the pitched roof block; the top of the pitched roof rod is connected with the pitched roof block, the bottom of the pitched roof rod is connected with the pitched roof base, and the ejection track of the pitched roof rod is controlled by the pitched roof copper sleeve and the pitched roof base; and the pitched roof copper sleeve is fixed with the pressing block.

Owner:宁波米勒模具制造有限公司

Injection molding process for multi-air-channel auxiliary plastic mold

The invention discloses a multi-air channel auxiliary plastic mold injection molding process, comprising the following steps: step (1) plastic mold design; step (2) mold precooling stage; step (3) melt injection stage; step (4) multiple Airway gas injection control stage; step (5) partial nitrogen filling stage; step (6) gas injection end stage; step (7) gas withdrawal stage. The invention eliminates the internal stress existing in the injection molded parts, so that the quality of the injection molded parts is high, and the production efficiency and yield of the mold are greatly improved.

Owner:滁州市博康模具塑料有限公司

A large pvc plastic pipe fitting injection mold hot runner disc pouring device

Owner:JIANGSU HIPPO PLASTICS

Device for regulating flow channel flow of tube blank vacuum forming mold

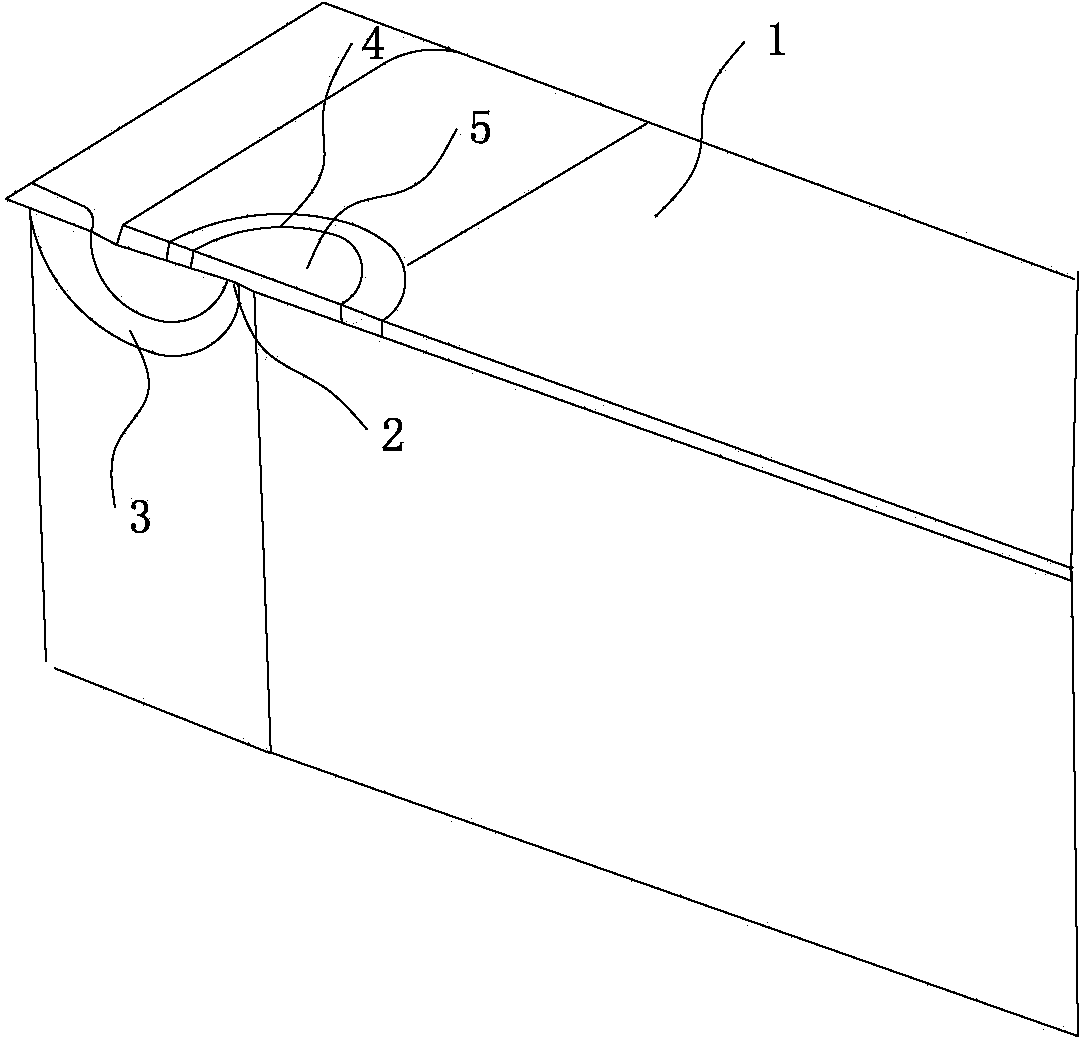

PendingCN111055478AImprove uniformityReduce vertical impactDomestic articlesHollow articlesPhysicsHollow form

The invention discloses a device for regulating flow channel flow of a tube blank vacuum forming mold. The device is characterized by comprising a tube blank vacuum forming mold body (1), wherein a hollow tubular main mandrel (2) is arranged in the tube blank vacuum forming mold body (1), a vacuum forming pipe (3) is arranged in the main mandrel (2), the vacuum forming pipe (3) is sleeved in the main mandrel (2) and are coaxially arranged with the main mandrel (2), the lower end of the main mandrel (2) protrudes out the lower surface of the tube blank vacuum forming mold body (1), the lower end of the tube blank vacuum forming mold body (1) is fixedly connected with an inner hollow forming mold (4), the lower end of the main mandrel (2) is sleeved in the forming mold (4), a lower runner arranged at intervals is formed between the outer surface of the lower section of the main mandrel (2) and the inner surface of the forming mold (4), the middle section of the main mandrel (2) is sleeved with a drainage ring (6). The device has the advantages that the defects of the prior art can be overcome, and the structural design is reasonable and novel.

Owner:青岛中兴源模具有限公司

Small plastic part laser melting extrusion molding method and apparatus thereof

The invention discloses a small plastic part laser melting extrusion molding method and an apparatus thereof, relates to the high-precision small plastic part molding processing field, and especially relates to an infrared laser melting and die extrusion molding based small plastic part molding method and an apparatus thereof. Traditional high-precision small plastic parts have the disadvantages of high injection molding processing cost, difficult control of the quality of the an injection part, and severe wastes of plastic raw materials and energy. In the invention, infrared laser rapid heating melting and molding die extrusion molding processing technologies are adopted for the high-precision thermoplastic small plastic part. The small plastic part laser melting extrusion molding method and the apparatus thereof have the advantages of high molding precision, good molding quality, high efficiency and low cost, are suitable for the batch automatic molding processing of high-precision small plastic parts, and have high application values.

Owner:盐城动益汽车配件有限公司

Molding method for panel of injection molded part and air-conditioner display apparatus

ActiveCN102729437BIncrease material thicknessReduce material thicknessLighting and heating apparatusSpace heating and ventilation detailsLED displayThermal deformation

The invention provides a molding method for the panel of an injection molded part. The method comprises the following steps: (1) allowing high-pressure water to flow into a die before injection so as to enable the temperature of the die to exceed viscous flow temperature for thermal deformation of resin; (2) injecting molten resin into the die; and (3) allowing the temperature of the die to rapidly drop to a temperature below thermal deformation temperature of the resin by using cooling water. The invention also provides an air-conditioner display apparatus which comprises a light source, a display box, an injection molded part and a pattern mask, wherein the injection molded part is molded and manufactured by using the molding method for the panel of an injection molded part, and the pattern mask is arranged at the front surface of the display box. The molding method provided in the invention overcomes the problems of warping, bogging-down and the like of an injection molded part and enables weld lines to be eliminated and glossiness of products to be improved. The air-conditioner display apparatus provided in the invention utilizes a highlighting LED display lamp to irradiate an area having a display pattern, which enables display icons to directly permeate the panel of the injection molded part and no display decorating parts to be needed.

Owner:GREE ELECTRIC APPLIANCES INC

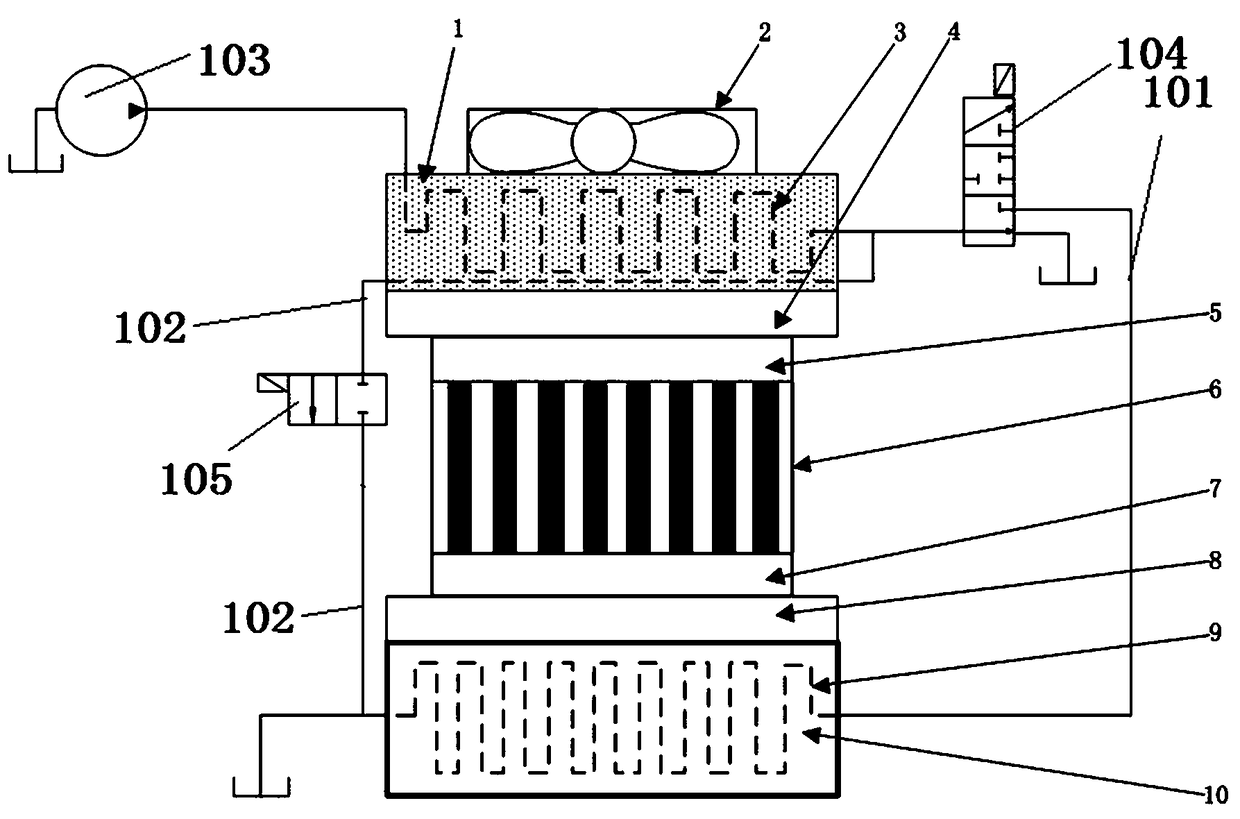

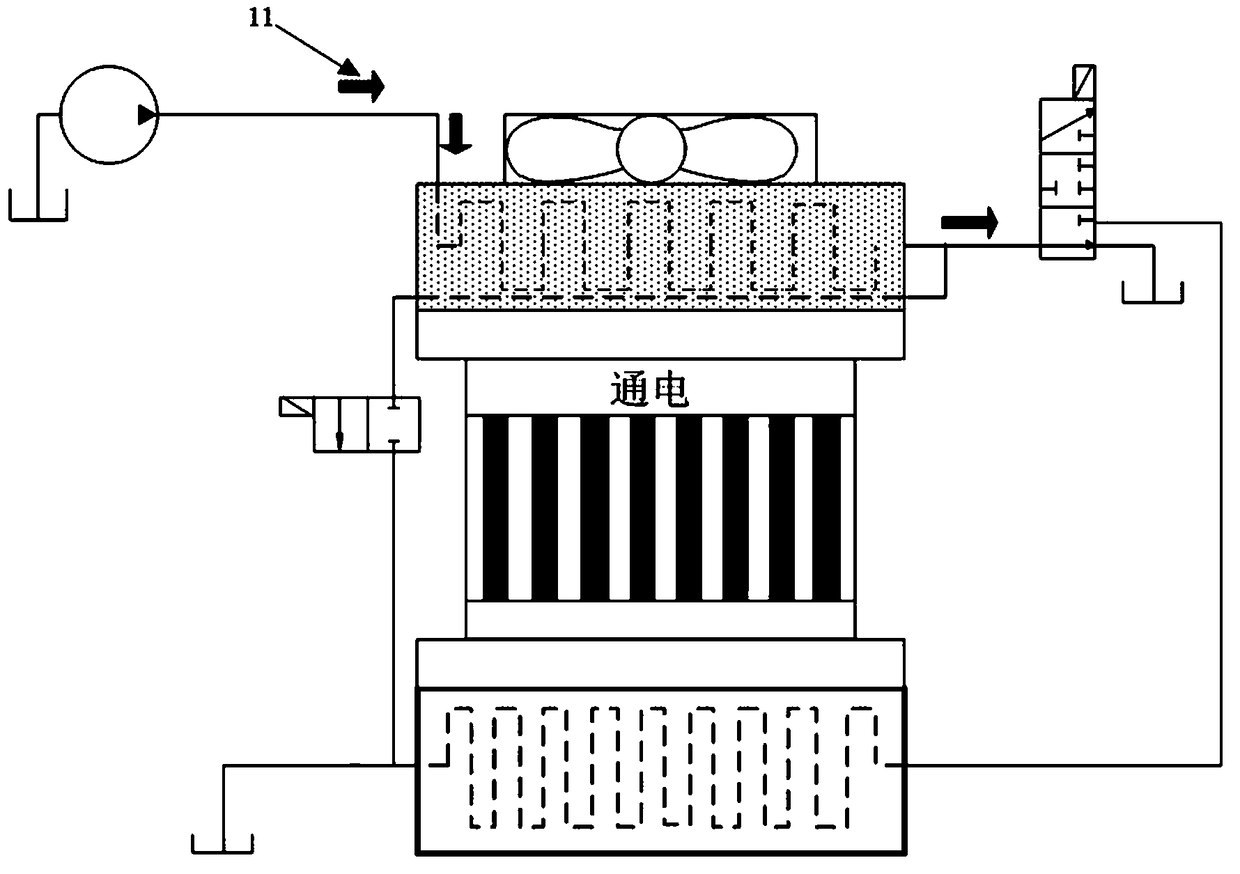

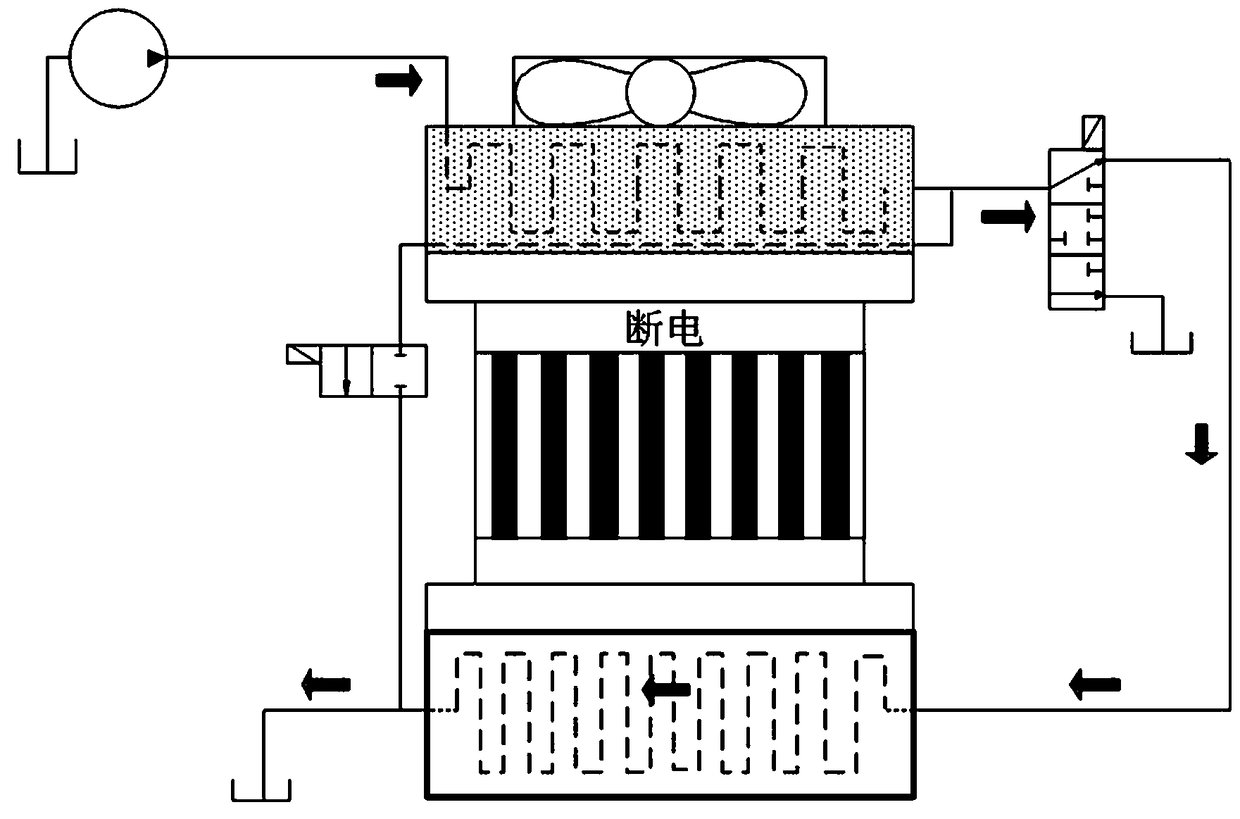

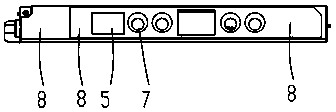

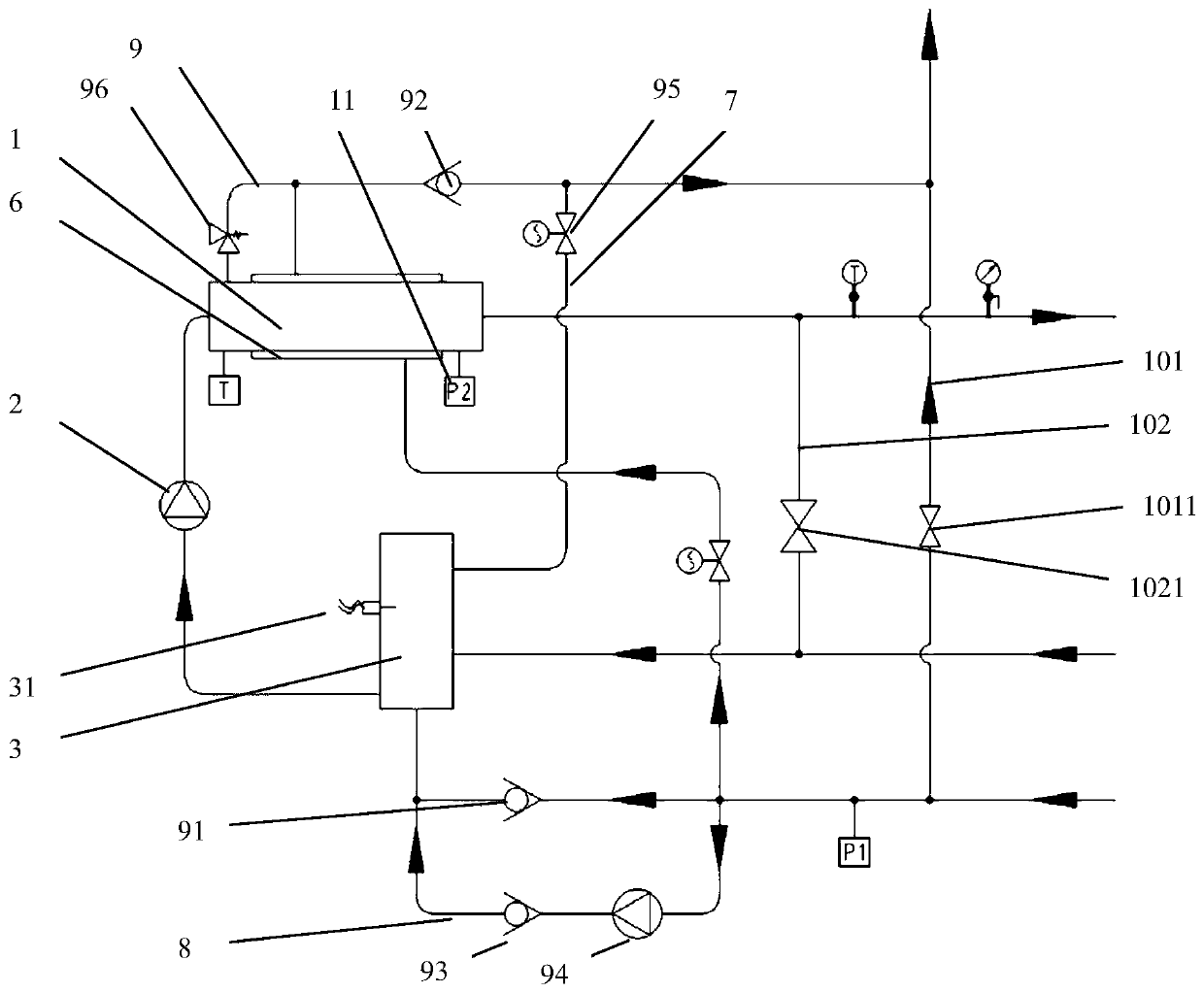

Mold rapid cooling and rapid heating device

The invention discloses a mold rapid cooling and rapid heating device. The device comprises a heater, a pumping, an auxiliary water tank and a valve set; the valve set is provided with a mold input opening, a mold return opening, a cold water inlet, a cold water outlet, a hot water inlet and a hot water outlet, wherein the mold input opening and the mold return opening are connected with a mold correspondingly; the valve set is operable to be in a first gear position or a second gear position, when the valve set is in the first gear position, the cold water inlet communicates with the mold input opening, and the cold water outlet communicates with the mold return opening; when the valve set is in the second gear position, the hot water inlet communicates with the mold input opening, and the hot water outlet communicates with the mold return opening; and the hot water outlet is connected with the auxiliary water tank, the auxiliary water tank is connected with the pumping, the pumping is connected with the heater, and the heater is connected with the hot water inlet. According to the mold rapid cooling and rapid heating device, the rapid switching of cold water and hot water in the mold can be realized, weld marks can be effectively eliminated, the injection molding process is reduced, the personnel expenditure is reduced, the cost is effectively reduced, and the delivery time is shortened.

Owner:SHINI ELECTRIC HEATING MACHINERY

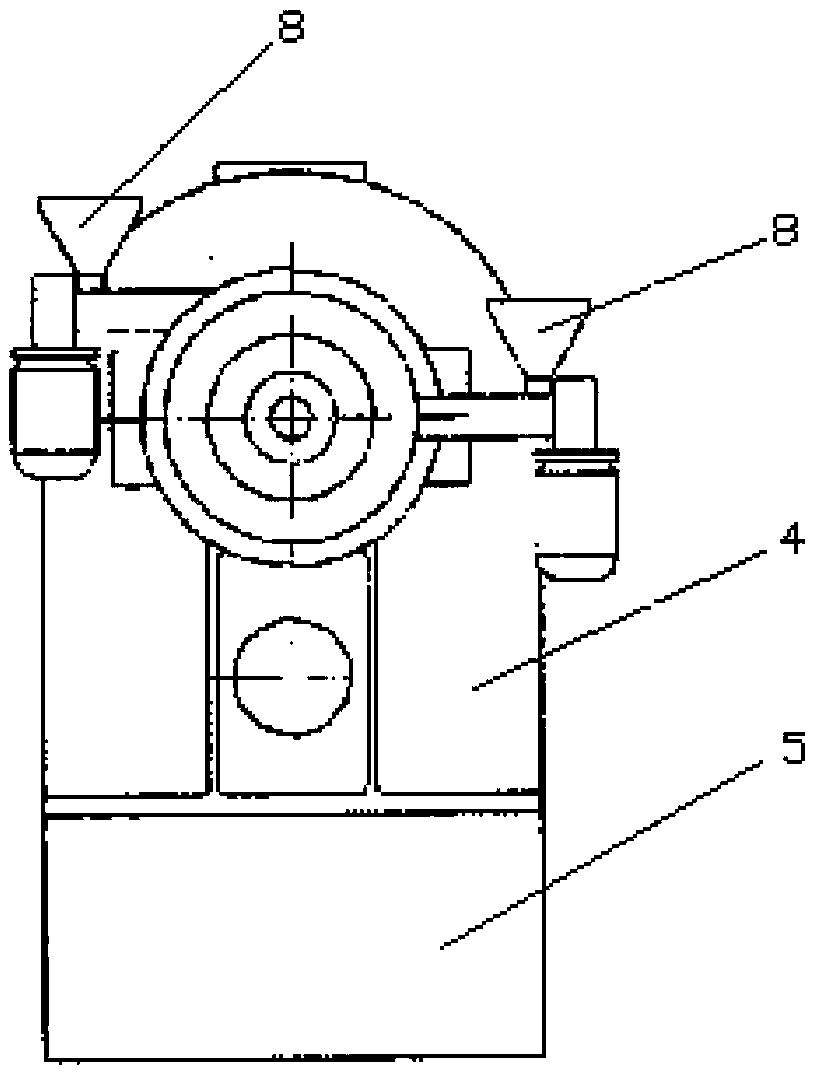

Novel multi-layer extrusion forming device

The invention discloses a novel multi-layer plastic extrusion device which belongs to the technical field of plastic extrusion, and solves the problems that weld marks are generated in the conventional plastic extrusion forming and the product quality is low in the market. The device comprises an engine base, wherein a bracket is arranged on the engine base; a motor box is arranged on the bracket; a conical sleeve is connected to the front side of the motor box. The device is characterized in that the conical sleeve comprises three layers; the middle layer is a rotating conical sleeve; an inner fixing conical sleeve and an outer fixing conical sleeve are respectively arranged on the inner layer and the outer layer of the rotating conical sleeve; spiral material conveying channels are respectively formed between the inner surface of the rotating conical sleeve and the outer surface of the inner fixing conical sleeve as well as between the outer surface of the rotating conical sleeve and the inner surface of the outer fixing conical sleeve. Weld marks on a product produced by using the device are effectively eliminated, the product quality is improved, and in addition, the quality of the product is further improved as filtering nets are arranged in the feeding ports of the feeding channels, so that the working efficiency is indirectly improved.

Owner:NINGBO KANGRUN MACHINERY TECH

An injection mold structure for high-gloss traceless automotive plastic products

ActiveCN110406056BEliminate weld linesPlay the role of high gloss without traceDomestic articlesHeating effectExhaust pipe

The invention discloses an injection mold structure for high-gloss traceless automotive plastic products, which includes a bottom plate, the upper end of the bottom plate is symmetrically fixedly connected with two vertically arranged brackets, and the top ends of the two brackets are fixedly connected with a box body , a cavity is opened in the box. The present invention adopts the linkage design of the opening and closing of the upper mold and the box body. When the upper mold moves downward, the supporting block fixedly connected with it is driven by the ejector rod to move. After the supporting block moves, the connecting rod is driven to move according to the lever, and the connecting rod According to the movement of the lever, the baffle connected with it is driven to move upwards. At this time, the bellows is separated from the baffle, and the inlet pipe is connected to the steam output end of the external boiler. At this time, the steam enters the cavity, bellows, upper mold and lower mold. Complete a cycle and discharge from the exhaust pipe. Due to the cooling and heating effect of high-temperature steam, it can eliminate the welding marks on the injection mold, so that the injection molded product has a high-gloss and trace-free effect.

Owner:乐星汽车电子(青岛)有限公司

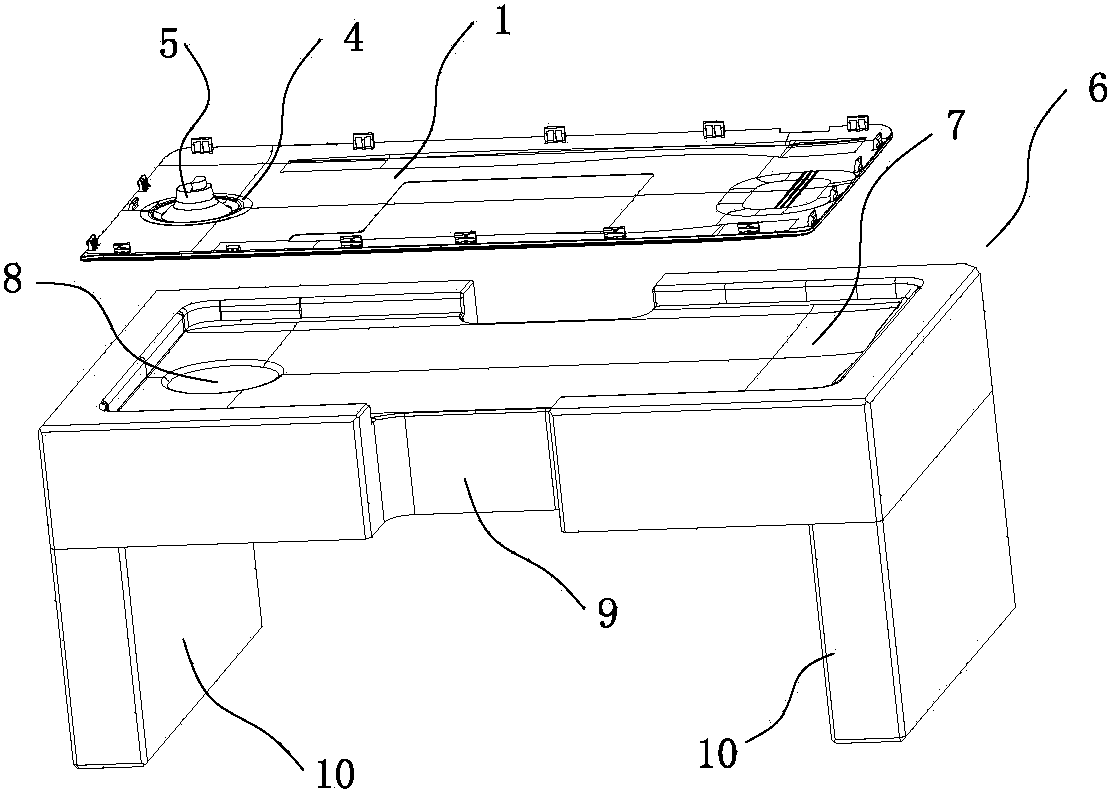

Ultrasonic vibration micro-foaming injection molding device and method for plastic inspection well

The invention relates to an ultrasonic vibration micro-foaming injection moulding device and an ultrasonic vibration micro-foaming injection moulding method for a plastic inspection well, and relates to the field of injection moulding machining for plastic inspection wells. The ultrasonic vibration micro-foaming injection moulding device comprises a fixed die plate, a movable die plate, a die core and hot runner system, an ultrasonic vibration device and a control system, wherein die cores comprise a main die core and a side pulling core, and a die cavity is arranged among the die cores, the fixed die plate and the movable die plate. According to the invention, a cavitation foaming effect of ultrasonic vibration on plastic is utilized, the die cavity is filled with a plastic melt through injection moulding to reach 85-90% of the volume of the die cavity at first, and then the plastic melt in the die cavity is subjected to overall ultrasonic vibration and cavitation micro-foaming through the main die core provided with an ultrasonic vibration mechanism, thus micro-foaming injection moulding machining for the plastic inspection well is realized. The ultrasonic vibration micro-foaming injection moulding device disclosed by the invention is simple to operate, high in moulding accuracy, and capable of saving plastic raw materials by 10-15%, reducing an injection moulding pressure by 60-80%, saving energy, avoiding or reducing generation of weld marks, enhancing the product strength and prolonging the service life.

Owner:江苏正林环保科技有限公司

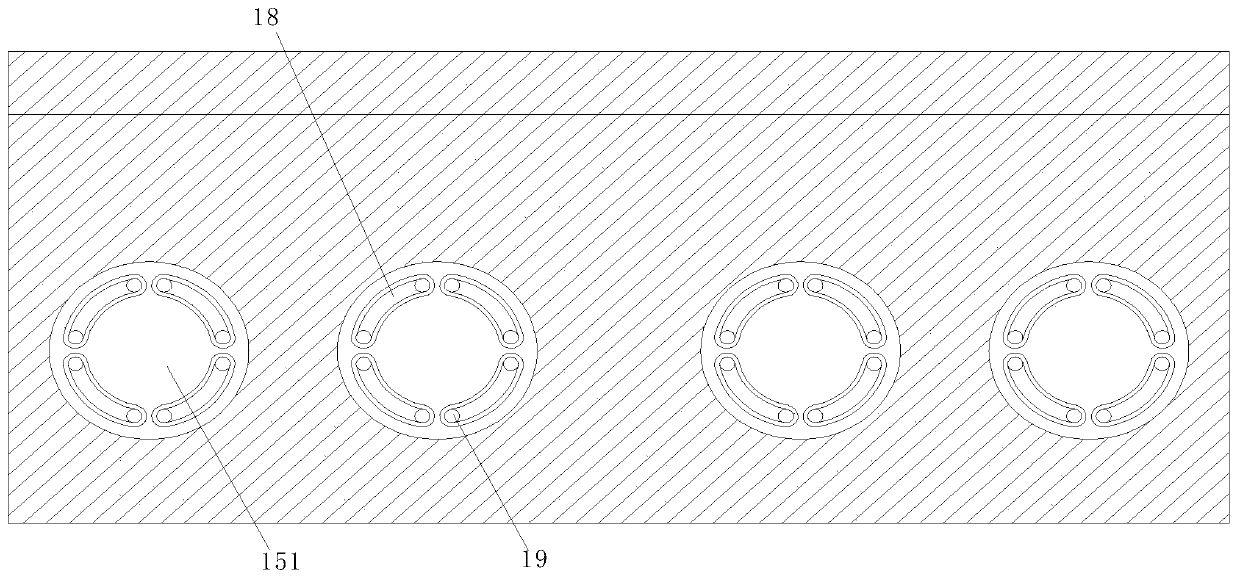

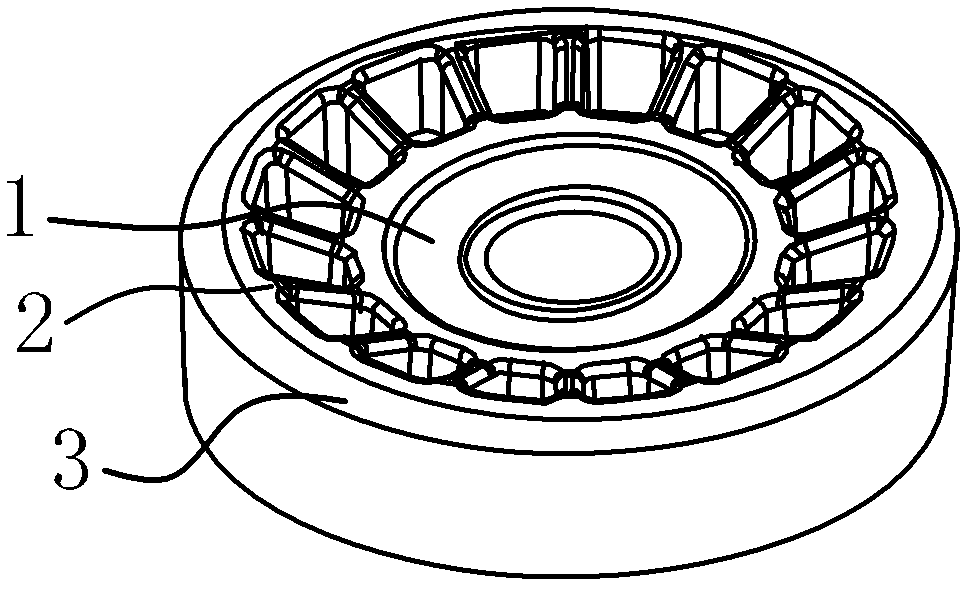

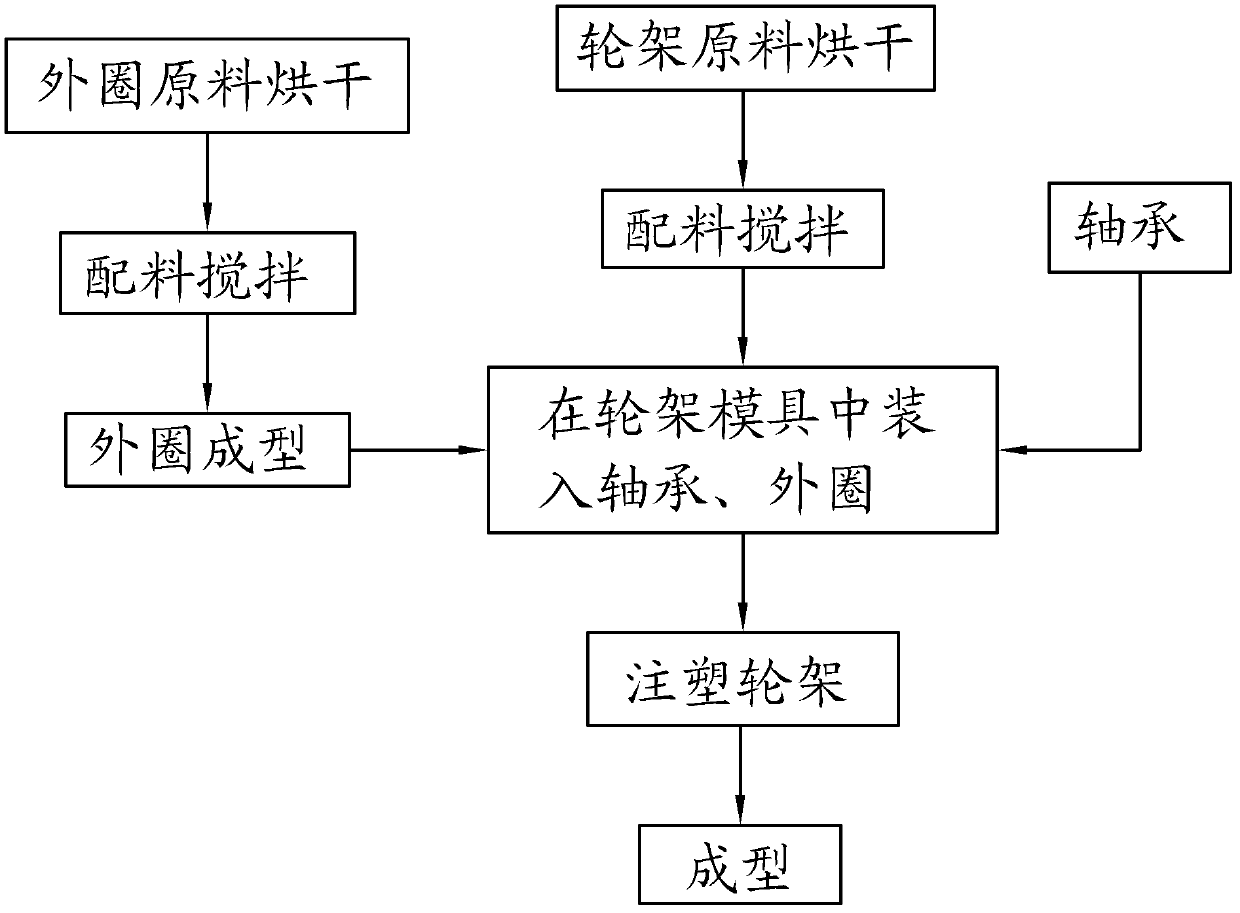

Method for manufacturing escalator roller

The invention provides a method for manufacturing an escalator roller, which belongs to the technical field of escalator rollers and solves the problems that an escalator roller is manufactured by means of mounting a bearing injection molding wheel carrier and then forming an outer ring in an injection molding manner in the prior art, adhesion is unsatisfactory generally, or assembly efficiency is low, assembly difficulty is high and the like. The method for manufacturing the escalator roller includes the steps: A, forming an outer ring in an injection molding manner through an outer ring mould; and B, forming the roller by respectively placing a bearing and the outer ring into a wheel carrier cavity in a wheel carrier mould, performing injection molding in the wheel carrier cavity between the bearing and the outer ring and stripping the mould to obtain an escalator roller blank. By the aid of the method for manufacturing the escalator roller, components do not need to be assembled, firmness of adhesion of the wheel carrier and the outer ring is improved, reliability of matching of the bearing and the wheel carrier is enhanced, and production efficiency is improved.

Owner:ZHEJIANG WANLI AUTOPART PROD

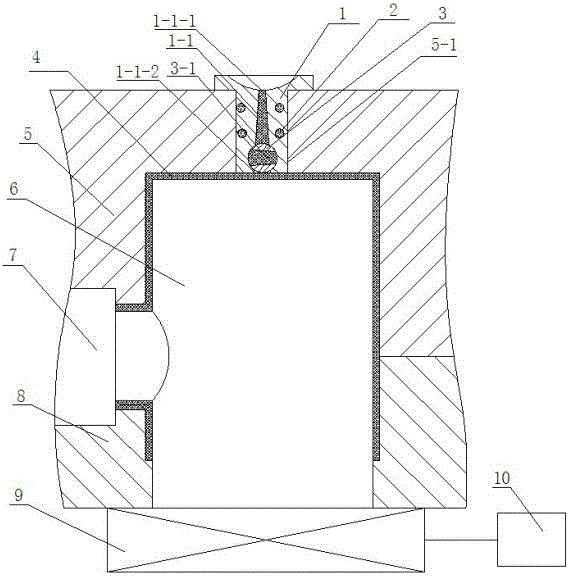

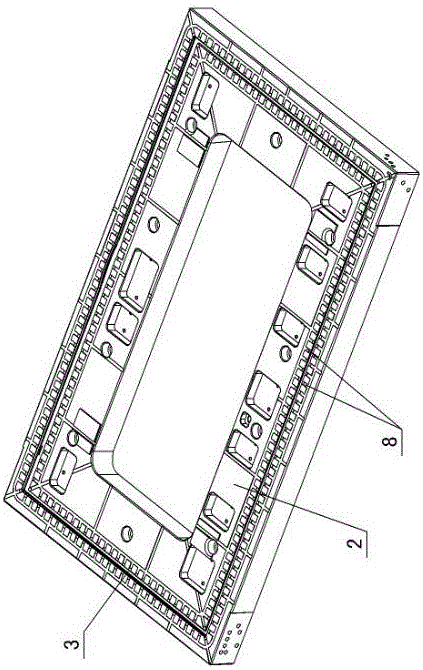

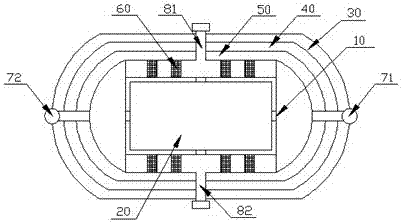

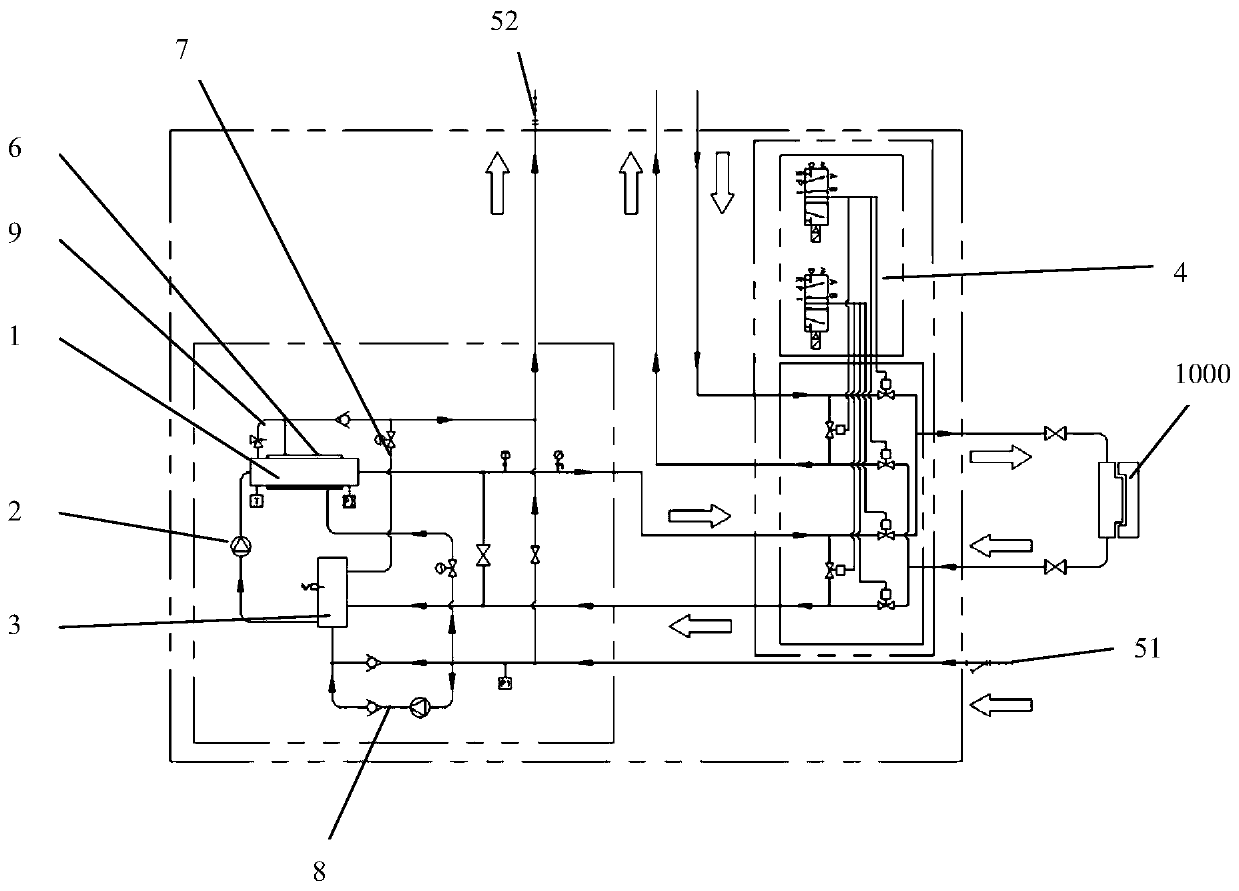

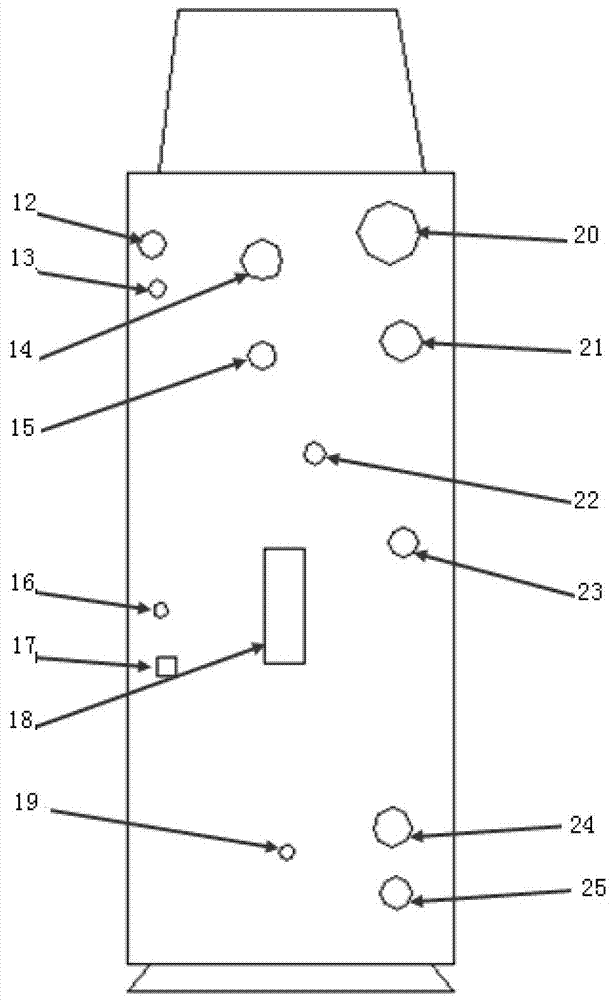

A rapid steam forming device for decorative panels

ActiveCN104162958BMeet the needs of rapid heating and coolingEliminate weld linesMolecular materialsEngineering

The invention relates to a quick steam forming device for a decoration panel. The device comprises a plastic injection mold and a steam former device. The device is characterized in that a water access way is arranged on the plastic injection mold; the water access way is connected with the steam former device through a pipe; before the plastic injection, a high-temperature and high-pressure steam water mixer is blown in the plastic injection mold through the water access by the steam former device, so that the temperature of the plastic injection mold is quickly raised to reach above a high molecular material glass conversion temperature; a molten high molecular material is injected in the plastic injection mold for plastic injection; after the plastic injection is finished, high-pressure cooling water is input in the plastic injection mold through the water access way by the steam former device, so that the temperature of the plastic injection mold is quickly decreased above a high molecular material deformation temperature; and after the cooling is finished, a formed product is taken out. Compared with the prior art, the quick steam forming device for the decoration panel has such advantages as low cost, good stability and low energy consumption.

Owner:SHANGHAI YONGXING PLASTICS

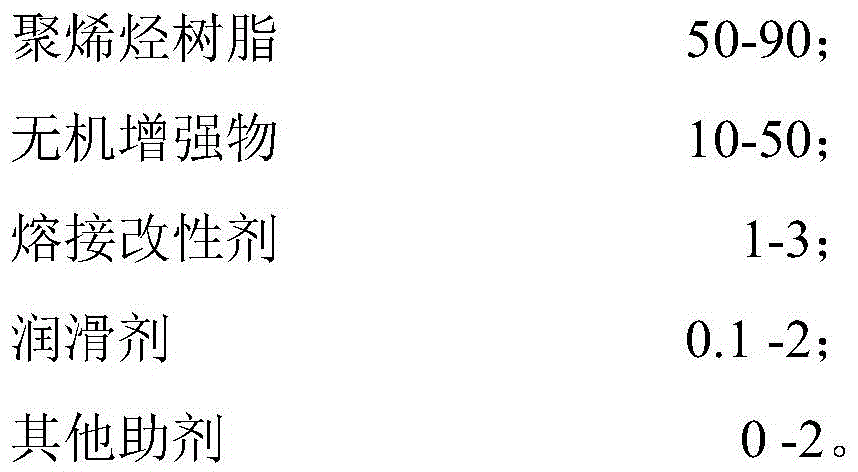

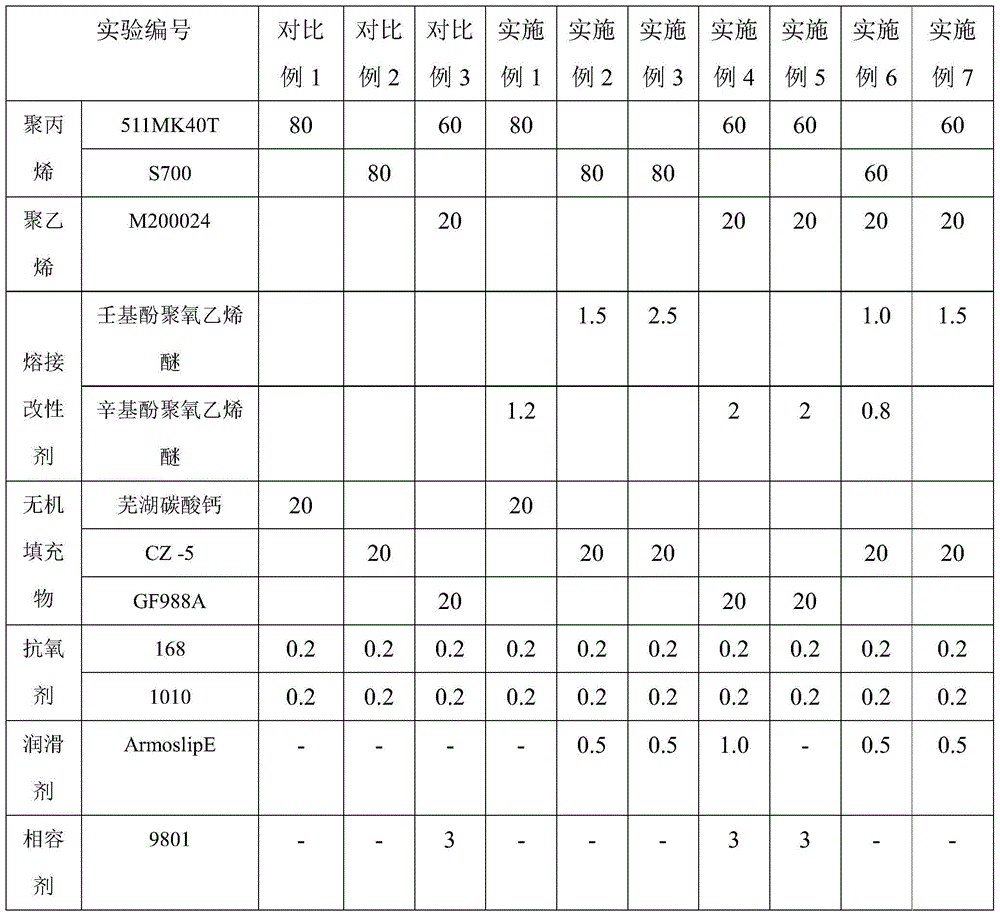

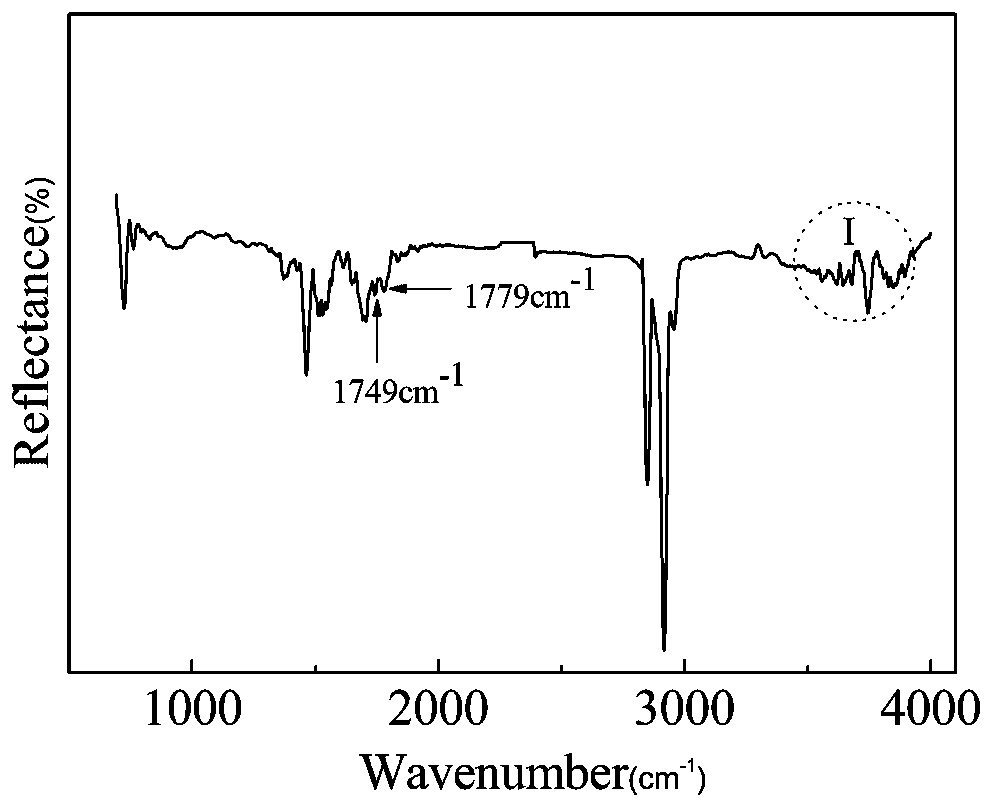

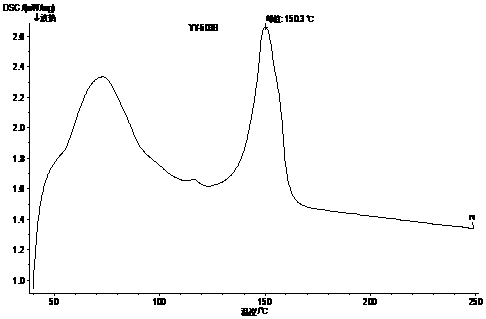

A kind of polyolefin reinforced material and preparation method thereof

The invention relates to a polyolefin reinforced material and preparation method thereof. The polyolefin reinforced material comprises the following components in parts by weight: 50-90 parts of polyolefin resin, 10-50 parts of inorganic reinforcement, 1-3 parts of fusion welding modifying agent, 0.1-2 parts of lubricating agent and 0-2 parts of other auxiliaries. Compared with the prior art, the polyolefin reinforced material has the advantages that the fusion welding mark strength during injection molding is improved by more than 85% on the basis of retaining the excellent mechanical property, and no appearance weld mark can be seen on the injection molding product.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

A kind of imitation metal ABS modified material and preparation method thereof

The invention relates to an imitation metal ABS modified material, and a metal imitation ABS modified material, which is composed of the following components and proportions: 70-95 parts of ABS, 0.5-10 parts of pigments, and a coupling lubricating compound modifier 1 ~5 parts, 5-10 parts of tackifier, 0-10 parts of filler, and 0.1-1 part of antioxidant, wherein, the coupling lubricating compound modifier has a brand name of YY-503, and its number-average molecular weight is 3000 ~5000, the low melting point of the coupling lubricating compound modifier is 75±5℃, and the high melting point is 150±10℃; the tackifier is C5 petroleum resin, and its average molecular weight is 1000~2500; the present invention can It overcomes the problems of serious weld lines, poor metal effect and reduced impact strength in the prior art, and has broad application prospects in the plastic product industry.

Owner:广东波斯科技股份有限公司

Device for regulating flow of tube blank plastic suction mold forming runner

InactiveCN111086192AImprove mixing uniformityAvoid weld linesDomestic articlesHollow articlesEngineeringHollow form

Owner:青岛中兴源模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com