Elevator sliding guide shoe liner made of ultra-high molecular weight polyethylene and preparation method for elevator sliding guide shoe liner

An ultra-high molecular weight, sliding guide shoe technology, which is applied in the field of material molding processing, can solve the problems of difficult extrusion and easy splitting, and achieve the effects of increasing shear resistance, overcoming shrinkage, and eliminating pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

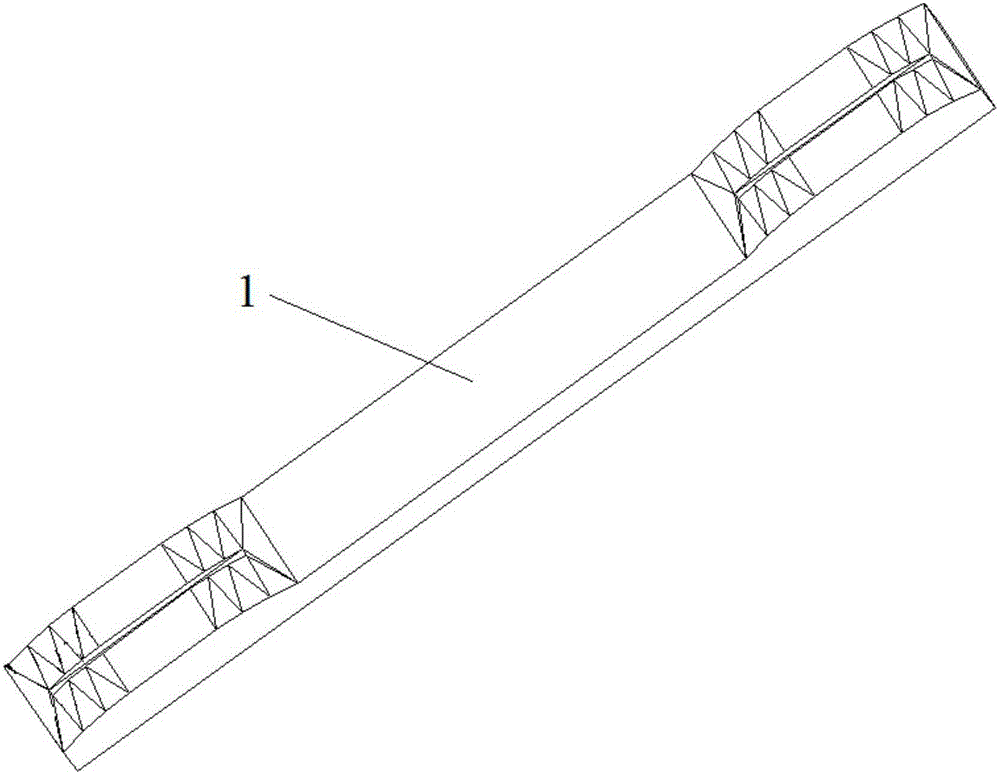

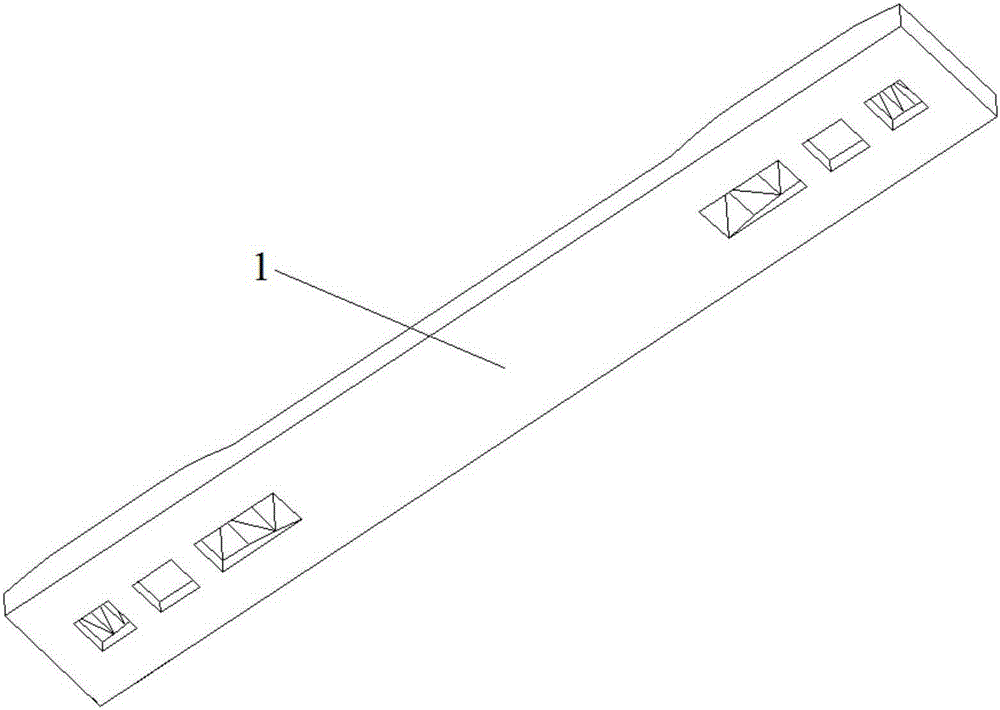

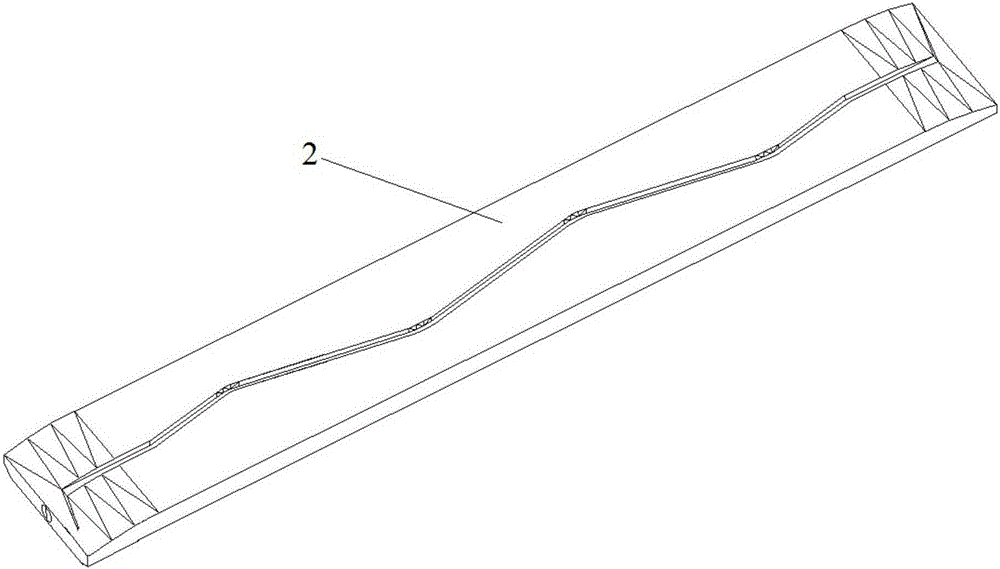

[0059] Such as Figure 1-5 As shown, an ultra-high molecular weight polyethylene elevator sliding guide shoe lining in this embodiment includes a product B2 and two products A1 that are oppositely arranged on the product B2 along the length direction of the product B2, and the product B2 and the two products The product A1 is combined into a configuration suitable for the shape of the elevator sliding guide shoe. The product A1 and product B2 are composite materials based on ultra-high molecular weight polyethylene resin and prepared by injection molding process.

[0060] Among them, the mass fraction of ultra-high molecular weight polyethylene resin in the composite material is 75%, and the rest is low molecular weight polyolefin resin. Wherein, the viscosity-average molecular weight of the ultra-high molecular weight polyethylene resin is 1.5 million, and the low molecular weight polyolefin resin is selected from commercially available TR550.

[0061] In this embodiment, th...

Embodiment 2

[0073] This implementation aims to produce a high wear-resistant and low friction coefficient ultra-high molecular weight polyethylene boot lining product. The material is ultra-high molecular weight polyethylene resin (75wt%), the molecular weight is 2.5 million, and 25% of the general flow modifier in the market is added. After blending and compounding, it is used as the production material of this embodiment.

[0074] The preparation method of the ultra-high molecular weight polyethylene elevator sliding guide shoe lining of the present embodiment specifically comprises the following steps:

[0075] (1) Using ultra-high molecular weight polyethylene resin or ultra-high molecular weight polyethylene resin as a matrix composite material as raw material, feeding through an injection molding screw machine, so that the raw material is injected into the molding mold of product A1 and product B2, and the template is closed. During the feeding process, control the back pressure to ...

Embodiment 3

[0084] In this example, product A1 and product B2 are composite materials based on ultra-high molecular weight polyethylene resin and prepared by injection molding process, wherein the mass fraction of ultra-high molecular weight polyethylene resin in the composite material is 45%, and the rest It is a low molecular weight polyolefin resin, wherein, the viscosity average molecular weight of the ultra-high molecular weight polyethylene resin is 1.8 million, the molecular weight of the low molecular weight polyolefin resin is 250,000, and the molecular weight distribution is >4.0.

[0085] In this embodiment, the coefficient of friction between the product A1 and the product B2 is 18 MPa, and the thickness of the product A1 and the product B2 is 9 mm.

[0086] The preparation method of the ultra-high molecular weight polyethylene elevator sliding guide shoe lining of the present embodiment specifically comprises the following steps:

[0087] (1) Using ultra-high molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com