Splicing type combination demolding mechanism for front grill mold of automobile

A technology of demolding mechanism and front grille, which is applied to household appliances, other household appliances, household components, etc., can solve the problem of difficulty in one-time processing of sliders, and achieve the advantages of convenient screw splicing, balanced pouring, and reduction of welding marks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

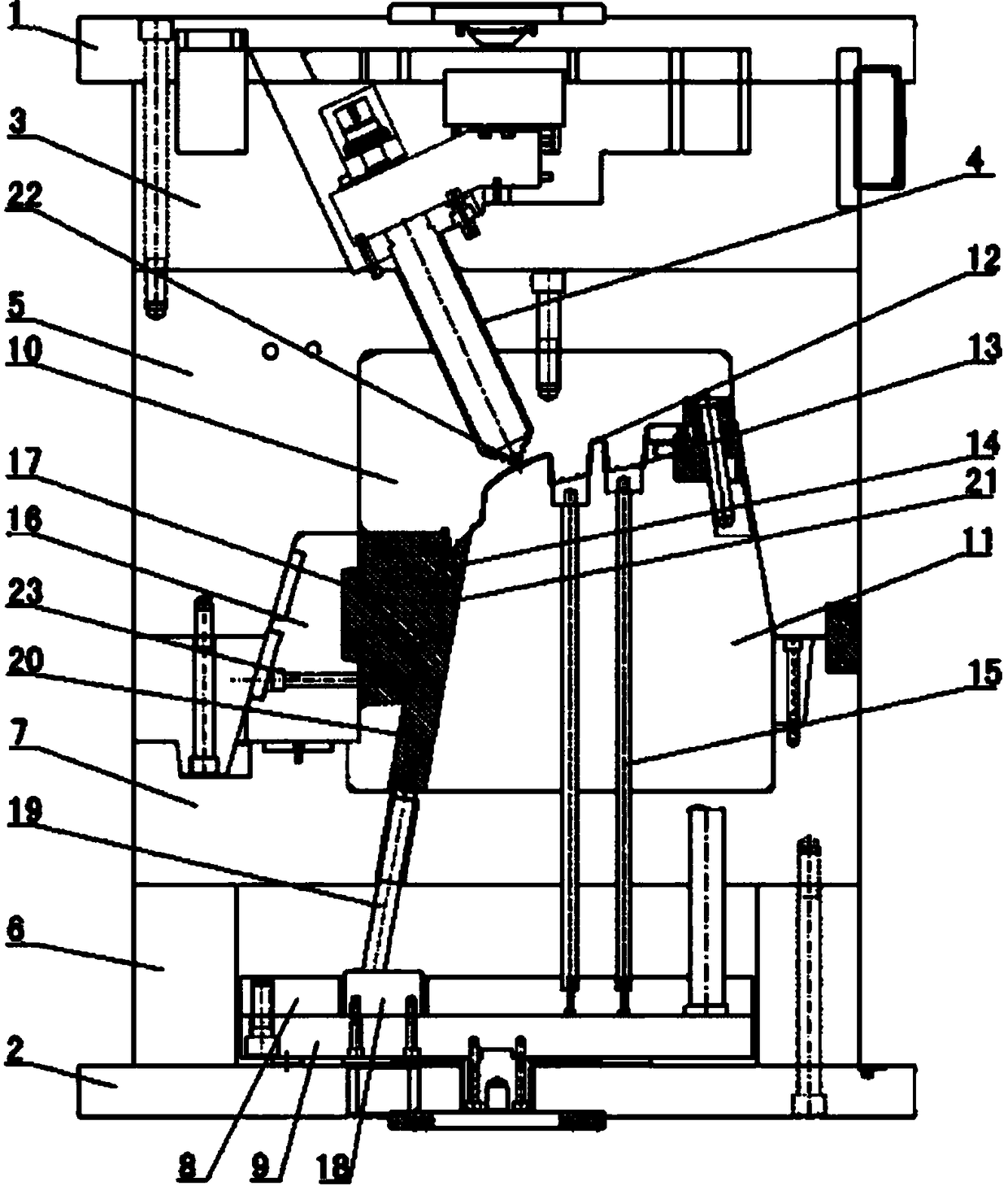

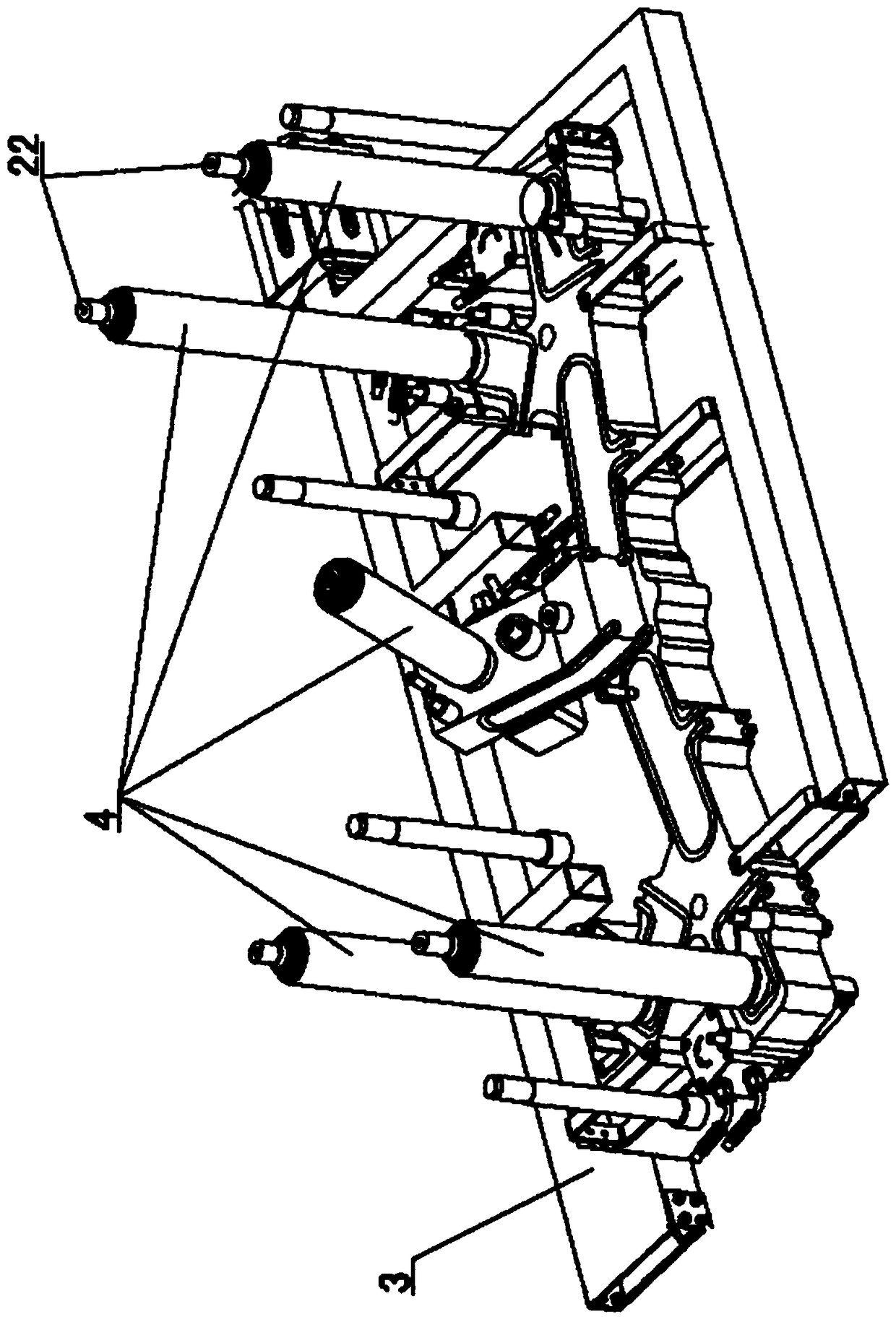

[0009] The invention relates to a splicing combined demoulding mechanism for the front grille mold of an automobile, such as figure 1 , figure 2 As shown, it includes the upper template 1 and the lower template 2 of the mold, the runner plate 3 is installed under the upper template, the hot runner nozzle 4 is installed in the runner plate, the fixed template 5 is installed under the runner plate, and the fixed mold insert 10 is installed in the fixed template , the mold foot 6 is installed on the lower template 2, the movable template 7 is installed on the mold foot, the movable mold insert 11 is installed in the movable template, and there is an injection-molded front grille 12 between the movable mold insert 11 and the fixed mold insert 10, The back side of the front grille is provided with installation buckles 13 and undercuts 14, an upper top plate 8 and a lower top plate 9 are arranged between the die feet 6, the upper top plate 8 is connected with a straight ejector rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com