Plastic injecting mold for casting system with low power consumption

A pouring system and injection mold technology, applied in the field of plastic molds, can solve the problems of difficult mold maintenance, long cycle time, difficult automatic shedding of nozzle materials, and easy removal of nozzle crochets. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

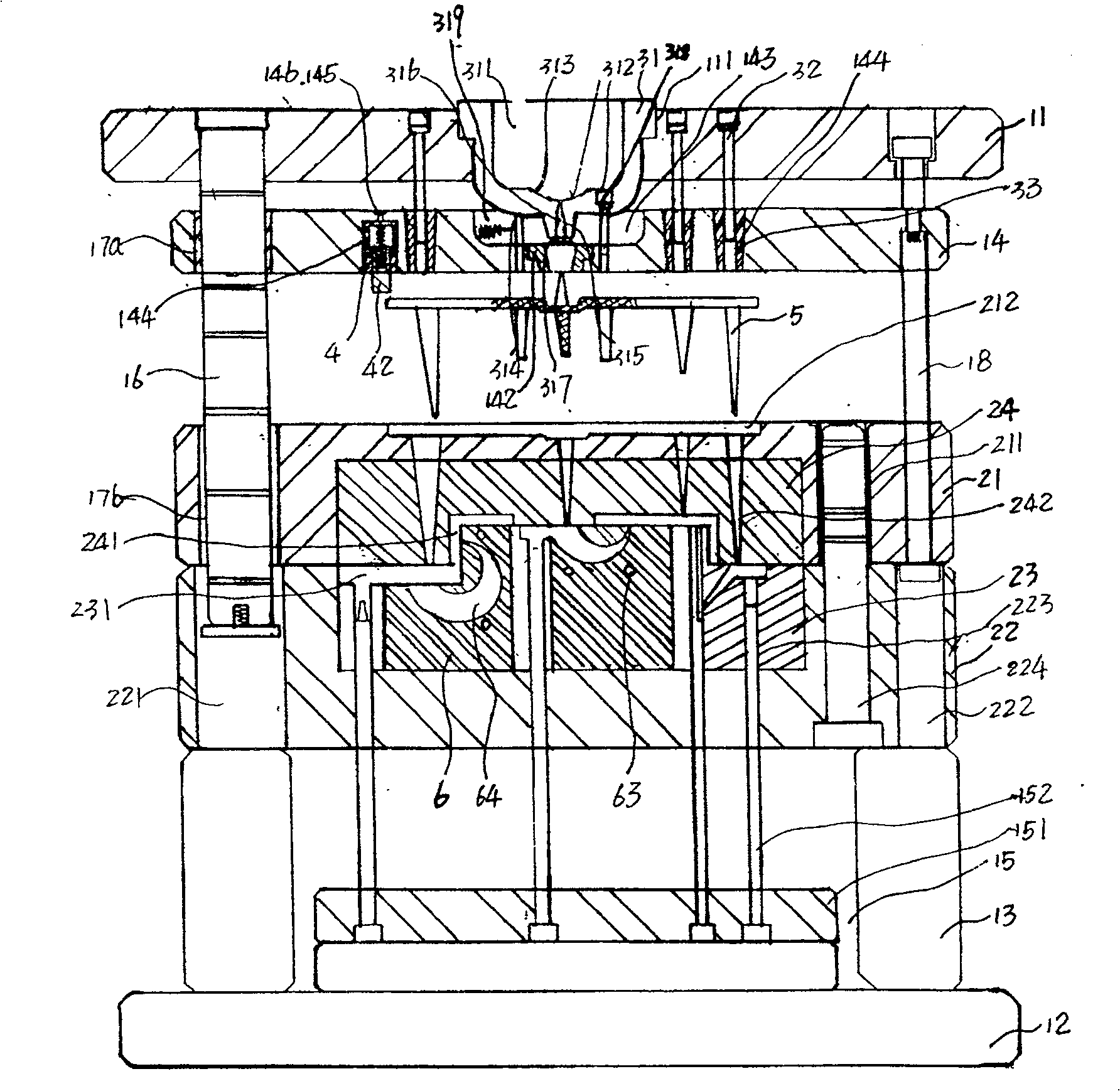

[0036]See figure 1 , A plastic injection mold with an energy-saving and consumption-reducing gating system, including a mold composed of an upper template 11, a lower template 12, a mold foot 13, a stripper plate 14, an ejection member 15, a guide post 16, and a guide sleeve 17a, 17b Frame; a molding part composed of cavity A plate 21 and cavity B plate 22, and male and female molds 23 and 24 installed in cavity A plate 21 and cavity B plate 22; pouring system.

[0037] The cavity B plate 22 is fixedly connected with the lower mold plate 12 through mold feet 13 and fasteners. The guide post 16 is fixedly installed on the upper mold plate 11 and passes through the guide sleeves provided on the stripper plate 14 and the cavity A plate 21 17a and 17b connect the upper template 11 with the stripper plate 14 and the cavity A plate 21; the stripper plate 14 and the cavity A plate 21 can slide on the guide post 16.

[0038] The stripper plate 14 is also equipped with tie rods 18 for div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com