A mold system for thermoplastic resin thick-walled products

A technology of thermoplastic resin and mould, which is applied in the field of mold system for thermoplastic resin thick-walled products. It can solve the problems of low applicability of low-flow resin, enlarged water inlet, shrinkage, etc., and achieves the effect of shortening the molding cycle and reducing weld lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

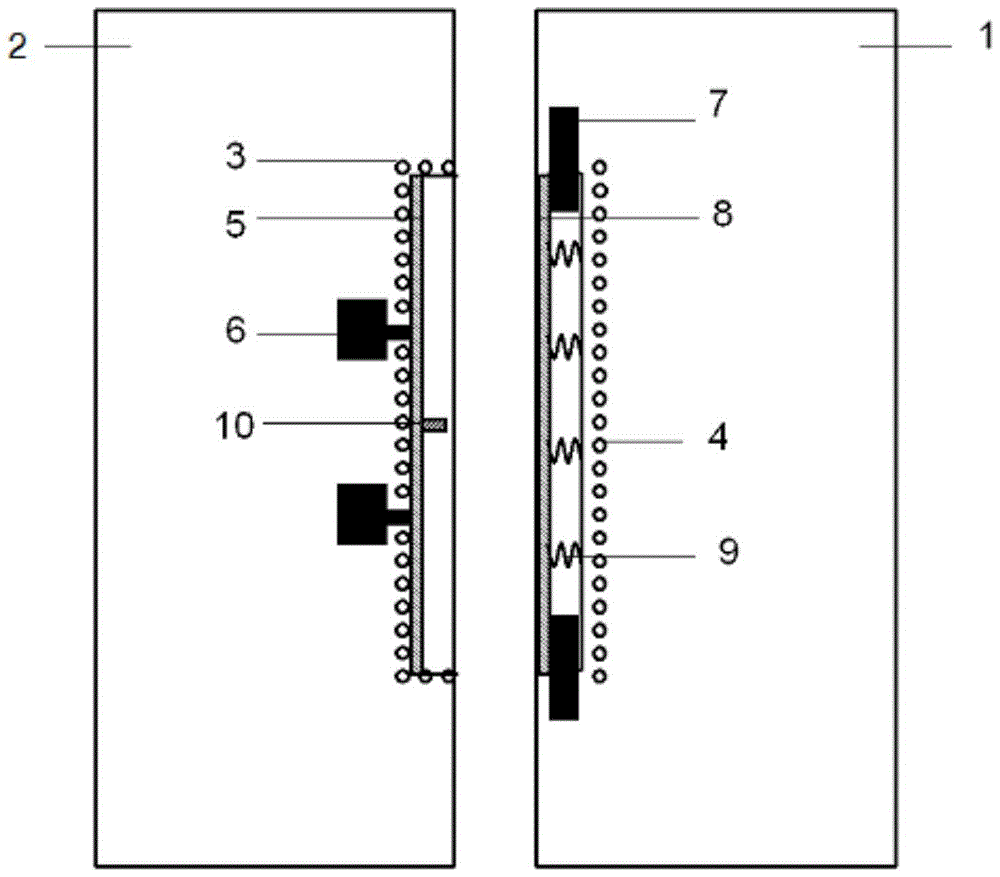

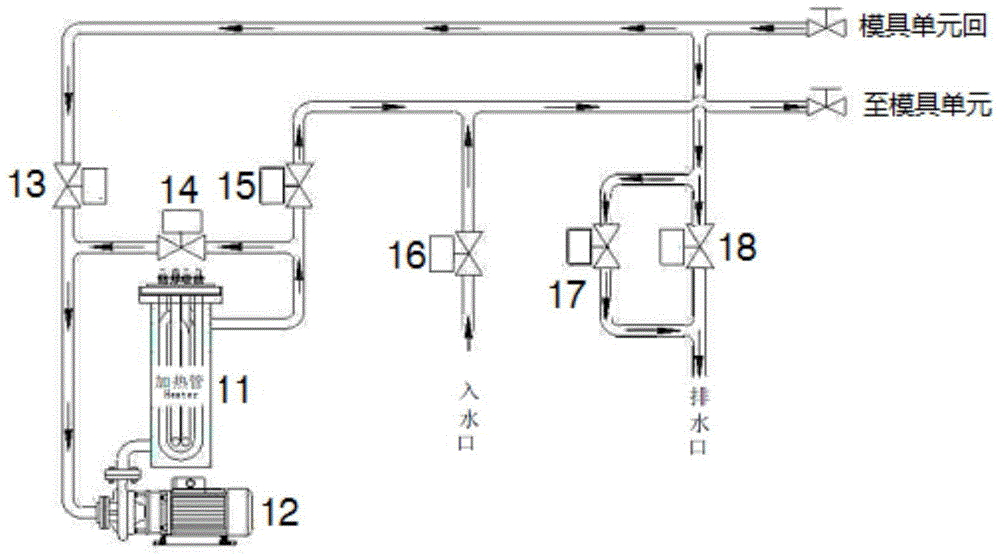

[0024] A mold system for thick-walled thermoplastic resin products, including a mold unit and a temperature-changing unit connected to the mold unit, the structures of which are as follows: figure 1 , 2 shown. The mold unit is composed of a fixed template 1 and a movable template 2 that match each other, and the temperature-variable unit is composed of a heating pipe 11, an air pump 12 and a pipeline connected to the mold unit to control the temperature of the mold unit.

[0025] Next, the two units are further described: the fixed template 1 includes a spring support block 8 arranged at the contact surface with the movable template 2, a high-pressure spring 9 connected to the spring support block 8, and cooling water communicated with the pipeline of the temperature-changing unit Passage 4, the movement of the spring support block 8 is controlled by the electromagnetic control switch 7. Among them, there are eight high-pressure springs 9 in total, which can withstand a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com