Injection mold for mobile phone shell production and processing

A technology for injection molds and mobile phone shells, which is applied in the field of injection molds for the production and processing of mobile phone shells. It can solve the problems of affecting the quality of finished workpieces, uneven density of finished workpieces, and easy generation of weld lines, etc., and achieves small temperature differences, increased temperature, and increased temperature. The effect of maximum heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Provides an achievable option for increasing mold temperature.

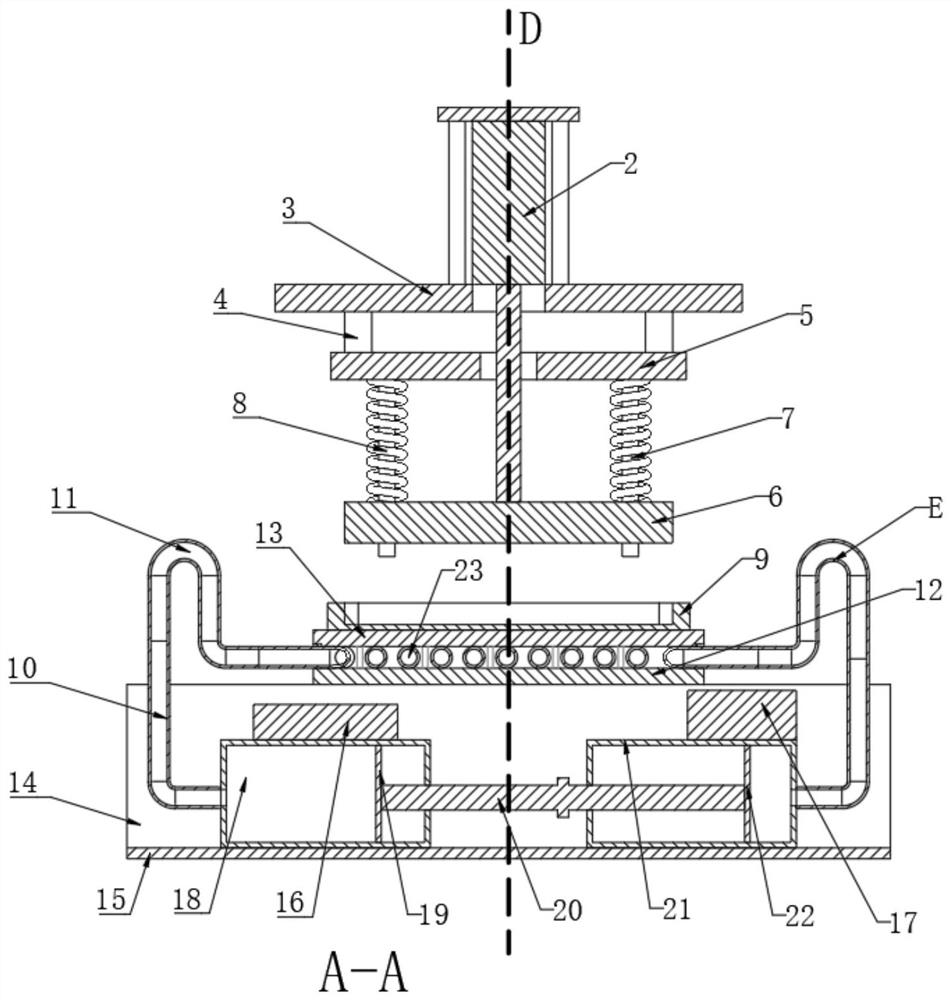

[0039] Such as Figure 7 As shown, the preventive mechanism for increasing the mold temperature includes a heat transfer pipe 23, the heat transfer pipe 23 is located between the heat transfer plate 13 and the inner bottom of the lower mold base 12, and the heat transfer pipe 23 is distributed in a serpentine shape to increase the heat exchange space. The heat transfer pipe 23 is in contact with the top of the lower mold base 12, and also includes a water supply mechanism for injecting or extracting a corresponding temperature into the heat transfer pipe 23.

[0040] By arranging the serpentine heat transfer pipe 23, the length and width of the mobile phone shell can be compounded, so that the bottom of the die 9 can be compounded, and by arranging the serpentine structure, the length of the heat transfer pipe 23 can be increased, so that the heat transfer plate 13 The temperature can be quickly raised to...

Embodiment 2

[0043] A second achievable option for increasing mold temperature is provided.

[0044] Such as Figure 8 As shown, the preventive mechanism for increasing the mold temperature includes a heating wire 26 and a power supply head 30 for providing power to the heating wire 26. The heating wire 26 is a coiled disk structure, and the heating wire 26 can be heated to a corresponding temperature when energized.

[0045] It can also be implemented by means of electric heating. By setting the heating wire 26, high temperature can be generated when the heating wire 26 is energized, and its temperature can be changed by changing its voltage. Because the commonly used heating wire is a fixed resistance value, by setting the heating wire 26 is a disc connection structure of vortex lines, which can increase the heating efficiency, rapidly increase the temperature of the local space, and can increase the temperature of the heat transfer plate 13 evenly, so that the temperature difference bet...

Embodiment 3

[0047] Provides a third achievable option for increasing mold temperature:

[0048] Such as Figure 9 As shown, the preventive mechanism for increasing the mold temperature includes a gas heater 27. The gas heater 27 can heat the internal gas and output the gas. A sealed space is formed between the heat transfer plate 13 and the inside of the lower mold base 12. The gas heater An air intake pipe 28 is communicated between the output end of 27 and the sealed space, and a switchable air outlet pipe 29 is communicated with the outer wall of the lower mold base 12, and the air outlet pipe 29 communicates with the inside of the sealed space.

[0049] The gas heater 27 can heat the air, and the heat of the air is relatively uniform. When it is transmitted to the sealed space through the intake pipe 28, the internal pressure increases and the heat transfer is accelerated, so that the heat transfer plate 13 can be heated quickly, so that The speed that die 9 heats up accelerates.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com