Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Quick pull away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

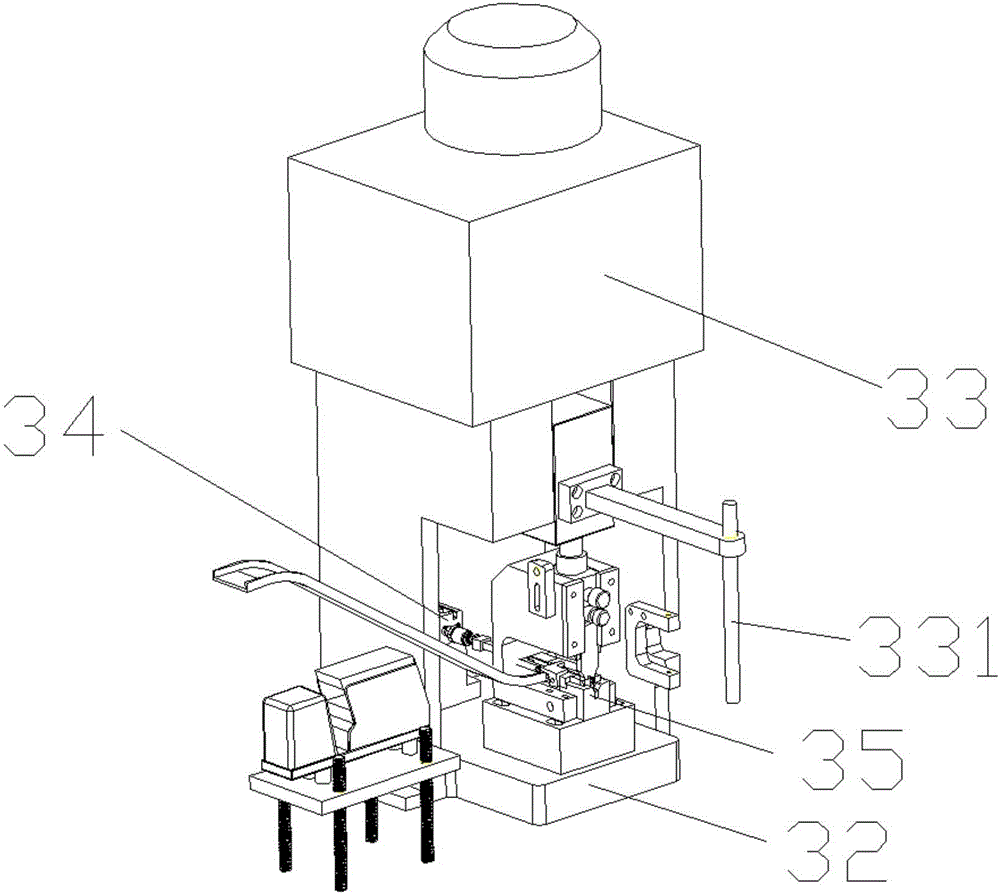

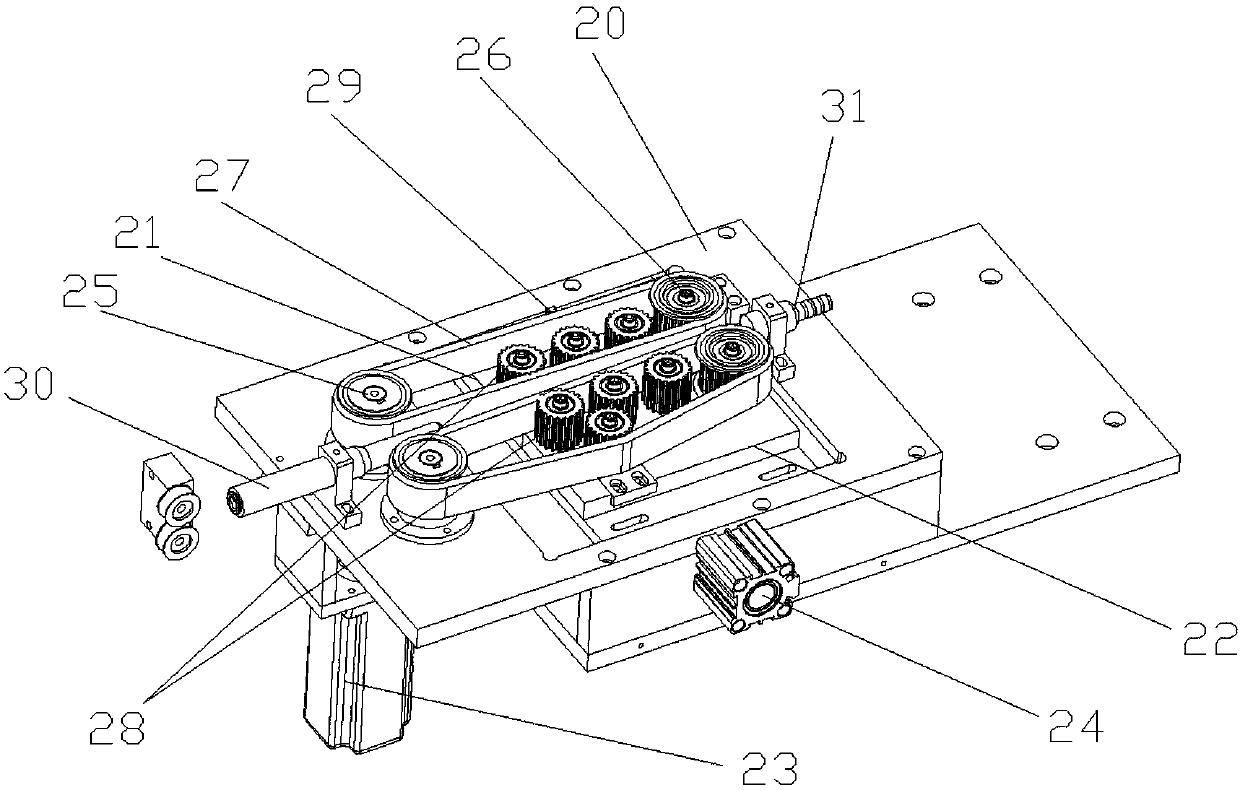

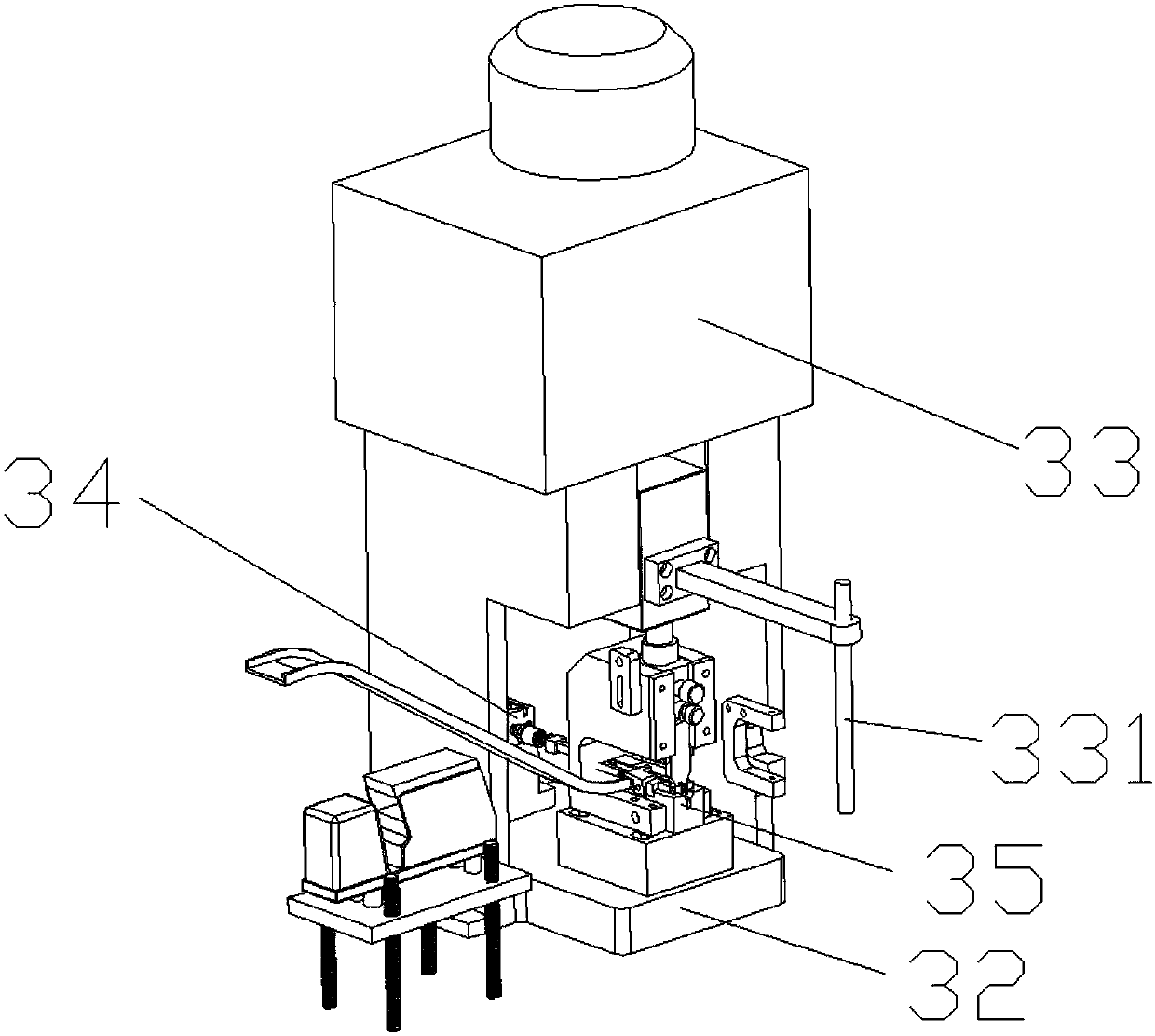

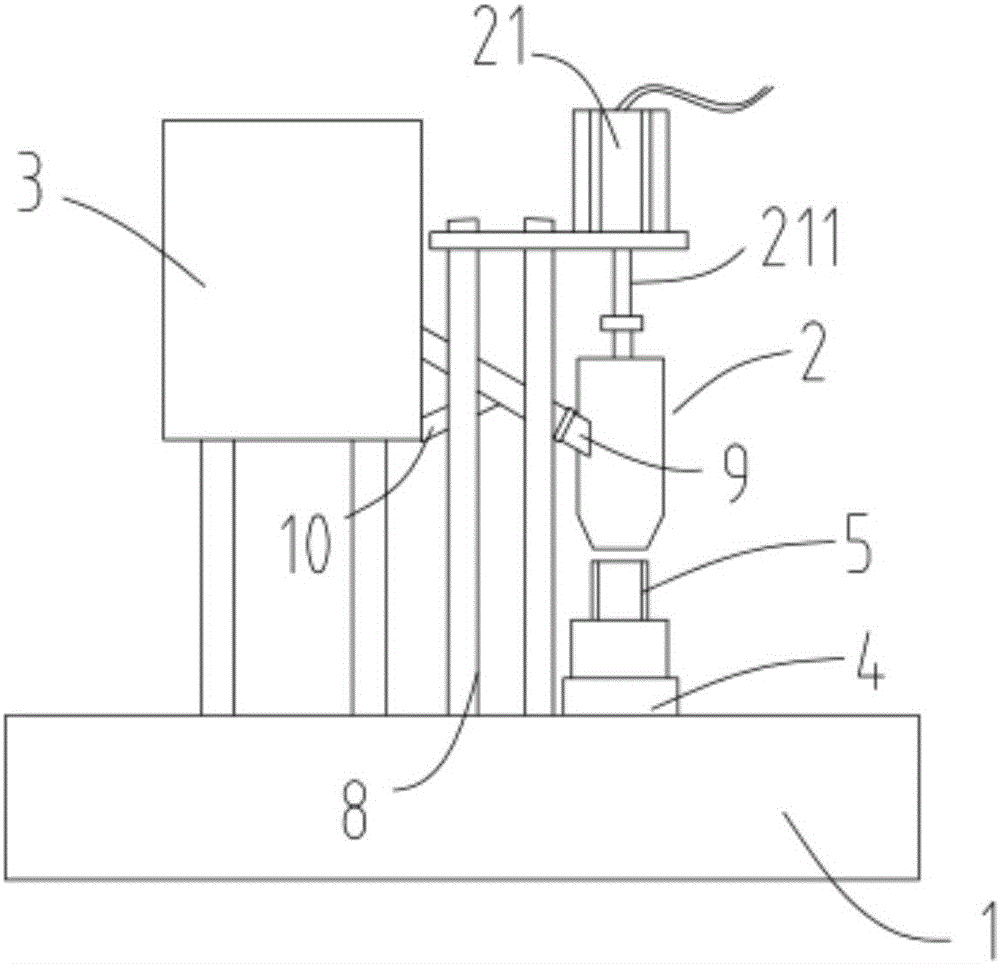

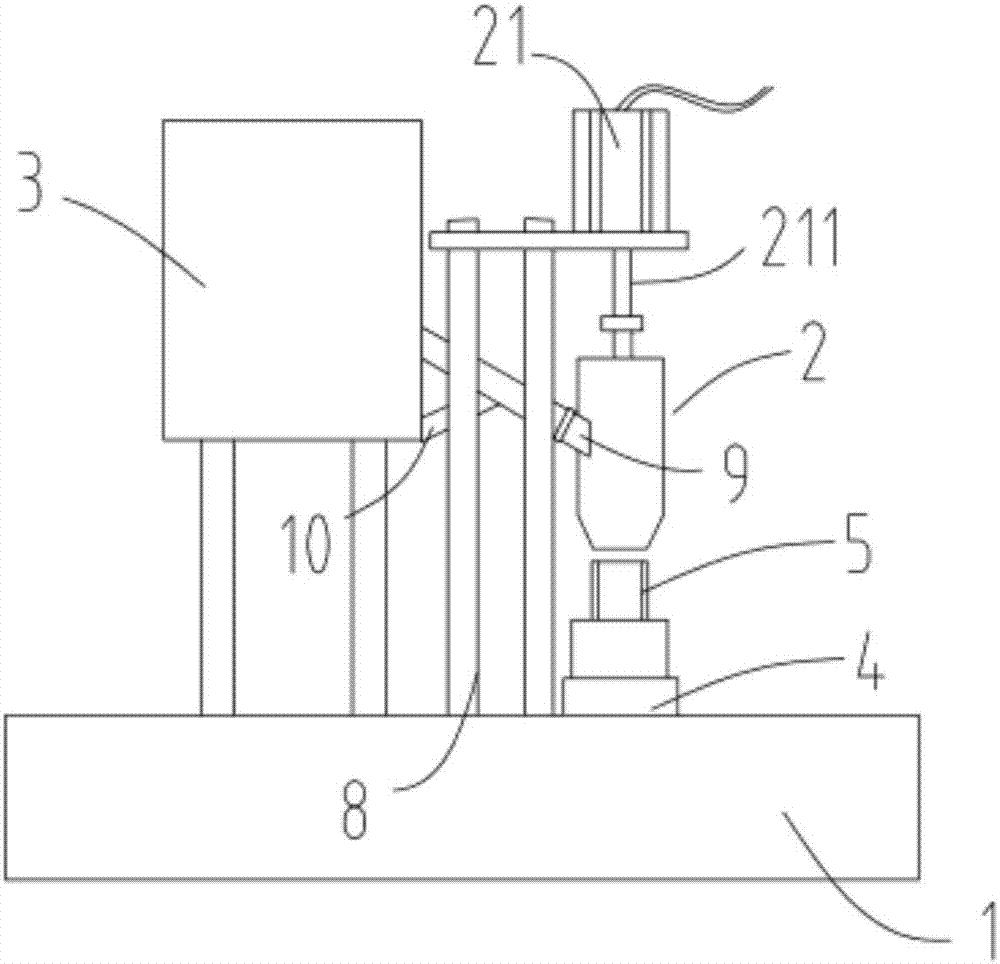

Peeling, shearing, riveting and twisting integrated machine

ActiveCN106270305AReduce turnaround timeSmall footprintApparatus for removing/armouring cablesApparatus for joining/termination cablesEngineeringMechanical engineering

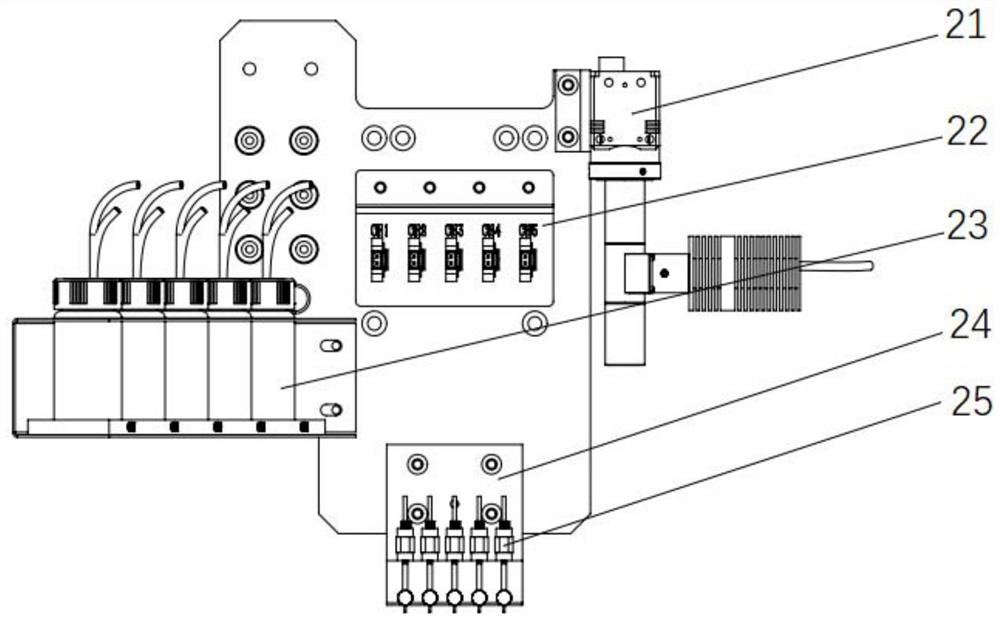

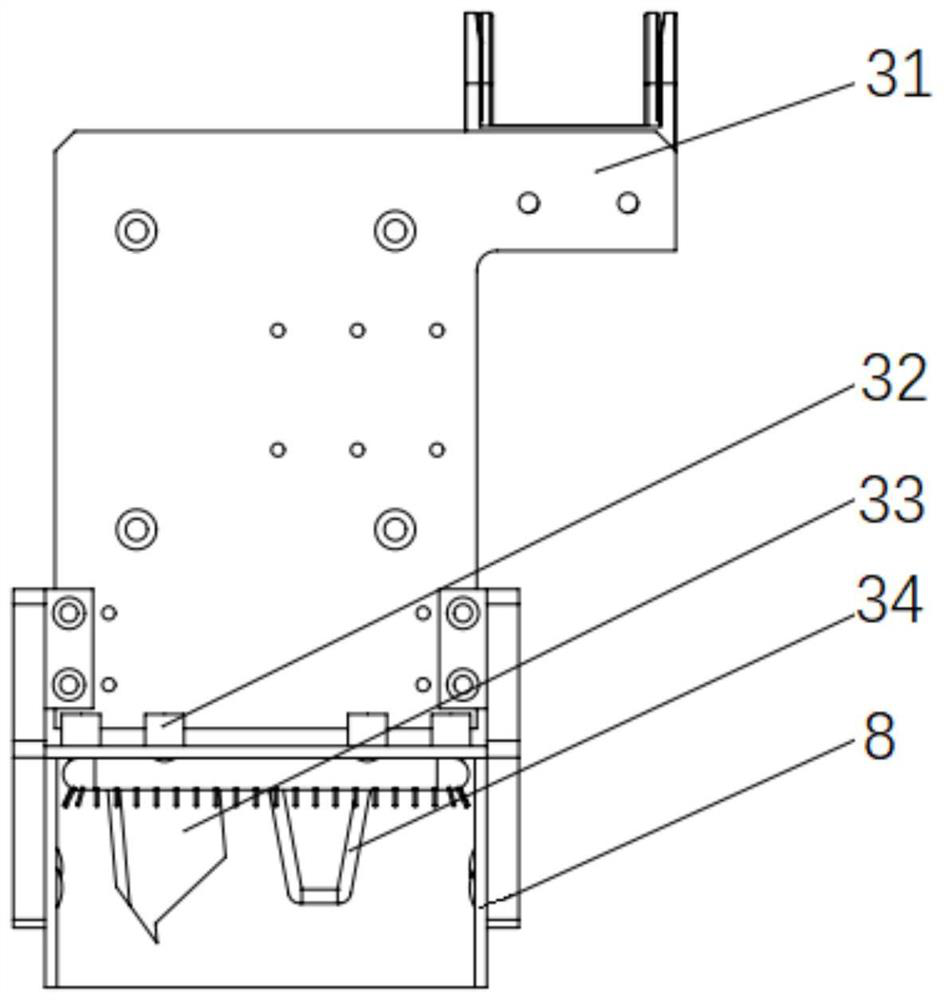

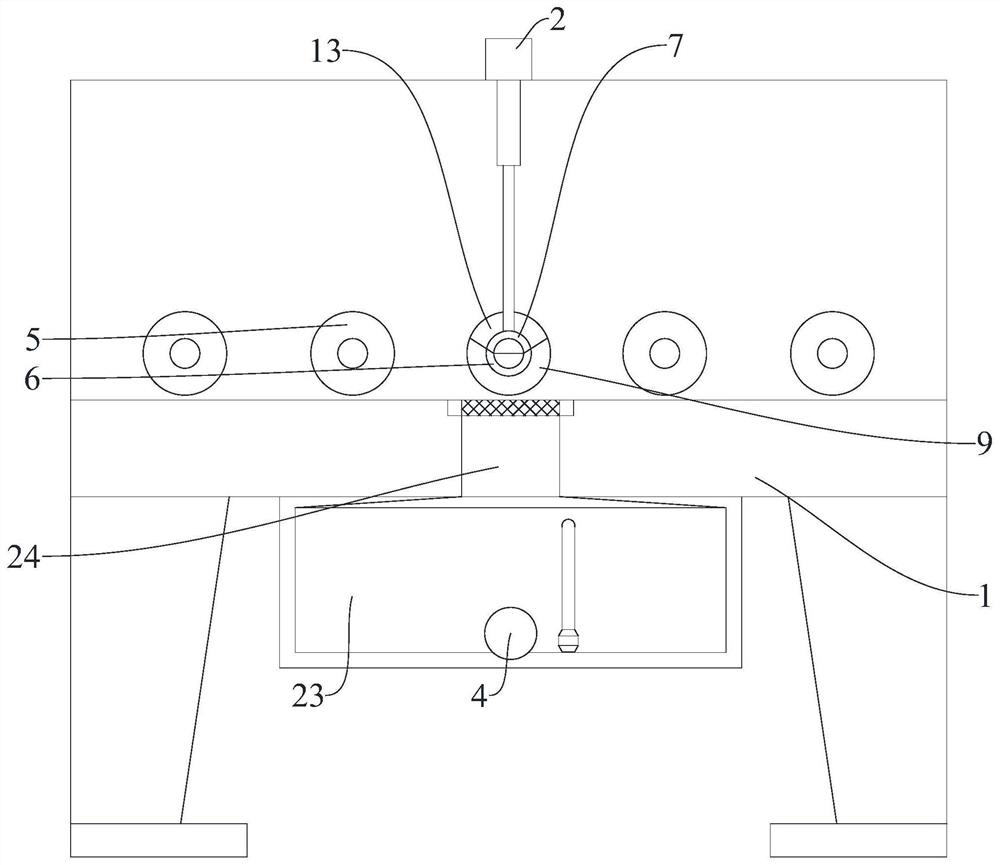

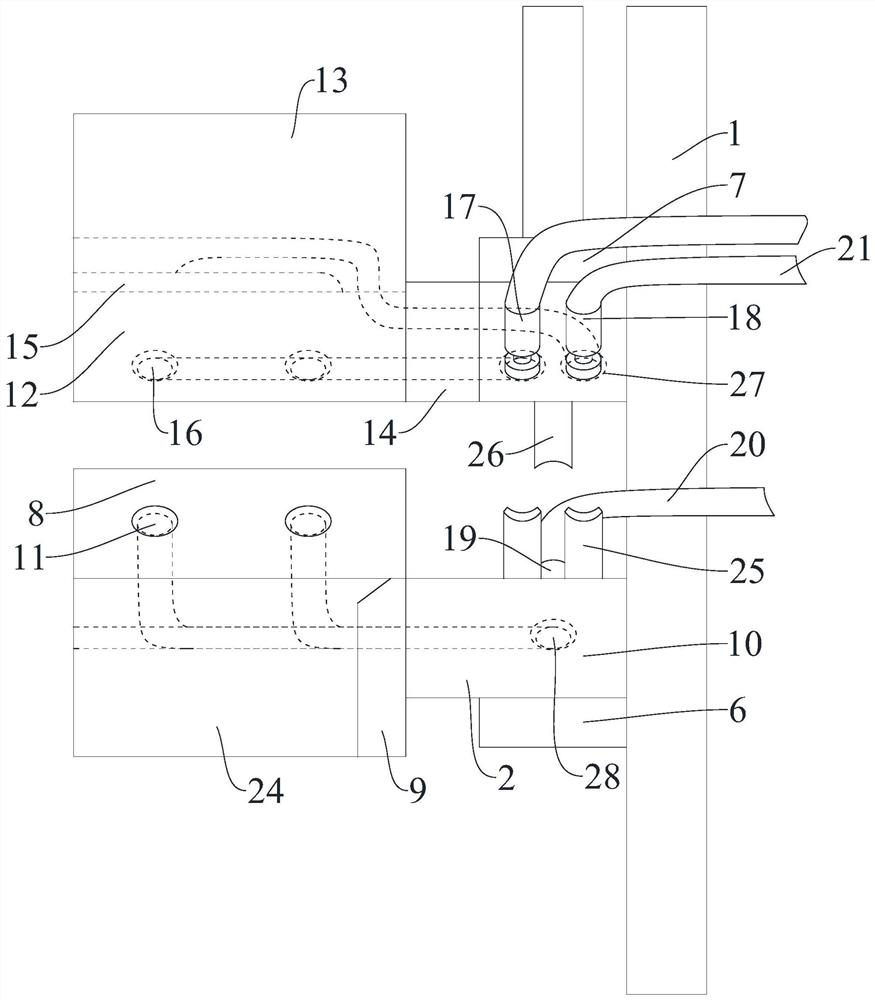

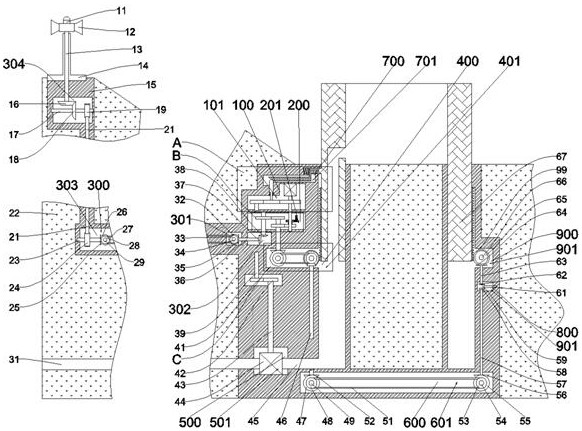

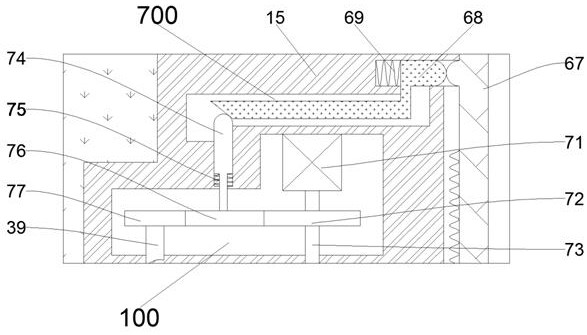

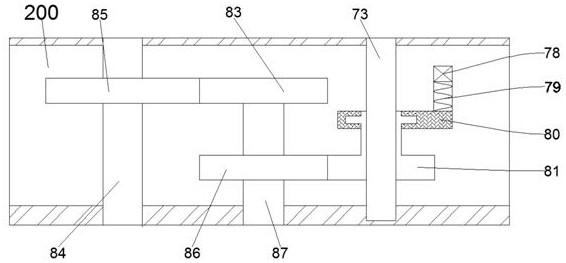

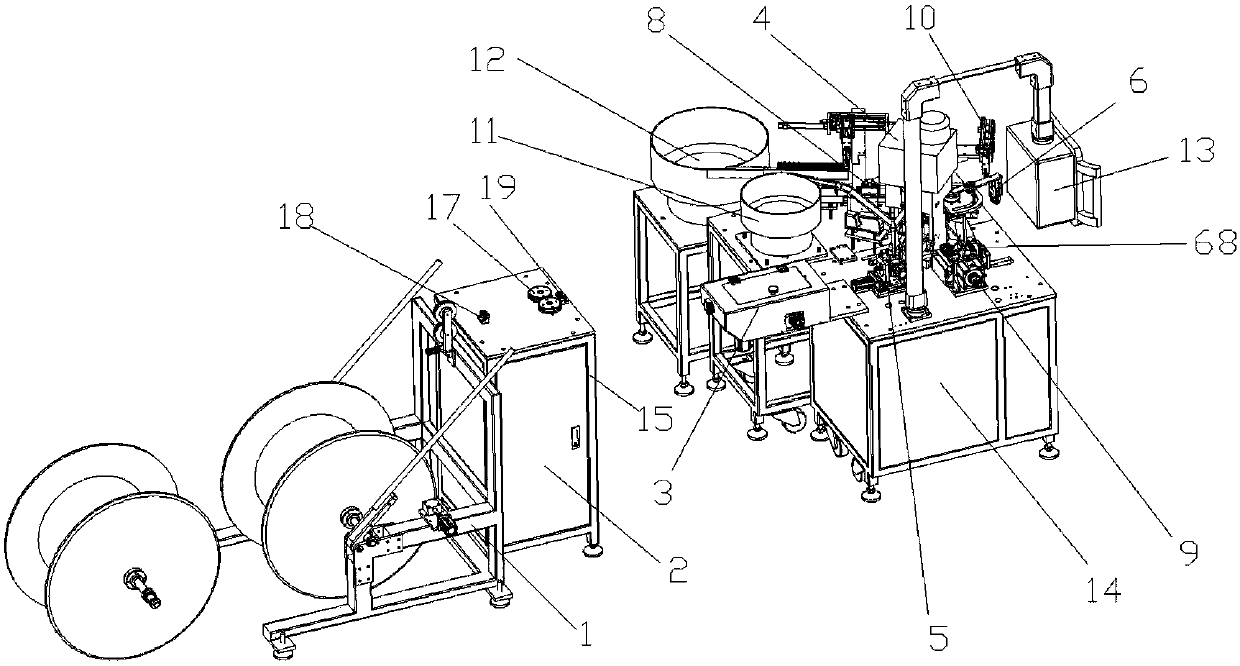

The invention discloses a peeling, shearing, riveting and twisting integrated machine. The peeling, shearing, riveting and twisting integrated machine comprises a wire feeding mechanism, a rotating mechanism, a terminal mechanism, a guiding-in mechanism, a feeding and taking mechanism, a cap twisting mechanism, a cutting and peeling mechanism, a wire taking mechanism, a terminal vibrating plate, a connector vibrating plate, a main air valve, a PLC and a touch screen as well as a pay-off rack, an auxiliary mechanism and a connector vibrating plate which are arranged outside the frame. The auxiliary mechanism, the wire feeding mechanism, the terminal mechanism, the terminal vibrating plate, the rotating mechanism, the guiding-in mechanism, the feeding and taking mechanism, the cap twisting mechanism, the connector vibrating plate, the cutting and peeling mechanism, the wire taking mechanism, the main air valve and the touch screen are respectively connected with the PLC electrically. After the scheme is adopted, the original scattered stations are integrated on equipment for processing and treating, production cost is reduced, and space utilization rate of the workshop is increased. The equipment is relatively high in degree of intelligence and convenient to operate.

Owner:支友光

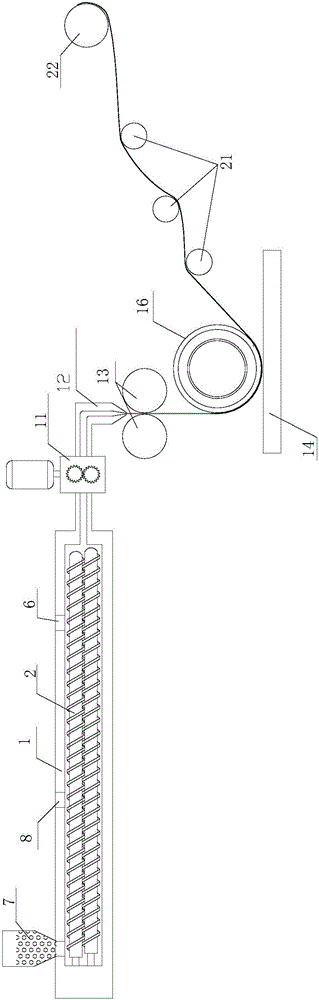

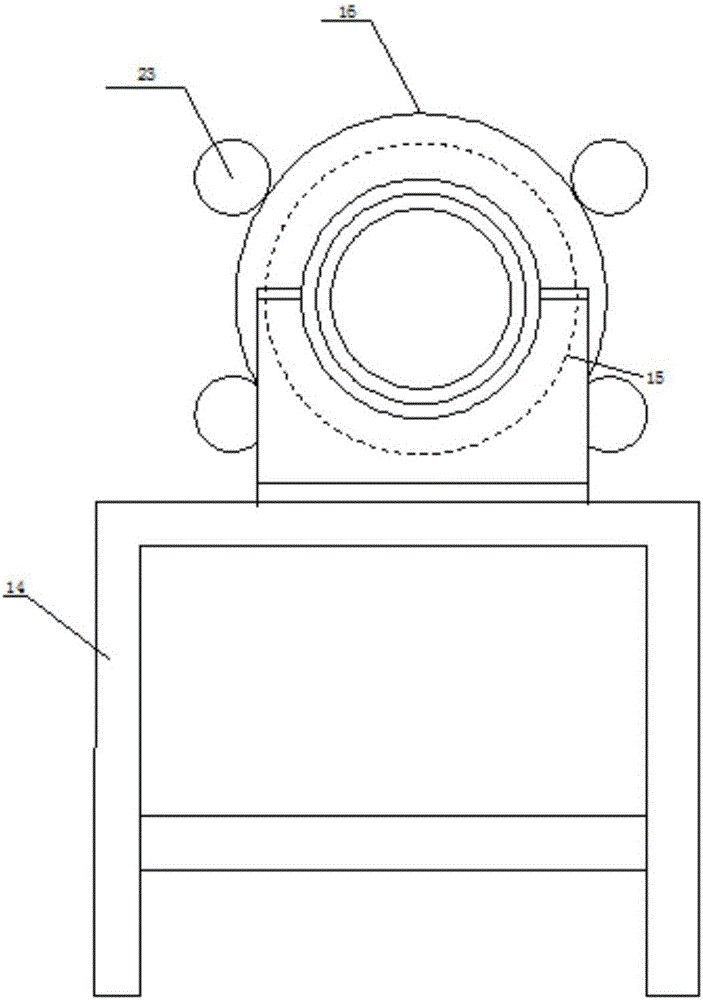

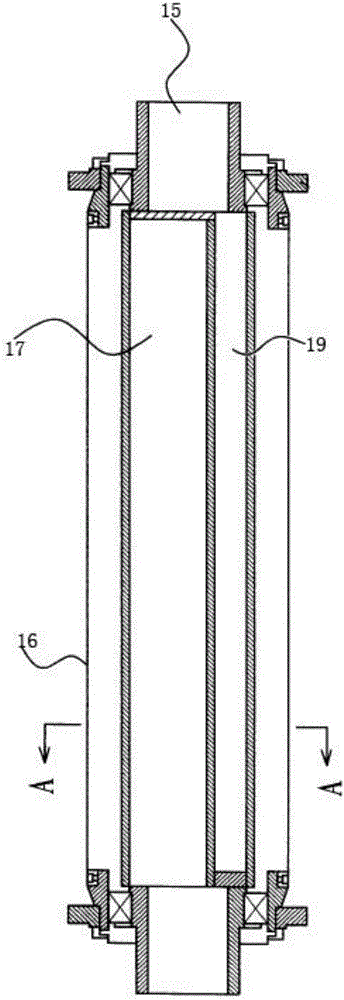

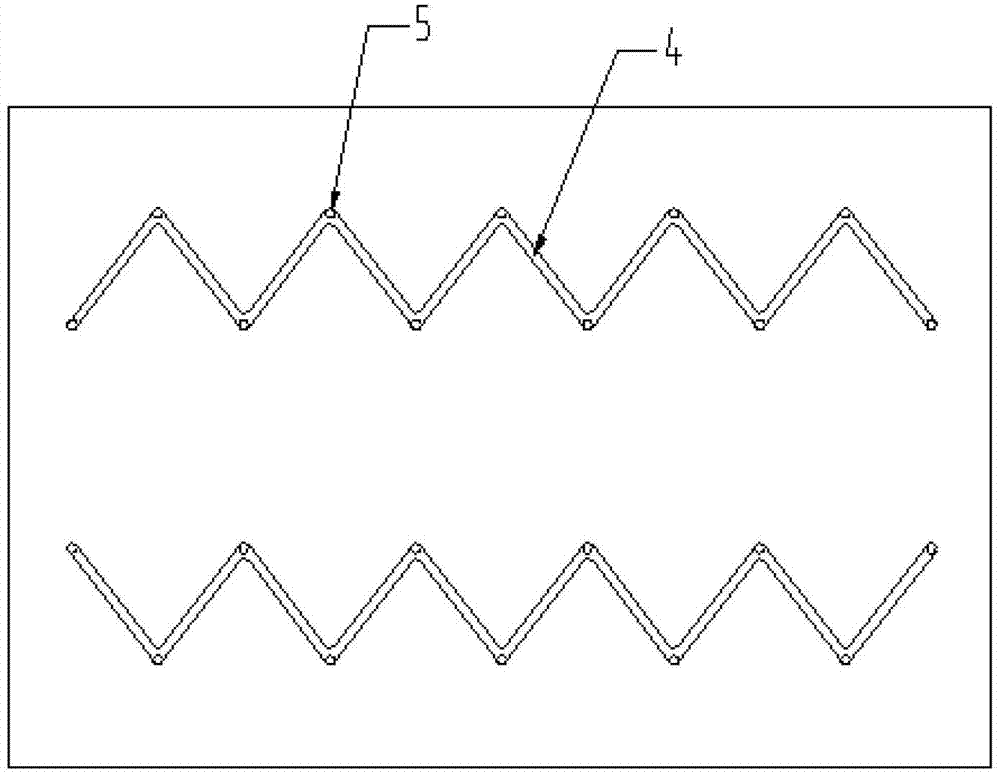

Perforated film capable of being biodegraded completely and preparation process, application and preparation device thereof

InactiveCN105860149AHas antibacterial propertiesSimple preparation processAbsorbent padsFlat articlesMaterials preparationPolyresin

The invention relates to a perforated film capable of being biodegraded completely and a preparation process, application and preparation device thereof. The perforated film capable of being biodegraded completely is prepared from, by weight, 95-100 parts of plant modified starch, 100-150 parts of biodegradable resin, 2-3 parts of zirconium phosphate silver-loaded antimicrobial powder, 0.5-20 parts of pasting agent, 0.3-10 parts of compatibilizer and 0.2-10 parts of dispersant. The preparation device of the perforated film comprises a low-speed mixing machine for raw material mixing, and a film extrusion molding device, a film perforating device and a winding device which are sequentially arranged. The film extrusion molding device comprises a screw extruder, a melt pump and a T-shaped die head which are sequentially connected and communicated. The preparation process of the perforated film comprises material preparation and pressed film molding processes. The prepared perforated film has an antimicrobial effect and can be biodegraded completely, and the preparation efficiency of the perforated film is improved through the preparation device.

Owner:SUZHOU HANFENG NEW MATERIAL +1

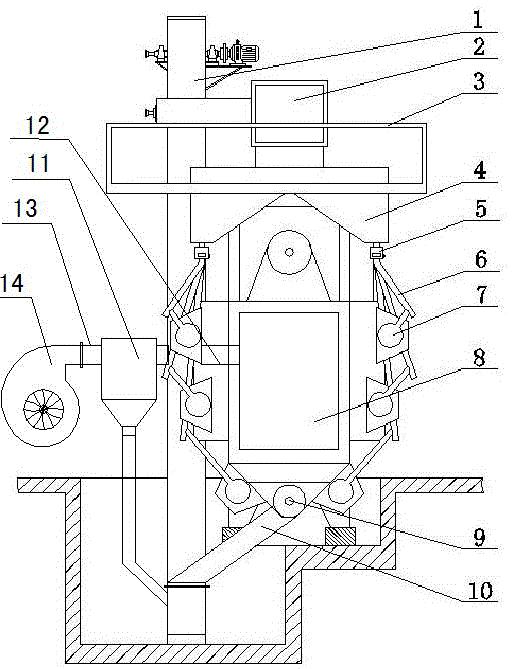

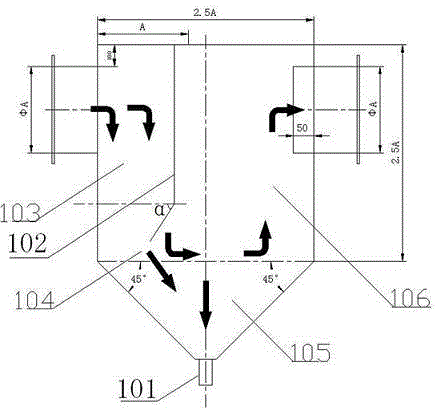

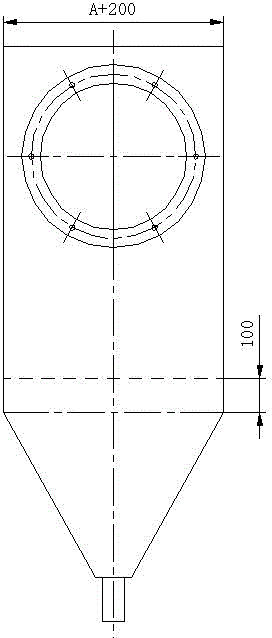

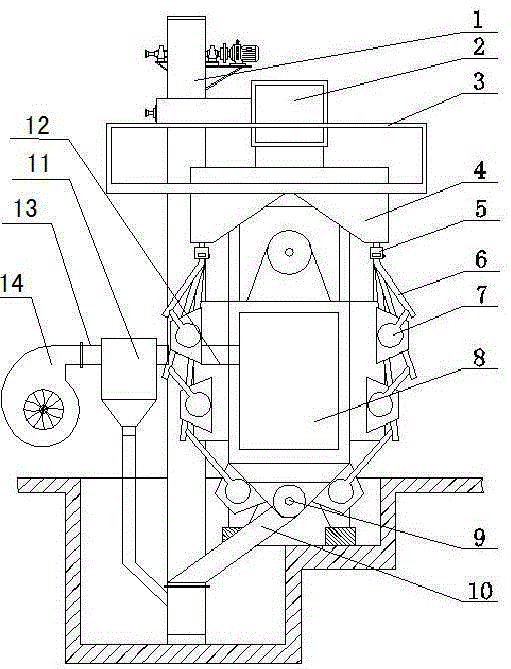

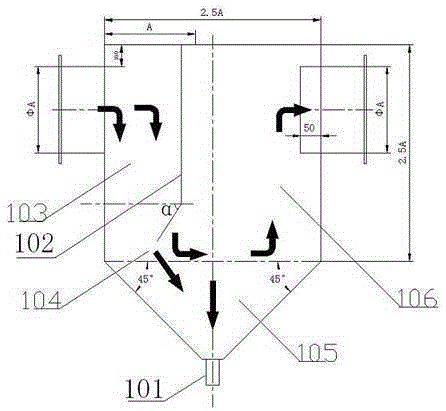

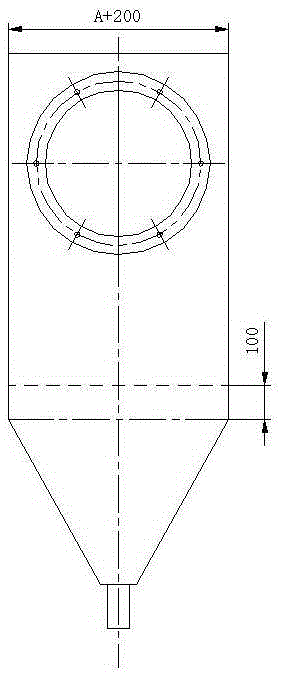

Environment-friendly shot-blasting cleaning machine having dust pre-separation function and using method thereof

ActiveCN103949980AAvoid damageEase of workAbrasive machine appurtenancesAbrasive blasting machinesProcess engineeringScrew conveyor

The invention discloses an environment-friendly shot-blasting cleaning machine having a dust pre-separation function. The environment-friendly shot-blasting cleaning machine comprises a lifting machine, a separator, a working platform, a sand feeding bucket, a shot supply valve, a sand dropping pipe, a shot-blasting machine, a shot-blasting cleaning chamber, a screw conveyor and a shot sliding slot, and also comprises an exhaust fan and a shot accumulating device which is connected with the shot-blasting cleaning chamber in a communication mode; fine dust in the shot-blasting cleaning chamber is pumped away by the exhaust fan, and at the same time, steel shots, steel sand and large-particle dust are pre-separated by the shot accumulating device. The invention also designs a using method of the environment-friendly shot-blasting cleaning machine having the dust pre-separation function. The designed environment-friendly shot-blasting cleaning machine having the dust pre-separation function and the designed using method thereof can pre-separate the fine dust, prevent increasing of the dust concentration from damaging the performance of a shot circulation system and a shot-sand separator, and can reutilize resources while improving the working efficiency.

Owner:江苏飞腾铸造机械有限公司

Shockproof cyclical pulper

The invention discloses a shockproof cyclical pulper which comprises a housing. A rotary shaft and a spiral blade are fixedly installed inside the housing, the bottom end of the rotary shaft extends out of the outer wall of the housing and is movably connected with a motor rotor, a feeding port is formed in the top of the housing, a discharging port is formed in the bottom of the housing, a screening plate is fixedly installed at the bottom of the discharging port, a water leaking tank is fixedly installed at the bottom of the housing and is fixedly connected with a water tank through a water outlet pipe and a first water pump, the water tank is fixedly connected with the feeding port of the housing through a water inlet pipe and a second water pump, the housing is fixed to the ground through supporting legs fixedly installed on two sides of the bottom of the housing, and shockproof screws are fixedly installed at the bottoms of the supporting legs. The shockproof cyclical pulper is provided with the water pumps and the water outlet pipe and can rapidly pump pulp in the housing and store the pulp in the water tank, the installed water inlet pipe can form a cyclical pulping system with the water outlet pipe, the first water pump, the second water pump and the water tank, and the installed shockproof screws can be absorb shock.

Owner:WUXI KING MO MACHINERY

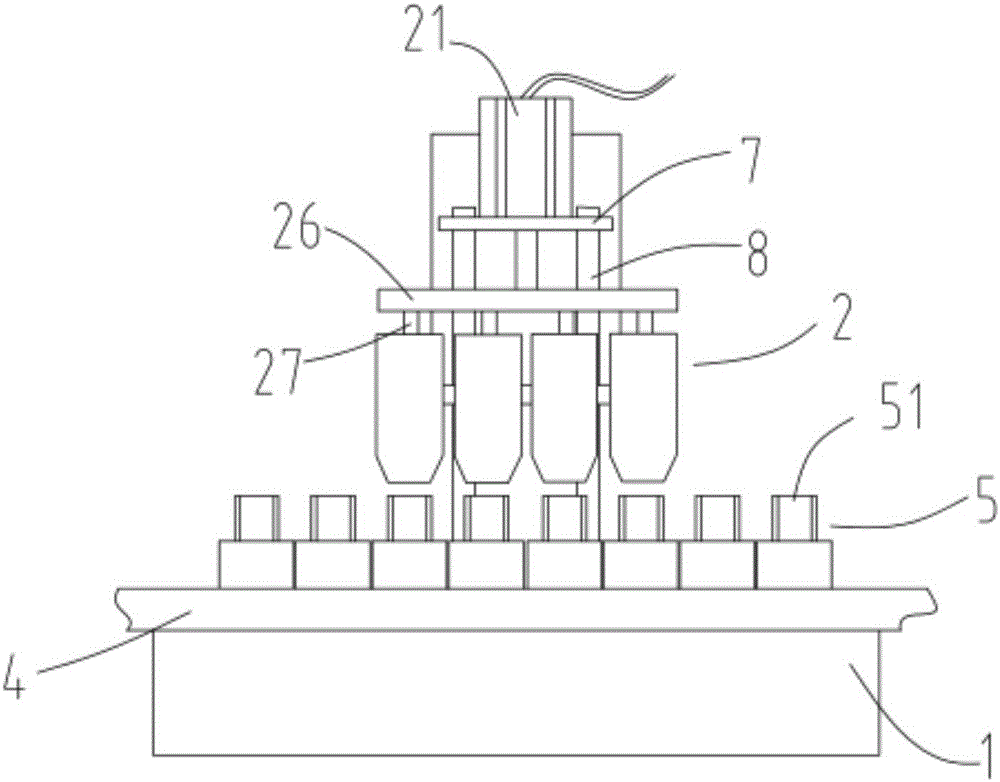

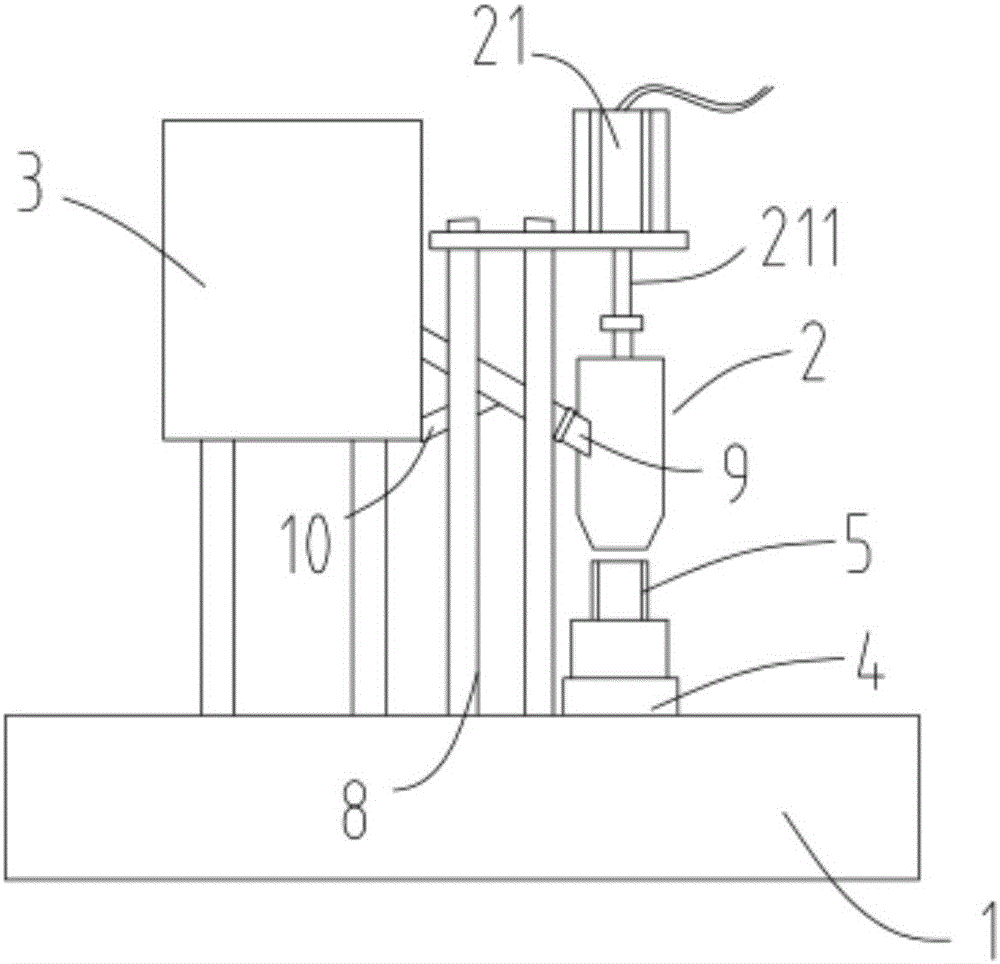

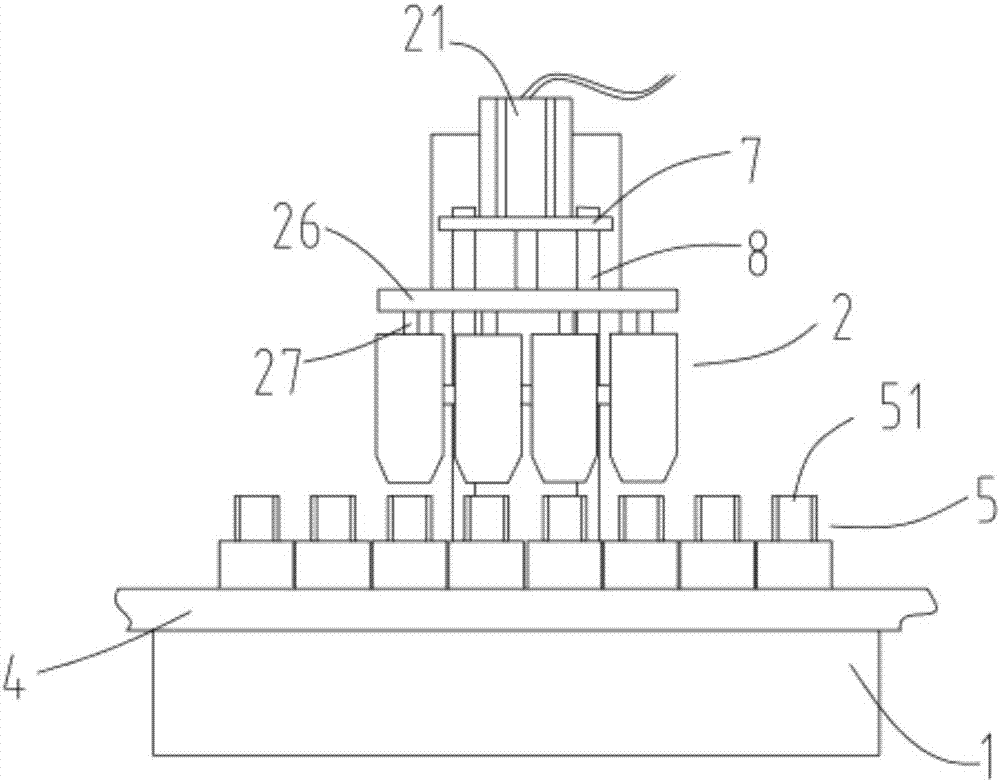

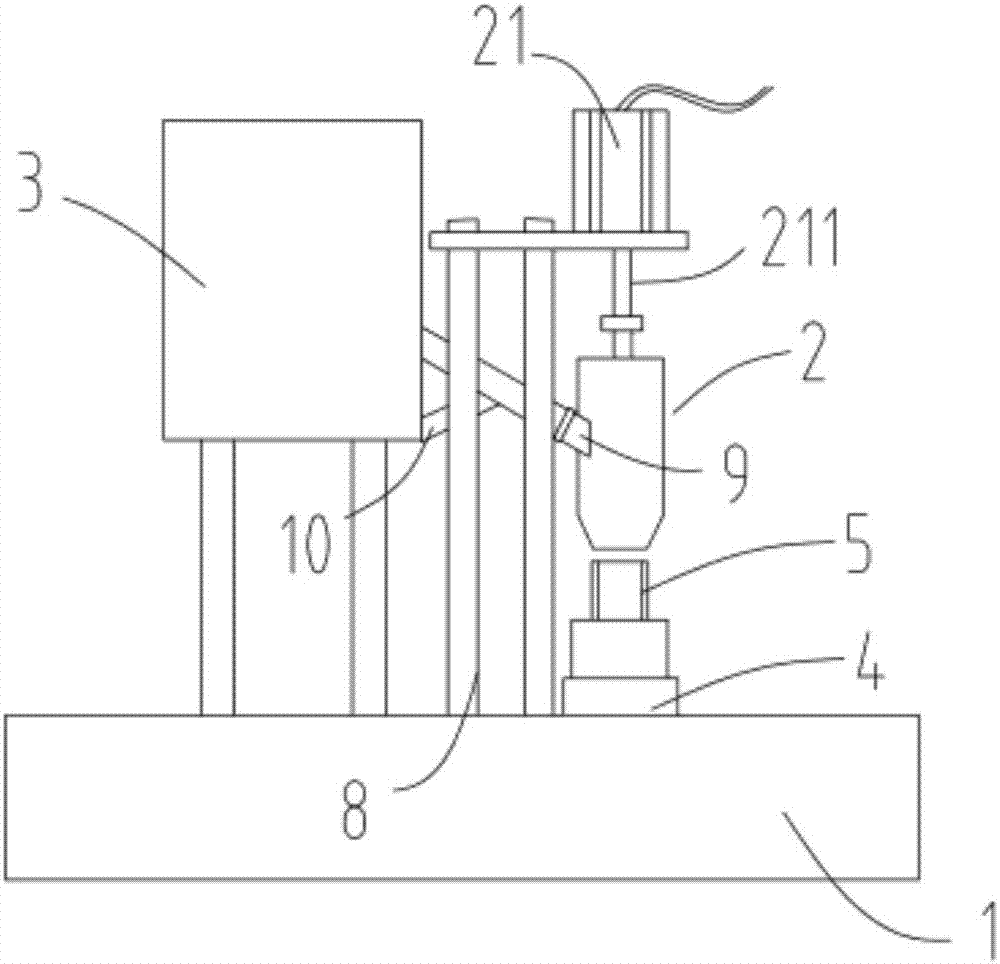

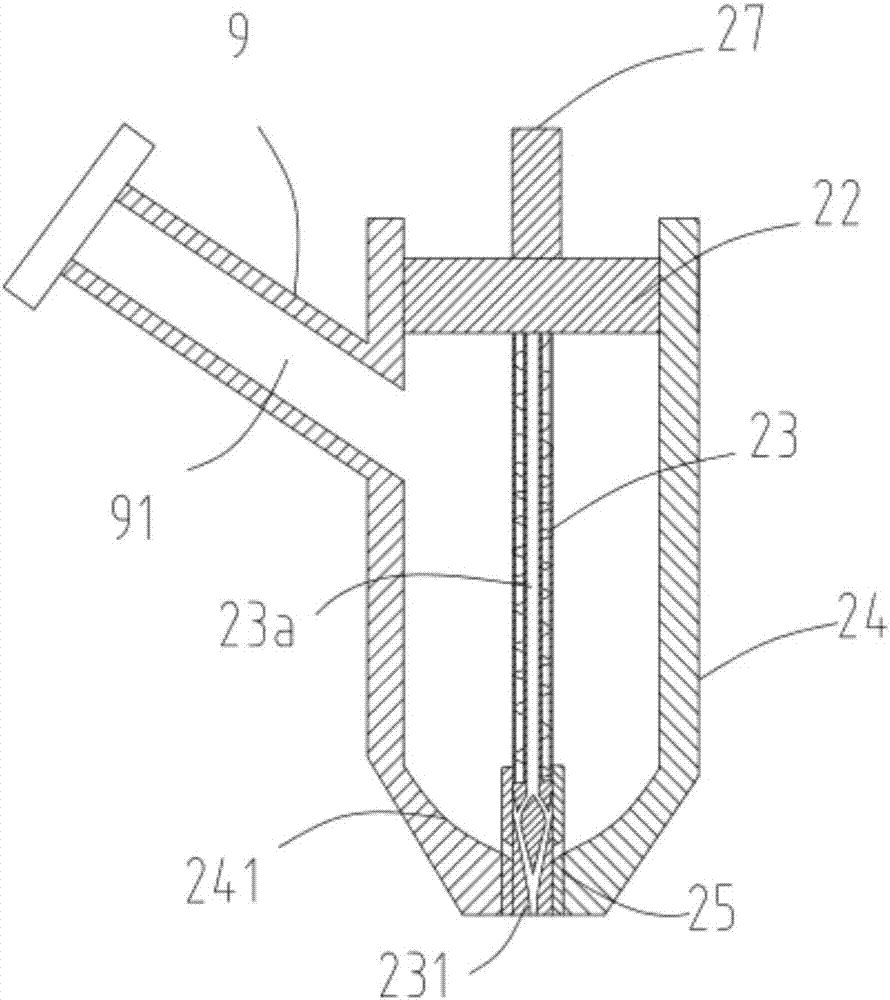

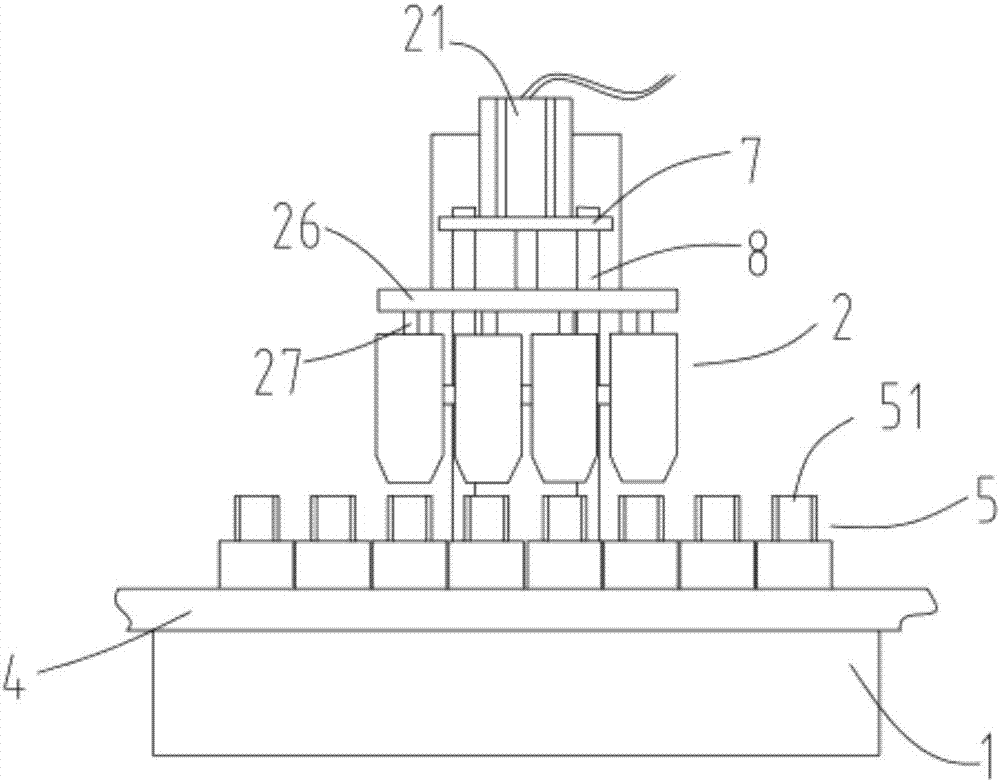

Equipment for uniformly injecting glue into battery

ActiveCN105789649AAvoid drippingReduce length of stayPrimary cell manufactureCell sealing materialsInjectorEngineering

The invention relates to equipment for uniformly injecting glue into a battery. The equipment comprises a bearing platform, a plurality of glue injecting components, a tank and an incoming material component, wherein the plurality of glue injecting components are arranged in parallel at equal intervals; the tank is used for storing glue; the incoming material component carries a plurality of battery steel shells; the glue injecting components vertically correspond to glue injecting openings of the battery steel shells; each of the glue injecting components comprise a power part, a pressing plate, a discharge rod, a glue injecting bucket and a material guide column; the pressing plates are arranged on top rods of the power parts; the discharge rods are arranged on the pressing plates; the material guide columns are arranged at the end parts of the discharge rods in a sleeving manner; the discharge rods can slide upwards and downwards relative to the inner walls of the material guide columns; the material guide columns are fixed on the glue injecting buckets; a semicircular material guide hole is formed in the end part of each discharge rod; a discharge hole is formed in each material guide column. By adopting the equipment, the problems that in the battery glue injecting process, the sealing property of a battery can be affected as the flowability is poorer as glue can be relatively greatly affected by the external environment, the glue injecting process is slow, the glue cannot be uniformly injected and distributed, and an injector can be easily blocked, are overcome.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

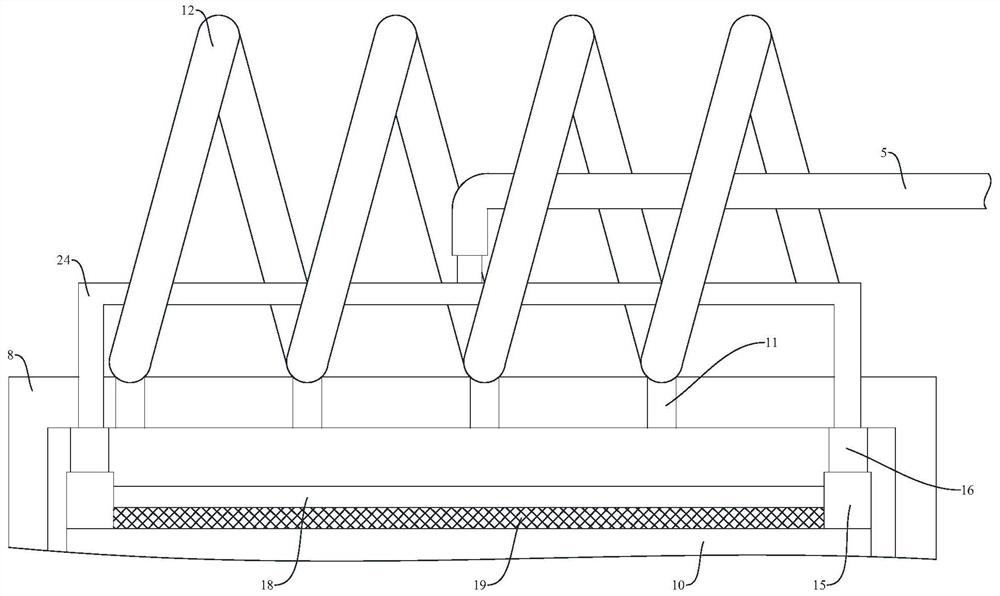

UV curing device with large irradiation range

ActiveCN113894026AImprove the irradiation strokeImprove curing effectPretreated surfacesCoatingsUV curingEngineering

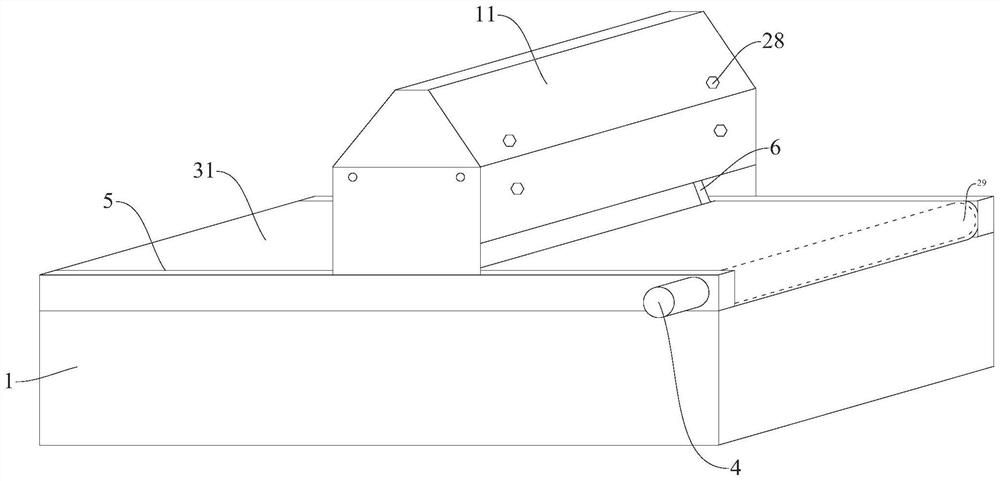

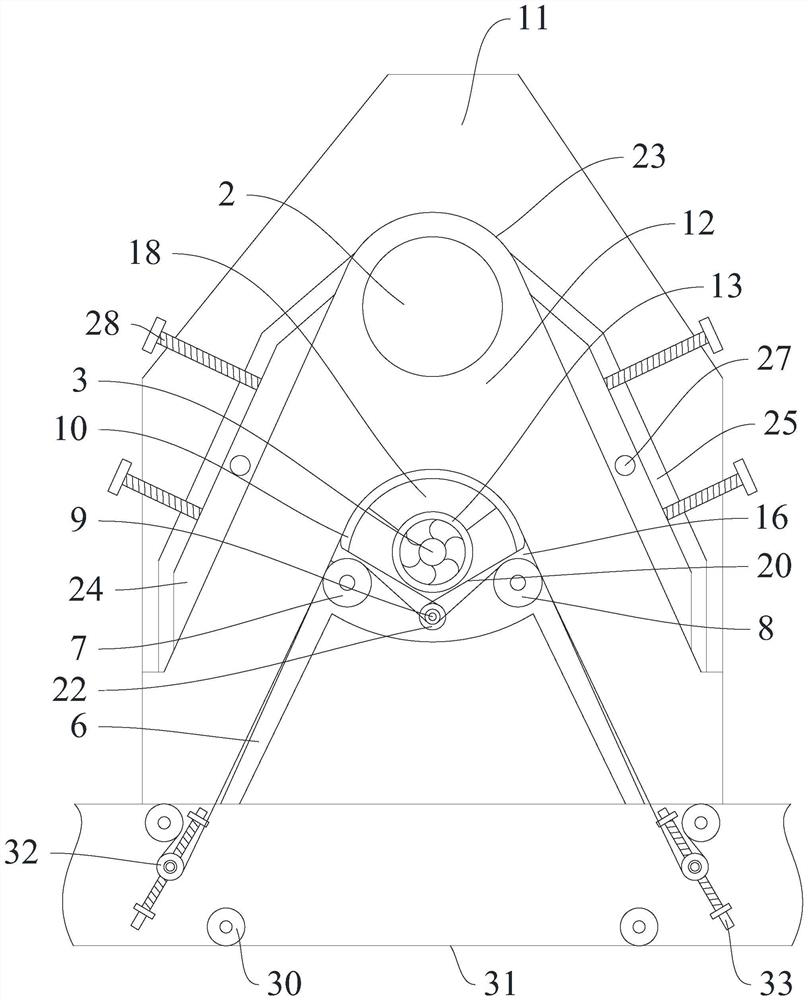

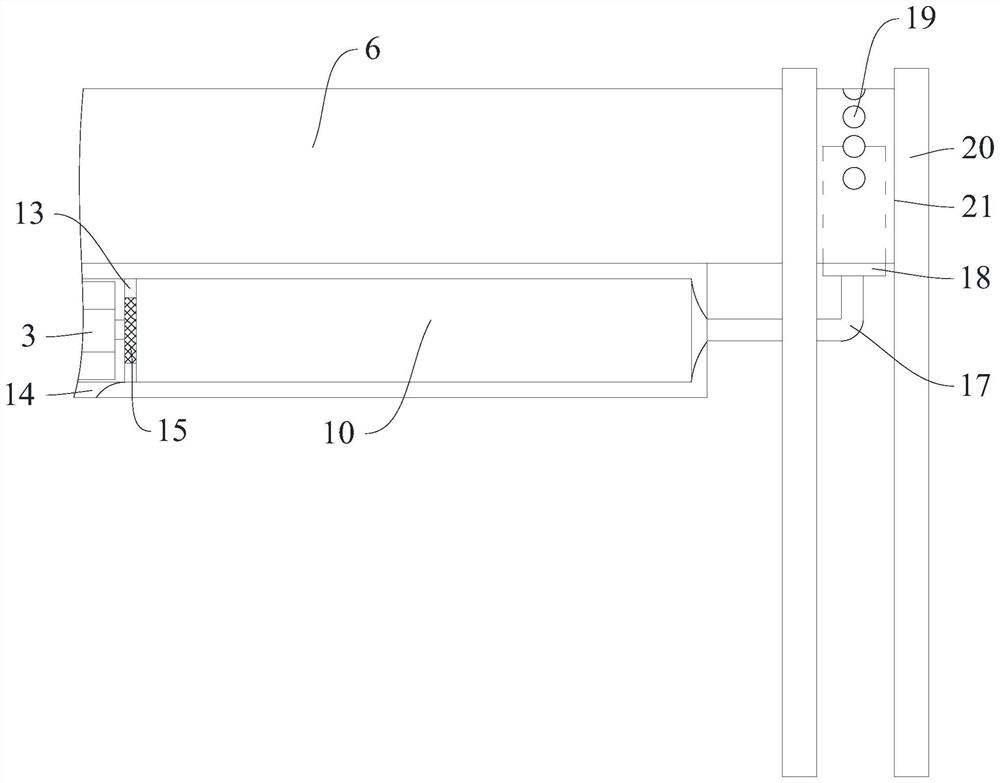

The invention relates to the technical field of UV curing equipment, and particularly relates to a UV curing device with a large irradiation range. The UV curing device comprises a main rack, UV curing lamps, a centrifugal fan and a driving motor. According to the UV curing device with the large irradiation range, the inverted V-shaped structural design is adopted in the UV irradiation section, through the direct irradiation and reflection phase structure, the irradiation stroke is greatly increased under the condition that the number of the UV curing lamps is not changed, and the curing effect is improved; heat generated by the irradiation section can be rapidly pumped away, and the stability and durability of the equipment are improved; the irradiation range of the UV curing device is adjustable, and the application range is wider; and an elastic lateral tensioning roller is installed between a guide roller laterally arranged on the inner side face of the main rack and an inner supporting roller, the attaching performance and tensioning degree of a belt conveying mechanism and the surface of a middle guide support can be improved, and the conveying stability is guaranteed.

Owner:JIANGSU GULIDE PRECISION PHOTOELECTRIC

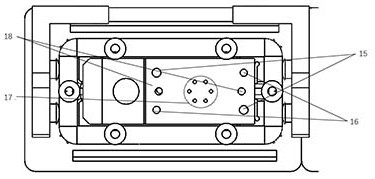

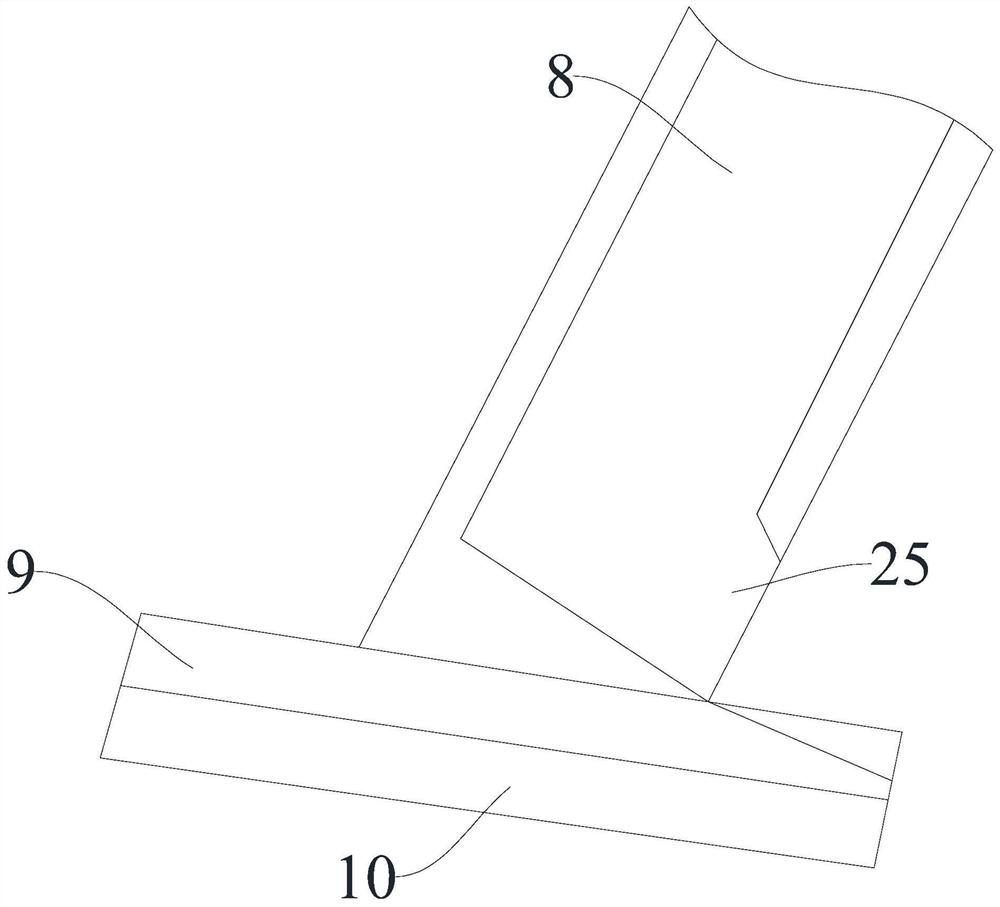

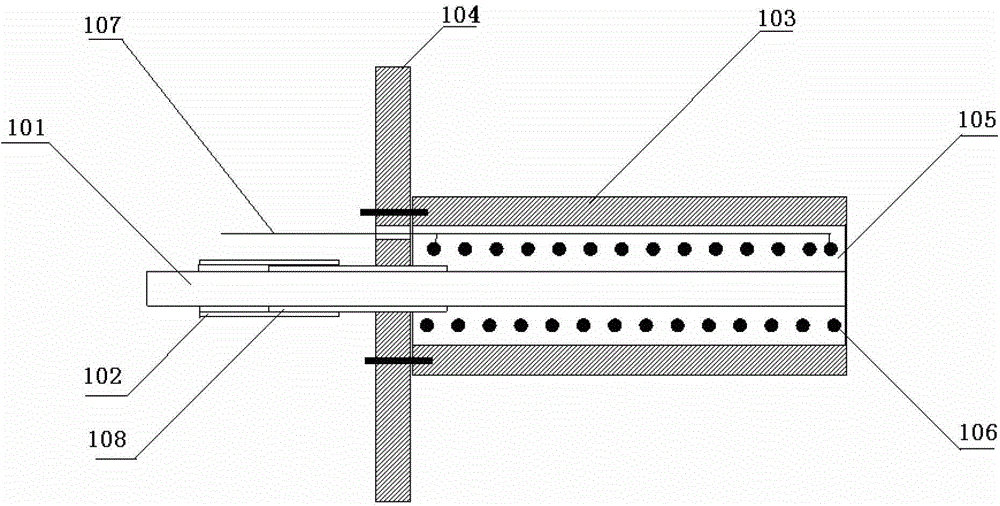

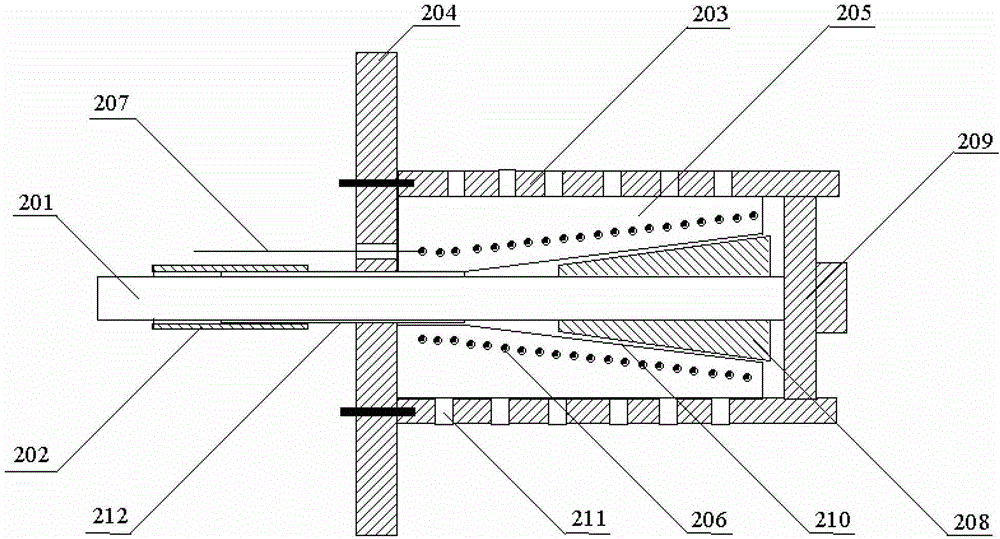

High-speed forming mold for plastic steel winding pipe

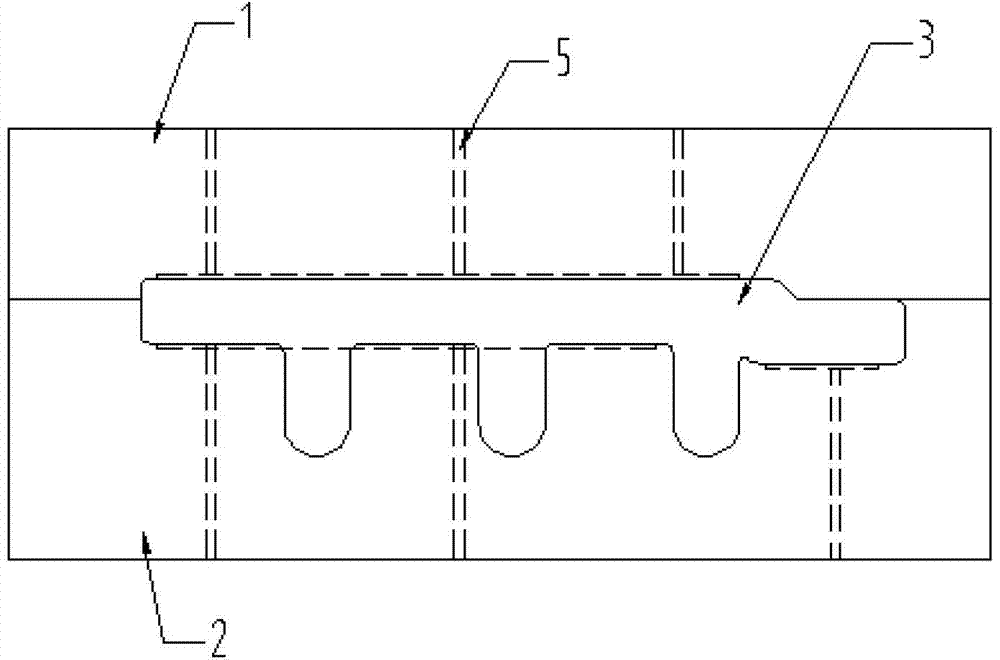

The invention discloses a high-speed forming mold for a plastic steel winding pipe. The high-speed forming mold for the plastic steel winding pipe comprises an upper mold and a lower mold; a mold cavity for shaping a sectional material for a plastic steel winding pipe is formed between the upper mold and the lower mold; the contact surfaces of the upper mold and the lower mold are respectively provided with cooling water baths; additionally, the upper mold and the lower mold are internally provided with vacuumizing holes communicated with the cooling water baths. According to the high-speed forming mold for the plastic steel winding pipe, the high-speed forming mold is internally provided with the cooling water baths and the vacuumizing holes communicated with the cooling water baths, water in the cooling water baths is pumped away rapidly, and the flowing circulation of the cooling water is accelerated, thereby achieving the best cooling effect; and the high-speed forming mold for a plastic steel winding pipe not only is good for shaping the sectional material, but also improves the stability of the sectional material, guarantees the quality of the sectional material, and establishes a good foundation for the production of the winding pipe.

Owner:昆山通塑机械制造有限公司

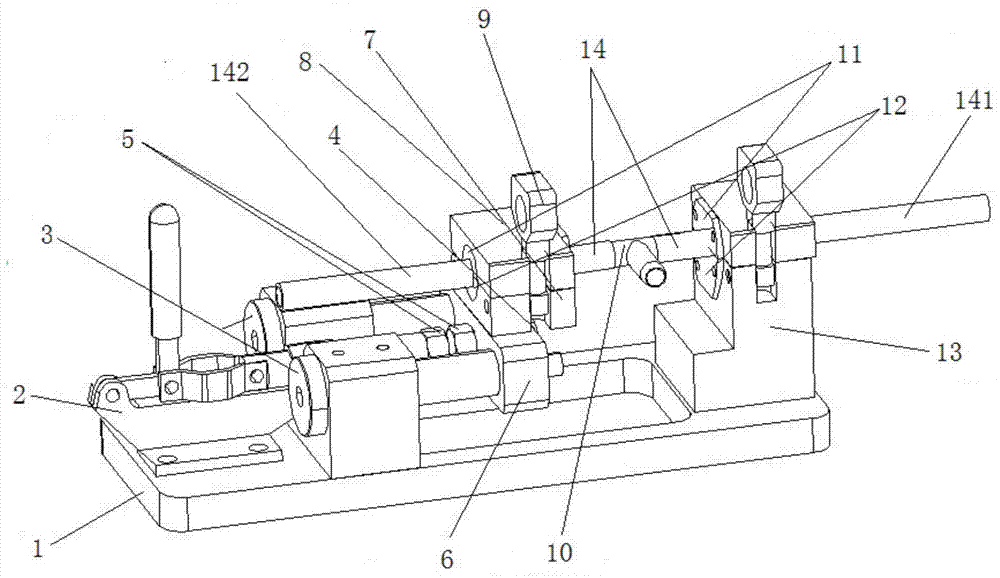

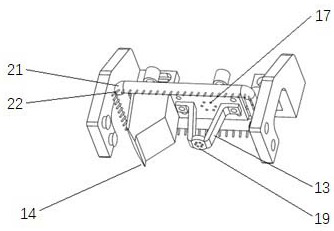

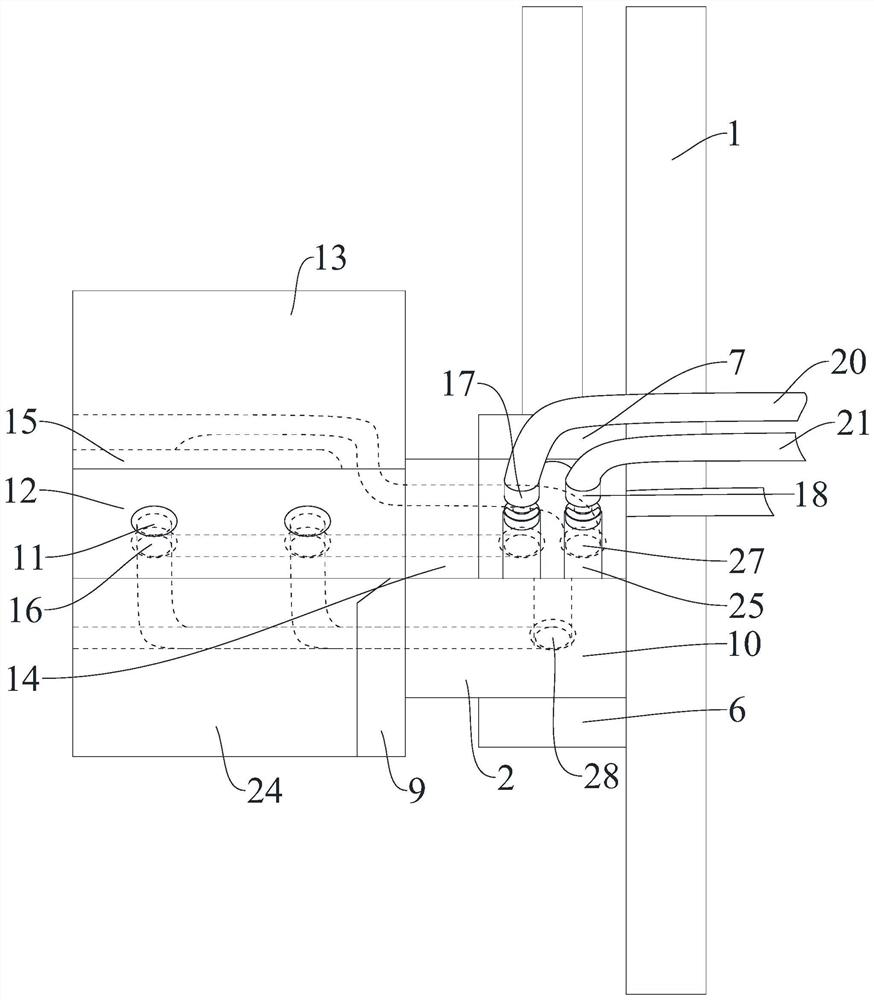

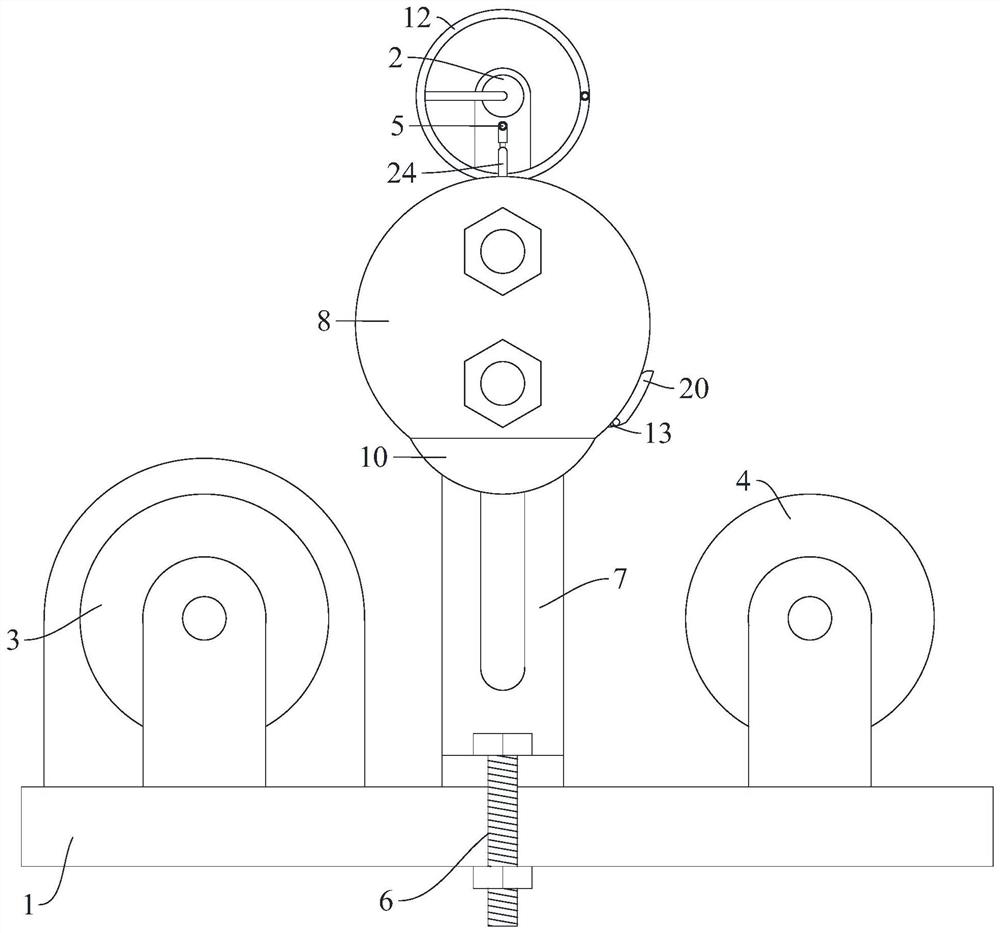

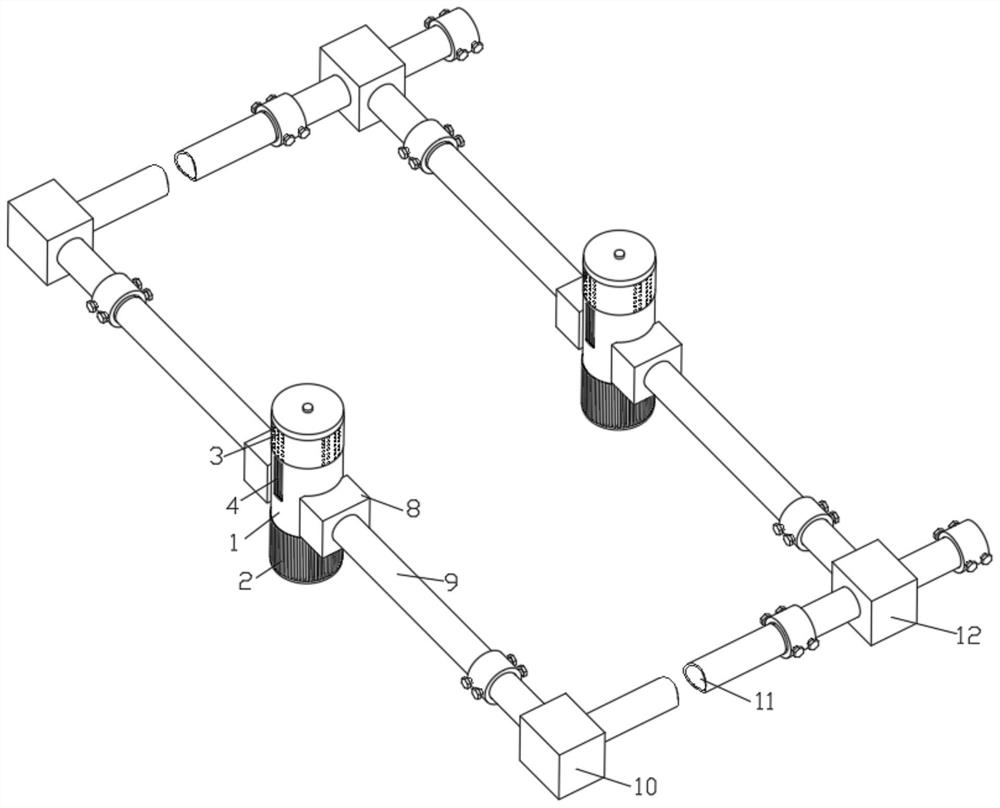

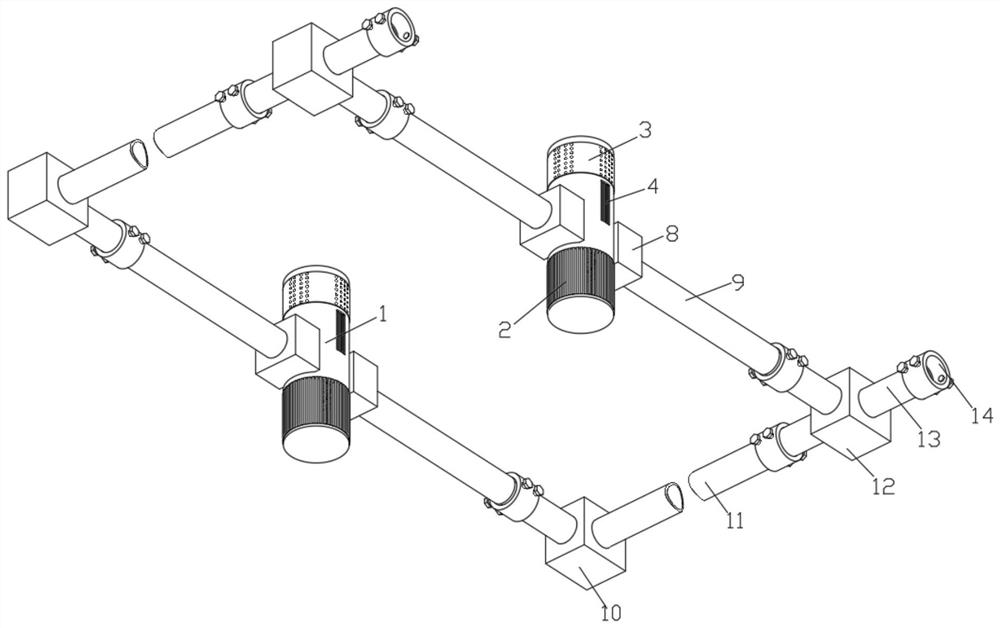

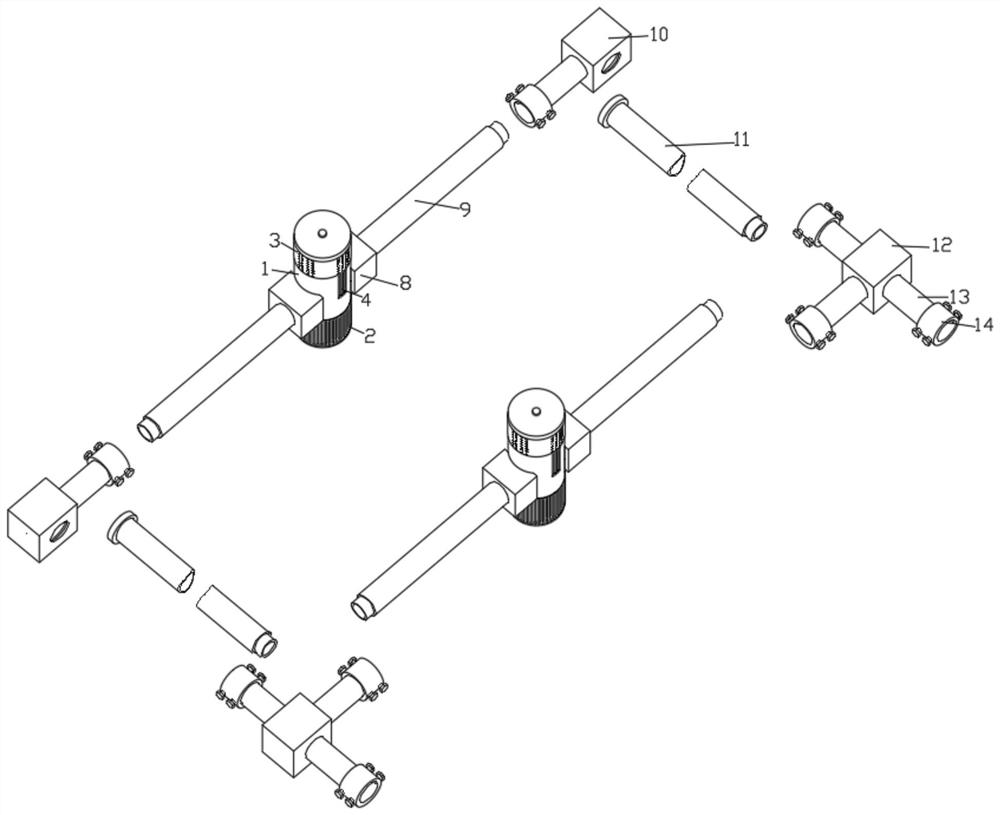

Tool for fast installing and tightly pressing tee joint of truck braking pipeline

The invention discloses a tool for fast installing and tightly pressing a tee joint of a truck braking pipeline. The tool for fast installing and tightly pressing the tee joint of the truck braking pipeline is characterized in that a clamp is fixed at the left end of a base through bolts, protruded blocks are arranged on the portion, at the right side of the clamp, of the base, two horizontally arranged sliding rails are fixed on the protruded blocks, the sliding rails are sleeved with a sliding block, the sliding block is fixedly connected with the connecting rod of the clamp through nuts, a lower die fixing block and a fixing block are fixed above the sliding block and at the right end of the base respectively, the lower die fixing block and one end of the upper portion of the fixing block are both hinged to an upper die fixing block through a horizontal shaft pin, the other ends of the upper die fixing blocks are connected with the lower die fixing block and the fixing block through hand spiral screws respectively, joint fixed upper dies and joint fixed lower dies are arranged between the upper die fixing block and the lower die fixing block and the upper die fixing block and the fixing block respectively, horizontal air pipes are arranged between the joint fixed upper dies and the joint fixed lower dies in a sleeved mode respectively, and the air pipes are connected with each other through the tee joint. According to the tool for fast installing and tightly pressing the tee joint of the truck braking pipeline, the structure and the design are simple, the air pipe upper die fixing blocks can turn over, the air pipes can be pulled away fast, installation and tight pressing are achieved through the clamp, fast installation is achieved, and the work efficiency is greatly improved.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Sliding type semi-closed cleaning device and cleaning method

PendingCN112958577AAchieve absolute fixationAvoid pollutionDrying gas arrangementsDirt cleaningWorking environmentEnvironmental engineering

The invention relates to the technical field of cleaning devices, and particularly relates to a sliding type semi-closed cleaning device and a cleaning method. The device comprises a cleaning mechanism, a protection mechanism and a support mechanism, the protection mechanism is arranged in the circumferential direction of the cleaning mechanism, a circumferential air pipe is arranged at the inner side of the protection mechanism, the air-outlet direction of the circumferential air pipe obliquely points to the protection mechanism from top to bottom, the support mechanism is provided with a support position, the bottom of the support position is provided with an inclined liquid drainage surface, and the bottom of the liquid drainage surface is provided with a liquid drainage hole. Compared with the prior art, the cleaning device is advantageous in that to-be-cleaned objects on the stations can be cleaned, and functions of air showering and air drying can be achieved; the support mechanism has the function of automatically adsorbing the to-be-cleaned objects, and absolute fixing of the to-be-cleaned objects can be achieved; cleaning liquid can be prevented from polluting other stations and equipment; rapid recovery of waste liquid can be realized, the waste liquid can be rapidly extracted, and accumulation is prevented; and residual gas can be pumped away, the influence on the external environment is reduced, and waste liquid steam is prevented from polluting the working environment.

Owner:上海睿度光电科技有限公司

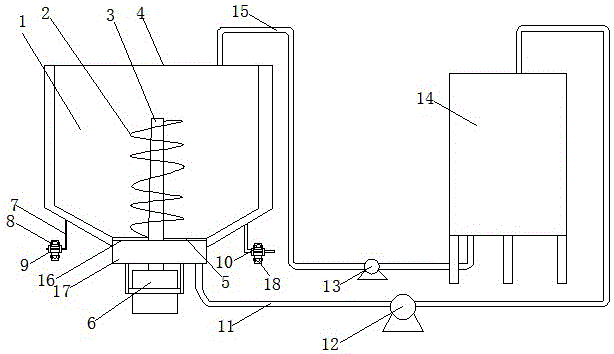

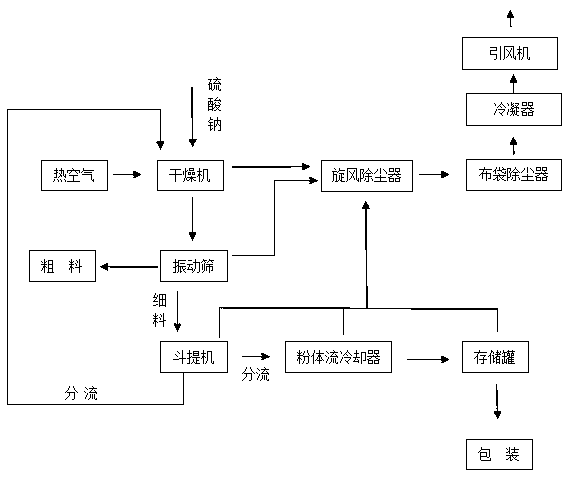

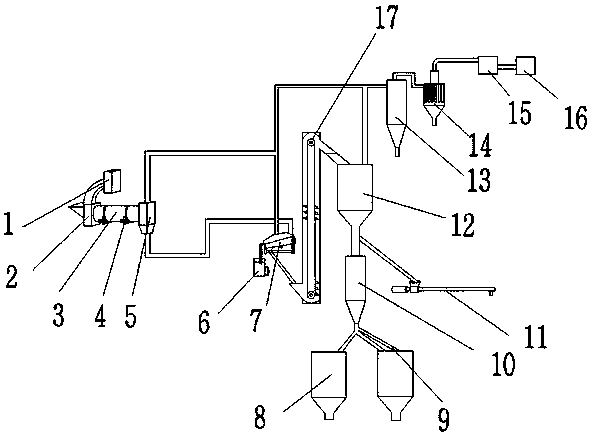

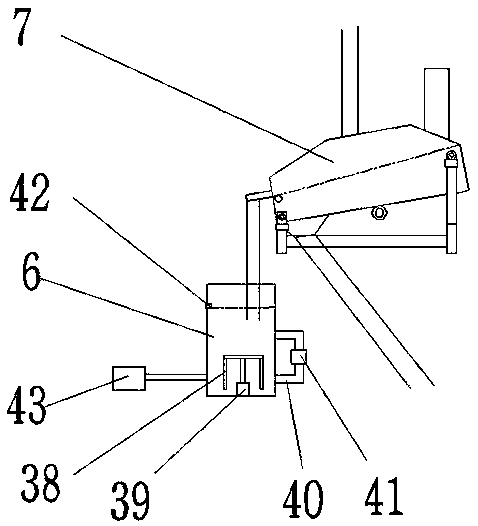

Industrial salt drying system and method

PendingCN111520975AKeep dryReduce risk of cakingCombination devicesSievingWater vaporProcess engineering

The invention provides an industrial salt drying system and method. The industrial salt drying system comprises a drying system, a screening and separating system and a dust removal system. The dryingsystem comprises a drying machine. The discharging end of the drying machine is connected with a vibrating screen of the screening and separating system. The vibrating screen is provided with a dustremoval opening. The dust removal opening is connected with the dust removal system. The vibrating screen is further provided with a fine material outlet and a coarse material outlet. The coarse material outlet is connected with a blocking barrel through a pipeline. According to the industrial salt drying system and method disclosed by the scheme, the drying effect is effectively improved, and meanwhile pollution of dust generated in the material drying and separating process to the environment is reduced; materials are preheated in advance before being dried, the material drying effect and efficiency are effectively improved, and large-batch production is facilitated; and the dust removal system effectively provides a negative pressure state in the drying and separating process, dust andwater vapor can be rapidly pumped away, condensation of the water vapor is reduced, the situation that condensation water influences the product quality is avoided, and the production efficiency is effectively improved.

Owner:HUNAN XIANGHENG SALT CHEM

Filter settling apparatus convenient to clean for medicine production

The invention discloses a filter settling apparatus convenient to clean for medicine production. The filter settling apparatus includes a support base. A filter shell is connected to the top outer wall of the support base through bolts. A limit block is connected to the circumferential inner wall of the filter shell through bolts. A filter screen plate is placed on the top outer wall of the limitblock. The circumferential inner wall of the filter shell is provided with a mounting groove. A positioning block is inserted into the inner wall of the mounting groove. The positioning block is located directly above the filter screen plate. Vertically placed supporting columns are connected to the outer walls of the four bottom corners of the support base through bolts. The same horizontally placed supporting frame is connected to the outer walls of the opposite sides of the supporting columns on one side. The filter settling apparatus convenient to clean for medicine production is providedwith the filter screen plate, which can filter medicine liquid. The filter settling apparatus convenient to clean for medicine production is provided with the limit block and the positioning block, and so the filter screen plate can be quickly and conveniently removed and cleaned, the mounting by the staff is convenient, and the working efficiency is improved.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

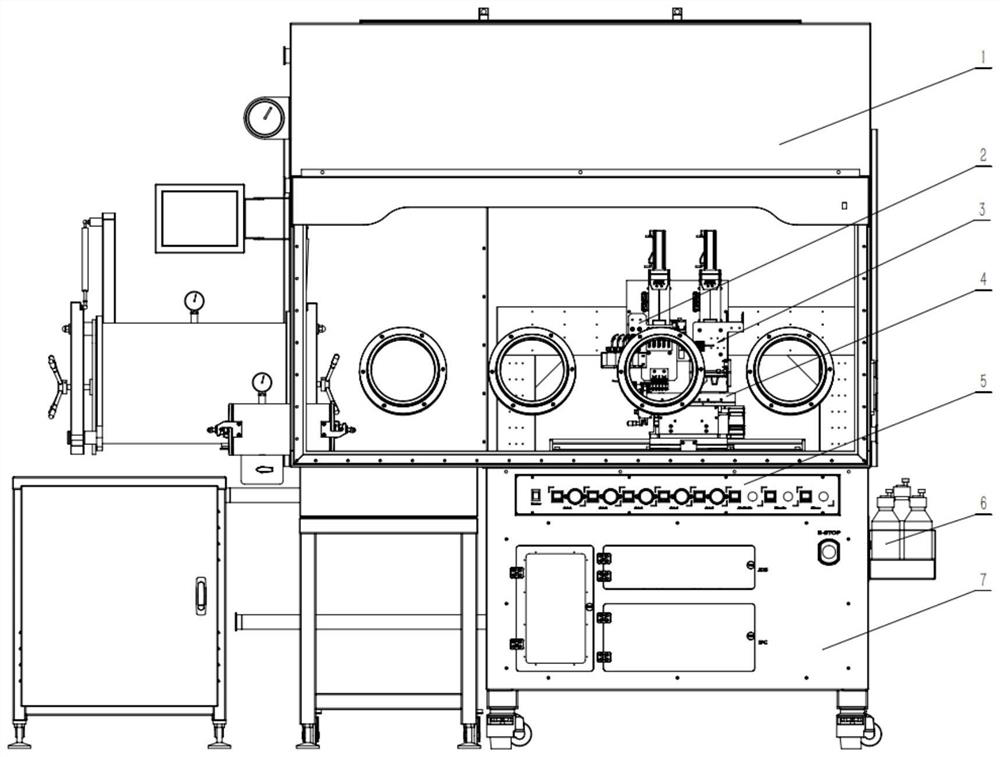

DNA synthesizer and synthesis method

PendingCN113103578ARealize motion controlAchieve absolute fixationAdditive manufacturing apparatusDrying gas arrangementsWorking environmentEnvironmental engineering

The invention relates to the technical field of DNA synthesis, in particular to a DNA synthesizer and a synthesis method. the DNA synthesizer comprises showering air-drying equipment; a protection device; a backplane printing device; and a positive pressure air source and a negative pressure air source, wherein the positive pressure air source is communicated to the spray head and the air knife assembly, and the negative pressure air source is communicated to the air exhaust pipeline, the liquid drainage hole and the spray head. Through cooperative use of the motion control card, the electric drive controller, the positive pressure air source and the negative pressure air source, motion control and electric drive control of the nozzle printing equipment mechanism are achieved. To-be-cleaned objects on the stations can be cleaned, and the functions of air showering and air drying are achieved; the bearing mechanism has the function of automatically adsorbing the to-be-cleaned object, and the to-be-cleaned object can be fixed. cleaning liquid can be prevented from polluting other stations and equipment; rapid recovery of waste liquid can be achieved, the waste liquid is rapidly extracted, and accumulation of the waste liquid on the bearing mechanism is prevented; and residual gas can be pumped away, the influence on the external environment is reduced, and waste liquid steam is prevented from polluting the working environment.

Owner:上海睿度光电科技有限公司

Integrated conveying and quenching mechanism for profile steel production

PendingCN113265521AOverall small sizeHigh degree of integrationFurnace typesHeat treatment furnacesAir pumpEngineering

The invention relates to the technical field of profile steel processing equipment, in particular to an integrated conveying and quenching mechanism for profile steel production. The integrated conveying and quenching mechanism comprises a main external machine frame, an electric lifter, an electric air pump and an electric liquid pump. The integrated conveying and quenching mechanism for profile steel production is provided with a lateral assembly support used for mounting a detachable bottom functional roller body and a lateral linkage support used for mounting a detachable top functional roller body, the lateral assembly support and the lateral linkage support are mounted in the main external machine frame, the lateral linkage support is driven by the electric lifter to ascend and descend, therefore, the detachable bottom functional roller body and the detachable top functional roller body are controlled to be separated and combined, quenching equipment is combined with a conveying mechanism, the size is more compact, and the integration degree is greatly improved; and the quenching equipment can be quickly combined to form conveying equipment, so that the functionality and the applicability are greatly enhanced.

Owner:东台市正祥金属制品有限公司

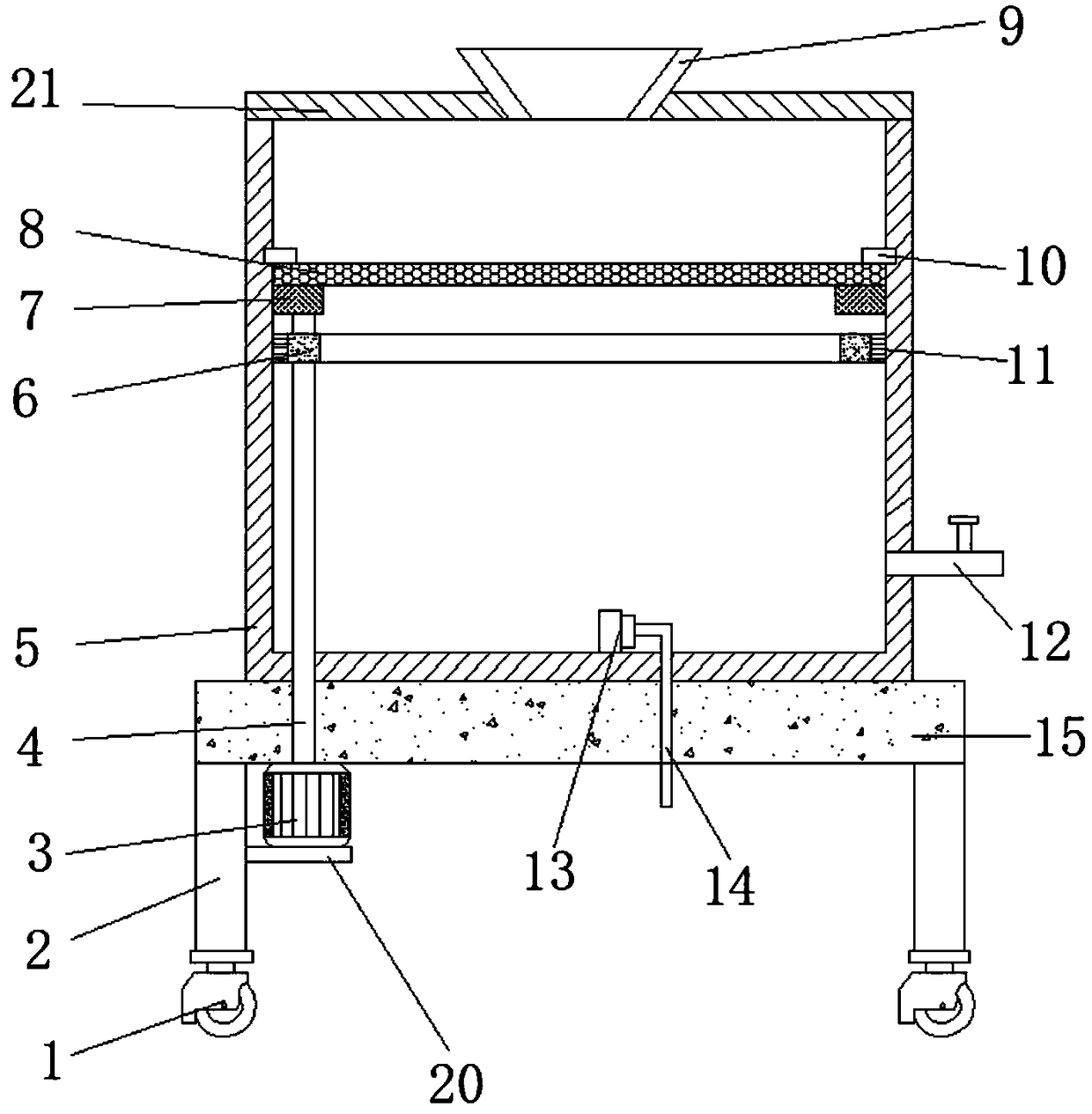

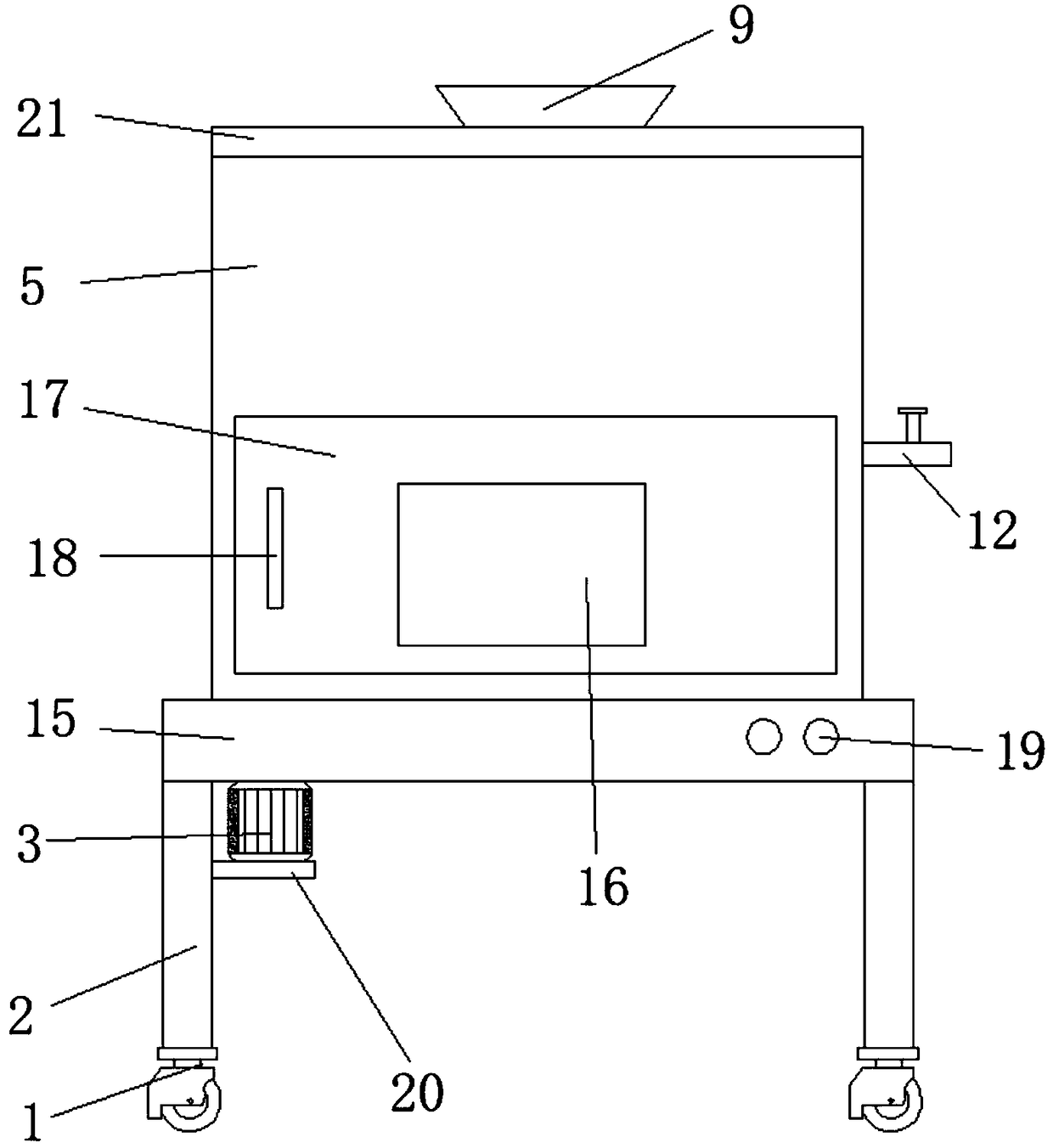

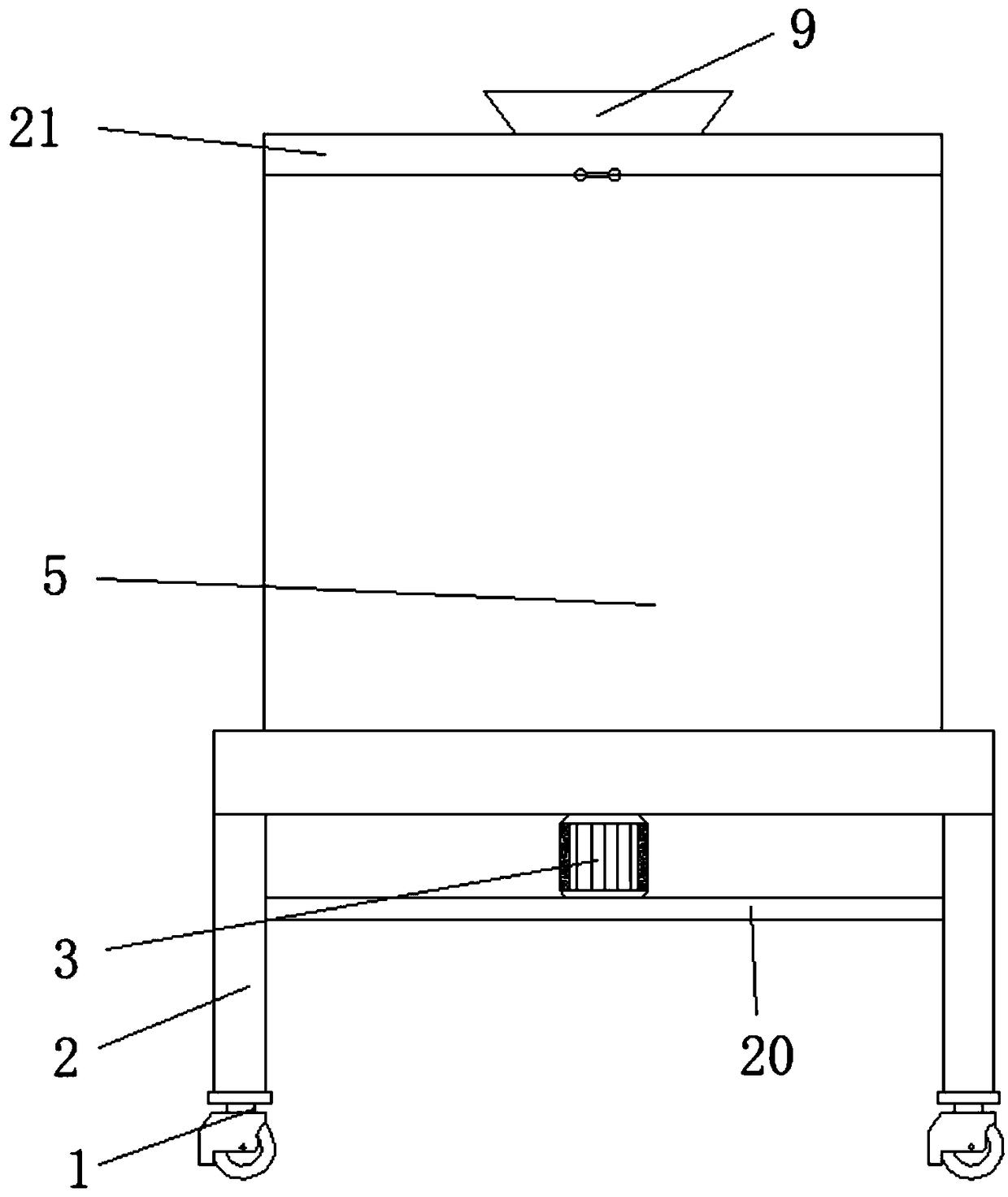

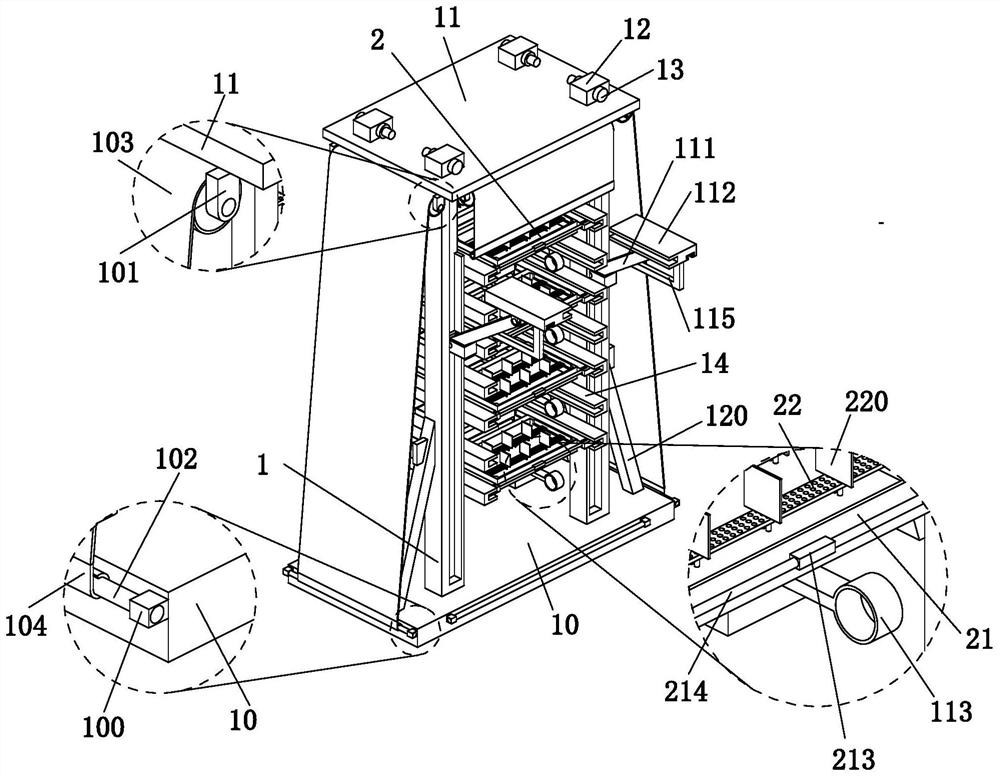

Edible fungus cultivation planting frame

InactiveCN113243250AEasy to transportSatisfy batch cultivationCultivating equipmentsMushroom cultivationEdible mushroomEnvironmental geology

The invention relates to an edible fungus cultivation planting frame. The edible fungus cultivation planting frame comprises a main unit and placing units, the main unit is placed on an existing ground, and the placing units are arranged in the main unit. The combined design concept is adopted for mounting and using the edible fungus cultivation planting frame, and the combined splicing mode adopted by the main unit can rapidly build and dismount the whole frame; meanwhile, transportation is convenient, the multiple placing units and a plurality of U-shaped plates are arranged, the distance between the placing units can be adaptively adjusted according to the cultivation requirements of edible mushrooms, and enough cultivation space is provided for the edible mushrooms; and meanwhile, batch cultivation of the edible mushrooms can be met, so that the single yield of the edible mushrooms can be increased.

Owner:江苏鸿福生物科技发展有限公司

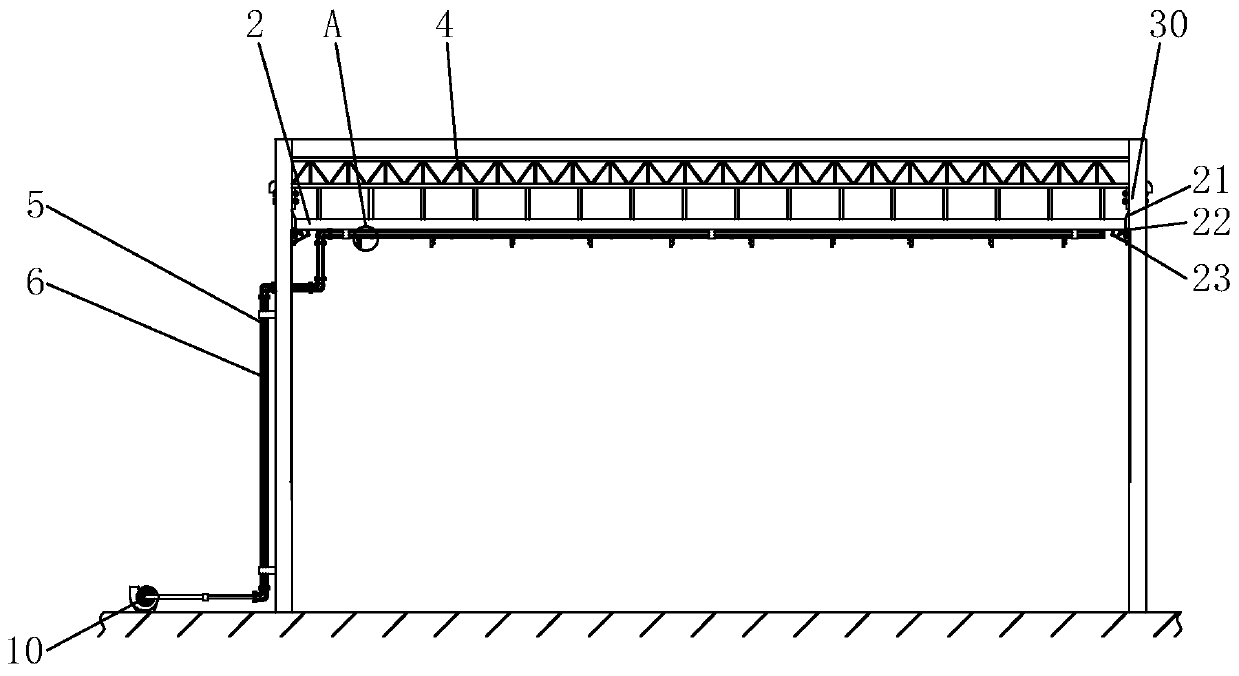

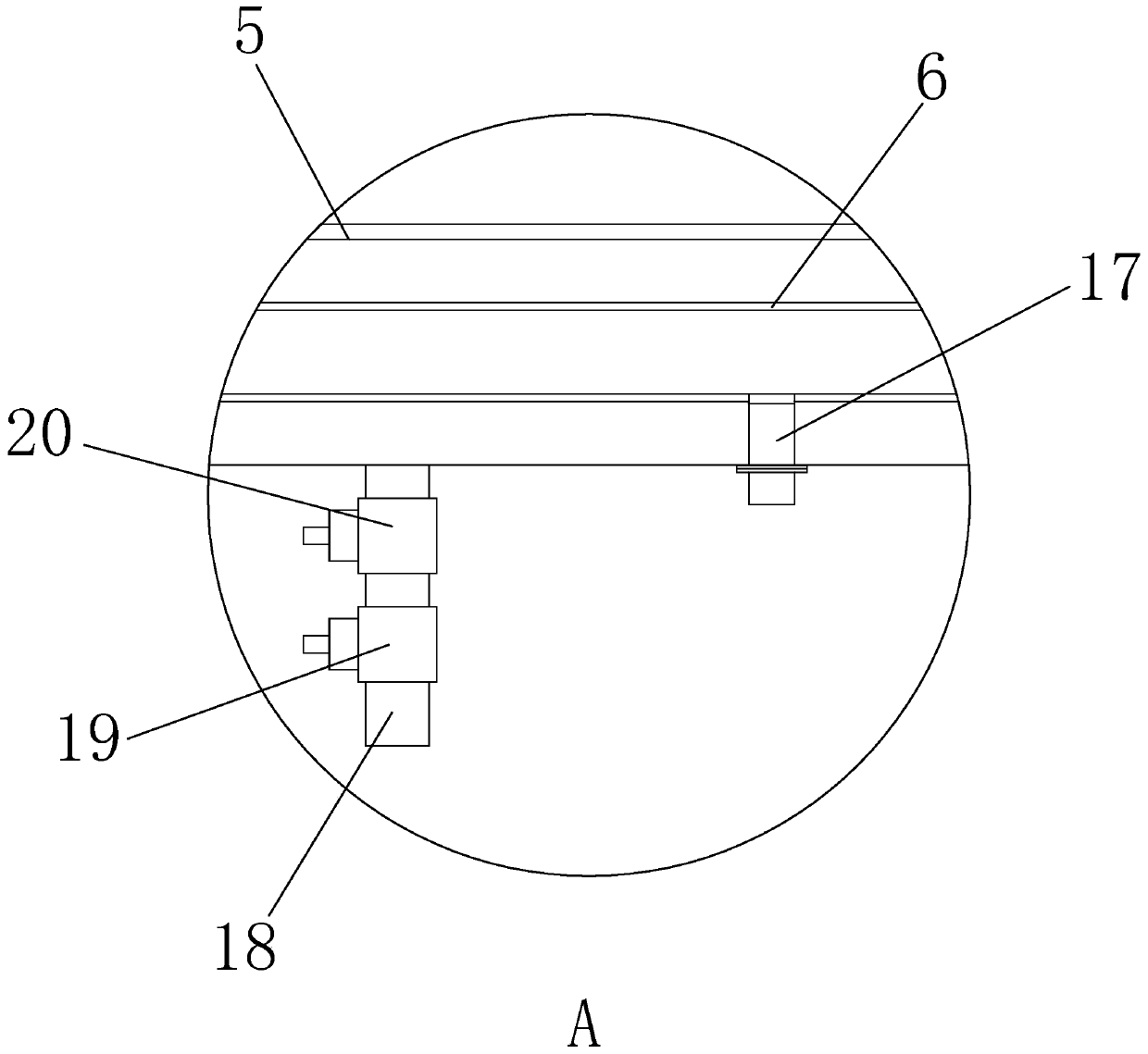

Ceiling for preventing combustible gas explosion

PendingCN110107125AGood shockproof functionSpeed up circulationBuilding roofsDucting arrangementsShock preventionEngineering

The invention discloses a ceiling for preventing combustible gas explosion, and relates to the technical field of building ceilings. The ceiling for preventing combustible gas explosion specifically comprises cross beams fixed to the top of two sides of a wall body and a ceiling body fixedly connected to the top surfaces of the cross beams, wherein the bottom surfaces of the cross beams are connected with a metal honeycomb plate through a plurality of suspenders which are uniformly arranged; the lower surface of the metal honeycomb plate is connected with an external air exhaust pipe through apipe clamp; the tail end of the air exhaust pipe is sealed through an end cover and is arranged on the lower surface of the metal honeycomb plate in an S-shaped roundabout mode; and an internal air exhaust pipe is arranged in the external air exhaust pipe; and at least four falling prevention mechanisms are symmetrically arranged on two sides of the metal honeycomb plate. A aluminum honeycomb core in the metal honeycomb plate is divided into a plurality of closed small chambers, so that the flow of air is prevented, heat and sound waves are not easy to propagate, and the functions of sound insulation, heat insulation, fire prevention and shock prevention are prominent; combustible gas leaked in the chambers is pumped out by an induced draft fan, and fresh air is input, so that the safetyof the indoor environment is improved.

Owner:NANJING TIANBEN SAFETY TECH

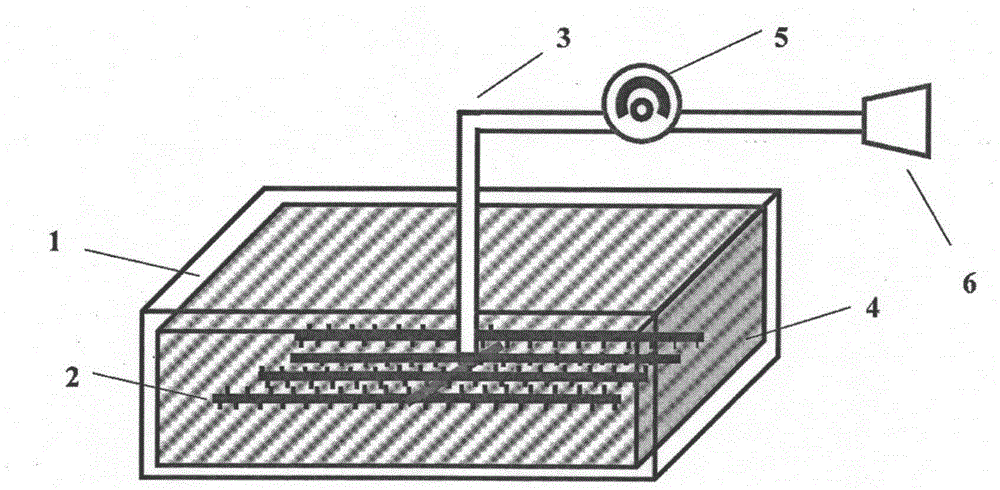

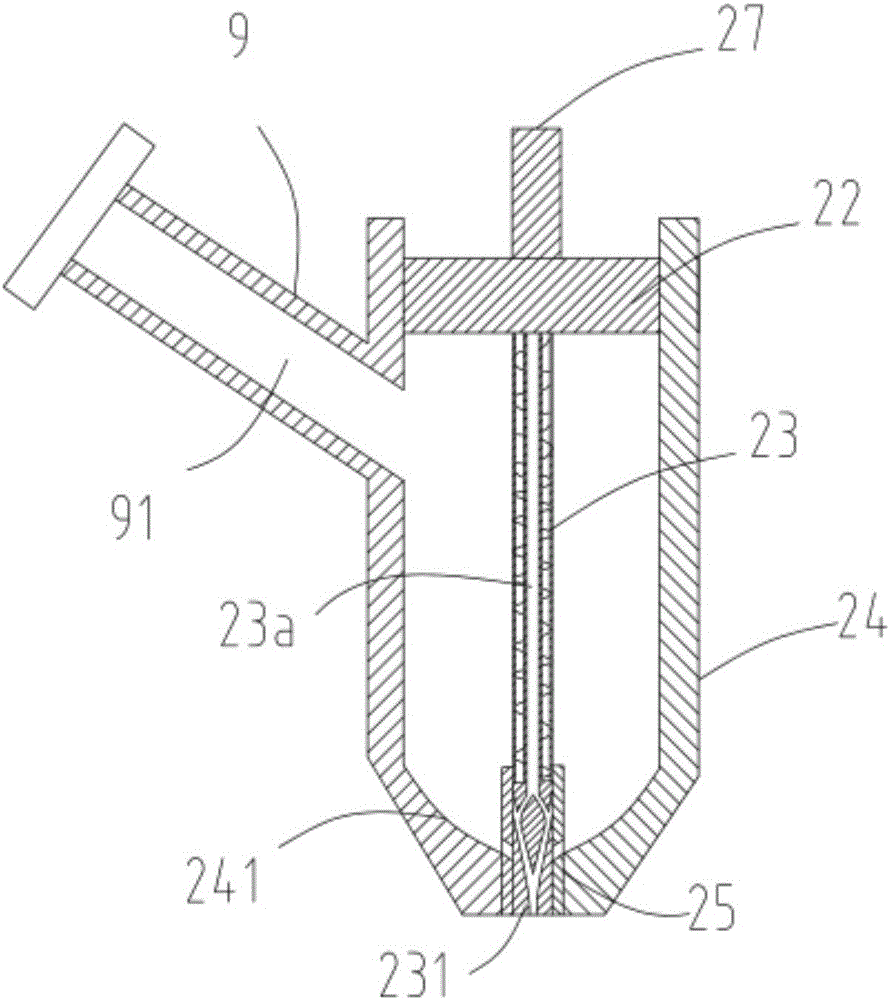

Nanofiber foam-based protein adsorptive separation device and preparation method thereof

ActiveCN104436754ALarge specific surface areaHigh porosityIon-exchange process apparatusIon-exchanger regenerationPharmacyCapillary network

The invention provides a nanofiber foam-based protein adsorptive separation device and a preparation method thereof. The nanofiber foam-based protein adsorptive separation device is characterized by comprising an open pore protection cover, wherein the open pore protection cover is internally provided with a nanofiber foam-based protein adsorption material; a liquid collection capillary network is arranged in the nanofiber foam-based protein adsorption material; the liquid collection capillary network is connected with a main infusion tube; and the main infusion tube is connected with a liquid collection tank through a pump. The nanofiber foam-based protein adsorptive separation device has the advantages of simple preparation process, low production cost, convenience in operation and strong expandability; and the protein adsorption material has the advantages of high mass transfer rate, high adsorption rate, high adsorption capacity, high protein dissolution rate and good pressure resistant property and the proteins in the solution can be intensively adsorbed onto the material through a direct extraction manner to realize the batch efficient continuous separation and adsorption of the protein-containing solution; therefore, the nanofiber foam-based protein adsorptive separation device has wide application prospect in the fields of biological pharmacy and the like.

Owner:DONGHUA UNIV

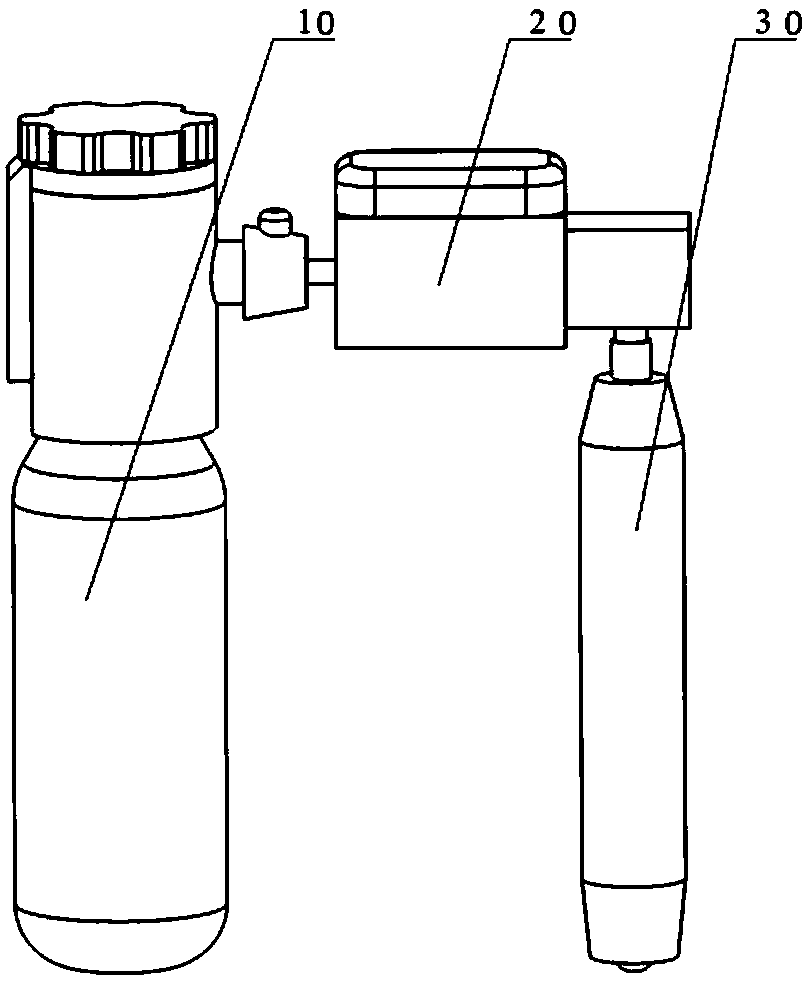

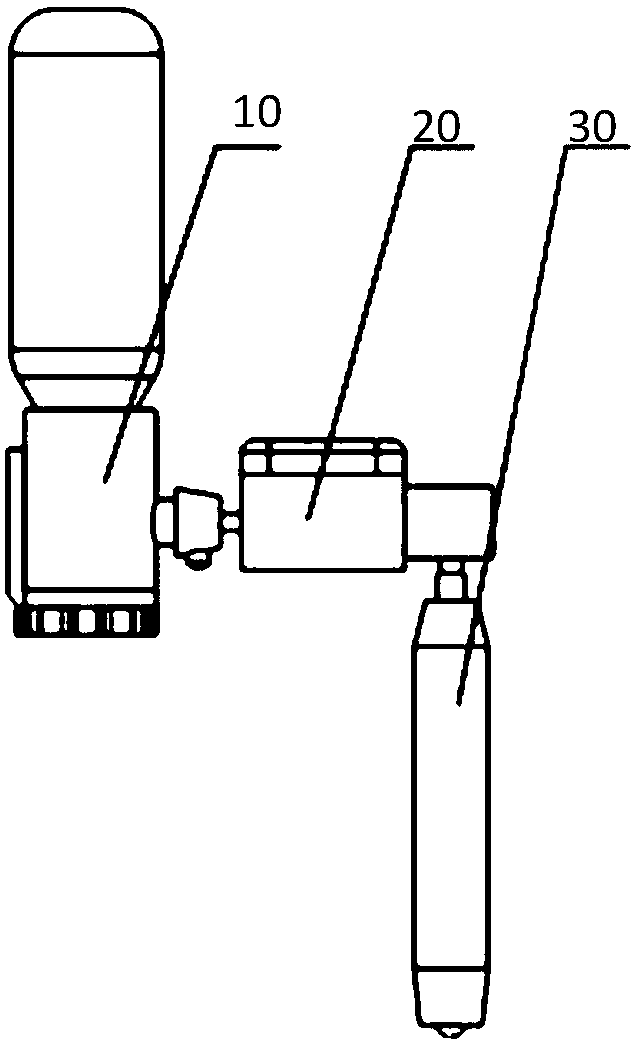

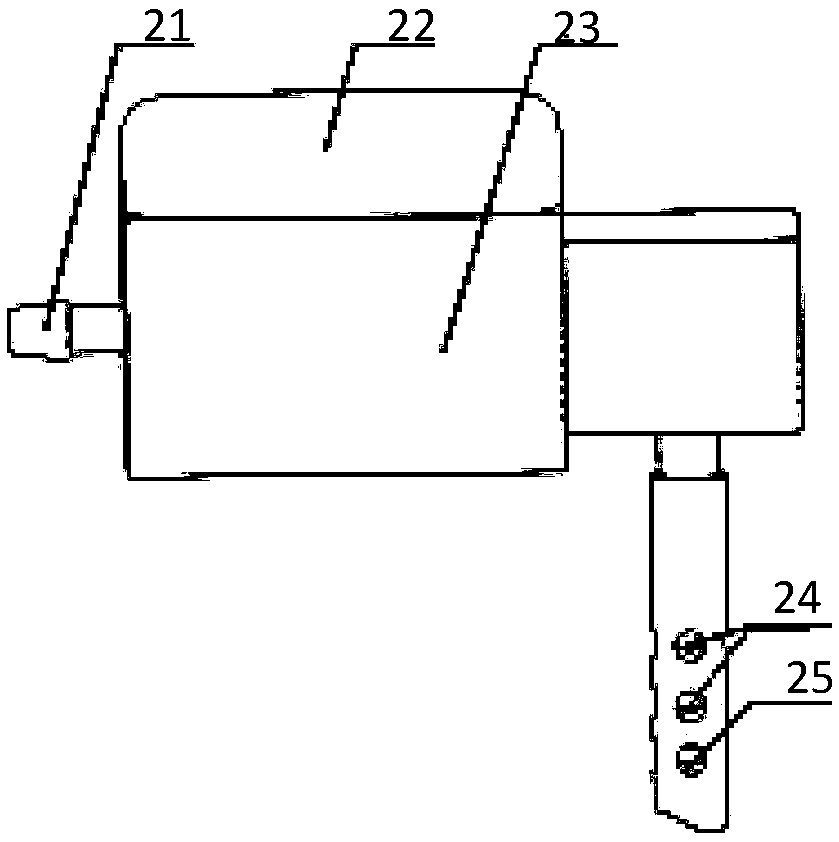

Front radome for aircraft

PendingCN112660362AReduce in quantityReduce post-use costsFuselagesCooling/ventilation/heating modificationsAviationRadar

The invention relates to the technical field of aviation structural parts, in particular to a front radome for an aircraft, which comprises an aircraft body, an outer dome body, an electric control hydraulic support rod and an inner mounting frame for mounting a radar. The front radome for the aircraft is fixedly connected with the front end of the aircraft body through the movable mounting bracket and the bottom limiting device, and the first reset spring and the lateral locking bolt are matched with each other, so that the number of external bolts is reduced, the invisibility is improved, later maintenance is facilitated, and the later use cost is greatly reduced; the electric control hydraulic supporting rod extrudes the elastic flow guide blades to turn over through the heat conduction copper plate, an inclined negative pressure turbulence mechanism is formed on the outer side of the lateral adjusting opening, the heat dissipation modes of the radome are more diverse, the heat dissipation effect is adjustable, the operation environment of the aviation radar is better, long-time efficient operation can be guaranteed conveniently, and the service life is prolonged.

Owner:常州宇翔圆航空科技有限公司

Shot blasting machine with dust pre-separation function and using method thereof

ActiveCN103949980BAvoid damageEase of workAbrasive machine appurtenancesAbrasive blasting machinesEngineeringScrew conveyor

Owner:江苏飞腾铸造机械有限公司

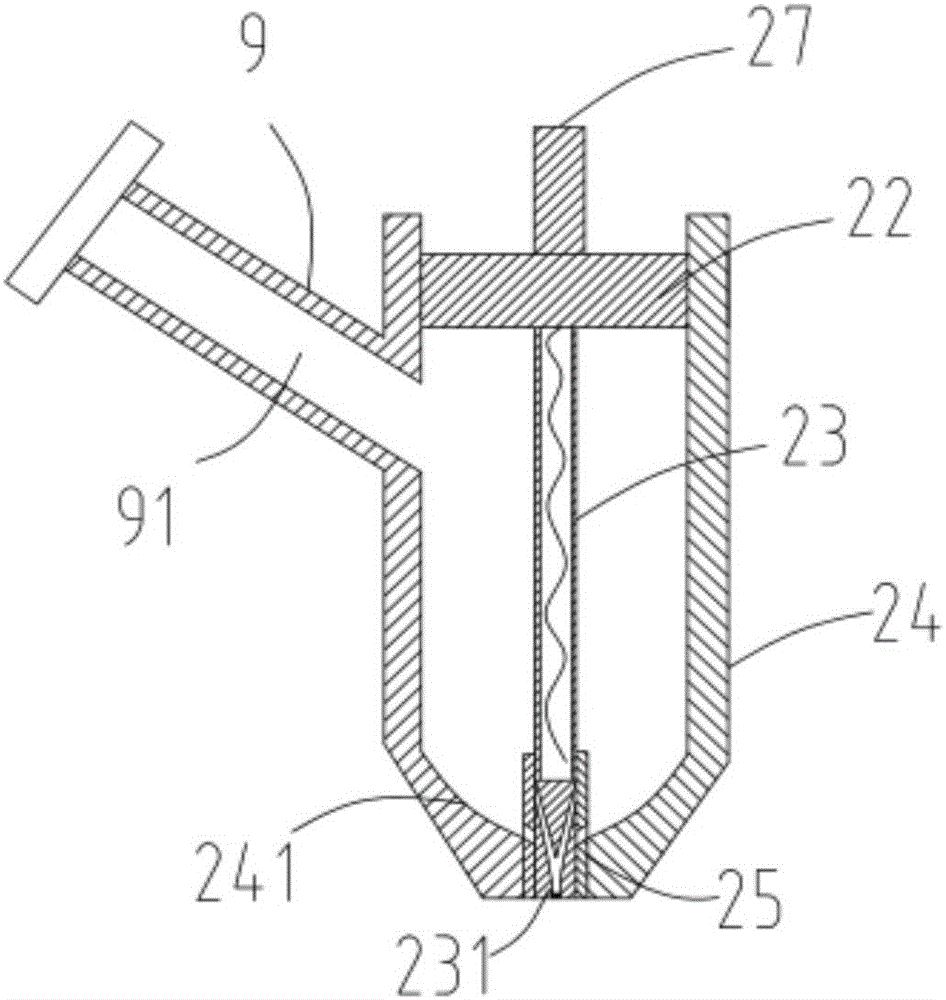

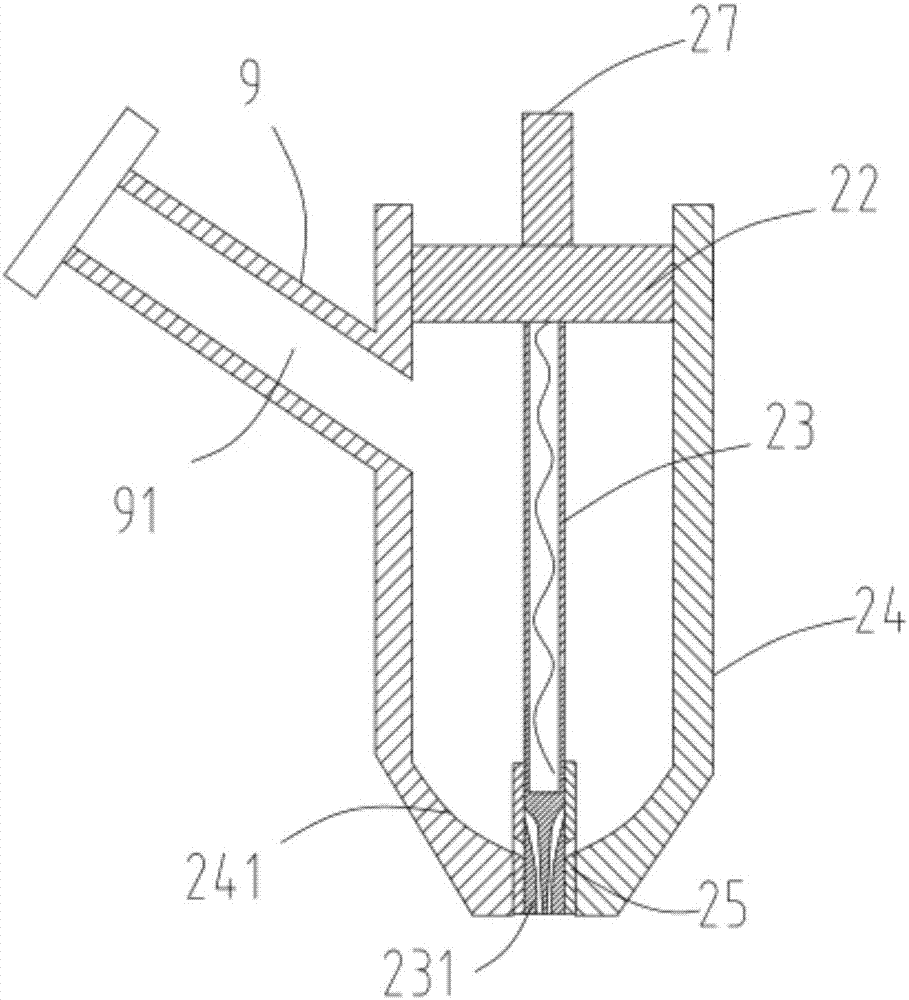

Blocking-prevention glue injection device of battery

ActiveCN105742726ACut off flowAvoid drippingFinal product manufactureCell sealing materialsColloidInjection device

The invention relates to a blocking-prevention glue injection device of a battery. The block-prevention glue injection device comprises a bearing table, a plurality of glue injection assemblies, a material tank and a supplied material assembly, wherein the plurality of glue injection assemblies are arranged in parallel at equal intervals, the material tank is used for storing colloid, a plurality of battery steel shells are carried in the supplied material assembly, the glue injection assemblies are in vertical correspondence to glue injection openings of the battery steel shells, each glue injection assembly comprises a power element, a press plate, a discharge rod, a glue injection barrel, and a material guide post, the press plate is arranged on a top rod of the power element, the discharge rod is arranged on the press plate, the material guide post sleeves the end part of the discharge rod, the discharge rod vertically slides relative to the inner wall of the material guide post, the material guide post is fixed on the glue injection barrel, a Y-shaped material guide hole is formed at the end part of the discharge rod, and a discharge hole is formed in the material guide post. By the blocking-prevention glue injection device, the problems that the mobility of the colloid is poor due to the influence of an external environment to further affect the tightness of the battery, generate a leakage phenomenon after injection completion and easily block an injection device during the glue injection process of the battery are solved.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

A battery uniform glue injection equipment

ActiveCN105789649BAvoid drippingReduce length of stayPrimary cell manufactureCell sealing materialsElectrical batteryInjection equipment

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Haemostasis device control device and control method thereof

PendingCN109009302ALower filling pressureGuaranteed hemostatic effectSurgeryEngineeringSelf adaptive

The invention relates to a haemostasis device control device and a control method thereof, and belongs to the medical apparatus technical field; the bleeding in a limb junction wound is hard to stop in the prior art; the control method comprises the following steps: S10, inserting the haemostasis device into the wound; S20, using the haemostasis device to pressurize for haemostasis and fixation. Under the control of an adaptive pressure adjusting system, the haemostasis device can realize limb junction penetrating injury or typhlosole wound blockout haemostasis and rapid blood clotting in a wound channel filling and pressurization expansion mode.

Owner:FIRST HOSPITAL AFFILIATED TO GENERAL HOSPITAL OF PLA

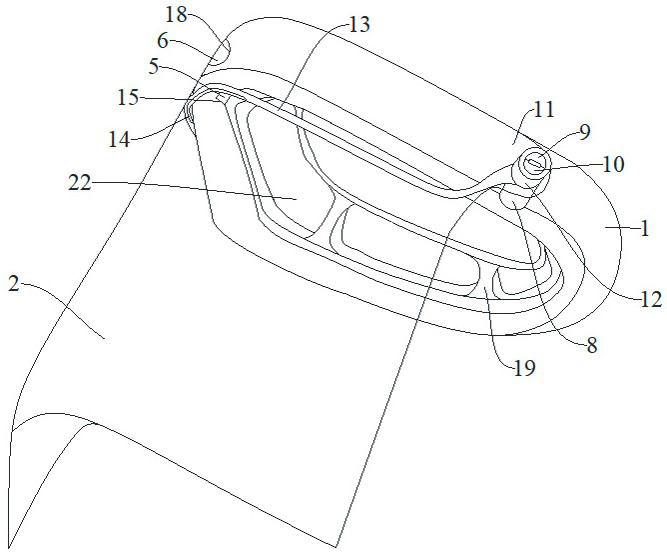

Protective mask with integrated air conditioning device

The invention relates to the technical field of internal air conditioning of protective masks, in particular to a protective mask with an integrated air conditioning device. The protective mask comprises a wearing head band, a transparent protective cover, an electric cooling fan, a lithium battery, an infrared temperature measurement sensor and a display screen for displaying temperature measurement values. According to the protective mask with an integrated air conditioning device, the wearing head band and the transparent protective cover are mounted in a split type mounting mode, the protective mask is assembled in cooperation with an arc-shaped assembling pad which is elastically mounted, the protective mask can be suitable for people with various head types without adjustment, loading and unloading can be completed by turning over a first turning assembly cylinder and a second turning assembly cylinder, the lateral sealing performance and damping after assembly can be improved through external metal elastic pieces, the sealing performance is high, angle limiting is firm, and the operation is quite easy and convenient; and the protective mask not only has the protective capability, but also has the functions of infrared temperature measurement and adjustment of air in the mask, so that the functionality is greatly enhanced.

Owner:南通林安安全设备科技有限公司

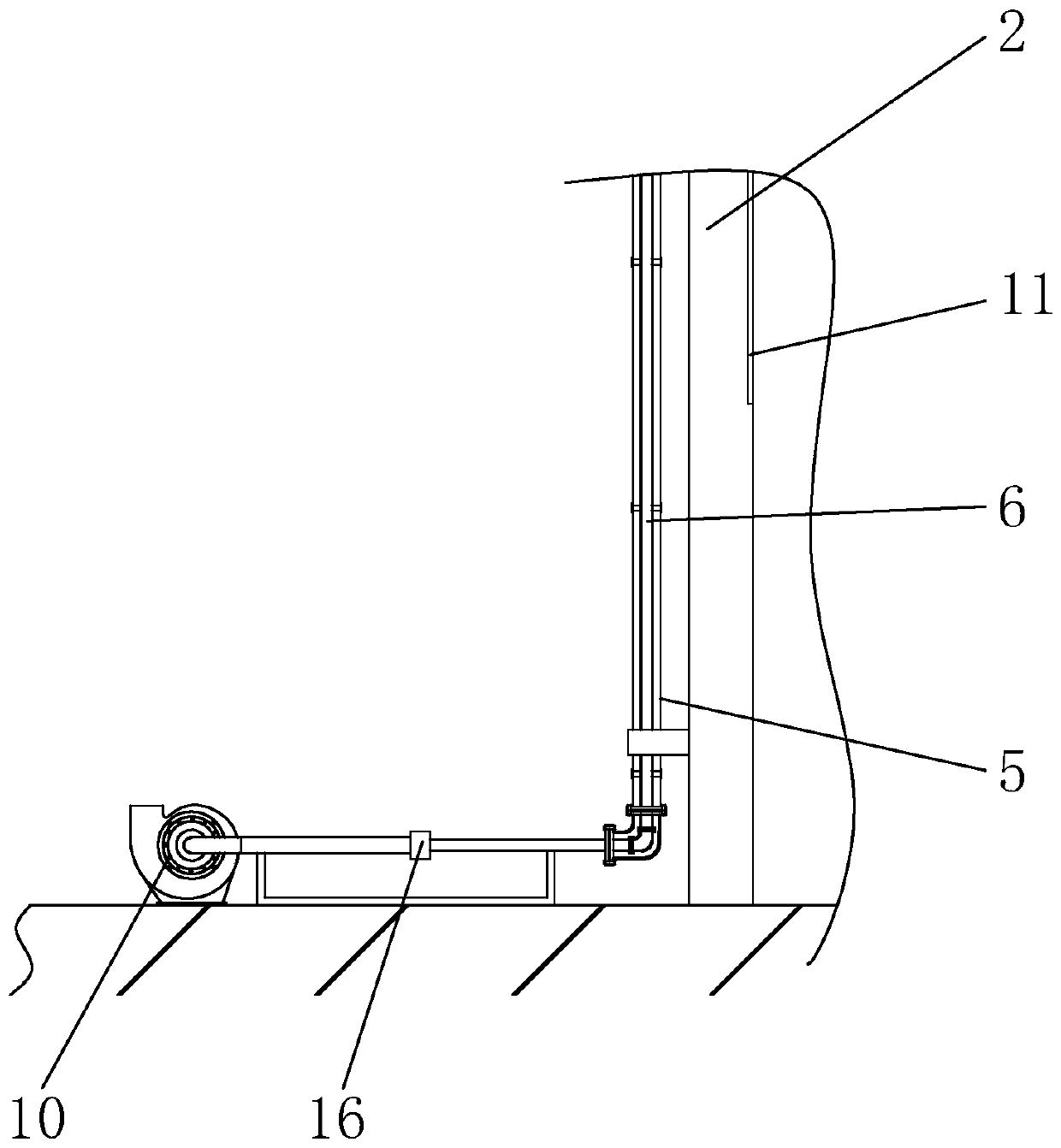

An overhead water cooling device for steel plate production conveyor belt

ActiveCN112857063BReduce surface impactReduce energy consumptionConveyorsDrying solid materials without heatThermodynamicsTransmission belt

The invention relates to the technical field of steel processing and production equipment, in particular to an overhead water cooling device for a steel plate production conveyor belt, which includes a main frame installed at the bottom, an electric fan, a main driving roller controlled by a driving motor, an auxiliary driven roller and an external transmission. water pipes. An overhead water-cooling device for a steel plate production conveyor belt of the present invention is installed at the bottom of the strip-shaped horizontal assembly opening on the upper surface of the main frame. A top assembly bracket is installed through bolts, and a built-in internal gravity is installed above the steel plate conveyor belt by using the top assembly bracket. The top installation tube of the drain tube installs, guides and drains the internal gravity drainage tube through the top gravity guide mechanism in the top installation tube, and controls the extrusion and lifting of the internal gravity drain tube through the steel plate to automatically perform top drainage, and uses gravity to drain the cooling water Natural flow falls on the surface of the steel plate for rapid cooling, reducing energy consumption, and at the same time reducing the impact of water on the surface of the steel plate.

Owner:江苏骏茂新材料科技有限公司

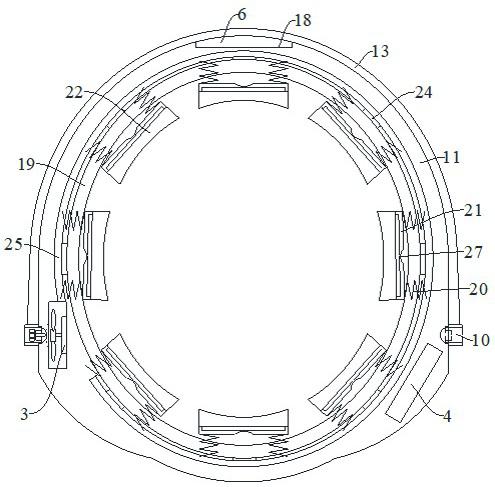

Centrifugal fan special for fire fighting access

ActiveCN112344484AQuick pull awaySolve the problem of low smoke extraction efficiencyDucting arrangementsPump componentsElectric machineryEngineering

The invention discloses a centrifugal fan special for a fire fighting access, and relates to the technical field of centrifugal fans, in particular to the centrifugal fan special for the fire fightingaccess. The fan comprises a centrifugal fan shell, the bottom of the centrifugal fan shell is fixedly connected with uniformly distributed ventilation plates, and the top of the centrifugal fan shellis fixedly connected with a heat dissipation cylinder; and heat dissipation plates are fixedly connected to the two sides of the exterior of the centrifugal fan shell. According to the centrifugal fan special for the fire fighting access, a motor is fixedly connected into the centrifugal fan shell, fan blades which are symmetrically distributed are fixedly connected to the exterior of a rotor atthe bottom end of the motor, and the heat dissipation cylinder and the heat dissipation plates are fixedly connected to the exterior and the outer side of the centrifugal fan shell correspondingly; and it can be guaranteed that the device can effectively extract away smoke in the fire fighting access, and then the problems that a centrifugal fan in an existing device is low in work efficiency, andheat of a motor is not prone to be dissipated in a closed environment are solved.

Owner:HEBEI QIANHAI BLOWER MFG

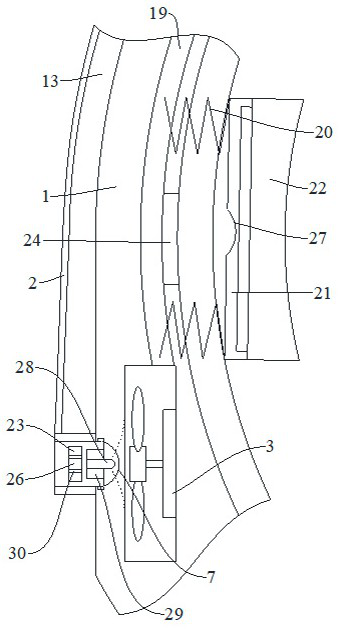

An anti-drowning protection device for a dam

ActiveCN110285033BEasy rescueQuick pull awayPositive displacement pump componentsPump controlArchitectural engineeringWater flow

The invention discloses a dam drowning preventing protection device. A device shell is included and arranged in a dam. A lifting protection cover capable of ascending and descending is arranged in the device shell. An alarm rod base is fixedly arranged on the top wall of the device shell and internally provided with a rotary alarm rod. An alarm device is fixedly arranged at the top end of the alarm rod. The dam drowning preventing protection device is simple in structure and convenient to maintain and use, and personnel accidentally entering the dam dangerous area can be protected against washing away by torrential water flow. Meanwhile, after the device runs, water in the device can be rapidly pumped out so that drowning personnel in the device can be effectively and safely protected, drowning caused by long-time oxygen deficit is avoided, and meanwhile convenience is provided for rapid rescue of rescue personnel.

Owner:日照市东港区水务集团有限公司

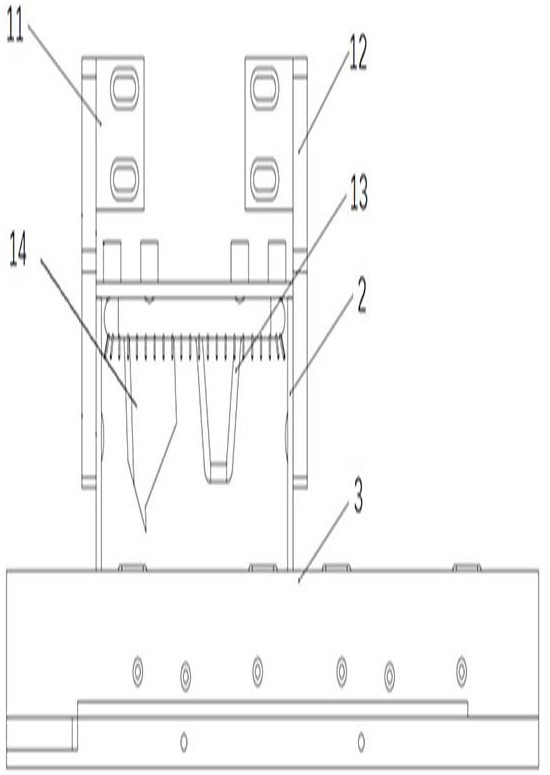

Stripping, shearing and riveting machine

ActiveCN106270305BQuick pull outQuick pull awayApparatus for removing/armouring cablesApparatus for joining/termination cablesEngineeringMechanical engineering

The invention discloses a peeling, shearing, riveting and twisting integrated machine. The peeling, shearing, riveting and twisting integrated machine comprises a wire feeding mechanism, a rotating mechanism, a terminal mechanism, a guiding-in mechanism, a feeding and taking mechanism, a cap twisting mechanism, a cutting and peeling mechanism, a wire taking mechanism, a terminal vibrating plate, a connector vibrating plate, a main air valve, a PLC and a touch screen as well as a pay-off rack, an auxiliary mechanism and a connector vibrating plate which are arranged outside the frame. The auxiliary mechanism, the wire feeding mechanism, the terminal mechanism, the terminal vibrating plate, the rotating mechanism, the guiding-in mechanism, the feeding and taking mechanism, the cap twisting mechanism, the connector vibrating plate, the cutting and peeling mechanism, the wire taking mechanism, the main air valve and the touch screen are respectively connected with the PLC electrically. After the scheme is adopted, the original scattered stations are integrated on equipment for processing and treating, production cost is reduced, and space utilization rate of the workshop is increased. The equipment is relatively high in degree of intelligence and convenient to operate.

Owner:支友光

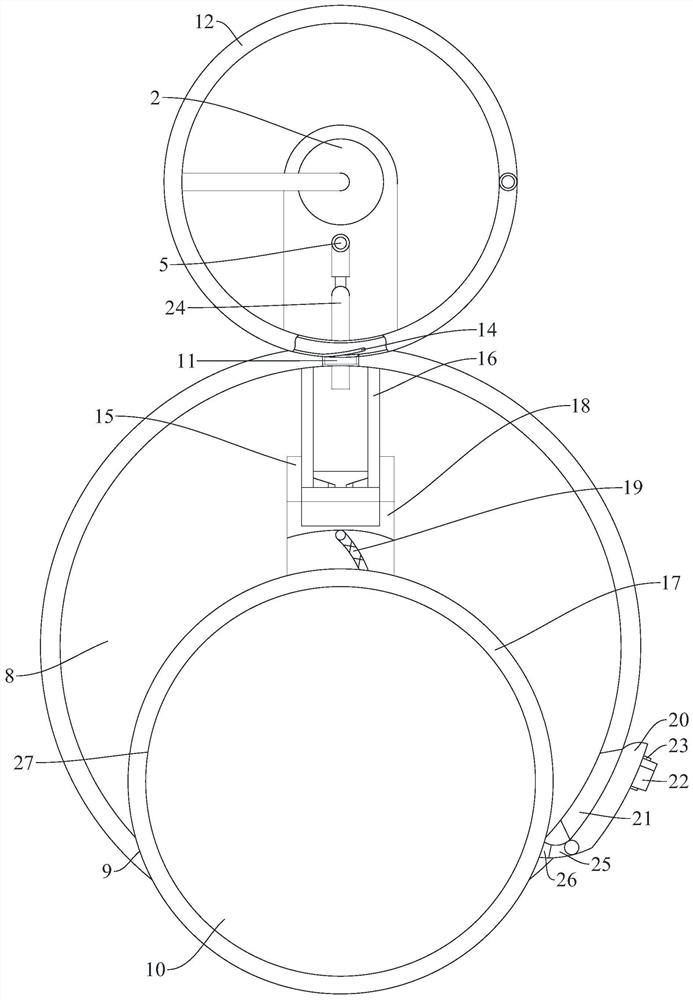

A detachable anchoring tool and its removal method

The invention discloses a demountable anchoring tool and a demounting method of the demountable anchoring tool. The demountable anchoring tool comprises a steel strand and a lockset used for locking the far end of the steel strand, the exposed section of the steel strand is sleeved with a sleeve pipe, the lockset comprises a barrel, a pressure bearing plate is fixed to the near end of the barrel, the barrel is filled with heat loss type high-strength materials, electric heating bodies are pre-buried in the heat loss type high-strength materials and are connected with a conductive wire, the conductive wire penetrates out of the barrel and extends outwards, and the far end of the steel strand penetrates through the pressure bearing plate, enters the barrel and is locked by the heat loss type high-strength materials. In the demounting process, the conductive wire is powered on, the electric heating bodies heat, the heat loss type high-strength materials are heated and damaged, binding force on the steel strand is lost, the steel strand automatically pops outwards under the action of the elasticity of the steel strand, and automatic demounting is achieved. The demountable anchoring tool is simple in structure, and can be conveniently demounted without arranging tensile equipment outside in the demounting process.

Owner:李小川

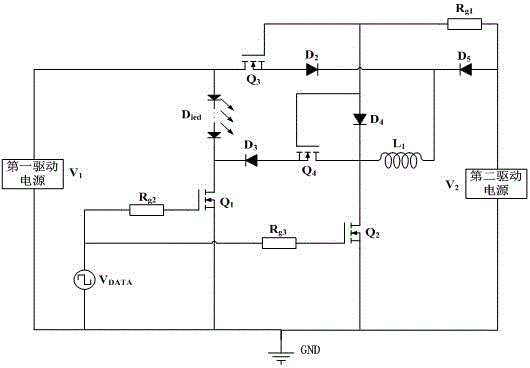

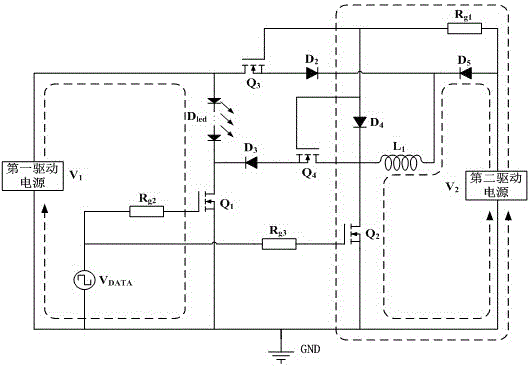

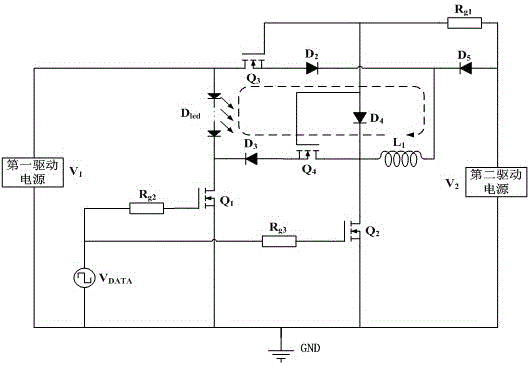

A resonant drive extraction circuit for led visible light communication

InactiveCN105375749BShorten off timeFast extraction speedClose-range type systemsPower conversion systemsCapacitancePower diode

The invention relates to a resonant drive extraction circuit for LED visible light communication. The resonant drive extraction circuit includes a first drive power supply, a second drive power supply, a power MOS switch tube Q1, a power MOS switch tube Q2, and a power MOS switch tube. Switching tube Q3, a power MOS switching tube Q4, a set of LED lamp load Dled, a power diode D2, a power diode D3, a power diode D4, a power diode D5, a resonant inductor L1, a gate resistor Rg1, a A gate resistor Rg2, a gate resistor Rg3, and a communication data modulation driving signal VDATA. The present invention proposes a resonant drive extraction circuit. By charging the additional resonant inductor L1 in advance during the turn-on period of the LED light load Dled, the inductance current reaches the maximum value when the LED light load Dled is turned off; when the LED light load Dled is turned off, let Resonance occurs between the inductor L1 and the junction capacitance of Dled to realize fast extraction of the charge stored in the junction capacitance, which speeds up the extraction speed of the charge and improves the LED visible light communication rate.

Owner:FUZHOU UNIV

Battery gluing device convenient to maintain

ActiveCN105789650ACut off flowAvoid drippingPrimary cell manufactureCell sealing materialsEngineeringInjection device

The invention relates to a battery gluing device convenient to maintain. The battery gluing device comprises a carrying platform, a plurality of gluing components, a storage tank and a feeding component. The gluing components are parallelly arrayed at equal intervals. The storage tank is used for storing glue. A plurality of steel battery shells are carried by the feeding component. Each gluing component comprises a power piece, a press plate, a discharge rod, a gluing barrel and a guide column. The press plates are arranged on ejection rods of the power pieces. The discharge rods are arranged on the press plates. The guide columns sleeve the ends of the discharge rods. The discharge rods slide up and down relative to the inner walls of the guide columns. The guide columns are fixed on the gluing barrels. Y-shaped guide holes are formed in the ends of the discharge rods. Discharge holes are formed in the guide columns. Ventilation pipelines communicated with the Y-shaped guide holes are arranged in the discharge rods. Electrical heating wires are arranged in hollow portions between the ventilation pipelines and the discharge rods. The battery gluing device has the advantages that the problems that during battery gluing, leakproofness of batteries is affected by low flowability caused by the fact that the glue is influenced by external environment, leakage exists after injection, injection devices are easy to block and injection channels are inconvenient to clean are solved.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

A battery glue injection equipment for convenient maintenance

ActiveCN105789650BCut off flowAvoid drippingPrimary cell manufactureCell sealing materialsElectrical batteryInjection equipment

The invention relates to a battery glue injection equipment for convenient maintenance, which includes a bearing table, several glue injection components arranged in parallel at equal intervals, a material tank for storing glue, and an incoming material component carrying several battery steel shells; the glue injection component includes Power part, pressure plate, discharge rod, glue injection barrel, material guide column; the pressure plate is set on the ejector rod of the power part; the discharge rod is set on the pressure plate; the material guide column is set on the end of the discharge rod, The rod slides up and down relative to the inner wall of the material guide column; the material guide column is fixed on the glue injection barrel; the end of the discharge rod is provided with a Y-shaped material guide hole; the material guide column is provided with a discharge hole; the inside of the discharge rod is provided with The ventilation pipe connected with the Y-shaped material guide hole; the hollow part between the ventilation pipe and the discharge rod is provided with a heating wire; the invention overcomes the problem that the flow of the colloid is affected by the external environment during the battery glue injection process and thus affects the battery. The tightness, leakage after injection, easy blockage of the injection device and inconvenient cleaning of the injection channel.

Owner:ZHEJIANG YUNBANG BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com