Nanofiber foam-based protein adsorptive separation device and preparation method thereof

A nanofiber, adsorption and separation technology, applied in separation methods, peptide preparation methods, solid adsorbent liquid separation, etc., can solve the problems of small specific surface area of adsorption matrix materials, single type of protein, and low protein dissolution rate, etc., to achieve The structure of the device can be designed, the broad application prospects, and the effect of high protein dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

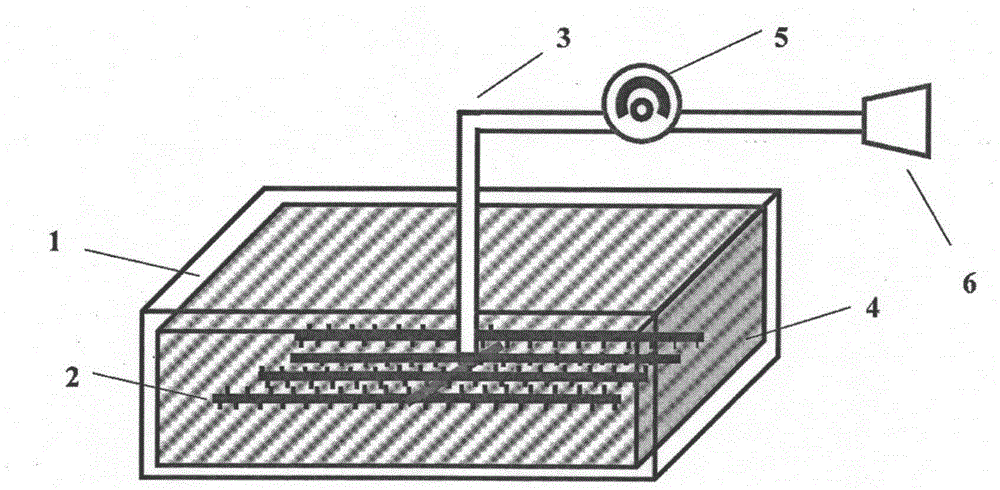

[0033] Such as figure 1 As shown, it is a nanofiber foam-based protein adsorption and separation device, and the nanofiber foam-based protein adsorption and separation device includes a perforated protective cover 1, and the perforated protective cover 1 is provided with a nanofiber foam-based protein adsorption material 4. The foam-based protein adsorption material 4 is provided with a liquid-collecting capillary network 2, and the liquid-collecting capillary network 2 is connected to the main infusion pipe 3, and the main infusion pipe 3 is connected to the liquid collection tank 6 through the pump 5.

[0034] The preparation method of the above-mentioned nanofiber foam-based protein adsorption and separation device, the specific steps are:

[0035] The first step: directly embed the liquid collection capillary network 2 in the nanofiber foam during the preparation of the nanofiber foam material; the liquid collection capillary network 2 includes the main pipe and the branch...

Embodiment 2

[0044] Such as figure 1 As shown, it is a nanofiber foam-based protein adsorption and separation device, and the nanofiber foam-based protein adsorption and separation device includes a perforated protective cover 1, and the perforated protective cover 1 is provided with a nanofiber foam-based protein adsorption material 4. The foam-based protein adsorption material 4 is provided with a liquid-collecting capillary network 2, and the liquid-collecting capillary network 2 is connected to the main infusion pipe 3, and the main infusion pipe 3 is connected to the liquid collection tank 6 through the pump 5.

[0045] The preparation method of the above-mentioned nanofiber foam-based protein adsorption and separation device, the specific steps are:

[0046] The first step: directly embed the liquid collection capillary network 2 in the nanofiber foam during the preparation of the nanofiber foam material; the liquid collection capillary network 2 includes the main pipe and the branch...

Embodiment 3

[0055] Such as figure 1 As shown, it is a nanofiber foam-based protein adsorption and separation device, and the nanofiber foam-based protein adsorption and separation device includes a perforated protective cover 1, and the perforated protective cover 1 is provided with a nanofiber foam-based protein adsorption material 4. The foam-based protein adsorption material 4 is provided with a liquid-collecting capillary network 2, and the liquid-collecting capillary network 2 is connected to the main infusion pipe 3, and the main infusion pipe 3 is connected to the liquid collection tank 6 through the pump 5.

[0056] The preparation method of the above-mentioned nanofiber foam-based protein adsorption and separation device, the specific steps are:

[0057] The first step: directly embed the liquid collection capillary network 2 in the nanofiber foam during the preparation of the nanofiber foam material; the liquid collection capillary network 2 includes the main pipe and the branch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com