A detachable anchoring tool and its removal method

A tool and anchoring technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of high processing precision, troublesome assembly, waste of materials, etc., and achieve the effect of low processing cost, simple disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

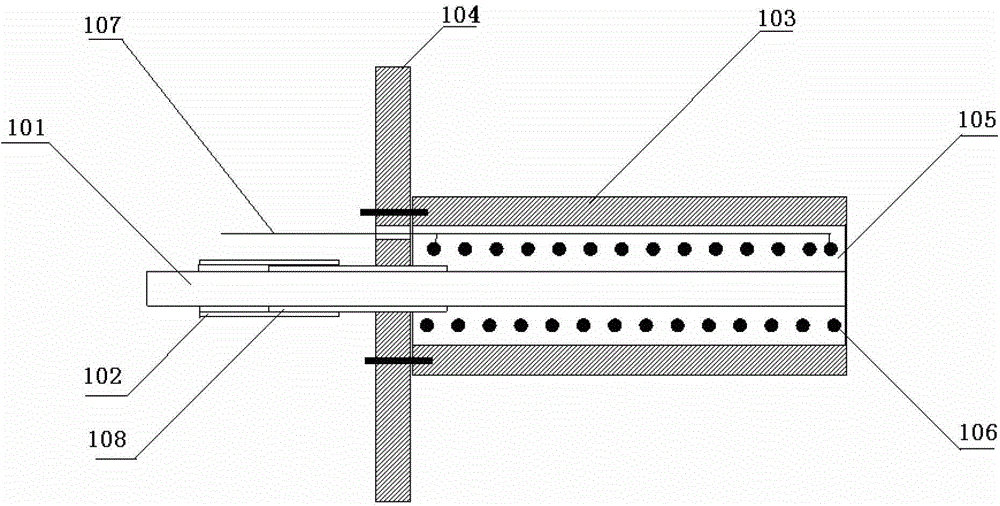

[0036] Such as figure 1 As shown, a detachable anchoring tool of the present invention includes a steel strand 101 and a lock for locking the distal end of the steel strand 101. The exposed section of the steel strand 101 is covered with a sleeve 102, and the lock includes a cylinder 103, the proximal end of the barrel 103 is fixed with a pressure bearing plate 104, and the barrel 103 is filled with a heat-damaged high-strength material 105, an electric heater 106 is pre-embedded in the heat-damaged high-strength material 105, and the electric heater 106 is connected with a conductive wire 107, The conductive wire 107 passes through the barrel 103 and extends outward, and the distal end of the steel strand 101 passes through the pressure plate 104 into the barrel 103 and is locked by the heat-damaged high-strength material 105 .

[0037] Wherein, the casing 102 can be made of (PVC) plastic casing, the cylinder body 103 is preferably a metal cylinder structure, the pressure bea...

Embodiment 2

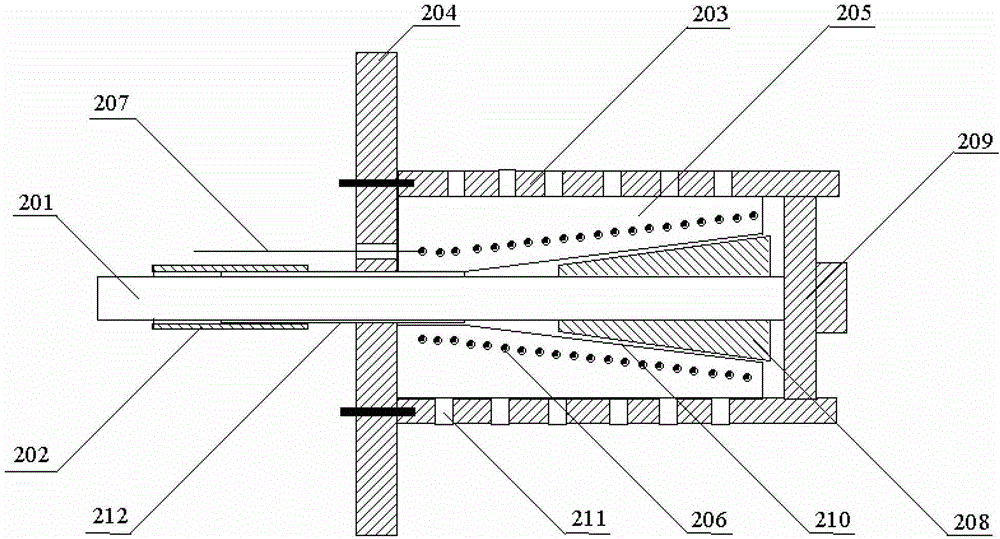

[0042] Such as figure 2 As shown, it is another form of detachable anchoring appliance, which further improves the anchoring appliance in Embodiment 1, specifically including steel strands 201 and locks for locking the distal ends of steel strands 201, steel strands 201 The exposed section of the stranded wire 201 is covered with a sleeve 202, the lock includes a cylinder 203, the proximal end of the cylinder 203 is fixed with a pressure bearing plate 204, the cylinder 203 is filled with a heat-damaged high-strength material 205, and the heat-damaged high-strength material 205 is An electric heating body 206 is pre-embedded, and the electric heating body 206 is connected with a conductive wire 207, and the conductive wire 207 passes through the cylinder body 203 and extends outward; the above-mentioned detachable anchoring device also includes: a toothed mouth is opened on the contact surface with the steel strand 201 The wedge-shaped clamp 208, the heat-damaged high-strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com