Multifunctional bolt stud maintenance device

A bolt stud and maintenance device technology, applied in metal processing equipment, grinding machines, metal processing, etc., can solve the problems of high scrap rate, heavy disassembly work, etc., and achieve the effect of reliable performance, strong practicability, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

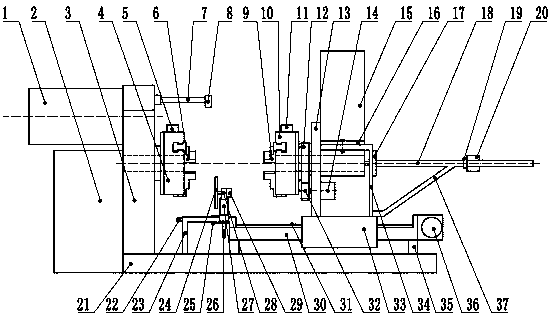

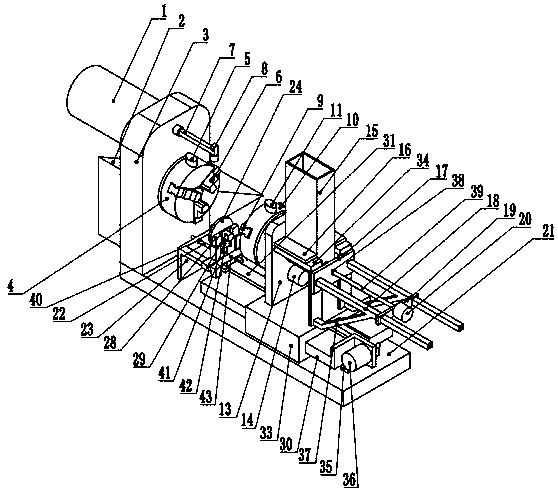

[0023] A multifunctional bolt and stud maintenance device, comprising at least a large base 21, characterized in that: a large bracket 3 is fixed on the left side of the large base 21, a motor-1 is fixed on the top of the large bracket 3, and the driving end of the motor-1 drives A left locking device is connected, and the left locking device is fixed on the right end face of the large bracket 3; the upper part of the large base 21 is fixed with a sliding mechanism through a plurality of supporting piles 35, the supporting mechanism is fixed above the sliding mechanism, and the motor 2 is fixed at the bottom of the supporting mechanism. 14. The driving end of motor two 14 is connected with a right locking device, and the right locking device is fixed on the left end surface of the supporting mechanism; the axes of the left locking device and the right locking device are on a straight line.

[0024] The invention solves the problems that nuts are difficult to be removed from bolts...

Embodiment 2

[0026] like figure 1 , figure 2 As shown, it is improved on the basis of Embodiment 1, and also includes a derusting device, which is fixed on the left side of the sliding mechanism and is located between the left locking device, the right locking device and the large base 21 .

[0027] Described derusting device comprises bottom support 23 at least, and bottom support 23 left ends are fixed on the big base 21, and bottom support 23 right ends are fixed on the slide mechanism, and bottom support 23 upper end surface is movably connected with slide block 43 that can move left and right, slide A horizontal driving motor 25 is fixed on the block one 43, and the driving end of the horizontal driving motor 25 is connected with a lead screw one 22. The left end surface of the bottom bracket 23 is fixed with a nut one 40, and the leading screw one 22 passes through the nut one 40 and extends to the bottom bracket. 23 outside; described slide block one 43 is also fixed with upper su...

Embodiment 3

[0031] like figure 1 , figure 2 As shown, it is improved on the basis of Embodiment 1 or Embodiment 2. The top of the right end surface of the large bracket 3 is fixed with a shooting rod 7, and the other end of the shooting rod 7 is fixed with a camera 8, and the camera 8 is located on the left locking device. , the top of the right locking device; the large bracket 3 is provided with a left connection through hole, the input shaft of the left locking device passes through the left connection through hole and is fixed with the large bracket 3, and the left end surface of the support mechanism is provided with The right connecting through hole, the input shaft of the right locking device passes through the right connecting through hole and is fixed with the supporting mechanism; the center lines of the left connecting through hole, the left locking device, the right locking device and the right connecting through hole are located at the same on a straight line.

[0032] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com