Environment-friendly shot-blasting cleaning machine having dust pre-separation function and using method thereof

A shot blasting machine and shot blasting cleaning technology are applied to used abrasive treatment devices, manufacturing tools, abrasive jet machine tools, etc., which can solve the problems of high labor intensity, deterioration and low cleaning efficiency, and reduce the difficulty of work. and strength, prevent performance damage, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

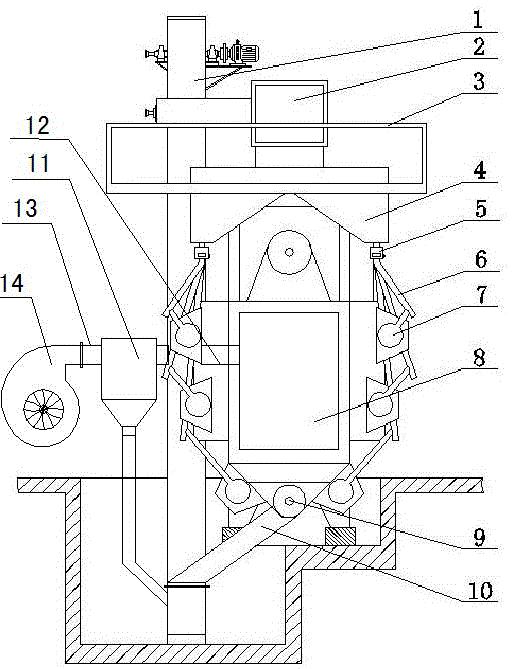

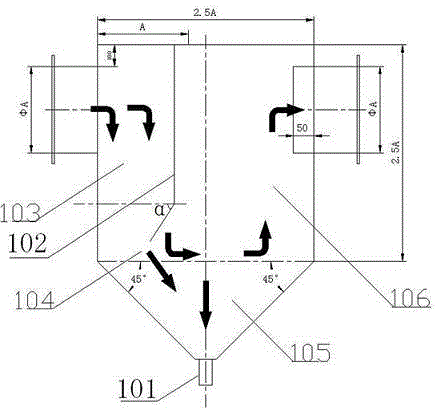

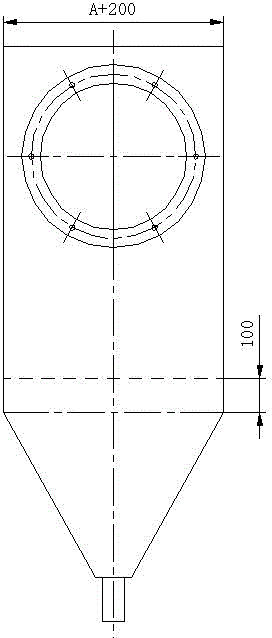

[0029] Such as figure 1 As shown, this embodiment provides an environmentally friendly shot blasting machine with a dust pre-separation function, including a hoist 1, a separator 2, a working platform 3, a sand inlet hopper 4, a shot valve 5, a sand falling pipe 6, Shot blasting device 7, shot blasting cleaning chamber 8, screw conveyor 9 and ball chute 10;

[0030] The hoist 1 is vertically arranged on one side of the shot blasting chamber 8, the separator 2 is arranged on the upper end of the hoist 1, and the outlet of the lower end of the separator 2 is connected to the sand inlet hopper 4, and the separator 2 and the sand inlet hopper 4 are connected. There is also a working platform 3 at the connection; the outlet at the lower end of the separator 2 is connected to two sand inlet buckets 4 and the two sand inlet buckets 4 are symmetrically arranged, and the outlet at the lower end of each sand inlet bucket 4 respectively passes through three sets of pill supply valves 5....

Embodiment 2

[0035] This embodiment provides a method for using an environmentally friendly shot blasting machine with dust pre-separation function, including the following steps:

[0036] Step (1): Put the workpiece to be cleaned into the shot blasting chamber 8, the shot material enters the sand feeding hopper 4 through the separator 2, opens the shot supply valve 5, and the shot material enters the shot blaster 7 along the sand falling pipe 6;

[0037] Step (2): The shot blaster 7 blasts the workpieces in the shot blasting cleaning room 8, and at the same time turns on the exhaust fan 14. At this time, due to the action of the exhaust fan 14, the fine dust generated in the shot blasting cleaning room 8 is blown away. Inhale the first air duct 12, and at the same time, due to the irregular collision of shot blasting in the shot blasting chamber 8, some pellets, sand and broken pellets enter the first air duct 12 at the same time;

[0038] Step (3): fine dust, pellets, sand and broken pel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com