Needle-valve order hot runner injection molding device

An injection molding device and hot runner technology, which is applied in the field of plastic parts manufacturing, can solve the problems that cannot meet the high appearance quality and high strength performance of large plastic parts, achieve smooth and full appearance streamlines, improve stability, and reduce internal The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

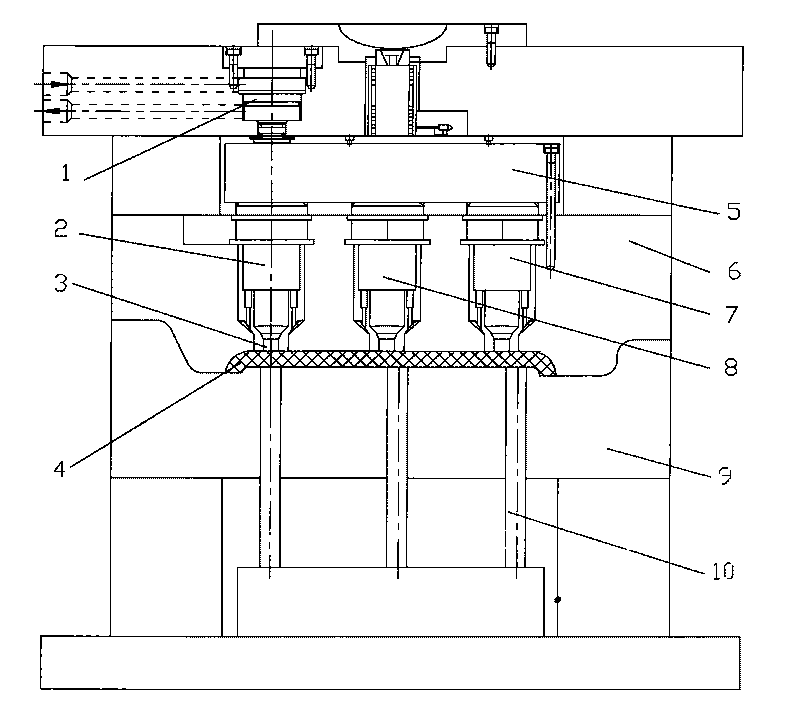

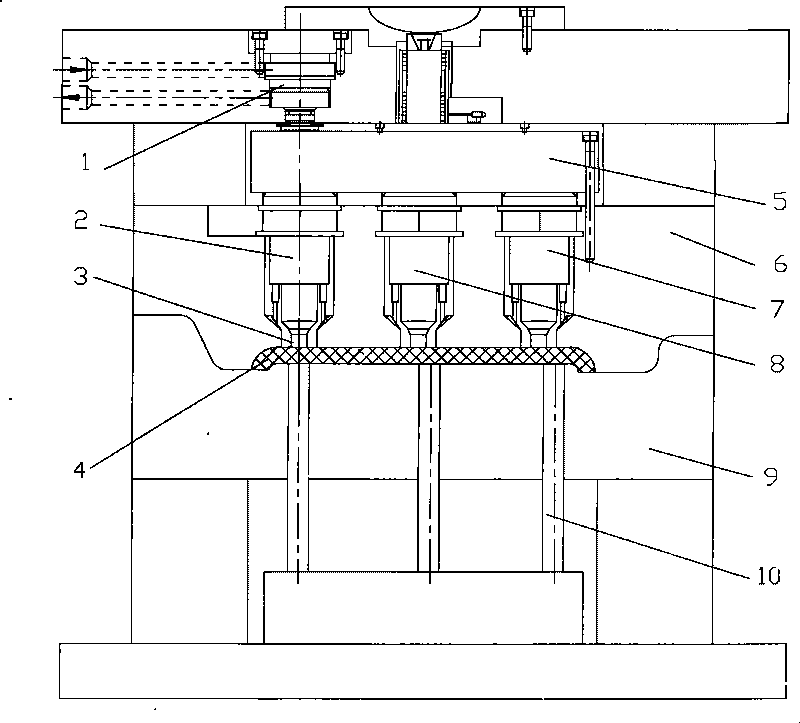

[0024] The plasticized molten plastic is injected into the mold cavity 4 to fill the mold by opening the sequence valve hot runner 8 and the needle valve gate 3 under the action of the sequence valve control cylinder 1, and the molten plastic entering at this time flows to the left and right sides Filling the mold, when they just flow through the sequence valve hot runner 2 or sequence valve hot runner 7 position, at this time the sequence valve hot runner 2 and sequence valve hot runner 7 are opened for feeding, and the molten material fed directly merges into the sequence valve hot flow The molten material in the channel 8 moves forward together to avoid the fusion and docking of the molten material in the two gates. When the sequence valve hot runner 2 and sequence valve hot runner 7 are opened, the sequence valve hot runner can be closed or continued to be opened 8 to adjust the smoothness of cavity filling and the flow balance of melt. Until the confluence melt fills the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com