High-brightness non-melted mark steam injection mold and using method thereof

An injection mold with no melting marks technology, which is applied in the field of high-gloss steam injection molds without melting marks, can solve the problems of increasing production cost and mold weight, prolonging mold production time, and increasing processing costs, so as to ensure the quality of the outer surface and improve the forming Quality, the effect of eliminating weld lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

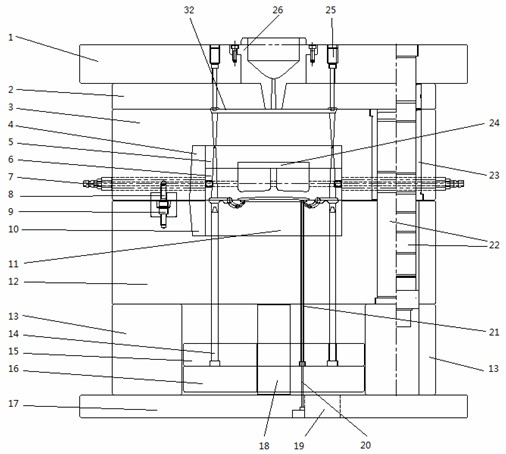

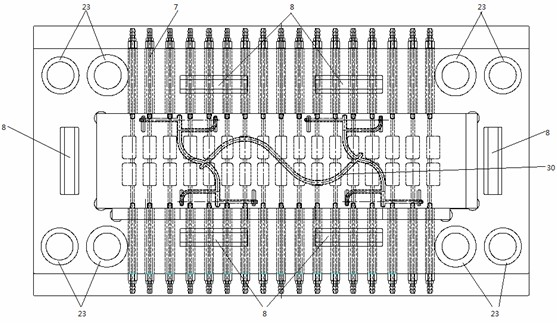

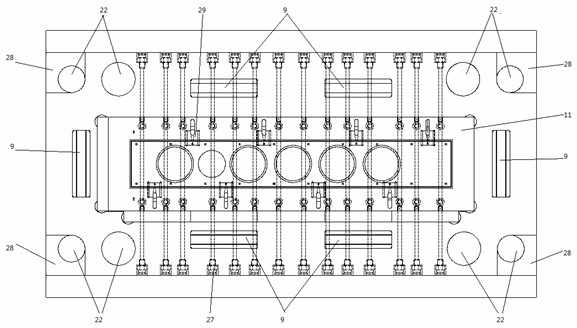

[0036] Such as Figure 1~3 As shown, the high-gloss non-melted steam injection mold includes an upper mold, a lower mold, a gating system 32, a cooling water channel and a push-out mechanism. The upper mold and the lower mold are stacked up and down. Die, the push-out mechanism is located below the lower die; the upper die includes the upper die panel 3, the first insert 5 of the upper die, the heat insulating plate 24 and the second insert 6 of the upper die, and the heat insulating plate 24 is fixed on the upper die second insert The lower end surface of an insert 5, the first insert 5 of the upper mold and the second insert 6 of the upper mold are fixed in the upper mold panel 3, and the second insert 6 of the upper mold is provided with a steam channel 7; the lower mold includes The lower mold panel 12 and the lower mold insert 11, the second upper mold insert 6 and the lower mold insert 11 form a cavity, and the lower mold panel 12 is provided with a cooling water channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com