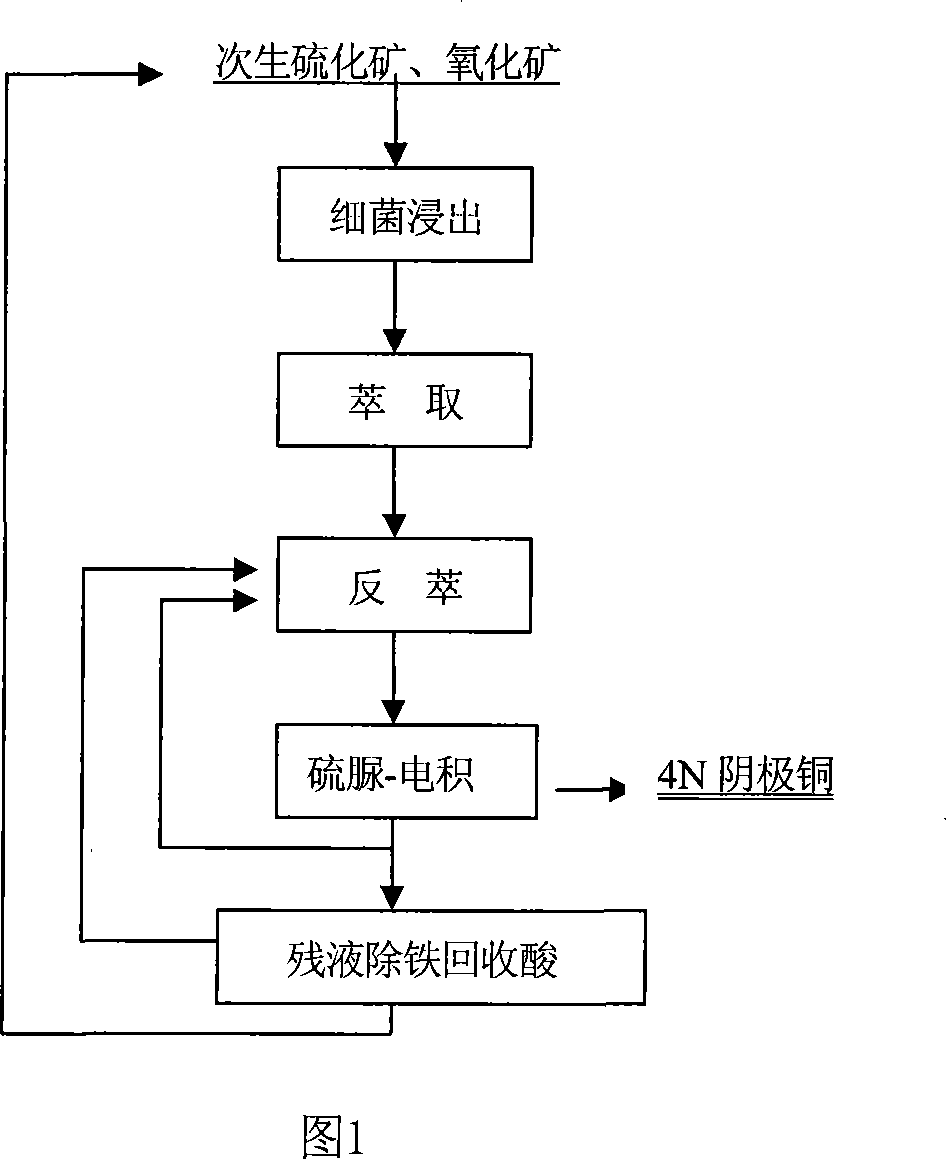

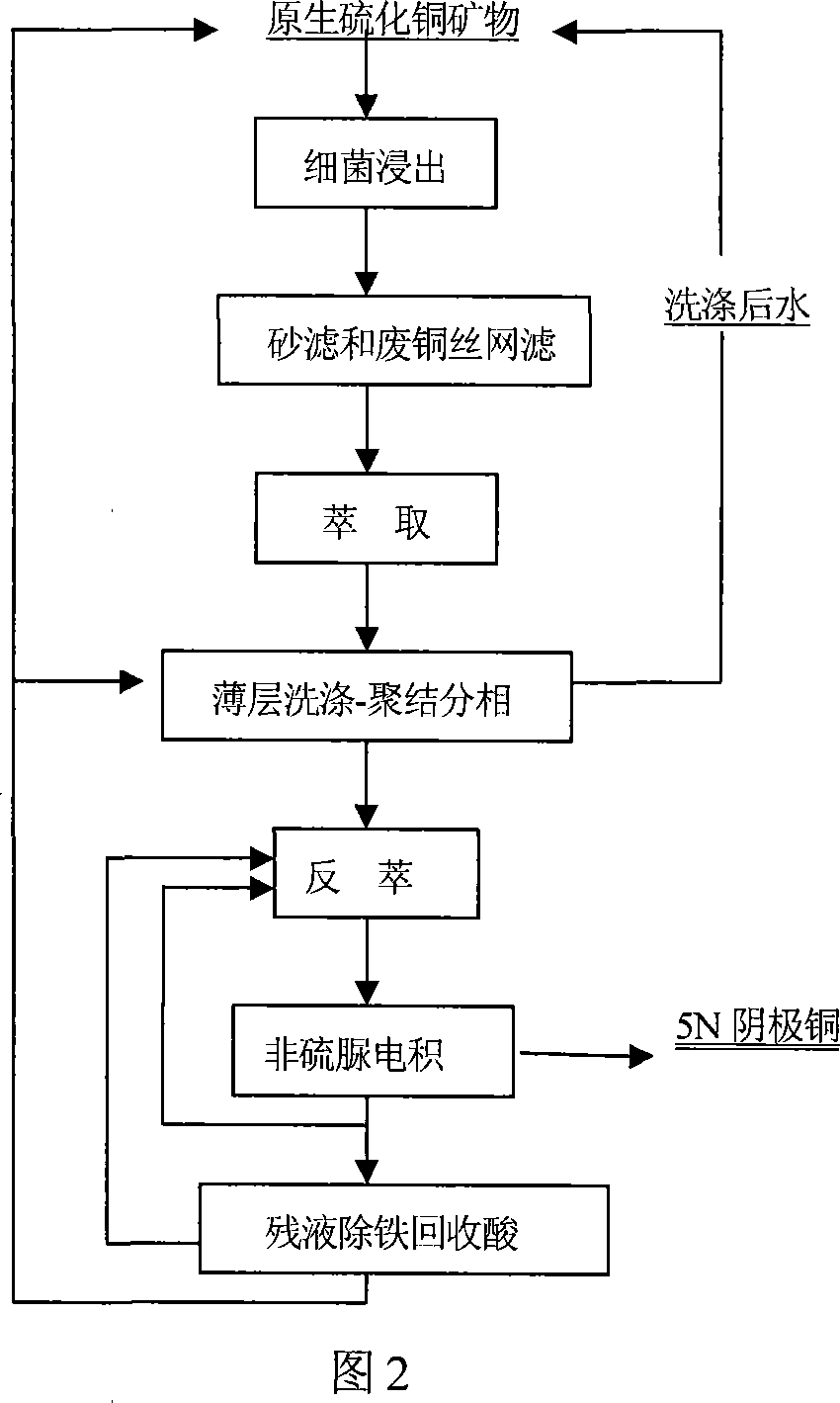

Method of preparing high purity copper by bacteria leaching primary sulfide ore

A technology of sulfide ore and high-purity copper, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problem of increasing the amount of electrowinning liquid treatment, high-value cobalt loss, extraction instability, extraction entrainment, and affecting the quality of cathode copper and other problems, to achieve the effect of enhancing the synergistic leaching effect, eliminating the formation of the third extraction phase, and stabilizing the quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Bacterial heap leaching

[0030]The primary copper sulfide ore in a certain mine is piled up. The mineral composition is mainly chalcopyrite and bornite, a small amount of other minerals, and the average grade of copper is 0.73%. The ore is crushed to a particle size of -50mm, the pile height is about 8m, and the ore volume is about 9,000 tons. Porous pipes are laid 3m above the bottom of the pile, and low-pressure air is supplied to provide oxygen, nitrogen and carbon sources required for bacterial growth. Initially, the acidic wastewater (indigenous strain source) mainly composed of A.f bacteria was used for culture. The composition of the culture solution is: 10% (W / V) chalcopyrite pulp, 5 g / L of ammonium sulfate, 0.5 g / L of potassium dihydrogen phosphate, and pH 1.8-2.5. The inoculum solution is inoculated in the sulfuric acid leaching solution with pH=2 at a ratio of 0.01-10% (v / v), and sprayed immediately. The spray intensity is about four-fifths of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com