Method for separating valuable metals from copper-cobalt alloy

A technology of valuable metals, copper and cobalt, applied in the direction of cobalt compounds, chemical instruments and methods, copper chloride, etc., can solve the problems of large wastewater discharge, slow rate, and high acid consumption, so as to improve the leaching rate and avoid acid consumption big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

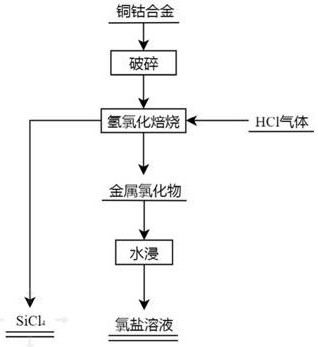

[0042] A method for separating valuable metals from copper-cobalt alloys, the process flow chart is as follows figure 1 shown, including the following steps:

[0043] S1: Use a jaw crusher or a ball mill to crush the copper-cobalt alloy, coarsely grind it, then sieve it, and weigh 4.00g of copper-cobalt alloy powder with a particle size of 0.1-0.335mm;

[0044]S2: Put the copper-cobalt alloy powder weighed in S1 into the alumina crucible and send it into the roasting furnace together. 20 minutes before the temperature rise, 50mL / min argon gas is introduced to discharge the residual air, and 100mL is introduced when the temperature rises to 550°C. / min of HCl gas, control the partial pressure of hydrogen chloride gas to 0.65MPa, and keep it warm for 8 hours, stop feeding HCl gas after the heat preservation is over, and wait for the sample to cool naturally;

[0045] S3: Weigh 2.00g of the cooled roasted product in S2, put it into a beaker with 100ml of pure water, and drop abo...

Embodiment 2

[0048] A method for separating valuable metals from copper-cobalt alloys, comprising the following steps:

[0049] S1: Use a jaw crusher or a ball mill to crush the copper-cobalt alloy, coarsely grind it, sieve it after coarse grinding, and then weigh 4.00 g of copper-cobalt alloy powder with a particle size of 0.1-0.335 mm.

[0050] S2: Put the copper-cobalt alloy powder in the alumina crucible and send it into the roasting furnace together. 20 minutes before the temperature rise, start to pass in 50mL / min argon gas to discharge the residual air; , control the partial pressure of hydrogen chloride gas to 0.8MPa, and keep it warm for 5 hours. After the heat preservation is over, stop feeding HCl gas, and wait for the sample to cool naturally.

[0051] S3: Weigh 2.00g of the cooled roasted product, put it into a beaker with 100ml of pure water, and add about 0.8g of concentrated hydrochloric acid (concentration greater than 33%) dropwise, place the beaker in a water bath at 50°...

Embodiment 3

[0054] A method for separating valuable metals from copper-cobalt alloys, comprising the following steps:

[0055] S1: Use a jaw crusher or a ball mill to crush the copper-cobalt alloy, coarsely grind it, sieve it after coarse grinding, and weigh 4.00 g of copper-cobalt alloy powder with a particle size of less than 0.05 mm.

[0056] S2: Put the copper-cobalt alloy powder in the alumina crucible and send it into the roasting furnace together. 20 minutes before the temperature rise, start to pass in 50mL / min of argon gas to discharge the residual air; Gas, control the partial pressure of hydrogen chloride gas to 0.65MPa, and keep it warm for 5 hours. After the heat preservation is over, stop feeding HCl gas, and wait for the sample to cool naturally.

[0057] S3: Weigh 2.00g of the cooled roasted product, put it into a beaker with 100ml of pure water, and add about 0.8g of concentrated hydrochloric acid (concentration greater than 33%) dropwise, place the beaker in a water bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com