Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Adjustable pore size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina fiber-enhanced nano-alumina foam ceramic and preparation method thereof

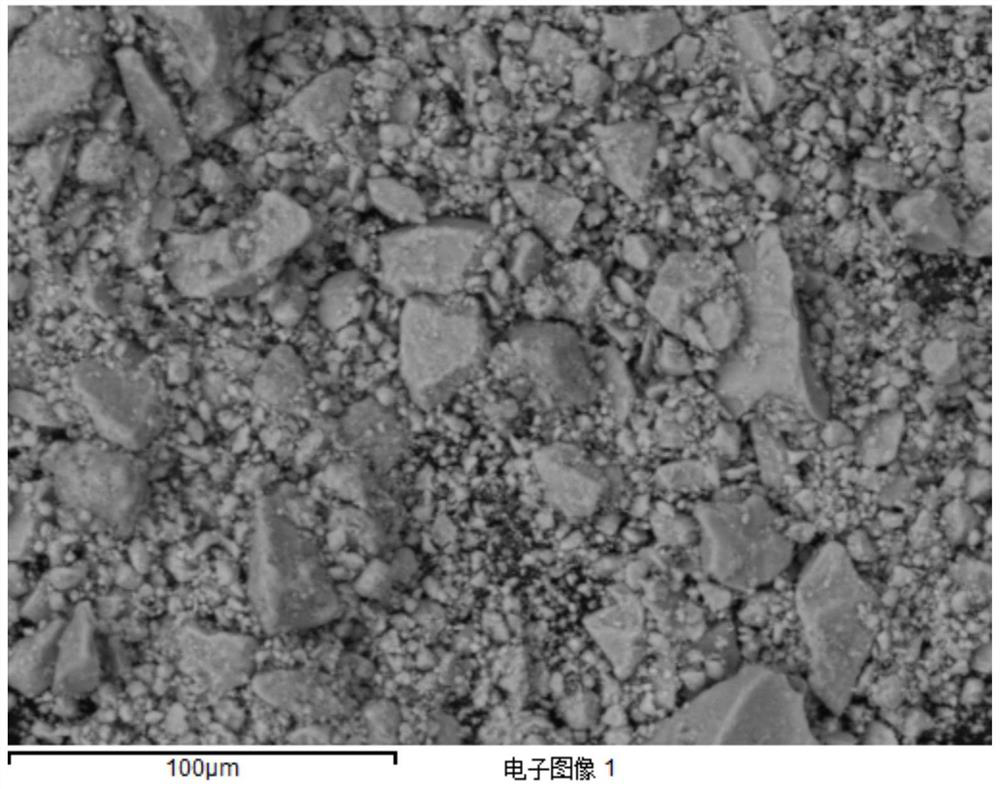

The invention belongs to the field of foam ceramic, and particularly relates to an alumina fiber-enhanced nano-alumina foam ceramic and a preparation method thereof. The alumina fiber-enhanced nano-alumina foam ceramic comprises the following raw materials: a nanometer aluminum oxide powder, a premix solution, a dispersing agent, aluminum oxide fiber, a foaming agent, an initiator and a catalyst, wherein premix solution is formed by adding a monomer and a crosslinking agent into an alcohol-water mixed solution; and the mass ratio of the alumina fiber to nano-alumina powder is (5-30): (95-70). By adopting the alcohol-water mixed solution as a solvent for gel casting, the surface tension among particles can be reduced, and the quality of dry blanks can be increased; the compressive strength of the finished product is more than 30MPa, the porosity is more than 50%, the volume density is less than 3g / cm<3>; the usage temperature is 1500-1750DEG C, the alumina fiber-enhanced nano-alumina foam ceramic is a lightweight and high temperature-resistant refractory material, and can be used in the field of lining materials of a high-temperature electric resistance furnace. The invention further provides a preparation method of the alumina fiber-enhanced nano-alumina foam ceramic, thus being suitable for industrial production.

Owner:JINING UNIV

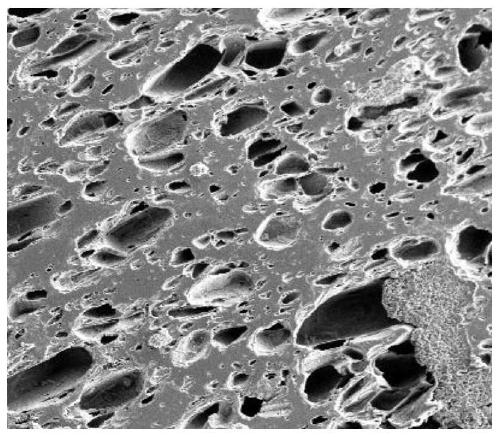

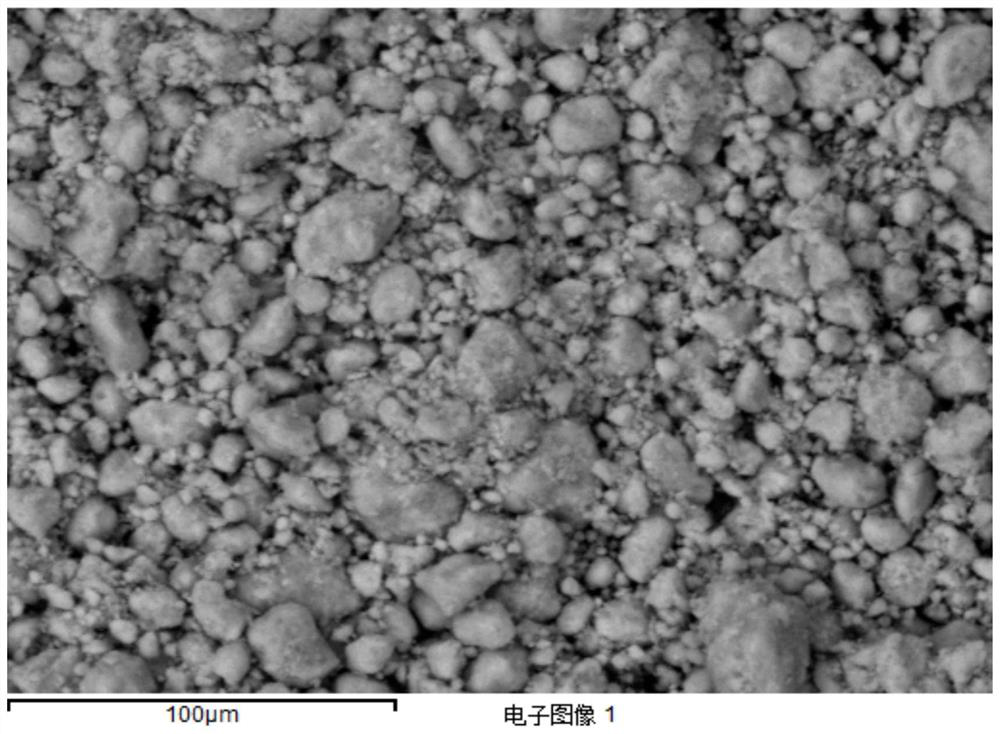

High-strength carbon aerogel as well as preparation method and application thereof

InactiveCN109850870AImprove mechanical propertiesOmit the replacement stepOther chemical processesCarbon preparation/purificationHexamethylenetetramineCarbonization

The invention discloses high-strength carbon aerogel as well as a preparation method and application thereof, and belongs to the technical field of preparation of phenolic and carbon aerogel. The preparation method comprises the following steps: industrial phenolic resin is used as a raw material, hexamethylenetetramine is used as a curing agent, ethylene glycol and water are used as solvents, mixing is performed, a sol-gel reaction is performed at a certain temperature, normal-pressure drying is performed to obtain phenolic aerogel, and carbonization is performed at a high temperature to obtain the carbon aerogel, wherein the aerogel microstructure is a three-dimensional network structure in which particles are interconnected. The preparation technology of the aerogel provided by the invention has the following three advantages: 1) the raw material is the industrial phenolic resin, so that the source is wide and the price is low; 2) the preparation cycle is short, the mixed liquid issolidified to obtain a wet gel without solvent replacement, the phenolic aerogel can be obtained by direct drying, and the preparation cycle is 2-3 days; and 3) normal-pressure drying is adopted, theequipment requirements are simple, and the processability is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

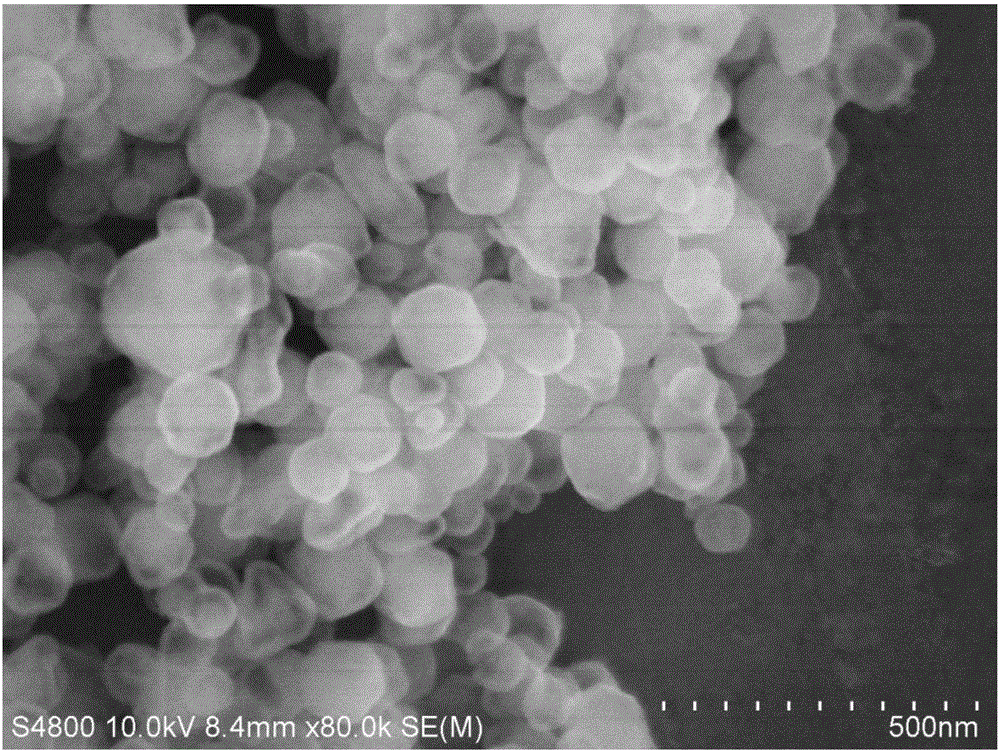

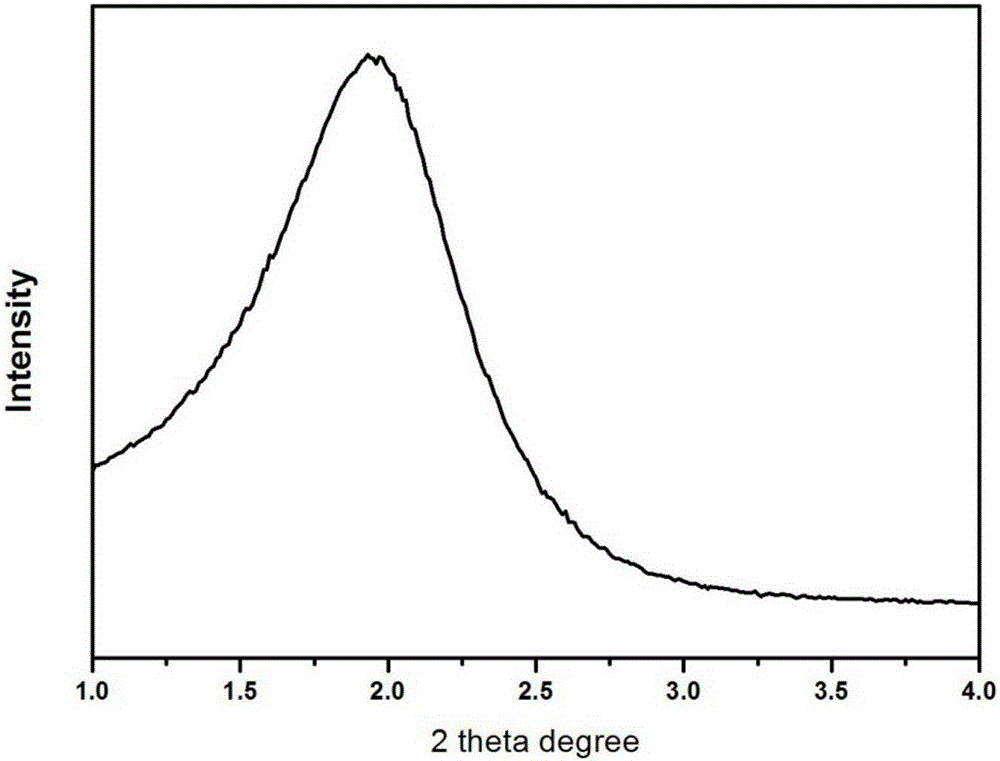

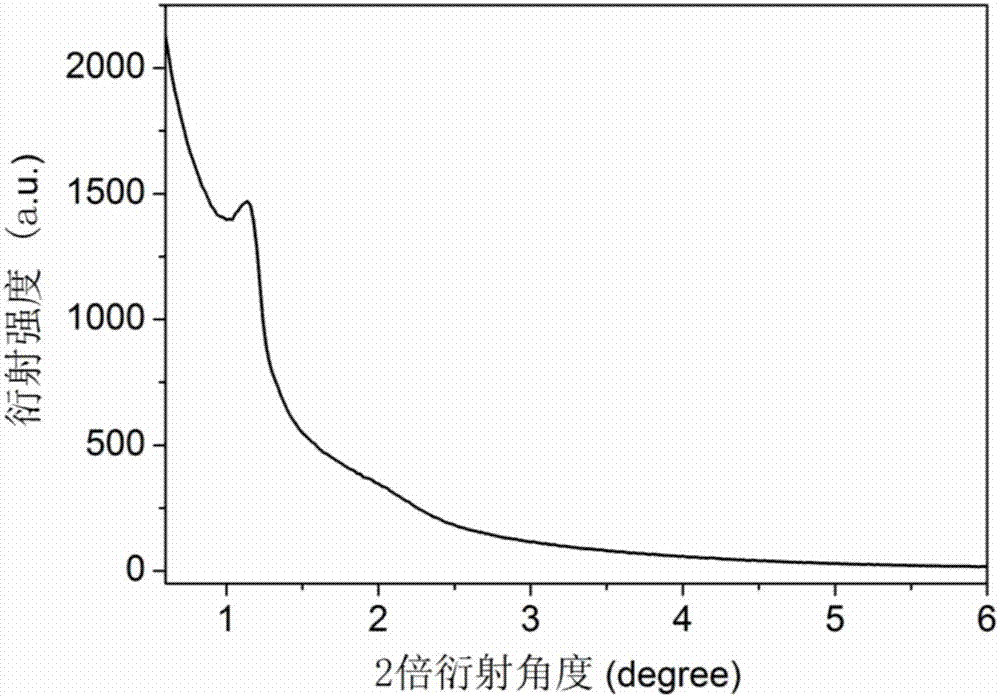

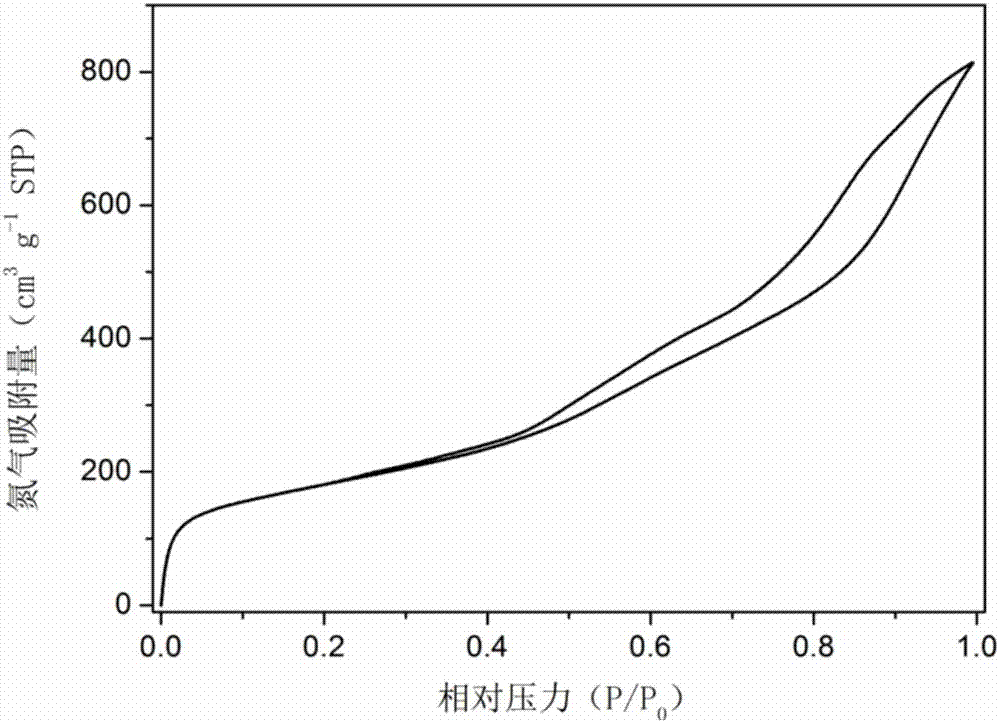

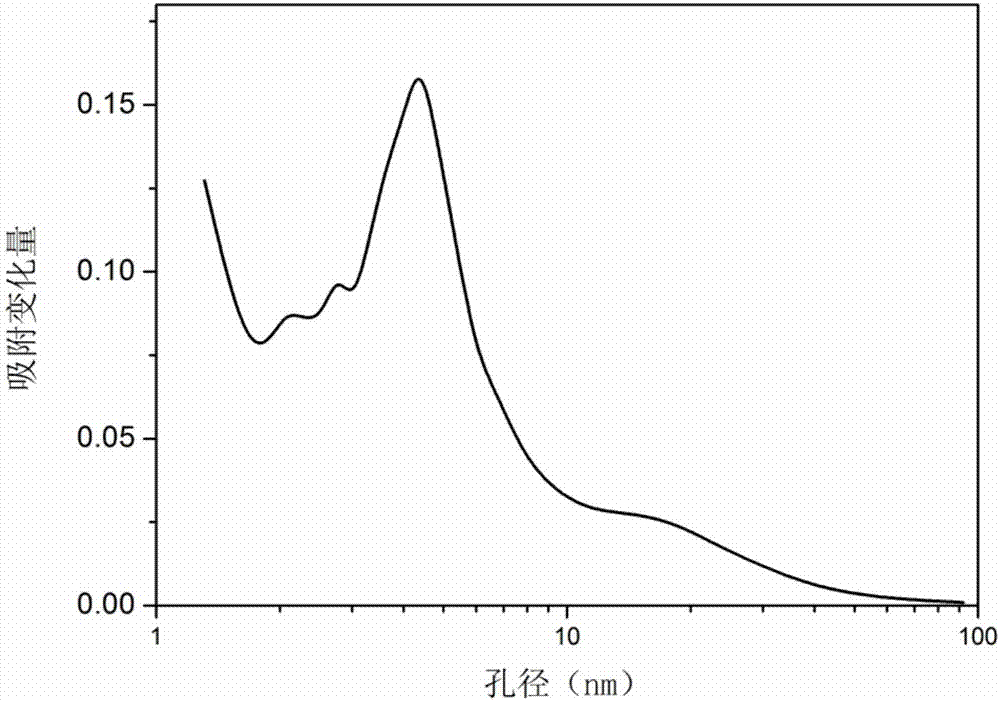

ZIF-8@MCM-41 molecular sieve and preparation method thereof

ActiveCN105170185ACoated evenlyGood chemical stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPorosityAfter treatment

The invention relates to a ZIF-8@MCM-41 molecular sieve and a preparation method thereof. The ZIF-8@MCM-41 molecular sieve is of a core-shell structure and is prepared with ZIF-8 particles as a core-phase material and a MCM-41 molecular sieve as a shell-phase material, wherein the MCM-41 molecular sieve is coated outside of the ZIF-8 particles. The preparation method comprises the following steps: 1) preparation of the ZIF8 particles; and 2) preparation of the ZIF-8@MCM-41 molecular sieve: dispersing the ZIF-8 particles in water, then adding a surfactant and alkali liquid, then heating the obtained dispersion liquid, slowly adding tetraethylortho silicate and continuously carrying out reaction, carrying out after-treatment so as to obtain white powder, then adding the white powder into an ethanol solution and carrying out heating reflux so as to remove the surfactant, and carrying out after-treatment so as to obtain the ZIF-8@MCM-41 molecular sieve. The ZIF-8@MCM-41 molecular sieve prepared by using the method provided by the invention has the advantages of large specific surface area, high porosity and excellent catalytic reaction activity.

Owner:WUHAN UNIV OF TECH

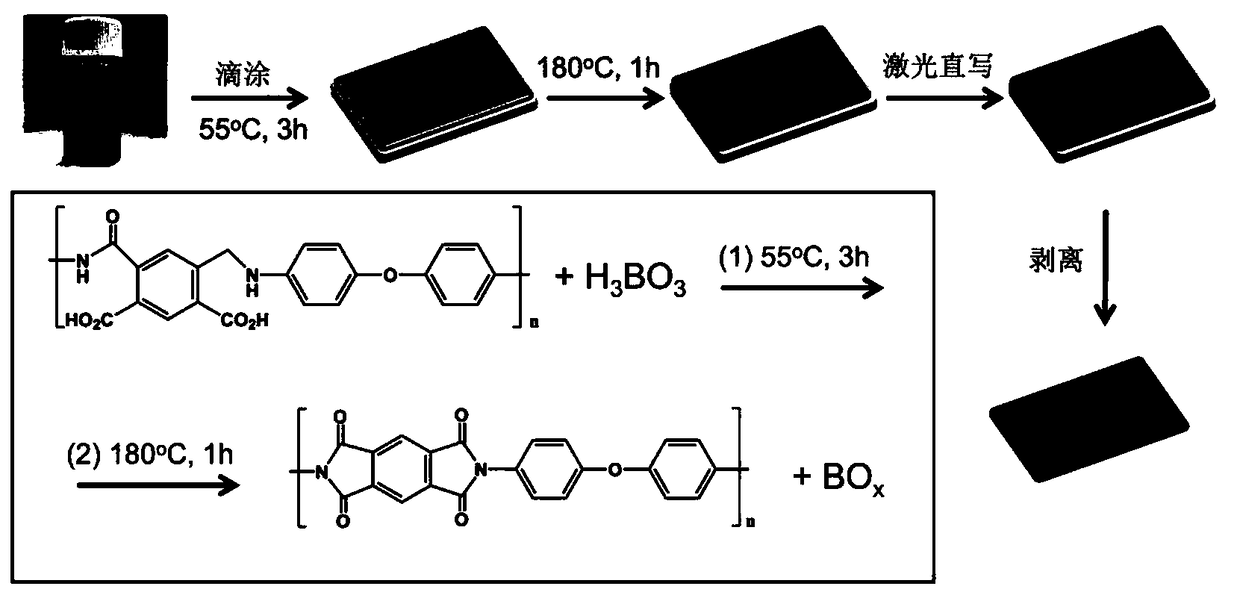

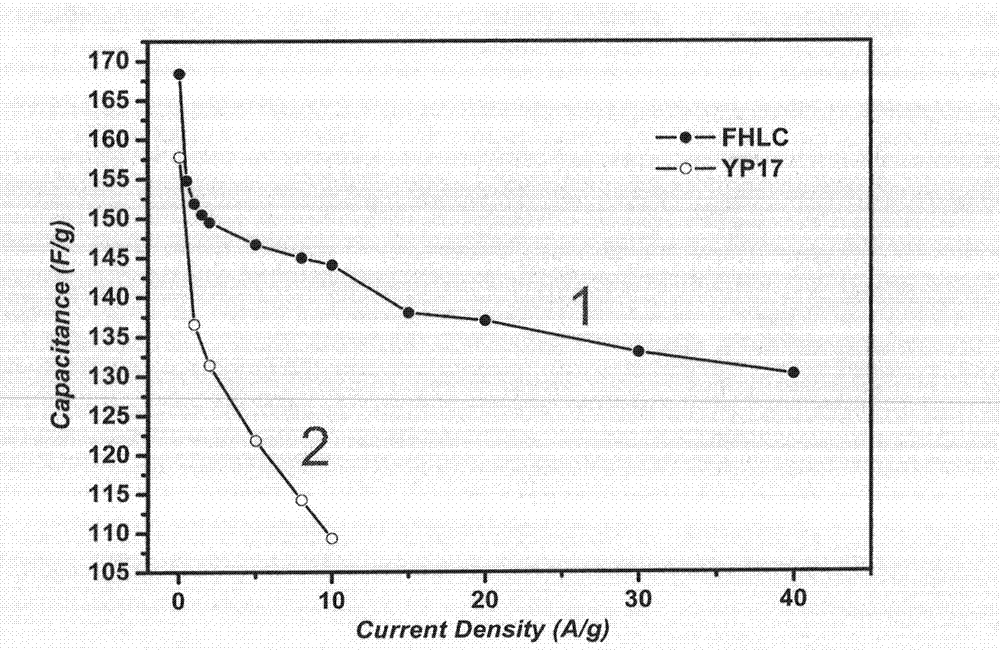

Preparation method of boron-doped porous carbon material

ActiveCN108597894AImprove performanceLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureComposite filmPorous carbon

The invention discloses a preparation method of a boron-doped porous carbon material. The preparation method comprises the following steps: (1) preparing a mixed solution; (2) preparing polyamide acid(PAA) / boric acid composite film; (3) preparing polyimide (PI) / boric acid composite film; and (4) preparing the boron-doped porous carbon material. The porous carbon material can be directly used forpreparing the high-performance miniature super-capacitor. The method is fast and simple and low in cost, the prepared porous carbon material is high in specific area, adjustable in aperture distribution and good in conductivity, the porous carbon material can be directly patterned and a certain amount of boron is doped, and the porous carbon material can be used for preparing the high-performanceminiature super-capacitor.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

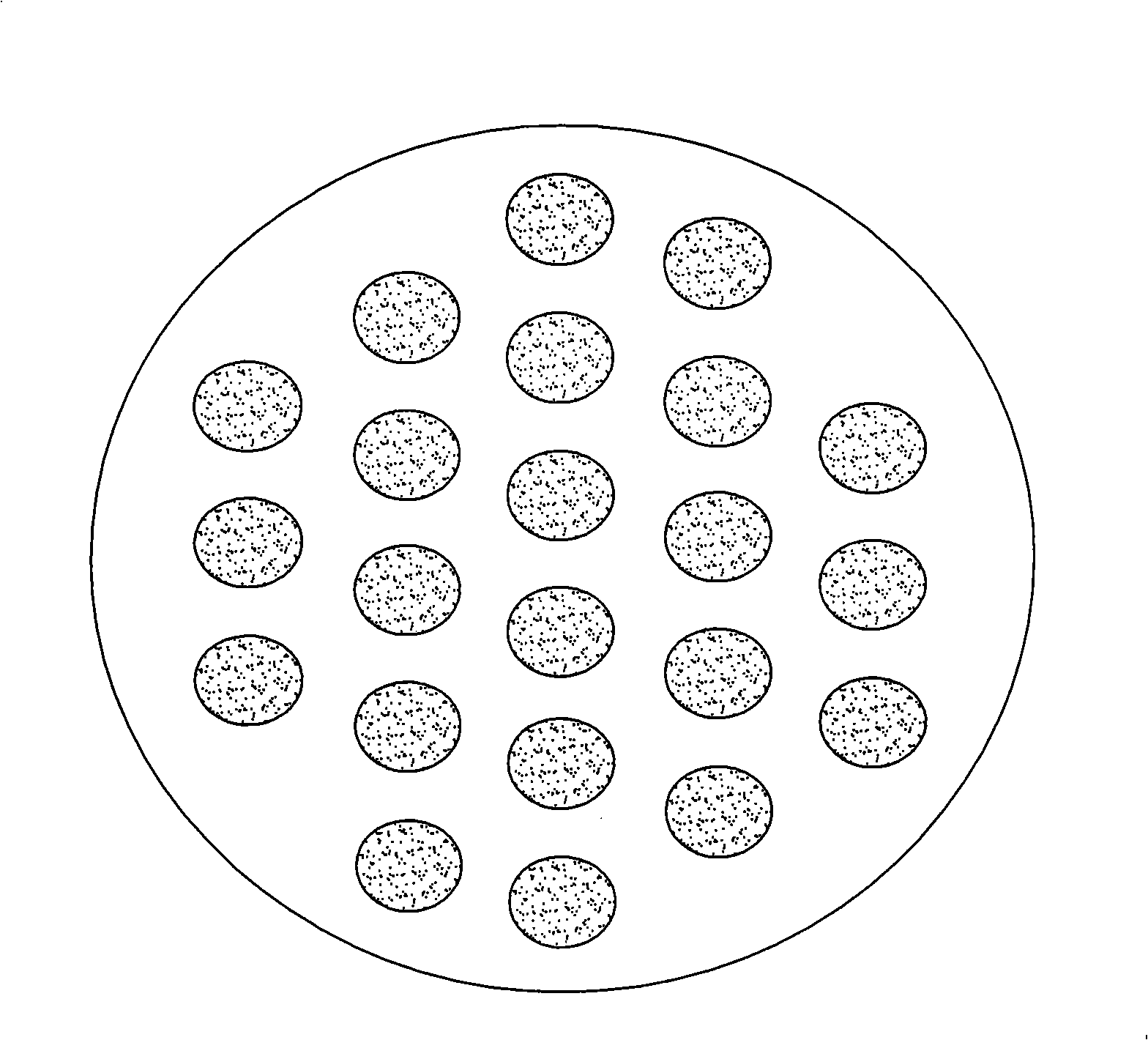

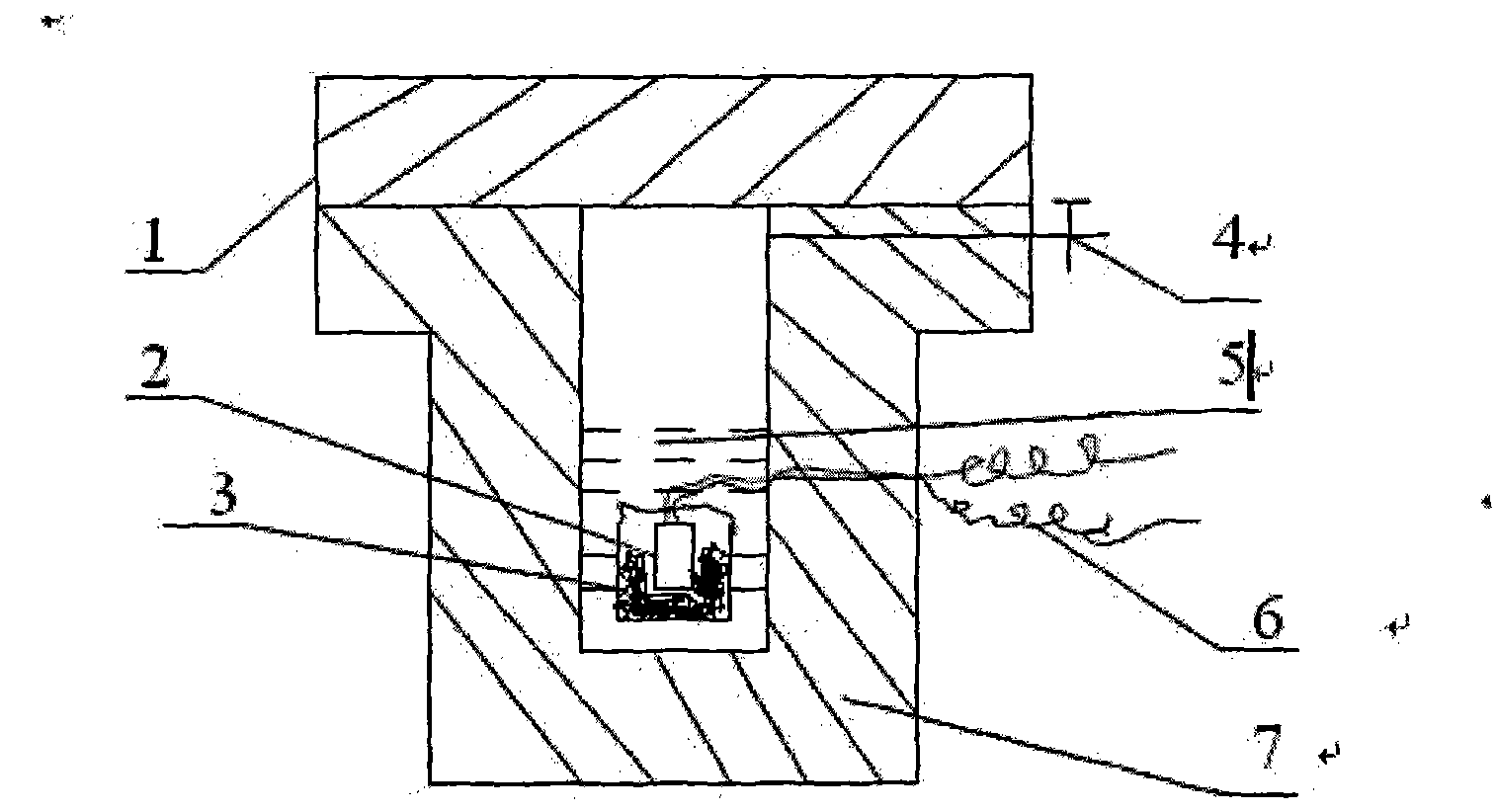

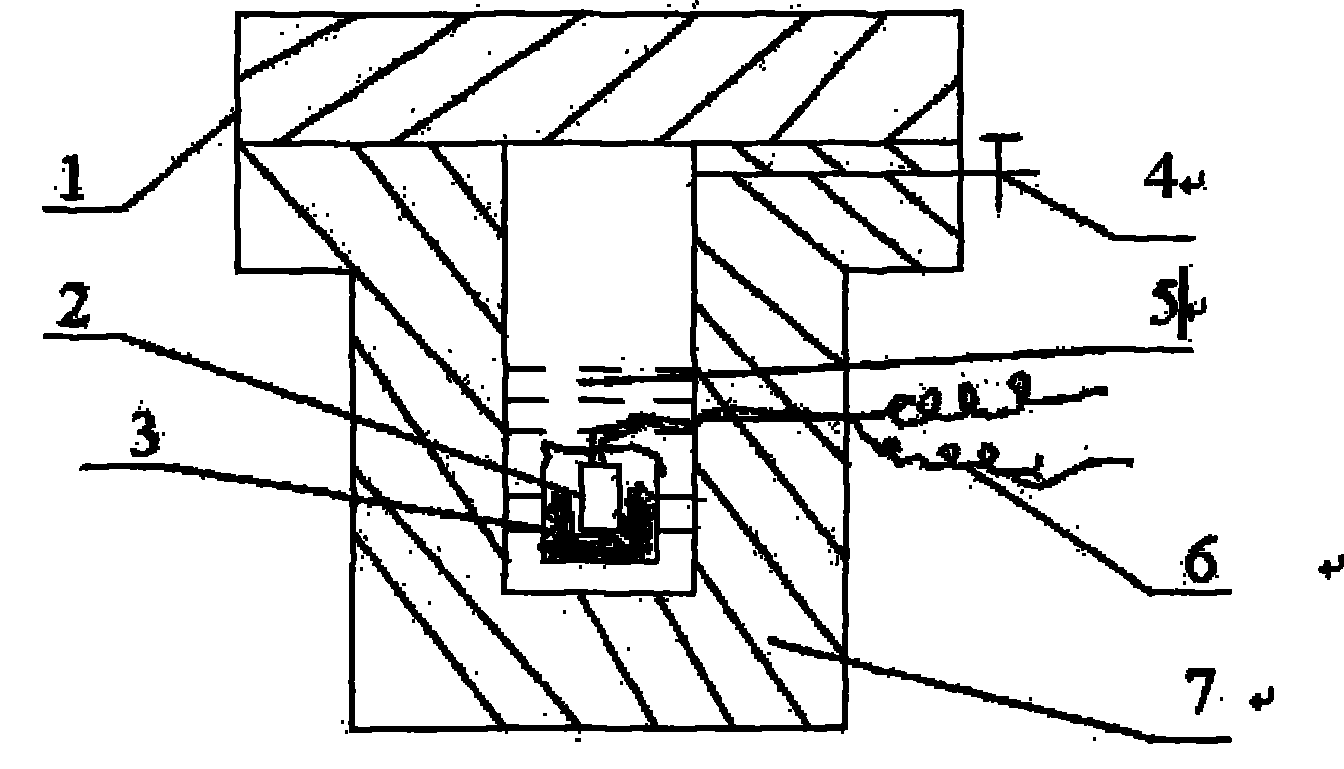

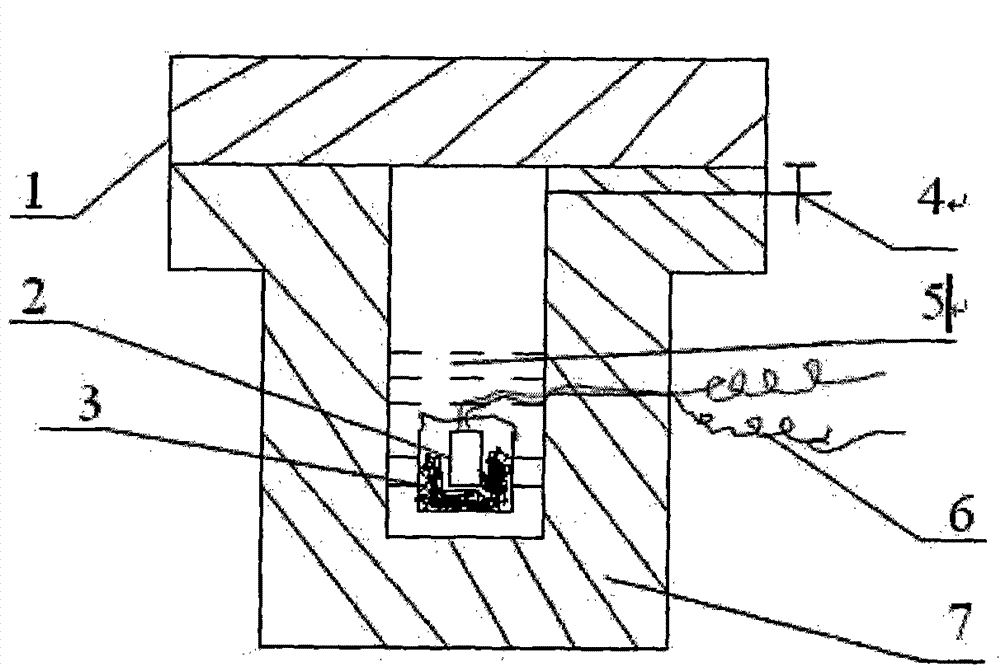

Method for preparing epoxy resin base polyalcohol integral pole and special mold thereof

InactiveCN101293148AEasy to manufactureMild reaction conditionsOther chemical processesSolid sorbent liquid separationChemical structureFirming agent

The invention relates to a preparation method of epoxy resin-based polymer monolithic column; a given quantity of the epoxy resin and firming agents and a low molecular weight polymer mixture with a good compatibility used as pore-forming agents are added in an empty tube column; solidification temperature is controlled so as to regulate the speed of polymerization reaction; after the solidification is finished, the pore-forming agents are removed by washing so as to get the polymer monolithic column. The preparation process of the invention is simple and environmental friendly. The invention also discloses a dedicated mould. The monolithic column can be made into various specifications and forms as required and has the advantages of evenly distributed aperture, adjustable size, strong hydrophilic property, acid and alkali resistance, solvent resistance and good thermostabilization; and a large number of reactive functional groups are contained in the chemical constitution of the material of the monolithic column, which is suitable for performing a plurality of chemical modifications to an inner surface of a pore canal so as to further functionalize. The preparation method of the epoxy resin-based polymer monolithic column can be applied extensively to the fields such as the extraction and recovery of solid phase, the preparation of chromatogram, the separation of biological medicines, the environmental protection and the catalysis etc.

Owner:NINGBO UNIV

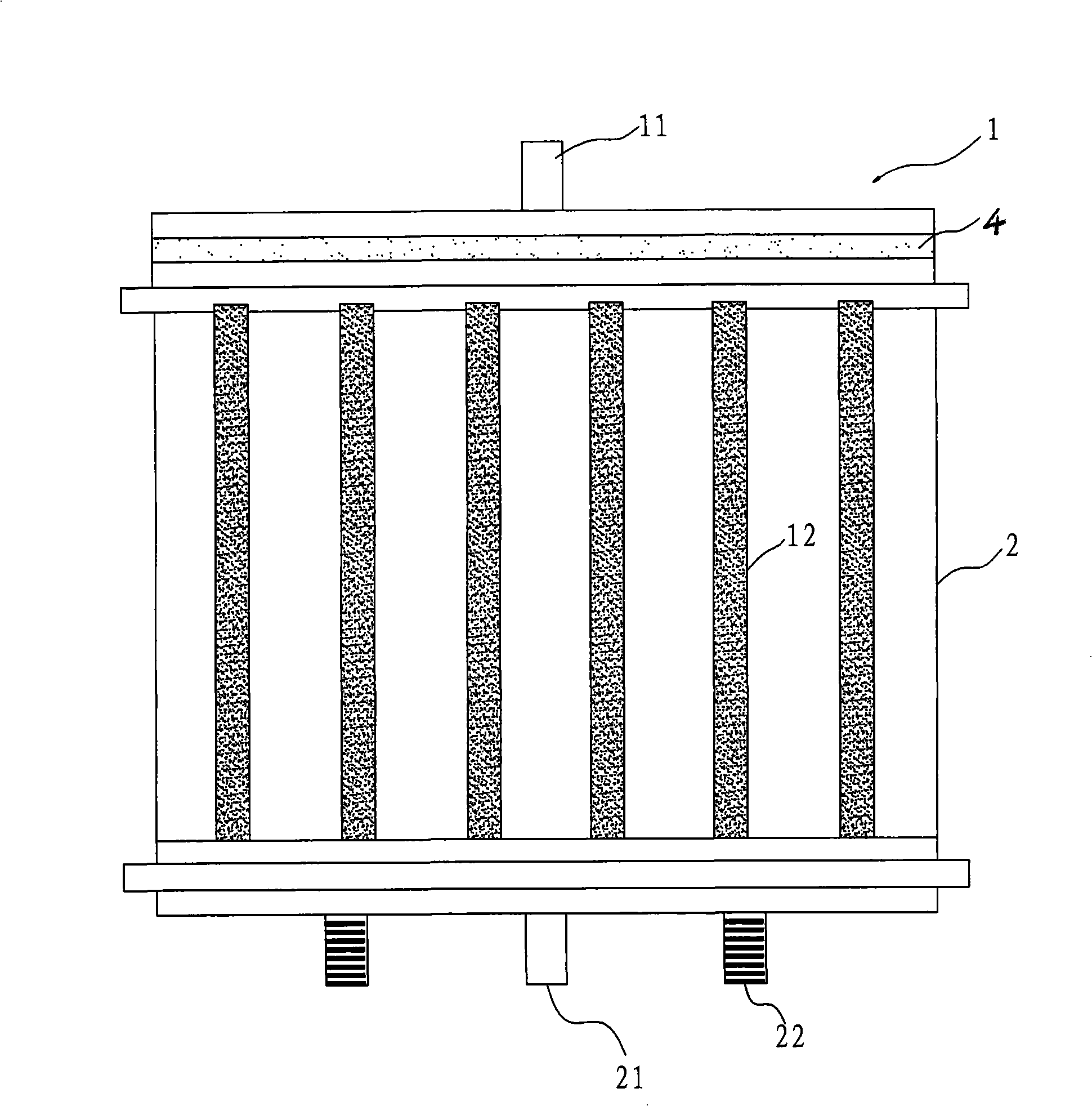

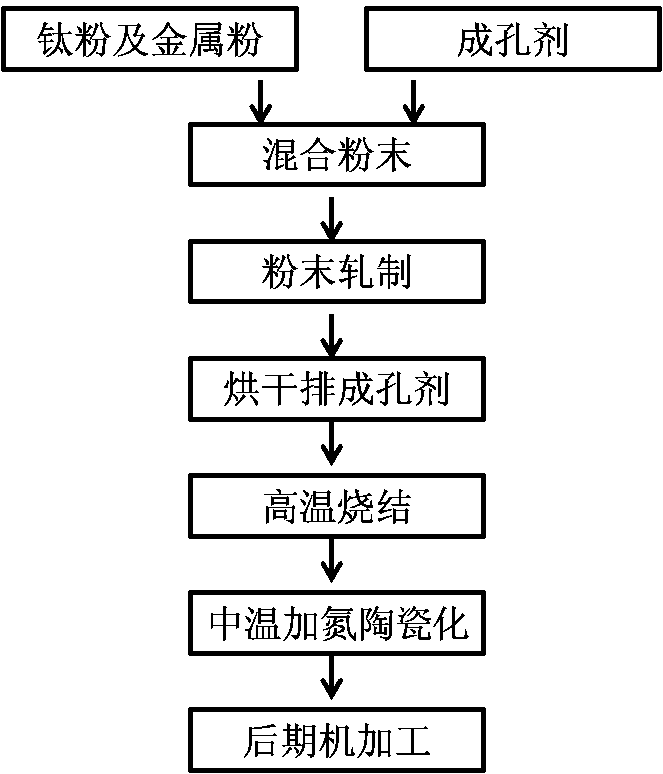

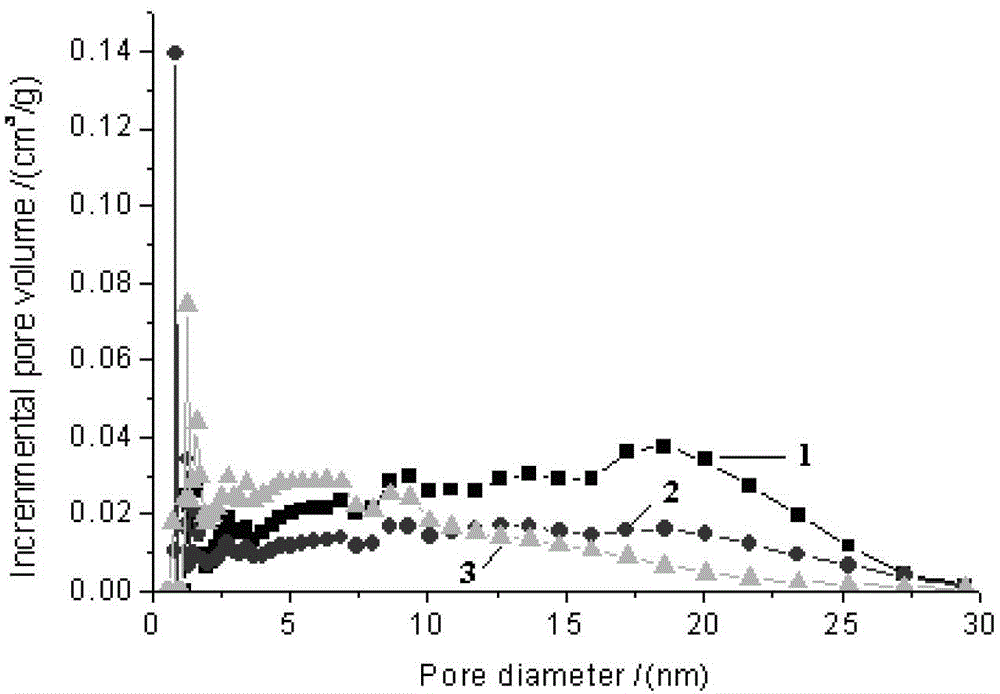

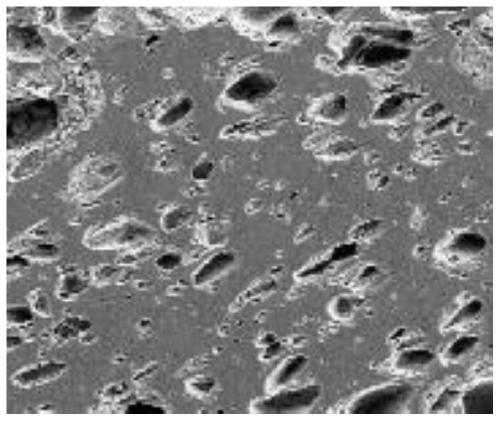

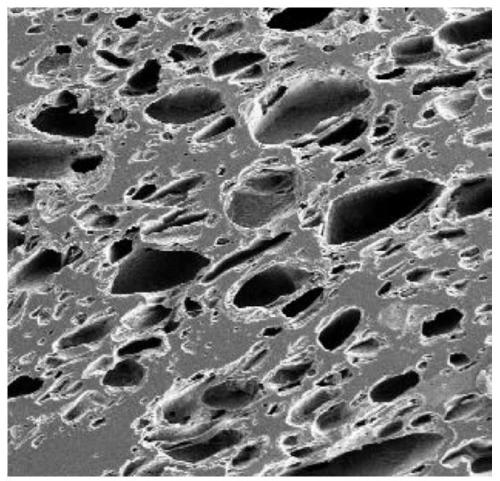

Porous metal-ceramic composite material gas spreading layer used for hydrogen fuel cell and preparation method thereof

ActiveCN102810680AAdjustable pore size distributionImprove operational efficiencyCell electrodesFuel cell detailsCeramic compositeHydrogen fuel cell

The invention describes novel gas spreading base material which uses titanium and an alloy thereof as the basic raw material and a metal-ceramic composite material porous thin strip made by a powder metallurgy processing technique and a thermal treatment surface layer material ceramic technique as a hydrogen fuel cell. The gas spreading layer of the composite material has good mechanical strength and can provide a stable structural support for a membrane electrode (MEA). By adopting the gas spreading layer of the composite material, a low-resistance contact between a catalyst electrode and a dual-polar plate is realized, so that the resistance in the cell is lowered, the current conducting efficiency is improved, and the running efficiency of the hydrogen fuel cell is improved.

Owner:北京开元新能科技有限公司

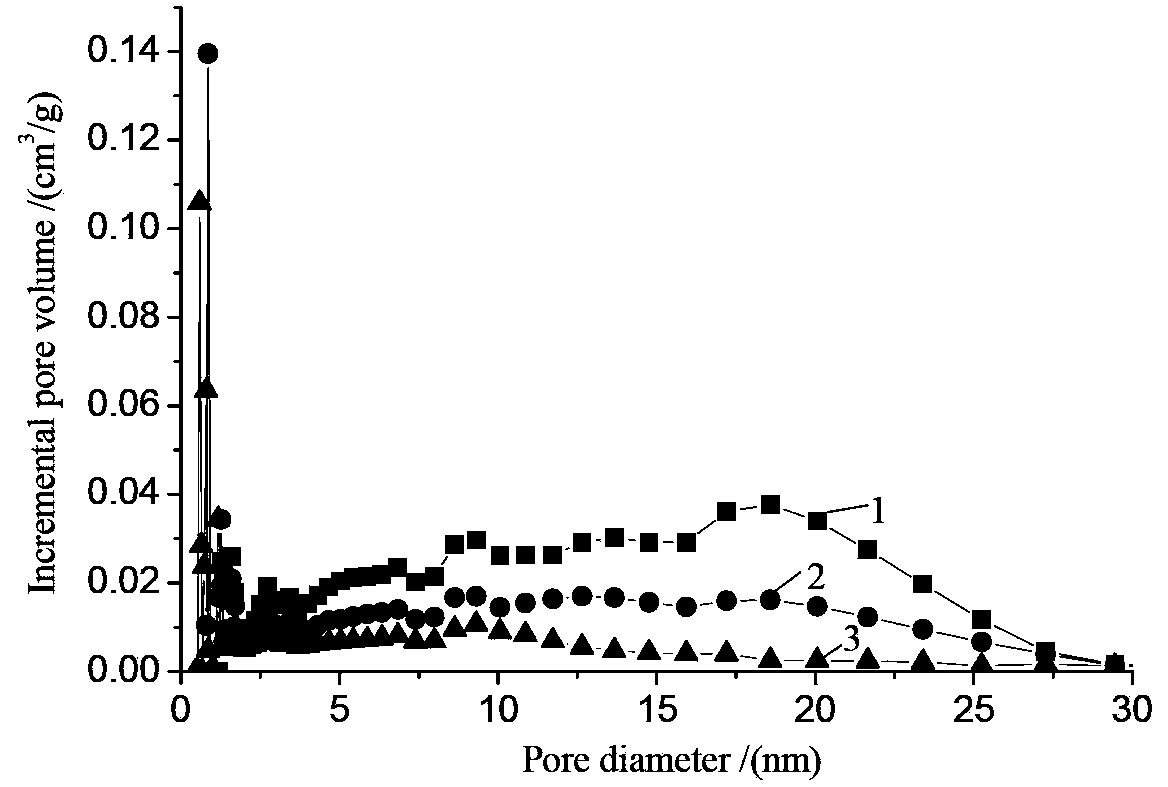

Supported cobalt-based catalyst for Fischer-Tropsch synthesis, and preparation method and application thereof

InactiveCN106582753AHigh mechanical strengthImprove thermal conductivityHeterogenous catalyst chemical elementsLiquid hydrocarbon mixture productionCobalt(II,III) oxideUltimate tensile strength

The invention provides a supported cobalt-based catalyst for Fischer-Tropsch synthesis. The supported cobalt-based catalyst is composed of cobaltosic oxide, an oxide of a precious-metal aid, an oxide of a non-precious-metal aid and a tungsten carbide carrier in a weight ratio of (10-80): (0-3): (0-20): 100. The supported cobalt-based catalyst has the advantages of high mechanical strength and good thermal conductivity.

Owner:中科潞安能源技术有限公司

Preparation method of C/SiC composite material

The invention provides a preparation method of a C / SiC composite material. The C / SiC composite material is prepared by preparing a porous C / C composite material by means of an infiltration method. Asa special high-activity porous body C / C is adopted to reactive infiltration, the mechanical property and the anti- ablation property of the material are improved. The preparation method can be also applied to rapid low-cost preparation of a ceramic-based composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

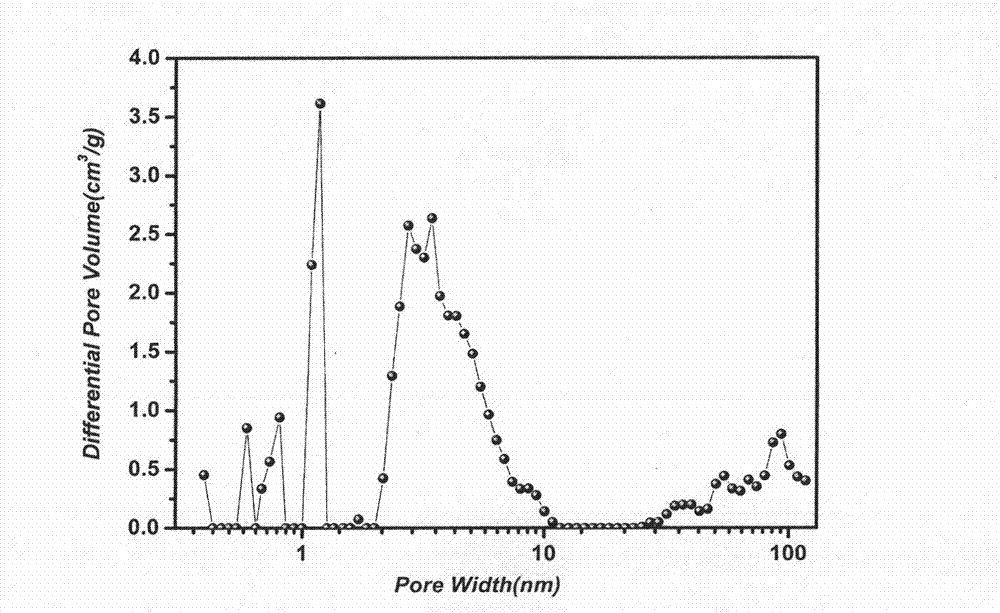

Cross-linking agent modified XAD-4 resin and method for preparing same

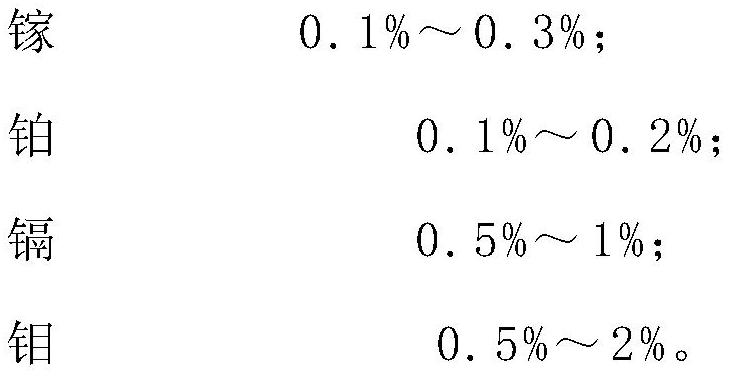

InactiveCN102977487AImprove pore structureNarrow pore size distributionOther chemical processesPore diameterFriedel–Crafts reaction

The invention discloses a cross-linking agent modified XAD-4 resin, which is a mesoporous resin containing rich micropores and prepared from a cross-linking agent and an XAD-4 resin through Friedel-Crafts reaction, wherein the pore diameters of the mesoporous resin are distributed between 1 to 9.5 nm, the average pore diameter is 2.58-4 nm, the specific surface area is 721-1284 m<2> / g, and the pore volume is 0.67-1.1 cm<3> / g. The method for preparing the cross-linking agent modified XAD-4 resin comprises the following step of carrying out the Friedel-Crafts reaction between the cross-linking agent and the XAD-4 resin to prepare the modified XAD-4 resin, wherein the dosage of the cross-linking agent is 50-100% of the quantity of the XAD-4 resin material. The adsorbent has the characteristics of large specific surface area, narrow pore diameter distribution and easily controllable porous structure, and is obviously superior to the XAD-4 resin in the adsorption capability to nonpolar and weakly polar materials; and therefore, the adsorbent is wide in application prospect in fields of treating and recycling phenols wastewater and the like.

Owner:CENT SOUTH UNIV

Preparation method of crosslinking nanofiltration membrane

InactiveCN104437142AUniform pore size distributionAperture adjustableSemi-permeable membranesChemistrySurface-active agents

The invention discloses a preparation method of a crosslinking nanofiltration membrane. The method comprises the steps of completely dissolving phenolic resin and tetraethenyl triamine in a certain mass ratio through a medium, wherein the mass ratio of phenolic resin to tetraethenyl triamine is (2-3):(5-6), and the mass ratio of phenolic resin to the medium is (8-10):(2-3); uniformly agitating to obtain a settled solution, wherein the medium is prepared from polyethylene glycol and a surface active agent OP-10 in the mass ratio of (4-8):(2-3); removing bubbles; adding a crosslinking agent, namely, a formaldehyde solution; continuously agitating; preserving heat for 1 to 24 hours at the temperature of 60 to 80 DEG C in a drying tank; agitating for 2 to 4 minutes at the rotating speed of 1,000 to 3,000r / min to obtain a casting membrane solution; coating a glass sheet with the generated casting membrane solution by a film casting method; drying under a vacuum condition at the temperature of 60 to 80 DEG C; soaking for 2 to 4 hours through a diethyl ether solution to remove the medium, namely, polyethylene glycol and the surface active agent OP-10; washing with alcohol and distilled water for a plurality of times; and then drying to obtain the crosslinking nanofiltration membrane. The method is performed under mild preparation conditions, does not have strict requirements, is convenient to operate, enables simple forming, and meets the demand on mass production; the prepared nanofiltration membrane is of a symmetric structure, and is uniform in pore size distribution, adjustable in pore size, and outstanding in repeatability.

Owner:华玉叶

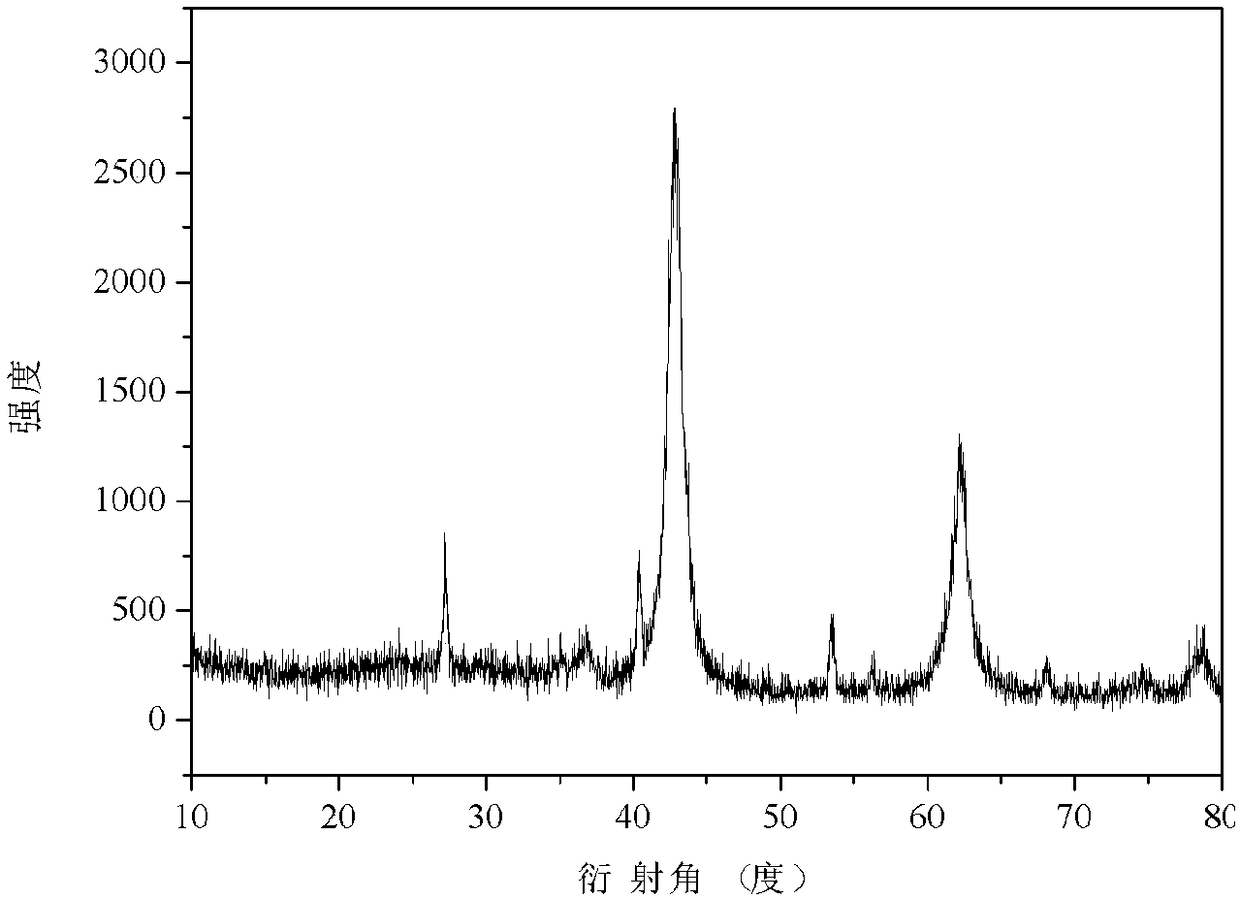

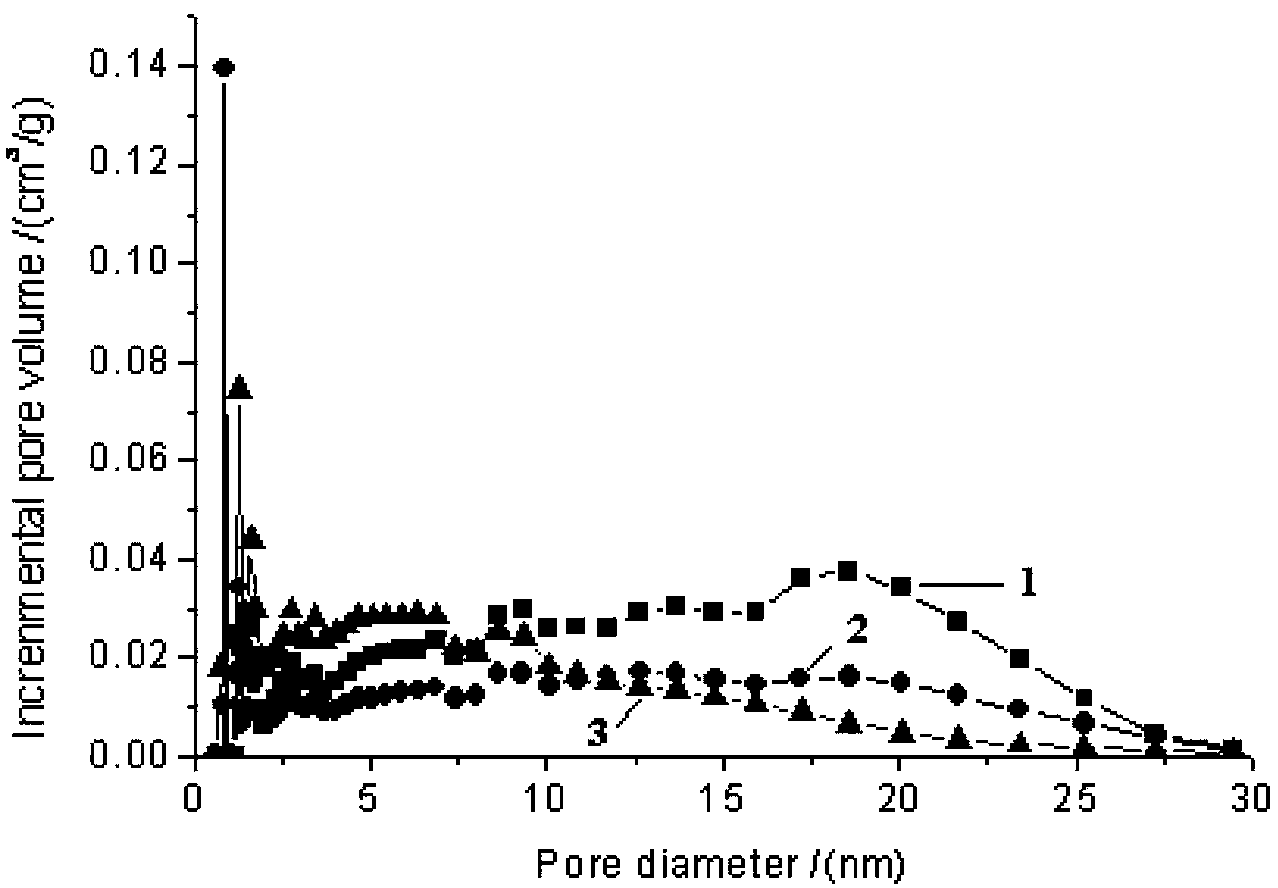

Supported cobalt-base catalyst and preparation method thereof, and application of catalyst in Fischer-Tropsch synthesis

InactiveCN106732651ALarge specific surface areaAdjustable pore size distributionHeterogenous catalyst chemical elementsLiquid hydrocarbon mixture productionActivated carbonCobalt(II,III) oxide

The invention relates to a supported cobalt-base catalyst which is composed of the following components in parts by weight: 15-60 parts of tricobalt tetraoxide, 0-1 part of noble metal aid oxide, 0-15 parts of non-noble metal aid oxide and 100 parts of activated carbon microspheres. The supported cobalt-base catalyst has the advantages of large specific area, centralized and adjustable pore size distribution, abundant pore structures, uniform and adjustable cobalt particle size and high selectivity for target products.

Owner:中科潞安能源技术有限公司

Adsorbent for removing hexafluoropropylene in octafluorocyclobutane and method for preparing adsorbent

ActiveCN107694509AEfficient removalLarge specific surface areaGas treatmentOther chemical processesHexafluoropropyleneSorbent

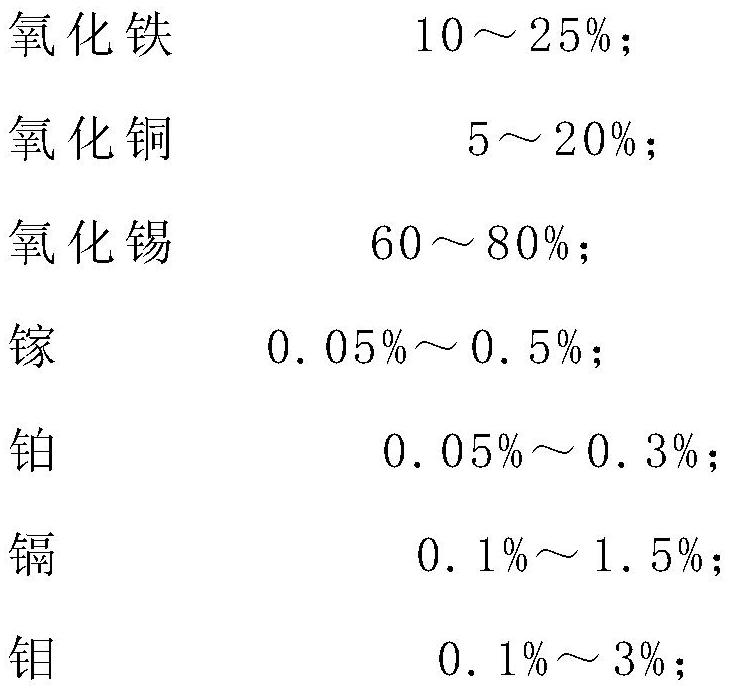

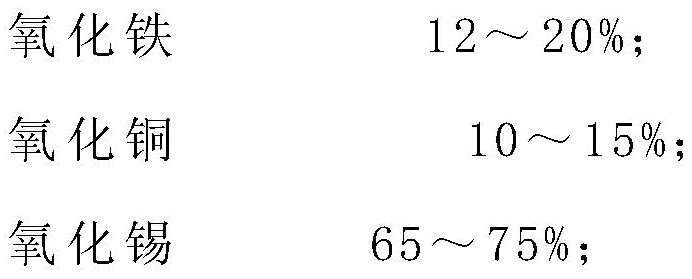

The invention discloses an adsorbent for removing hexafluoropropylene in octafluorocyclobutane. The adsorbent comprises, by weight, 10-25% of iron oxide, 5-20% of copper oxide, 60-80% of tin oxide, 0.05-0.5% of gallium, 0.05-0.3% of platinum, 0.1-1.5% of cadmium and 0.1-3% of molybdenum. The invention further discloses a method for preparing the adsorbent. The method includes steps of (1), addingsalt solution of the iron oxide, the copper oxide and the tin oxide into a hydrothermal reactor and uniformly stirring the salt solution of the iron oxide, the copper oxide and the tin oxide; (2), adding salt solution of the gallium, the platinum, the cadmium and the molybdenum into the hydrothermal reactor and carrying out doping modification; (3), adding metal mesh packing into the hydrothermalreactor, placing the hydrothermal reactor with the added metal mesh packing into a drying oven and carrying out reaction on solution in the hydrothermal reactor at the hydrothermal treatment temperatures of 110-160 DEG C for 40-70 min. The adsorbent and the method have the advantage that the hexafluoropropylene in the octafluorocyclobutane can be effectively removed by the adsorbent.

Owner:SUZHOU JINHONG GAS CO LTD

Preparation method of Ca-Mg-Al-Si porous microcrystalline glass

The invention discloses a preparation method of a Ca-Mg-Al-Si porous microcrystalline glass, and belongs to the field of microcrystalline glass filter materials. The preparation method comprises following steps: weighing MgO, SiO2, CaO, Na2CO3, Na2B4O7, Al2O3, Fe2O3, and stainless steel slag, evenly mixing, adding the mixture into a crucible, placing the crucible in a muffle furnace, maintaining atemperature of 1400 to 1500 for 3 to 5 hours; taking out the mixture, quenching the mixture by cold water to obtain water quenched glass; breaking the water quenched glass, ball-milling the glass, fully mixing the glass with NaCl, placing the mixture in an electric spark plasma sintering furnace, carrying out hot pressed sintering for 1 to 3 minutes at a constant temperature of 650 to 725 DEG C under a pressure of 45 to 50 kN; placing sintered and moulded Ca-Mg-Al-Si porous microcrystalline glass into water, washing, and soaking to obtain the Ca-Mg-Al-Si porous microcrystalline glass. The provided preparation method can obtain the porous microcrystalline glass for different filter objects, the porosity and pore size of the microcrystalline glass are adjustable, the strength is high, and the microcrystalline glass has communicated pores.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

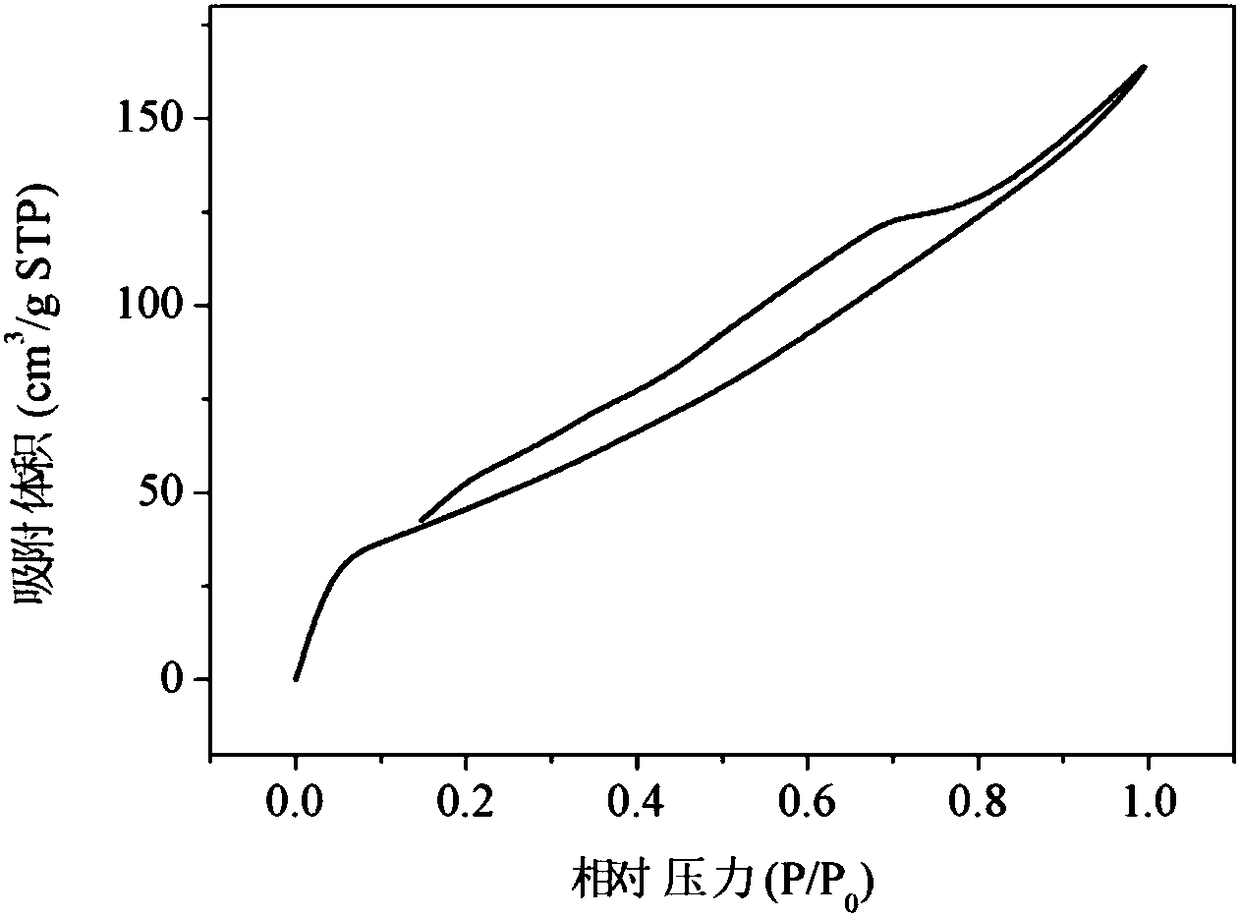

Mesoporous magnesium oxide material and preparation method thereof

The invention discloses a mesoporous magnesium oxide material and a preparation method thereof, and belongs to the technical field of preparation and application of magnesium oxide materials. Glucoseis added into water to obtain a glucose aqueous solution; magnesium nitrate is added into the glucose aqueous solution and stirred for 5-10 min under the condition of room temperature, and a magnesiumnitrate and glucose aqueous solution is obtained; the magnesium nitrate and glucose aqueous solution is subjected to heat treatment at the temperature of 100-120 DEG C for 24-48 hours, and water molecules in the solution are evaporated to obtain a magnesium nitrate and glucose mixture; finally, the mixture is subjected to heat treatment at 500-600 DEG C for 2-4 hours to obtain the mesoporous magnesium oxide material. The prepared mesoporous magnesium oxide material is of a three-dimensional porous structure, the pore size is 2-10 nm, the volume of pores is 0.5-1.5 cm<3> / g, and the BET specific surface area is 100-300 m<2> / g. The prepared mesoporous magnesium oxide material is large in specific surface area, high in porosity and controllable in pore size distribution, and also has excellent characteristics of the magnesium oxide materials. The mesoporous magnesium oxide material has important application prospects in many fields due to the special mesoporous structure.

Owner:JILIN UNIV

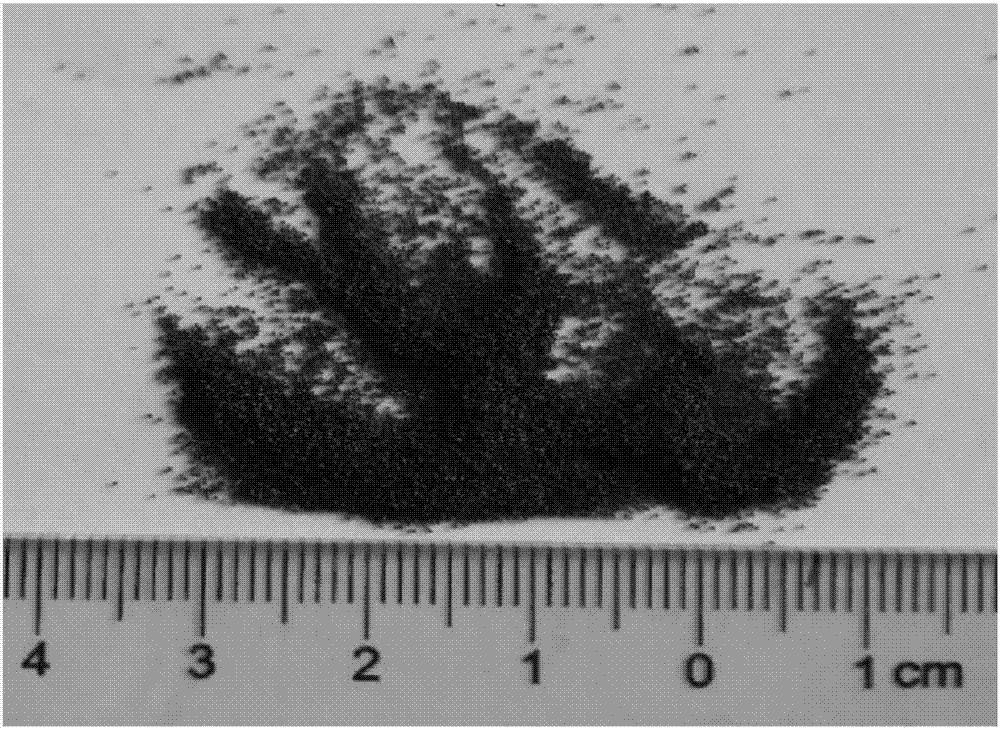

Composite material prepared from cork oak bark softwood and aluminum oxide and preparation method

PendingCN113354440AAdjustable pore size distributionHigh porosityCeramicwareHeat conservationThermal transmittance

The invention relates to the technical field of heat insulation and heat preservation materials, in particular to a cork aluminum oxide porous composite material prepared by utilizing the natural cell structure and flame retardant property of cork, and particularly relates to a composite material prepared from cork oak bark cork and aluminum oxide and a preparation method. The material contains the following components in parts by weight: 70-98 parts of aluminum oxide, 1-25 parts of softwood and 1-5 parts of binder, the softwood is used as a pore-forming agent, the softwood / aluminum oxide porous composite material is prepared by using the natural cellular structure and flame-retardant characteristic of the softwood, and the pore size distribution and porosity are adjustable; the cork / alumina porous composite material prepared by the invention has the advantages of high porosity, small density, high compression strength, low thermal conductivity and favorable heat insulation property, can be used as a furnace lining material of a high-temperature kiln, effectively solves the problem of shortage of high-temperature furnace lining materials in China, and has important significance for realizing energy conservation and emission reduction and improving the additional value of cork products; the material can be widely applied to the heat insulation fields of high-temperature furnaces, buildings, transportation, aerospace and the like.

Owner:山东省栓皮栎产业技术研究院有限公司 +2

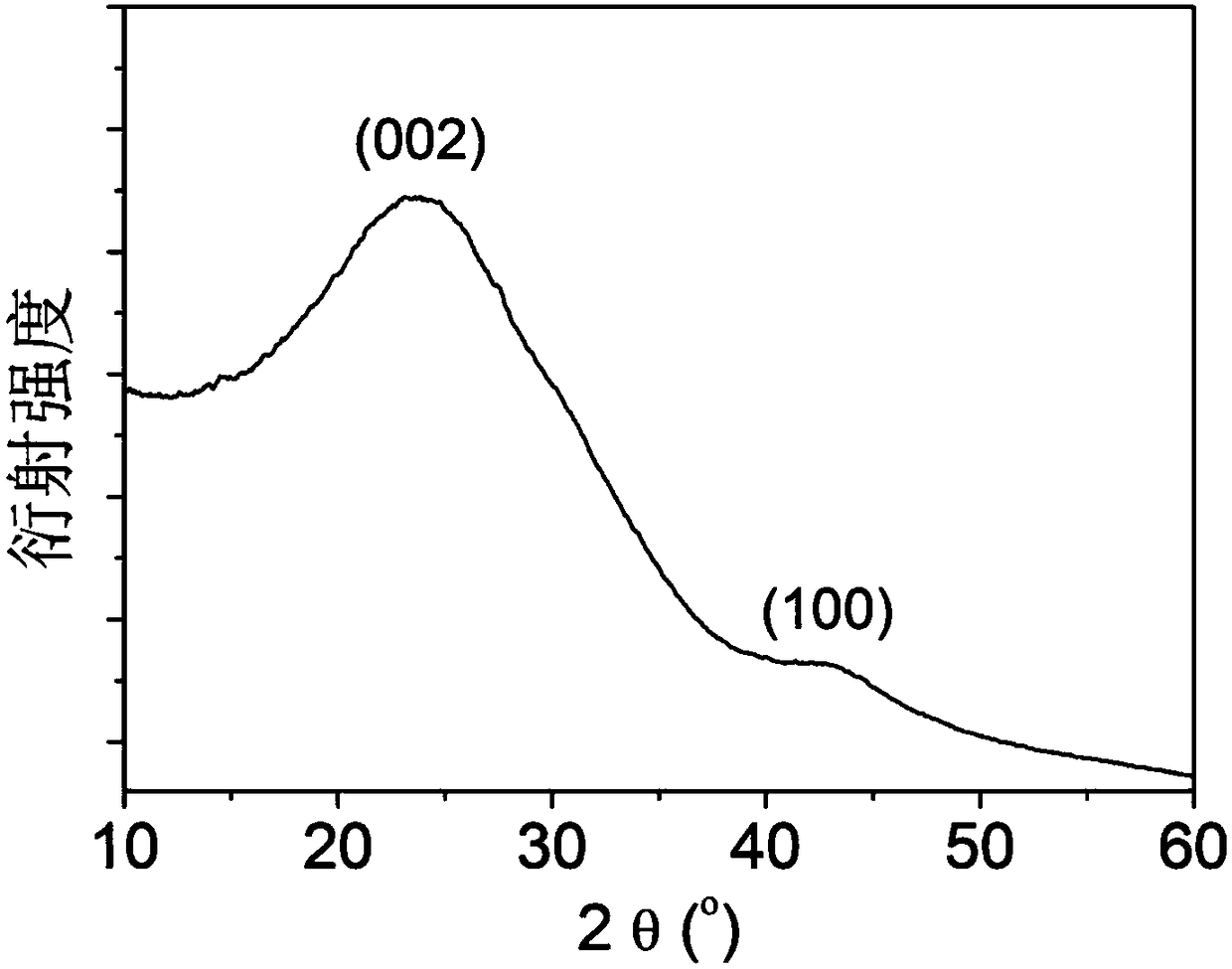

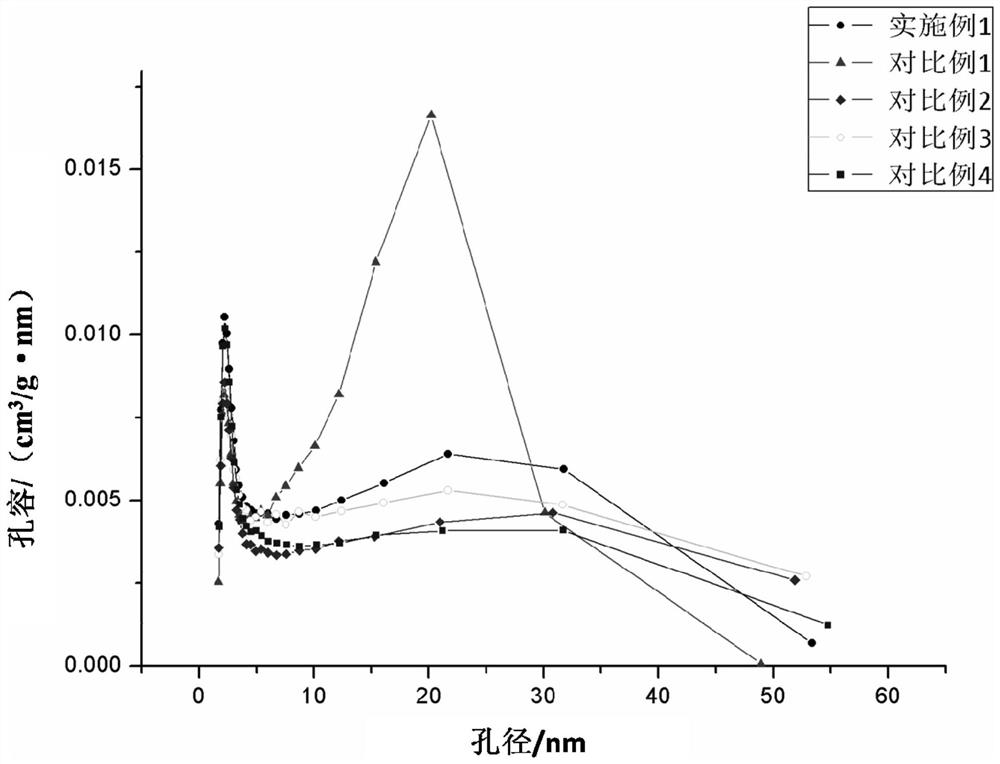

Hard carbon negative electrode material for sodium ion battery based on phenolic resin and its preparation method and application

ActiveCN109742383BIncrease energy densityHigh capacity densityCell electrodesSecondary cellsElectrical batterySodium-ion battery

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Mesoporous magnesium silicate/polybutylene succinate composite scaffold as well as preparation method and application thereof

InactiveCN107320783AImprove connectivityUniform pore sizeTissue regenerationProsthesisIn vivoPoly(butylene succinate)

The invention discloses a mesoporous magnesium silicate / polybutylene succinate composite scaffold as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing polybutylene succinate with an organic solvent, so as to obtain a mixture I; (2) mixing mesoporous magnesium silicate and a pore-foaming agent with the mixture I in the step (1), so as to obtain a mixture II; and (3) compressing the mixture II in the step (2), removing the organic solvent, and removing the pore-foaming agent, and drying. By utilizing the mesoporous magnesium silicate / polybutylene succinate composite scaffold, the adhesion and proliferation of an MC3T3-E1 cell and activity expression of ALP can be obviously promoted, and in-vivo osteogenesis can be promoted. The preparation method is simple and convenient in operation, and the prepared mesoporous magnesium silicate / polybutylene succinate composite scaffold has good pore connectivity, uniform aperture and excellent in-vitro degradability and biological activity and is capable of releasing silicon and magnesium ions and beneficial to osteoblastic differentiation.

Owner:上海禾麦医学科技有限公司

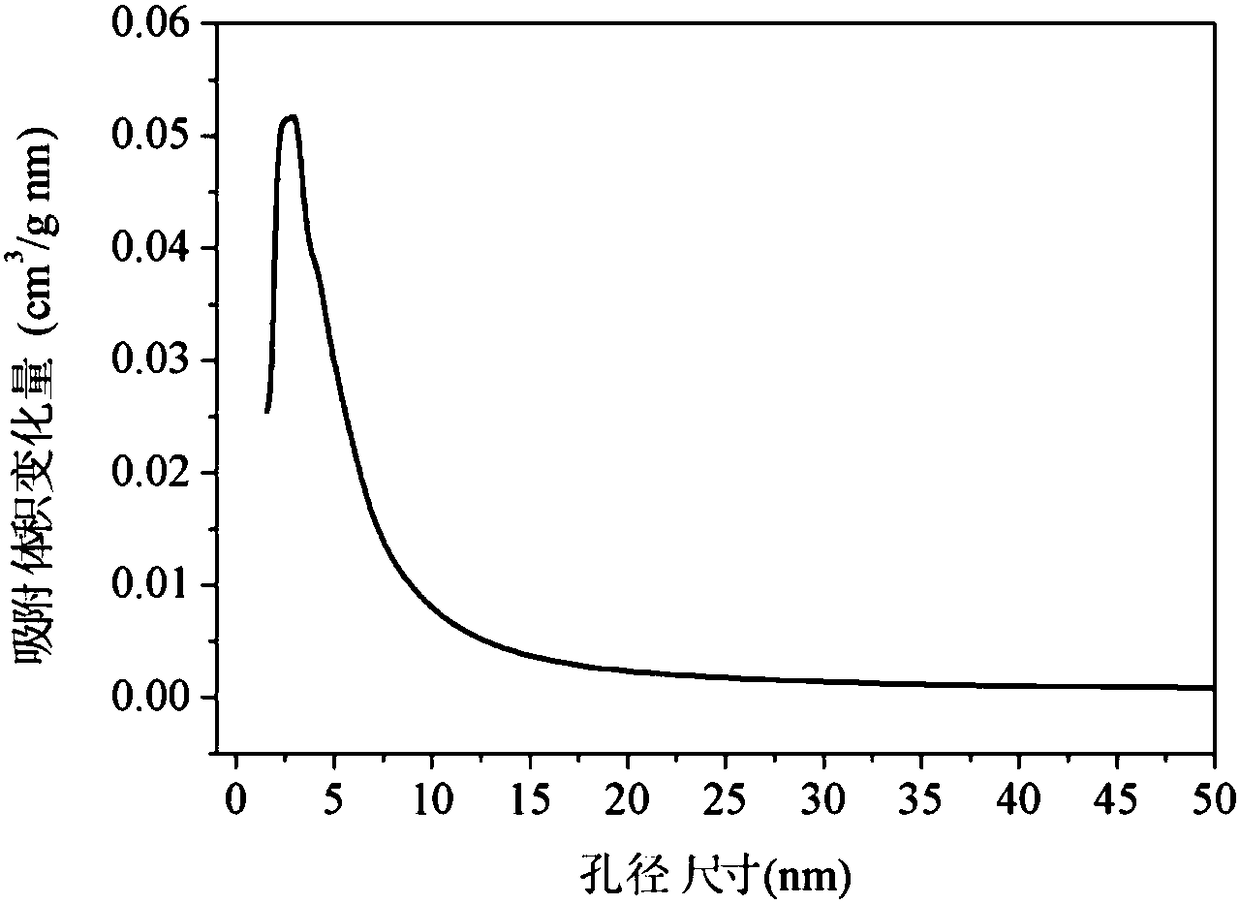

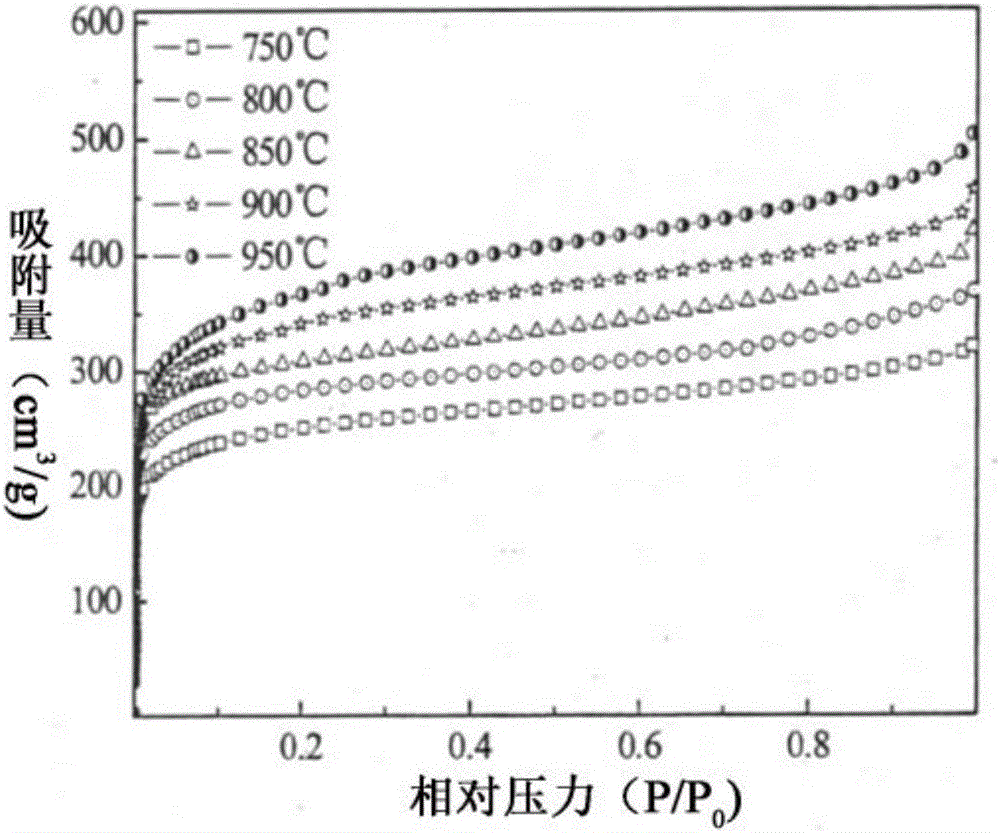

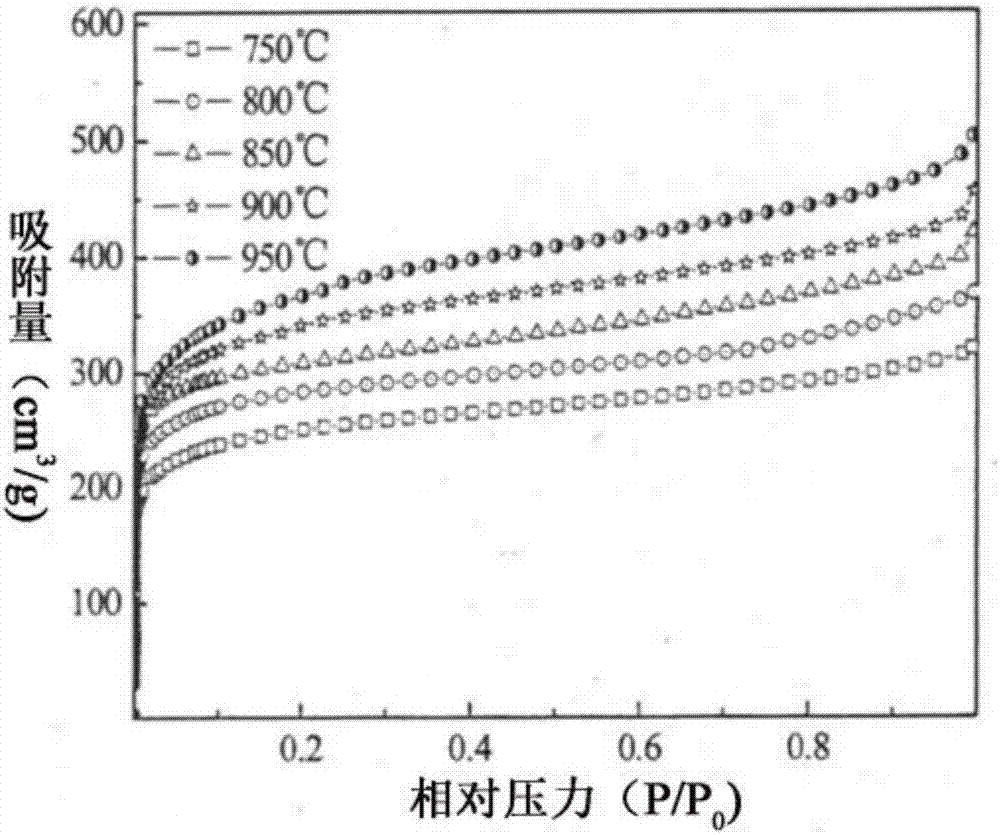

Mesoporous carbon material and preparation method thereof

ActiveCN107973287ALarge specific surface areaHigh porosityMaterial nanotechnologyCarbon preparation/purificationCarbon compositesHydrofluoric acid

The invention relates to a mesoporous carbon material, which takes mesoporous silica as a template and uses glucose as a carbon source, and a preparation method of the mesoporous carbon material, belonging to the technical field of preparation and application of carbon materials. The preparation method comprises the steps of adding 1-10g of the glucose into 1-6g of the mesoporous silica, and stirring for 5-10min at the room temperature so as to obtain a mixture of the mesoporous silica and the glucose; after that, carrying out heat treatment for 12-24h at the temperature of 180-200 DEG C so asto prepare a mesoporous silica and carbon composite material; carrying out heat treatment for 2-4h at the temperature of 800-900 DEG C so as to prepare a mesoporous silica and mesoporous carbon composite material, adding a hydrofluoric acid aqueous solution into the composite material, and stirring for 12-24h at the room temperature; finally, carrying out centrifugal separation on the obtained solution, washing, and drying to obtain the mesoporous carbon material. The mesoporous carbon material has a three-dimensional porous structure, the pore sizes are 2-5nm, the pore volumes are 0.5-1.5cm<3> / g, and the BET specific surface area is 400-900m<2> / g.

Owner:JILIN UNIV

Method for preparing light nano porous ceramics

InactiveCN101962298AHigh porosityHigh strengthNanostructure manufactureCeramic materials productionDetonatorDetonation

The invention discloses a method for preparing light nano porous ceramics, which comprises: mixing raw materials, primary minerals and explosive, filling the mixed materials in a closed detonation container, placing a detonator, and sealing the materials and the detonator by a waterproof material; filling water into the closed detonation container as pressure-keeping and cooling medium; priming the detonator and collecting detonation products, and sieving the collected products; and performing single-phase hot pressed sintering of the sieved products. In the invention, the nano powder prepared from nano ceramics is obtained by impacting the crushed raw materials with the huge energy provided by detonation reaction instantly, the energy consumption is extremely low, and the reaction time is extremely short. The method has a great significance for improving production efficiency and improving benefits.

Owner:NANJING UNIV OF SCI & TECH

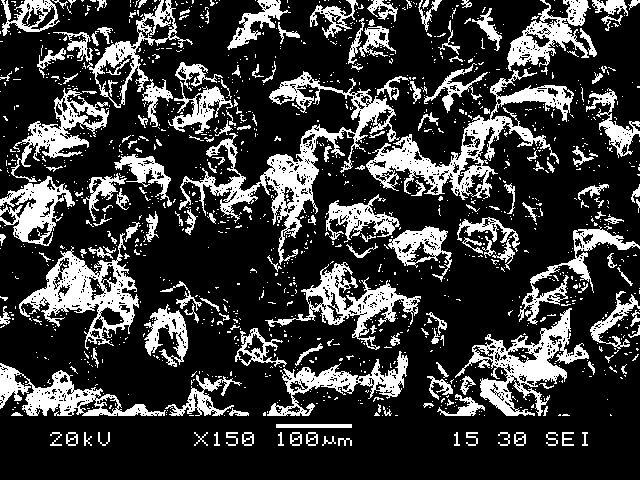

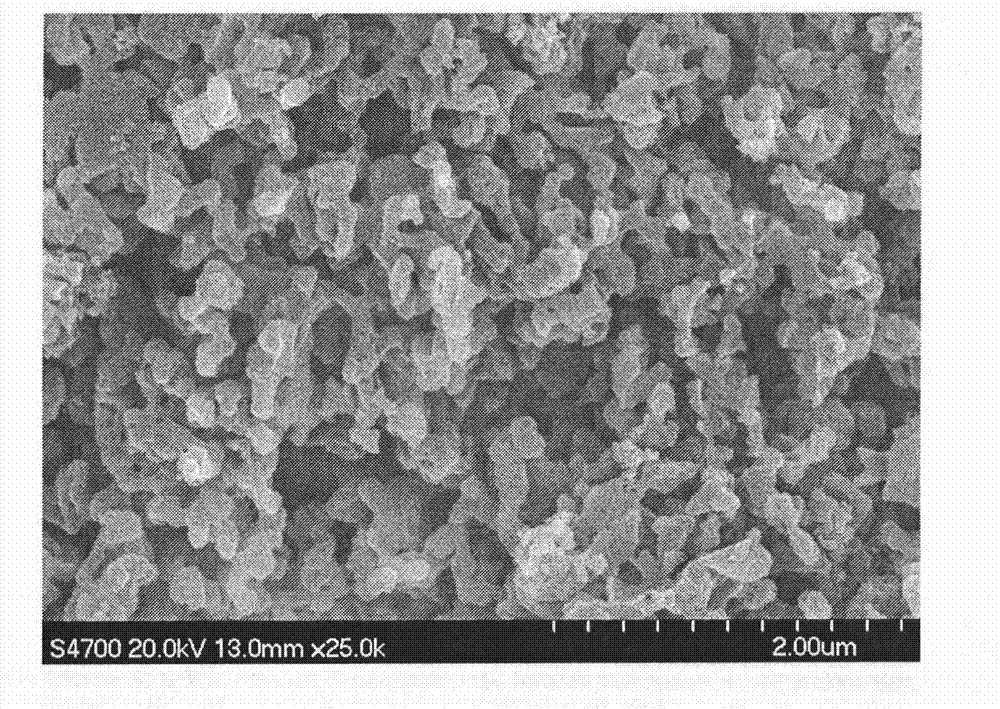

Porous carbon material and preparation method thereof

InactiveCN102107863BAdjustable pore size distributionUniversal adsorptionOther chemical processesCapacitor electrodesPore distributionPorous carbon

The invention relates to a porous carbon material and a preparation method thereof. The porous carbon material with fish scale as a raw material is prepared by using the organic and inorganic matters in fish scales as a carbon source and a natural template, and the particular method comprises the following steps: allowing dry fish scale to perform precarbonization at 300-350 DEG C; well mixing the precarbonized fish scale and an alkaline activator with a mass ratio of 1:0.5-1:3, performing activation and carbonization, performing post-treatment to remove inorganic salts, washing with deionized water to obtain a neutral solution, drying to obtain a carbon material with multilevel pore distribution. The preparation method of the invention is simple and low in cost, is applicable to industrial production; and the prepared porous carbon material is applicable to adsorption materials and super capacitors, and has a high adsorption quantity and a good specific energy rate property. The invention opens up a new way for the effective utilization of fish scale which is a waste in fishery.

Owner:BEIJING UNIV OF CHEM TECH

Rare earth composite oxide with high heat resistance and preparation method thereof

ActiveCN112573569ALarge specific surface areaAdjustable pore size distributionLanthanum oxide/hydroxidesCerium oxides/hydroxidesHeat resistanceCerium

The invention provides a rare earth composite oxide with high heat resistance and a preparation method thereof, and belongs to the field of rare earth materials. The rare earth composite oxide comprises the following components in parts by weight: 50-90 parts of ZrO2, 5-40 parts of CeO2, 5-20 parts of rare earth oxide except cerium oxide, and 0-10 parts of transition metal oxide. According to theinvention, the sulfate is added in two steps in the early stage and a structure regulator is added in the later stage to control the granularity, pore size distribution, specific surface area and porevolume of the rare earth composite oxide, so that the thermal stability of the rare earth composite oxide is improved at the same time.

Owner:JIANGMEN KANHOO IND

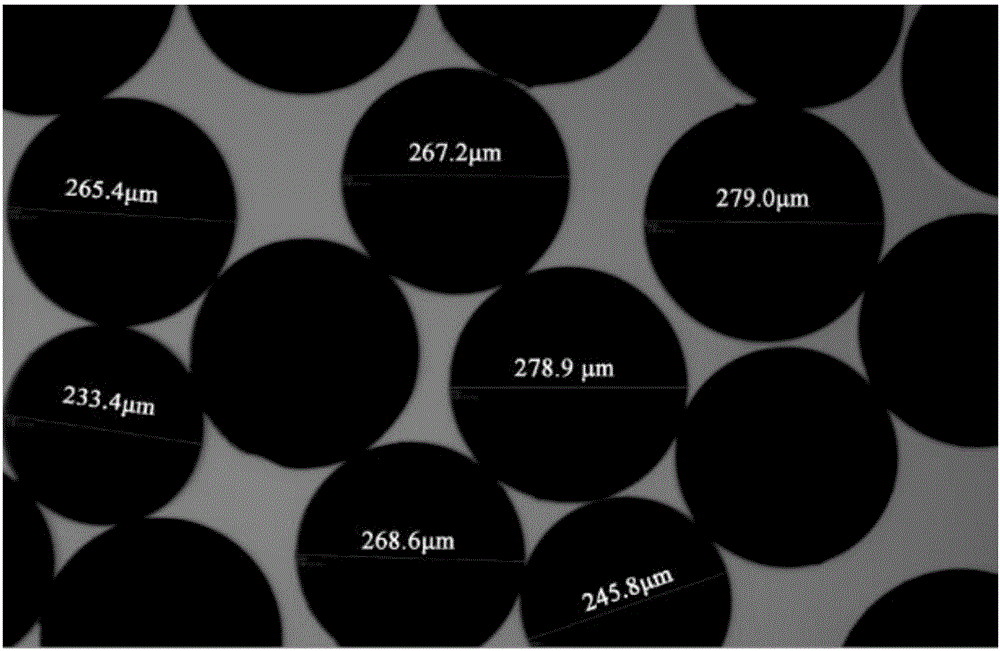

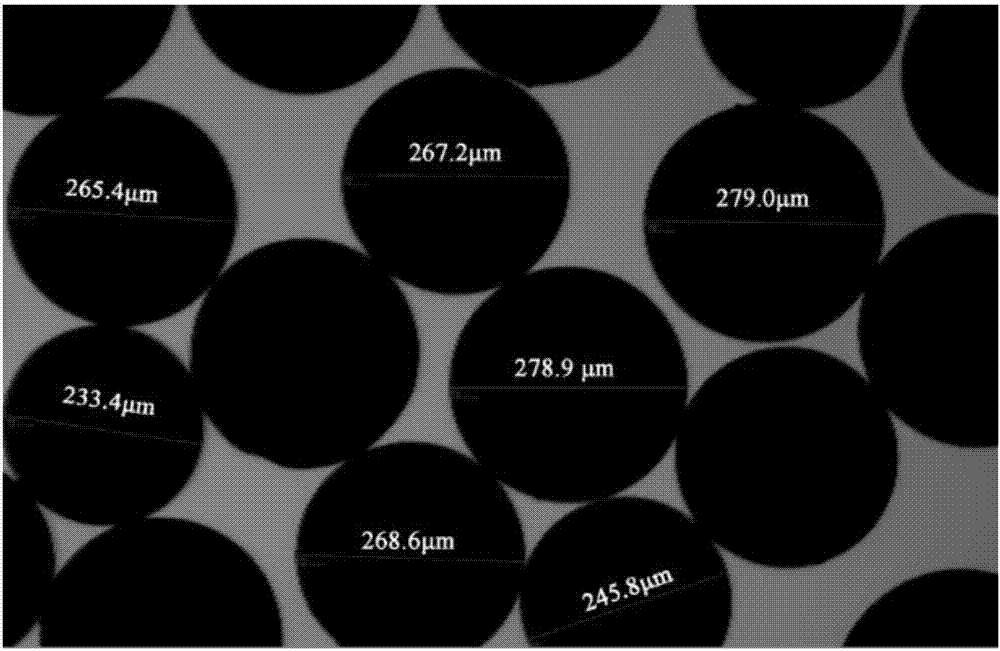

Submillimeter-level polystyrene-base spherical active carbon, and preparation method and application thereof

ActiveCN106219543AReduce manufacturing costSave raw materialsOther chemical processesAlkali metal oxides/hydroxidesMicrosphereDivinylbenzene

The invention discloses a submillimeter-level polystyrene-base spherical active carbon, and a preparation method and application thereof. The preparation method comprises the following steps: preparing polystyrene-base microspheres from styrene and divinylbenzene, swelling the polystyrene-base microspheres in carbon tetrachloride, adding a catalyst, and curing to form to obtain the super-crosslinked thermosetting polystyrene-base resin spheres; immersing the resin spheres in a saturated sodium chloride solution, cleaning sequentially with dilute hydrochloric acid, a sodium hydroxide solution and deionized water to a neutral state, and drying; carrying out high temperature carbonization and vapor activation to obtain polystyrene-base spherical active carbon; and carrying out surface modification on the polystyrene-base spherical active carbon by air oxidation and high-temperature nitrogen heat treatment. The preparation method is simple in technique, and lowers the production cost. The obtained spherical active carbon has the advantages of smooth surface, high sphericity and large specific area (up to 960-1400 m<2> / g), can be used for adsorbing urotoxin creatinine, and has wide application prospects in the field of uremia treatment.

Owner:CHANGZHOU YINGZHONG NANO TECH

A rare earth composite oxide with high heat resistance and its preparation method

ActiveCN112573569BLarge specific surface areaAdjustable pore size distributionLanthanum oxide/hydroxidesCerium oxides/hydroxidesHeat resistanceCerium

The invention provides a rare earth composite oxide with high heat resistance and a preparation method thereof, belonging to the field of rare earth materials. The rare earth composite oxide of the present invention comprises the following components by weight: 50-90 parts of ZrO 2 , 5-40 parts of CeO 2 , 5-20 parts of rare earth oxides other than cerium oxide and 0-10 parts of transition metal oxides. The present invention controls the particle size, pore size distribution, specific surface area and pore volume of the rare earth composite oxide by adding sulfate in two steps in the early stage and adding the structure regulator in the later stage, and simultaneously increases the thermal stability of the rare earth composite oxide.

Owner:JIANGMEN KANHOO IND

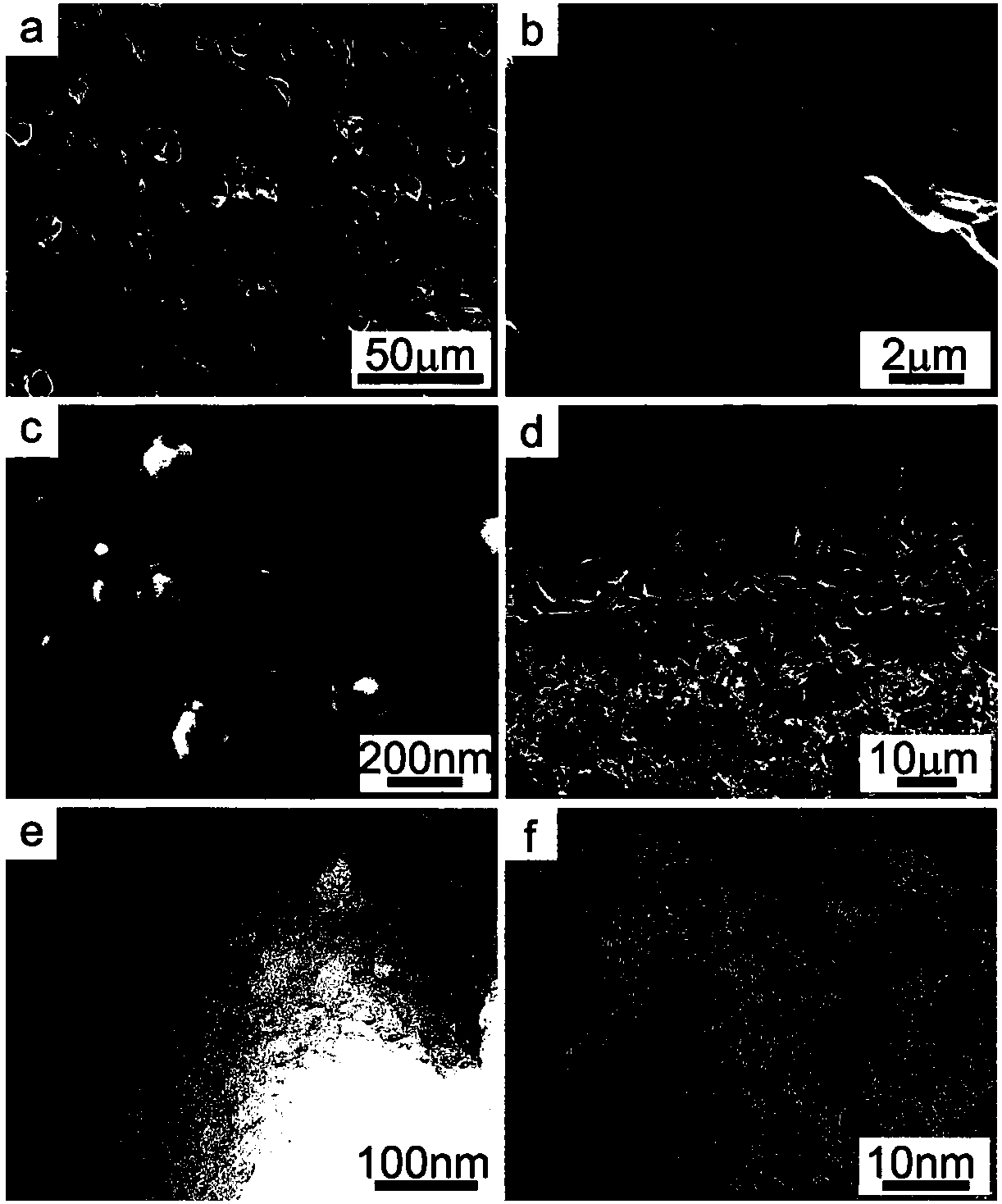

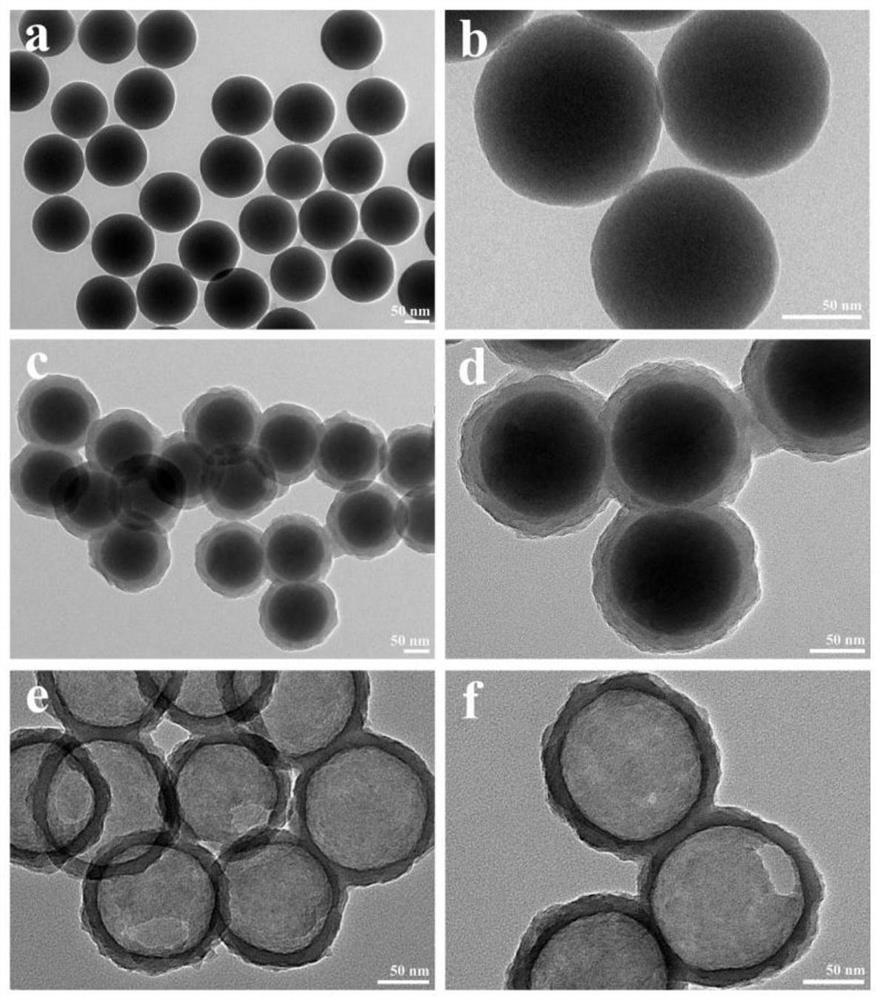

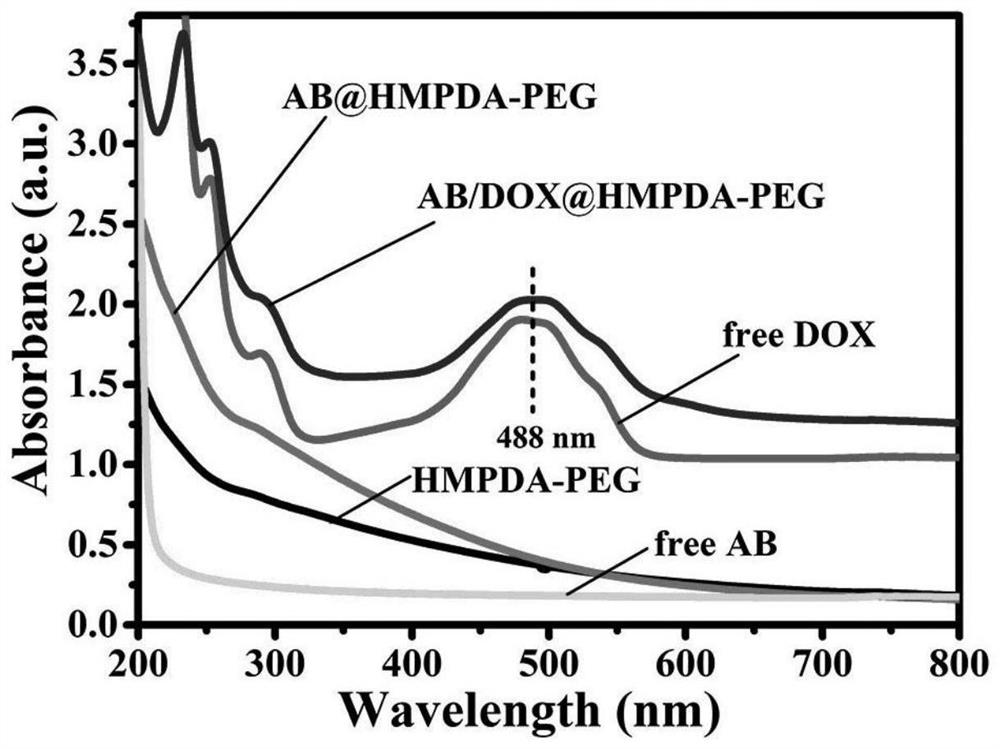

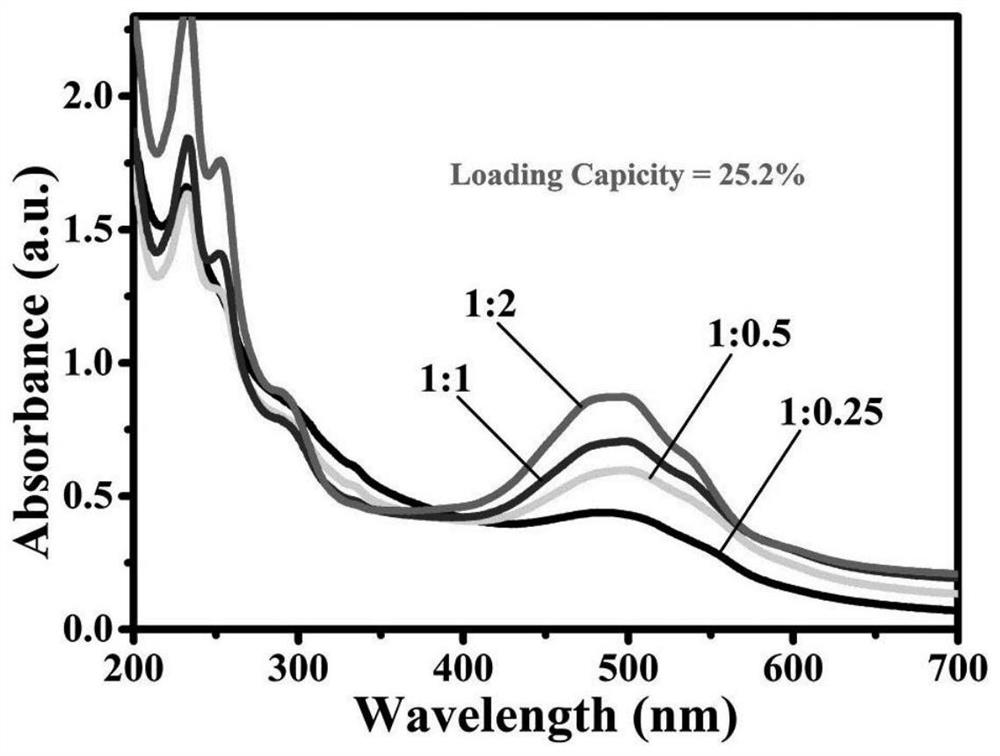

Ammoniaborane/hollow mesoporous polydopamine/polyethylene glycol nanocomposite particles and its preparation and application

ActiveCN112618514BWide variety of sourcesLow costOrganic active ingredientsInorganic boron active ingredientsCancer cellPolyethylene glycol

The invention provides ammonia borane / hollow mesoporous polydopamine / polyethylene glycol nanocomposite particles, the chemical formula of the nanocomposite particles is AB@HMPDA‑PEG, with solid silica as the core and mesoporous polydopamine as the shell , etched with hydrofluoric acid to obtain hollow mesoporous polydopamine HMPDA, PEG-modified on the surface of the shell, and then encapsulated ammonia borane AB small-molecule prodrug by hydrogen bond force. The invention also provides the preparation method and application of the nanocomposite particles. Compared with the prior art, the AB@HMPDA‑PEG nanocomposite particles of the present invention can target anticancer drugs and gaseous prodrugs to the cancer site, increase the long circulation time in the body while reducing the toxic side effects on normal tissues and cells , Overcome multidrug resistance to kill cancer cells more efficiently, further improve the therapeutic effect, and have great potential in promoting the combined application of gas therapy and cancer chemotherapy, and enhancing the efficacy of cancer treatment.

Owner:EAST CHINA NORMAL UNIV

A kind of porous c/c composite material and its preparation method

ActiveCN108840698BHigh porosityUniform distribution of poresCeramicwarePore distributionCarbon matrix

The present invention proposes a porous C / C composite material and a preparation method thereof, which are obtained through a precursor impregnation-curing-cracking process, and the precursor is composed of resorcinol, formaldehyde and water. Under the action of saturated vapor pressure, the present invention forms pores by occupying water in the phenolic resin, and finally obtains a porous resin carbon matrix suitable for reactive infiltration with high porosity, uniform pore distribution and adjustable pore size distribution.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

An adsorbent for removing hexafluoropropylene in octafluorocyclobutane and its preparation method

ActiveCN107694509BEfficient removalLarge specific surface areaGas treatmentOther chemical processesHexafluoropropyleneOctafluorocyclobutane

The invention discloses an adsorbent for removing hexafluoropropylene in octafluorocyclobutane. The adsorbent comprises, by weight, 10-25% of iron oxide, 5-20% of copper oxide, 60-80% of tin oxide, 0.05-0.5% of gallium, 0.05-0.3% of platinum, 0.1-1.5% of cadmium and 0.1-3% of molybdenum. The invention further discloses a method for preparing the adsorbent. The method includes steps of (1), addingsalt solution of the iron oxide, the copper oxide and the tin oxide into a hydrothermal reactor and uniformly stirring the salt solution of the iron oxide, the copper oxide and the tin oxide; (2), adding salt solution of the gallium, the platinum, the cadmium and the molybdenum into the hydrothermal reactor and carrying out doping modification; (3), adding metal mesh packing into the hydrothermalreactor, placing the hydrothermal reactor with the added metal mesh packing into a drying oven and carrying out reaction on solution in the hydrothermal reactor at the hydrothermal treatment temperatures of 110-160 DEG C for 40-70 min. The adsorbent and the method have the advantage that the hexafluoropropylene in the octafluorocyclobutane can be effectively removed by the adsorbent.

Owner:SUZHOU JINHONG GAS CO LTD

Cross-linking agent modified XAD-4 resin and method for preparing same

InactiveCN102977487BWide pore size distributionLarge average pore sizeOther chemical processesCross-linkSorbent

The invention discloses a cross-linking agent modified XAD-4 resin, which is a mesoporous resin containing rich micropores and prepared from a cross-linking agent and an XAD-4 resin through Friedel-Crafts reaction, wherein the pore diameters of the mesoporous resin are distributed between 1 to 9.5 nm, the average pore diameter is 2.58-4 nm, the specific surface area is 721-1284 m<2> / g, and the pore volume is 0.67-1.1 cm<3> / g. The method for preparing the cross-linking agent modified XAD-4 resin comprises the following step of carrying out the Friedel-Crafts reaction between the cross-linking agent and the XAD-4 resin to prepare the modified XAD-4 resin, wherein the dosage of the cross-linking agent is 50-100% of the quantity of the XAD-4 resin material. The adsorbent has the characteristics of large specific surface area, narrow pore diameter distribution and easily controllable porous structure, and is obviously superior to the XAD-4 resin in the adsorption capability to nonpolar and weakly polar materials; and therefore, the adsorbent is wide in application prospect in fields of treating and recycling phenols wastewater and the like.

Owner:CENT SOUTH UNIV

Method for preparing light nano porous ceramics

InactiveCN101962298BHigh porosityHigh strengthNanostructure manufactureCeramic materials productionDetonatorDetonation

The invention discloses a method for preparing light nano porous ceramics, which comprises: mixing raw materials, primary minerals and explosive, filling the mixed materials in a closed detonation container, placing a detonator, and sealing the materials and the detonator by a waterproof material; filling water into the closed detonation container as pressure-keeping and cooling medium; priming the detonator and collecting detonation products, and sieving the collected products; and performing single-phase hot pressed sintering of the sieved products. In the invention, the nano powder prepared from nano ceramics is obtained by impacting the crushed raw materials with the huge energy provided by detonation reaction instantly, the energy consumption is extremely low, and the reaction time is extremely short. The method has a great significance for improving production efficiency and improving benefits.

Owner:NANJING UNIV OF SCI & TECH

A kind of submillimeter polystyrene-based spherical activated carbon and its preparation method and application

ActiveCN106219543BReduce manufacturing costSave raw materialsCarbon compoundsOther chemical processesCreatinine riseWater vapor

The invention discloses a submillimeter-level polystyrene-base spherical active carbon, and a preparation method and application thereof. The preparation method comprises the following steps: preparing polystyrene-base microspheres from styrene and divinylbenzene, swelling the polystyrene-base microspheres in carbon tetrachloride, adding a catalyst, and curing to form to obtain the super-crosslinked thermosetting polystyrene-base resin spheres; immersing the resin spheres in a saturated sodium chloride solution, cleaning sequentially with dilute hydrochloric acid, a sodium hydroxide solution and deionized water to a neutral state, and drying; carrying out high temperature carbonization and vapor activation to obtain polystyrene-base spherical active carbon; and carrying out surface modification on the polystyrene-base spherical active carbon by air oxidation and high-temperature nitrogen heat treatment. The preparation method is simple in technique, and lowers the production cost. The obtained spherical active carbon has the advantages of smooth surface, high sphericity and large specific area (up to 960-1400 m<2> / g), can be used for adsorbing urotoxin creatinine, and has wide application prospects in the field of uremia treatment.

Owner:CHANGZHOU YINGZHONG NANO TECH

A kind of c/sic composite material preparation method

ActiveCN108892524BImprove mechanical propertiesImprove anti-ablation performanceCeramicwareMaterials preparationHigh activity

The invention provides a preparation method of a C / SiC composite material. The C / SiC composite material is prepared by preparing a porous C / C composite material by means of an infiltration method. Asa special high-activity porous body C / C is adopted to reactive infiltration, the mechanical property and the anti- ablation property of the material are improved. The preparation method can be also applied to rapid low-cost preparation of a ceramic-based composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com