High-strength carbon aerogel as well as preparation method and application thereof

A carbon aerogel, high-strength technology, applied in the preparation/purification of carbon, chemical instruments and methods, colloid chemistry, etc., can solve the problems of restricting large-scale production and application, poor mechanical properties, cumbersome steps, etc., and achieve shortened preparation Cycle time, good molding ability, and the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

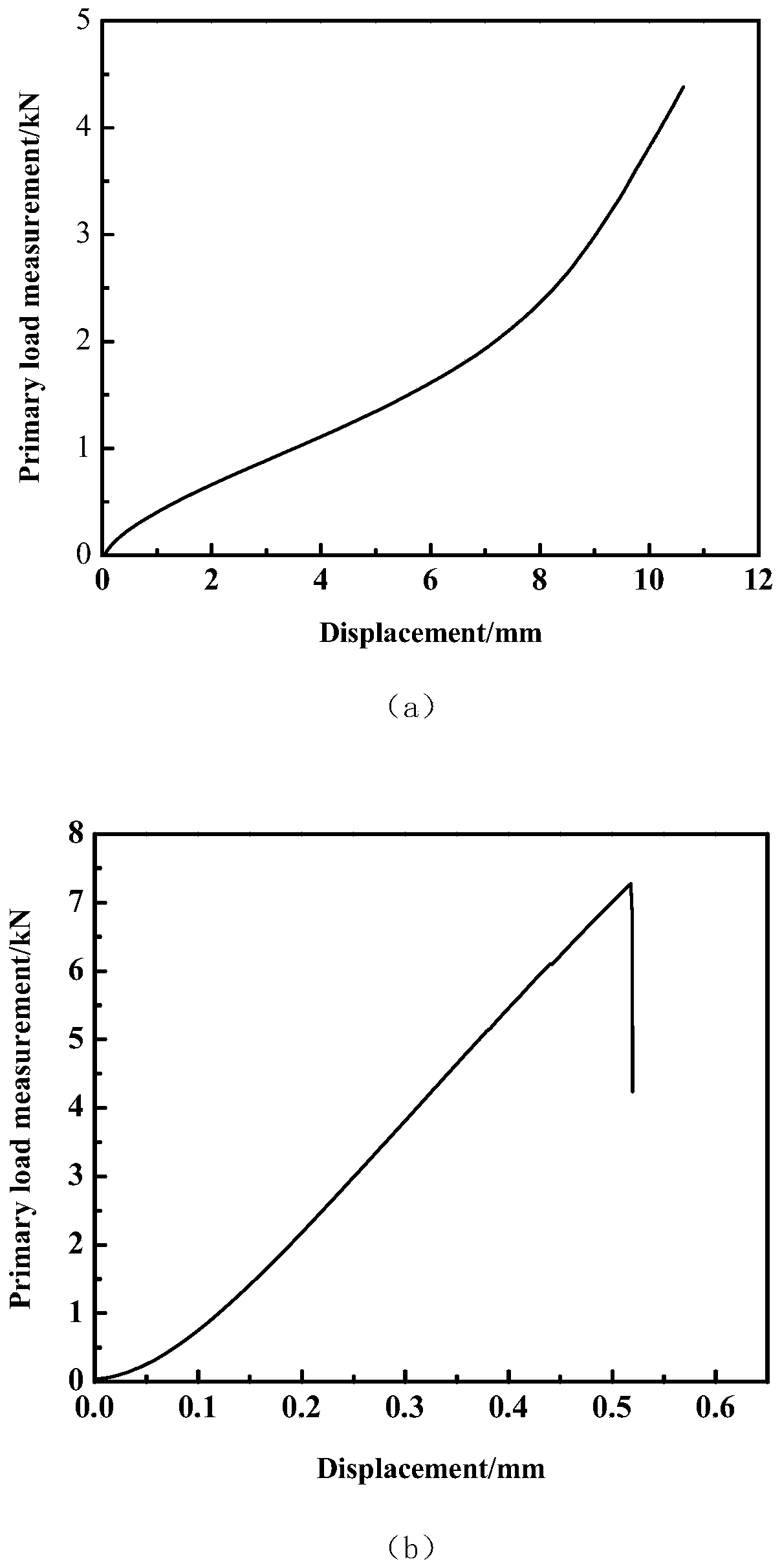

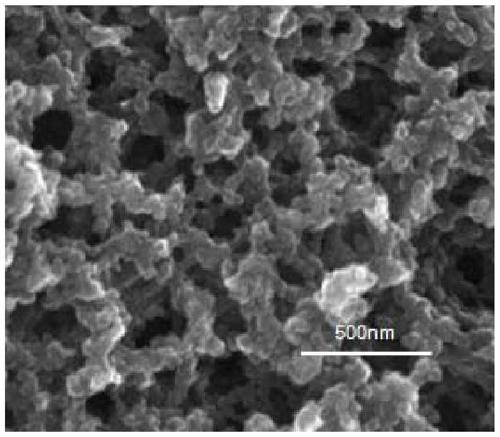

Embodiment 1

[0034] Mix phenolic resin, ethylene glycol, hexamethylenetetramine, and water in a weight ratio of 63:139:5:2, stir for 30 minutes, place in a dry box, keep warm at 50°C for 5 hours, and Insulate at 110°C for 15 hours, and at 170°C for 3 hours to obtain a wet gel. Dry the wet gel in a drying oven at 80°C for 30 hours at normal pressure to obtain a phenolic airgel. Put the obtained phenolic airgel into In the carbonization furnace, the temperature was raised to 900°C under the protection of argon, and the high-strength carbon airgel was obtained after holding the heat for 3 hours. The prepared phenolic airgel has a bulk density of 0.43g / cm 3 , the compressive strength is 6.3MPa, and the volume density of the carbon airgel obtained after carbonization is 0.52g / cm 3 , The compressive strength is 53.1MPa. figure 1 It is phenolic airgel (density 0.43g / cm 3 ) and the corresponding carbon aerogel (0.51g / cm 3 ) load-displacement curves, the compressive strengths are 6.3MPa and 53....

Embodiment 2

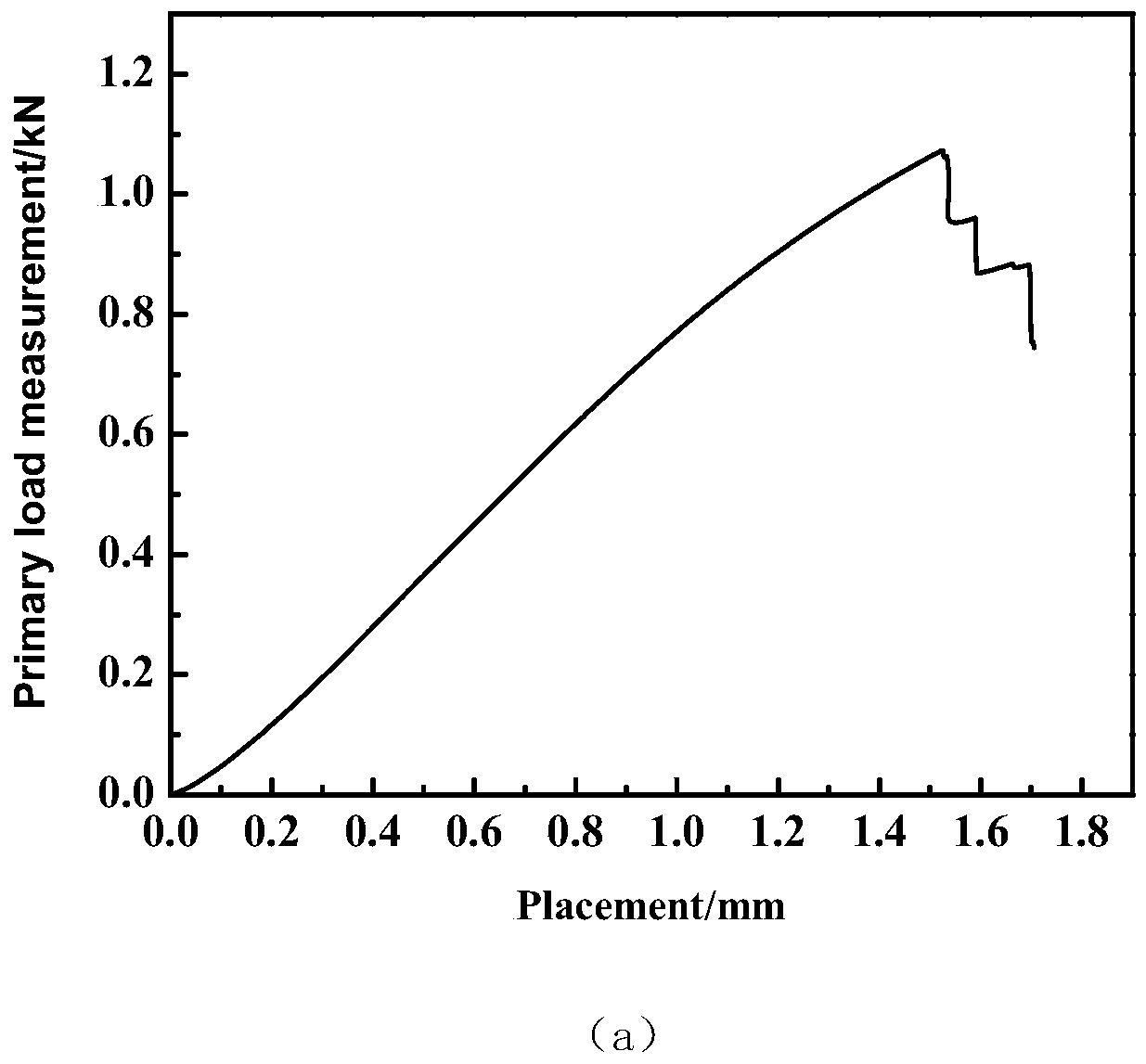

[0036] Mix phenolic resin, ethylene glycol, hexamethylenetetramine, and water in a weight ratio of 38:138:5:2, stir for 30 minutes, place in a dry box, and keep it warm for 5 hours at a temperature of 50°C. Insulate at 110°C for 15 hours, and at 170°C for 3 hours to obtain a wet gel. Dry the wet gel in a drying oven at 80°C for 30 hours at normal pressure to obtain a phenolic airgel. Put the obtained phenolic airgel into In the carbonization furnace, the temperature was raised to 900°C under the protection of argon, and the carbon aerogel was obtained after keeping the temperature for 3 hours. The prepared phenolic airgel has a bulk density of 0.19 g / cm 3 , the compressive strength is 0.8MPa, and the volume density of the carbon airgel obtained after carbonization is 0.24g / cm 3 , The compressive strength is 1.7MPa. image 3 It is phenolic airgel (density 0.19g / cm 3 ) and the corresponding carbon aerogel (0.24g / cm3 ) load-displacement curves, the compressive strengths are 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com