Rare earth composite oxide with high heat resistance and preparation method thereof

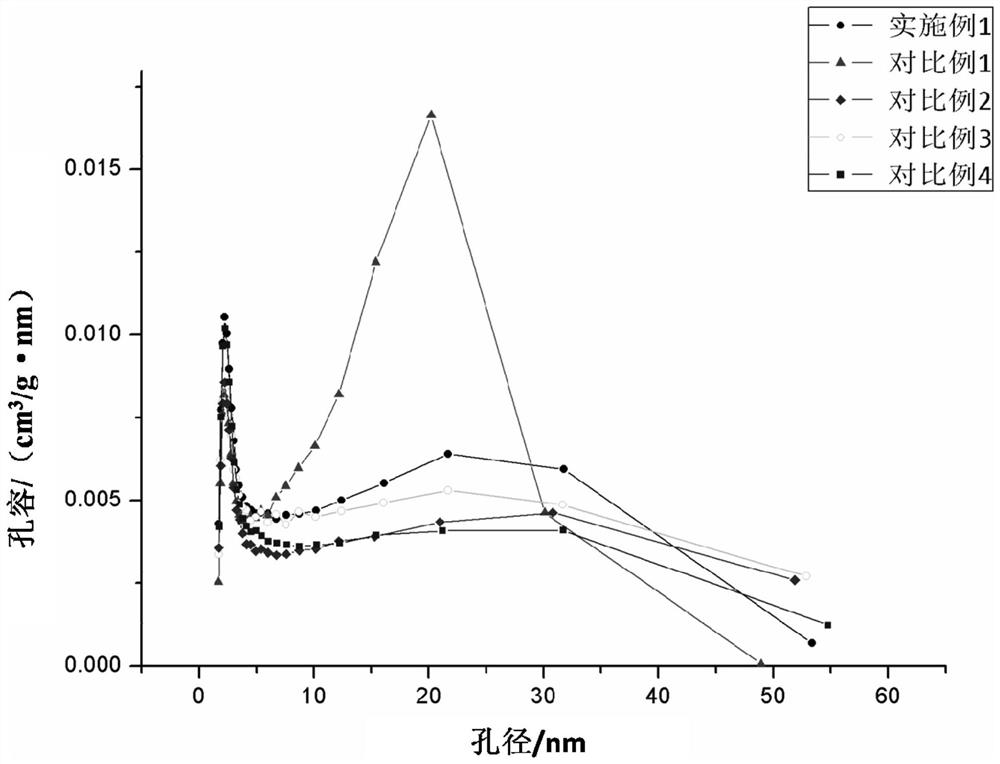

A rare earth oxide and rare earth composite technology, applied in the preparation/processing of rare earth metal compounds, rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, etc., can solve the problem of poor thermal stability, specific surface area, etc. low problems, to achieve the effects of high thermal stability, large specific surface area, and adjustable pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

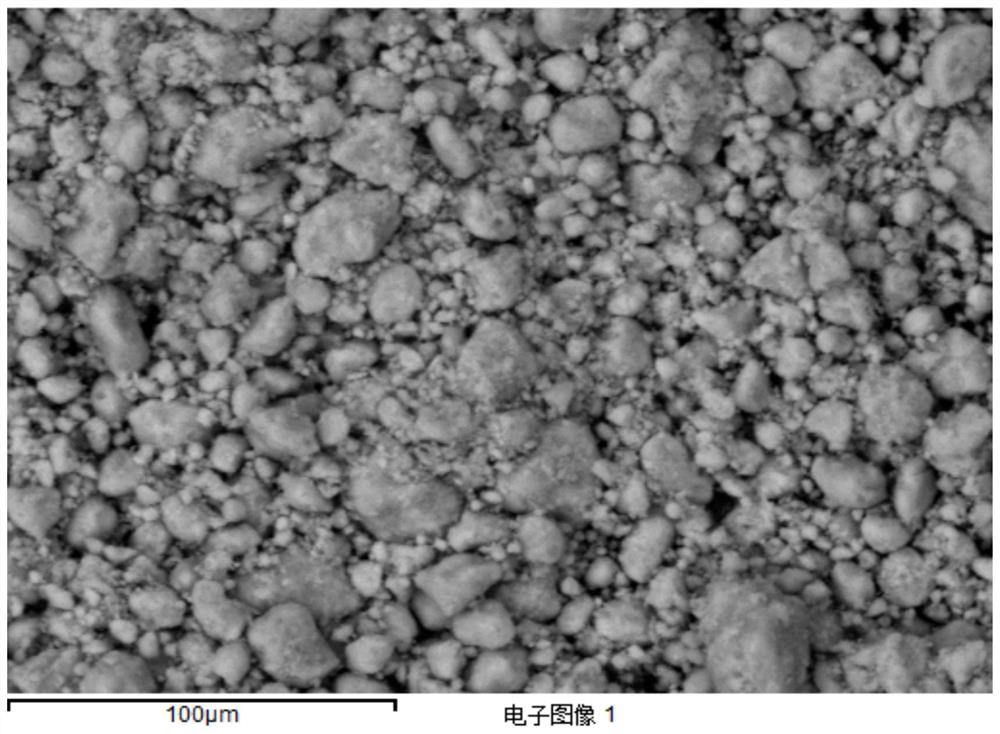

Embodiment 1

[0033] The rare earth composite oxide in this embodiment includes the following components in parts by weight: 60 parts of zirconia, 30 parts of ceria, 2 parts of lanthanum oxide, and 8 parts of yttrium oxide.

[0034] The preparation method of the rare earth composite oxide of this embodiment is:

[0035] (1) Add potassium sulfate to the zirconium nitrate solution with a mass fraction of 2wt%, and the sulfate group is 23% of the weight of zirconium dioxide; stir until the potassium sulfate solid is completely dissolved, heat the solution to 100°C and keep it warm for 60 minutes to obtain the basic formula Zirconium sulfate sol;

[0036] (2) adding mass fraction to the basic zirconium sulfate sol of step (1) gained is the potassium sulfate solution of 5wt%, and the sulfate radical is 12% of zirconium dioxide weight; Slaking 60min at 100 DEG C, obtains basic zirconium sulfate Precursor;

[0037] (3) cooling the basic zirconium sulfate precursor obtained in step (2) to 50° C.,...

Embodiment 2

[0042] The rare earth composite oxide in this embodiment includes the following components in parts by weight: 60 parts of zirconia, 30 parts of ceria, 2 parts of lanthanum oxide, and 8 parts of yttrium oxide.

[0043] The preparation method of the rare earth composite oxide of this embodiment is:

[0044] (1) Add potassium sulfate to the zirconium nitrate solution with a mass fraction of 2 wt%, and the sulfate radical is 8% of the weight of zirconium dioxide; stir until the potassium sulfate solid is completely dissolved, heat the solution to 100°C and keep it warm for 120 minutes to obtain the basic formula Zirconium sulfate sol;

[0045] (2) adding mass fraction to the basic zirconium sulfate sol of step (1) gained is the potassium sulfate solution of 5wt%, and the sulfate group is 46% of zirconium dioxide weight; Slaking 60min at 100 DEG C, obtain basic zirconium sulfate Precursor;

[0046] (3) cooling the basic zirconium sulfate precursor obtained in step (2) to 50° C.,...

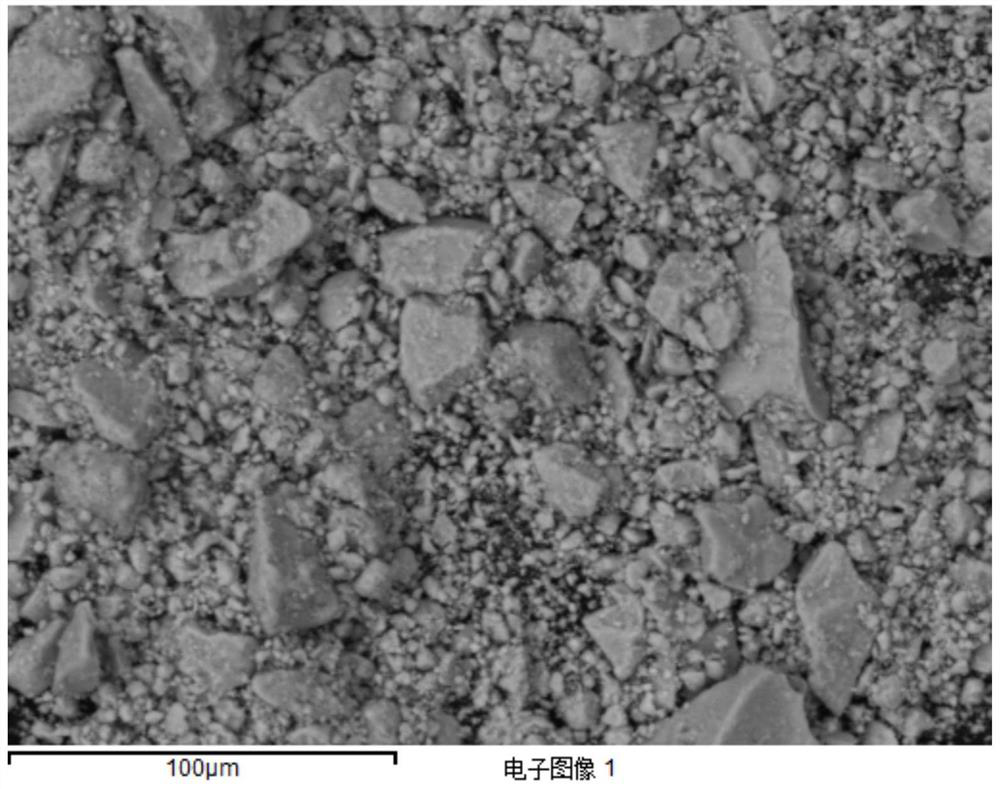

Embodiment 3

[0051] The rare earth composite oxide in this embodiment includes the following components in parts by weight: 90 parts of zirconia, 5 parts of ceria, and 5 parts of yttrium oxide.

[0052] The preparation method of the rare earth composite oxide of this embodiment is:

[0053] (1) Add zirconium sulfate to the zirconium oxychloride solution with a mass fraction of 5wt%, and the sulfate radical is 16% of the weight of zirconium dioxide; stir until the zirconium sulfate solid is completely dissolved, heat the solution to 95° C. and keep it warm for 60 minutes to obtain Basic zirconium sulfate sol;

[0054] (2) adding mass fraction to the basic zirconium sulfate sol of step (1) gained is the sodium sulfate solution of 20wt%, and the sulfate group is 24% of zirconium dioxide weight; Slaking 60min at 100 DEG C, obtain basic zirconium sulfate Precursor;

[0055] (3) cooling the basic zirconium sulfate precursor obtained in step (2) to 50° C., adding cerium chloride and yttrium chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com