Method for preparing light nano porous ceramics

A nano-microporous and ceramic technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems that the technology cannot meet the requirements of performance indicators, reduce manufacturing costs, and gel injection molding toxicity, and achieve pore size and porosity. Adjustable, improved production efficiency, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

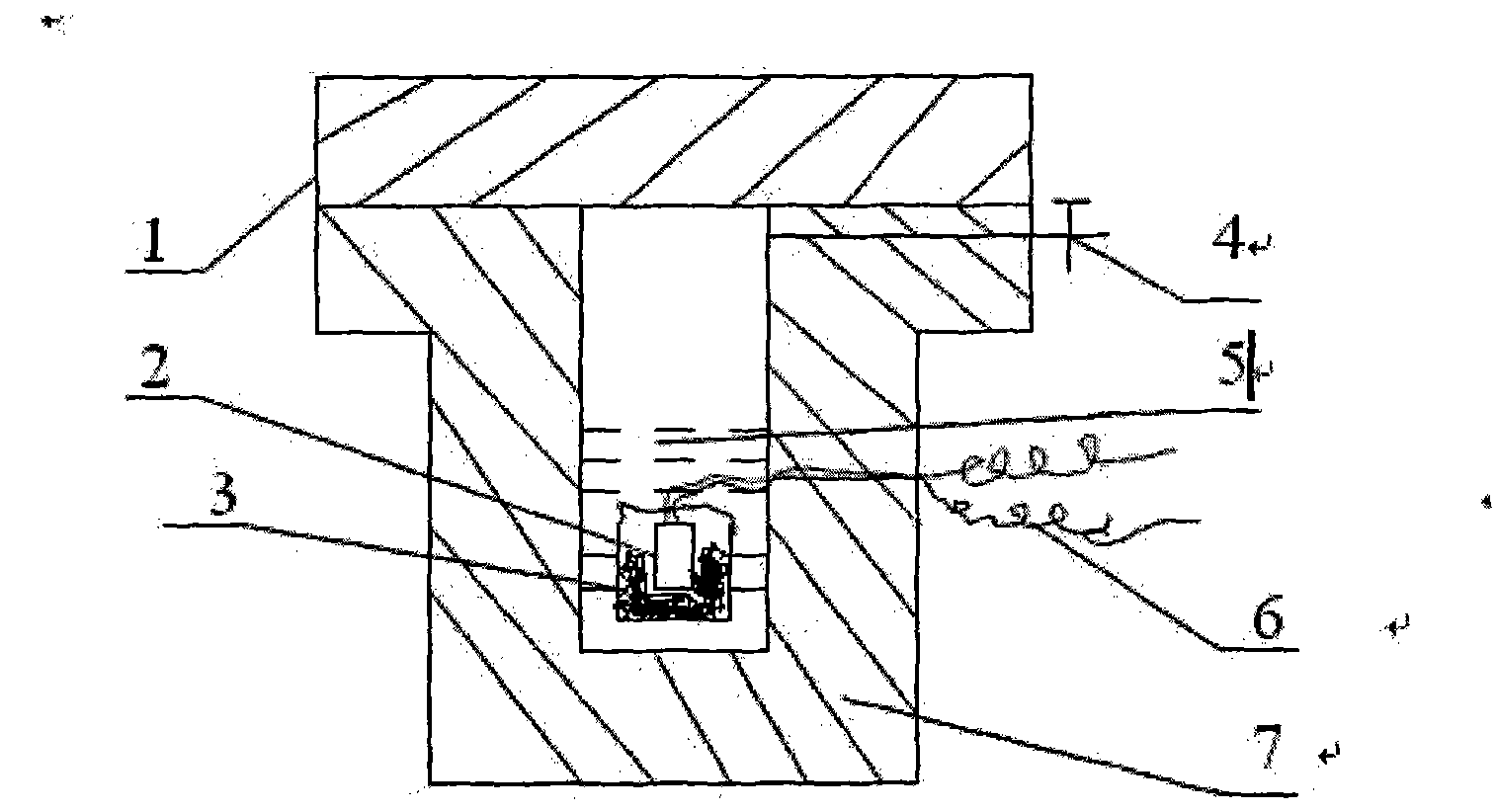

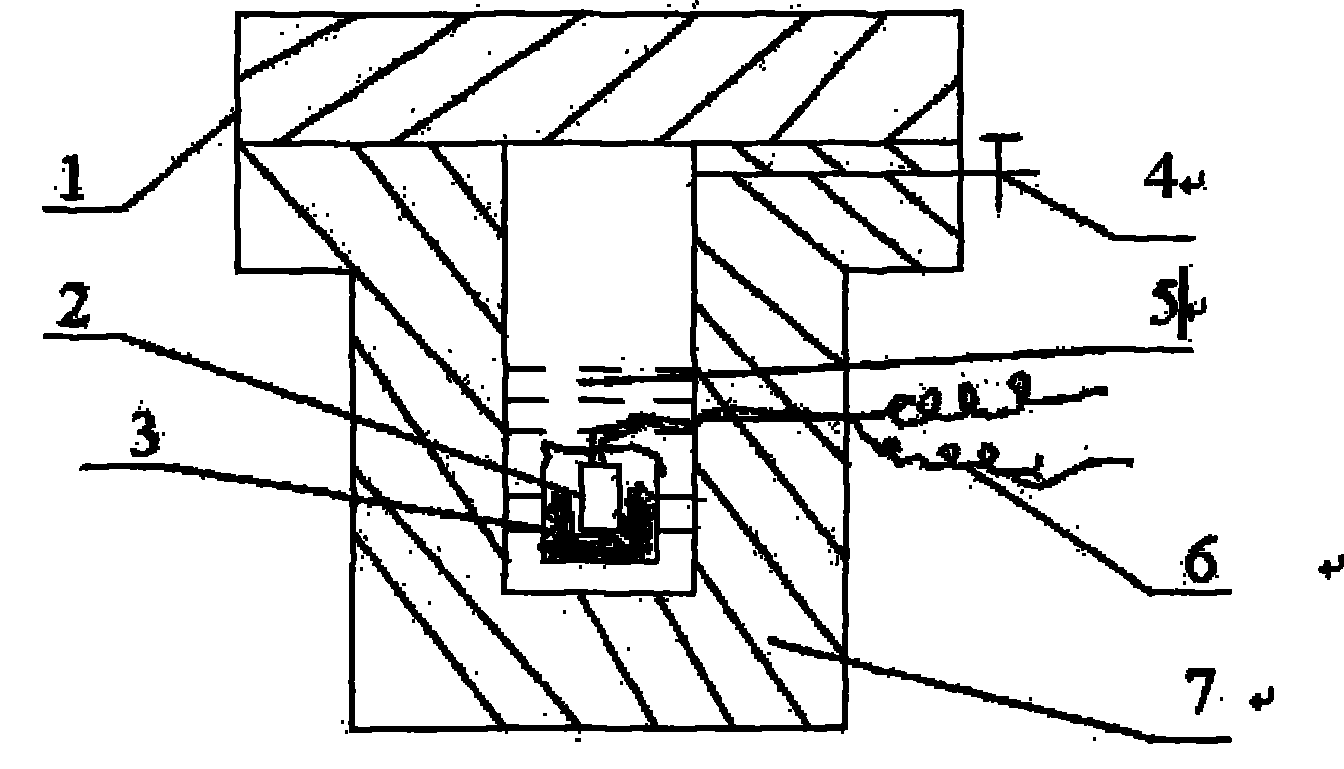

[0014] In conjunction with the accompanying drawings, a method for preparing lightweight nano-microporous ceramics of the present invention includes the following steps: Step 1, mixing raw materials, primary minerals and explosives, and loading the above-mentioned mixed material 3 into a closed detonation container 7, insert the detonator 2, and then seal the material and the detonator with a waterproof material; the above-mentioned raw material is a mixture of one or two or more of waste sludge, waste ceramics, and waste slag, and the mass percentage of the raw material is 50% to 75%. %; the primary mineral is one or a mixture of two or more of feldspar, kaolin, and clay, and the mass percentage of the primary mineral is 20%-45%; the mass percentage of the explosive is 1%-15%. The waterproof material includes oil paper and plastic film; the explosive includes trinitrotoluene, ammonium nitrate nitrocellulose, nitroglycerin, RDX, and trinitrotoluene / RDX. The explosive is prefer...

Embodiment 1

[0025] In a volume of 1M 3 Inject 0.4M into the cartridge 3 Water is used as protection and cooling medium, with 7 parts of explosives (TNT / RDX mass ratio is 70 / 30), 40 parts of aluminum oxide content is 19%, the waste ceramics that silicon oxide content is 74%, 30 parts of waste sludge, and 23 parts The clay is crushed and mixed, packaged with a 8# detonator in a plastic bag and suspended in the cylinder, ignited and detonated, and the product after the explosion is collected and passed through a 100-mesh sieve to remove impurities such as metal wires and tape fragments, and heated in a single phase at 850 °C Pressing and sintering to obtain a density of 0.44kg / m 3 , The porosity is 65%, the nano-microporous ceramics with a pore size of 600nm, and the compressive strength is 8.2MPa.

Embodiment 2

[0027] In a volume of 2M 3 Inject 0.8M into the cartridge 3 Water is used as protection and cooling medium, with 15 parts of explosives (TNT / RDX mass ratio is 30 / 70), 25 parts of waste slag with alumina content of 15% and silicon oxide content of 70%, 30 parts of waste sludge, 20 parts of kaolin , 10 parts of clay were crushed and mixed, packaged with a 8# detonator in a plastic bag and suspended in the cylinder, ignited and detonated, and the products after the explosion were collected and passed through a 100-mesh sieve to remove impurities such as metal wires and tape fragments, and placed at 950 ° C Single-phase hot pressing sintering to obtain a density of 0.32kg / m 3 , Nano-microporous ceramics with a pore size of 20nm, and a compressive strength of 3.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com