Mesoporous magnesium silicate/polybutylene succinate composite scaffold as well as preparation method and application thereof

A technology of polybutylene succinate and polybutylene succinate, which is applied in the field of mesoporous magnesium silicate/polybutylene succinate composite scaffold and its preparation and application, can solve bone regeneration In order to solve the problems of slow osseointegration, poor osteogenic differentiation, and slow cell response, the pore size distribution can be adjusted, the adhesion can be promoted, and the operation is easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

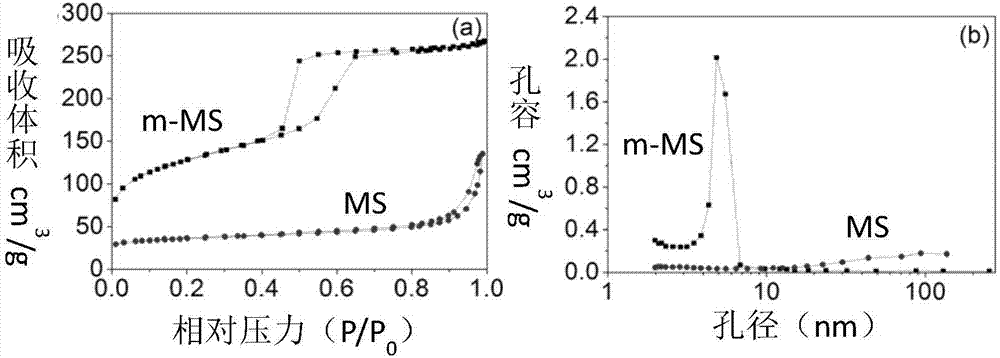

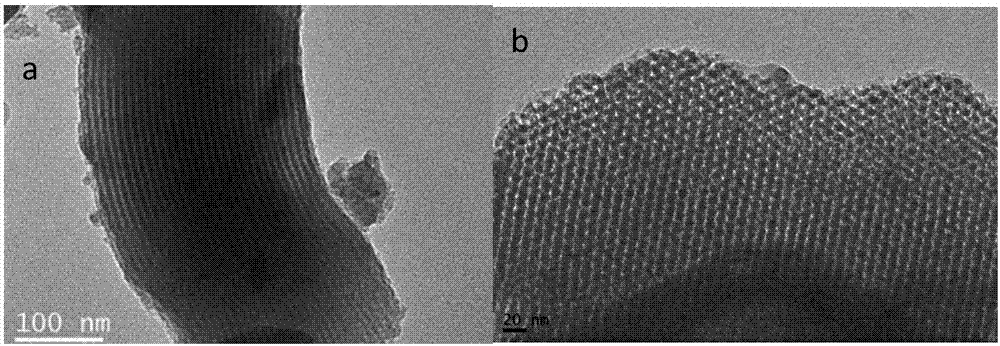

[0071] (1) Preparation of mesoporous magnesium silicate (m-MS)

[0072] First, place a mixed solution of 30mL deionized water and 120mL 2.0mol / L dilute hydrochloric acid in a 50°C water bath. Then, 4.0 g of P123 (EO20PO70EO20, 5800, Sigma Aldrich) was accurately weighed, added to the above mixed solution, and stirred for 30 minutes until clear. Subsequently, 4.8g magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2 O), accurately weighed 8.5g tetraethyl orthosilicate (TEOS) was added in the above-mentioned clear solution, and stirred for 5 hours. After standing still, filter with suction, wash with deionized water, and filter with suction again, repeat 3 times, and place in a 60°C electric blast drying oven (DHG-9070A, Shanghai Yiheng Scientific Instrument Co., Ltd.) to obtain a white powder. Put the powder into a stainless steel mold, and use a tablet press (YP-15t, Tianjin Jinfulun Technology Co., Ltd.) to make a disc sample (Φ12×2mm) under a pressure of 2 MPa. Finally, the...

Embodiment 2

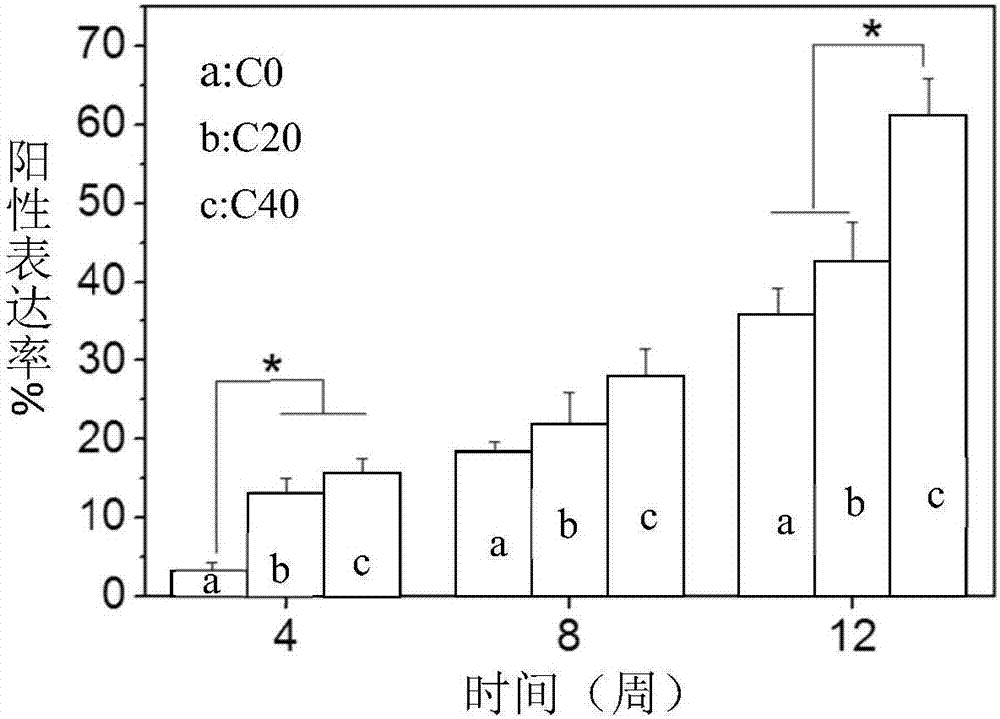

[0076] Accurately weigh 0.6 g of PBSu with a weighing bottle, and dissolve it in 2 mL of dimethylformamide solution. Add 0.4g of the mesoporous magnesium silicate (m-MS) powder prepared in Example 1 and keep stirring to make it uniformly dispersed, after fully mixing, add 8g of sodium chloride particles (particle size is 300-500 μm), mix and stir for 10 minute. Then the above mixture was added into a stainless steel mold, under the pressure of 0.2MP, pressed for 2 minutes. The obtained samples were dried naturally in a fume hood for 12 hours to evaporate the solvent. The material was then soaked in deionized water for 48 hours to remove the porogen (sodium chloride particles), and the deionized water was changed every 8 hours. Finally, the sample was placed in an oven at 37°C for 12 hours to obtain bone repair scaffold material C40.

Embodiment 3

[0078] (1) Preparation of mesoporous magnesium silicate (m-MS)

[0079] First, place a mixed solution of 40mL deionized water and 130mL 2.5mol / L dilute hydrochloric acid in a water bath at 45°C. Then, 5.0 g of P123 (EO20PO70EO20, 5800, Sigma Aldrich) was accurately weighed, added to the above mixed solution, and stirred for 30 minutes until clear. Subsequently, weigh 5.0g magnesium nitrate hexahydrate (Mg(NO 3 ) 2 ·6H 2O), accurately weighed 8.7g tetraethyl orthosilicate (TEOS) was added in the above-mentioned clear solution, and stirred for 6 hours. After standing still, filter with suction, wash with deionized water, and filter with suction again, repeat 3 times, and place in a 60°C electric blast drying oven (DHG-9070A, Shanghai Yiheng Scientific Instrument Co., Ltd.) to obtain a white powder. Put the powder into a stainless steel mold, and use a tablet press (YP-15t, Tianjin Jinfulun Technology Co., Ltd.) to make a disc sample (Φ12×2mm) under a pressure of 2 MPa. Fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com