Porous metal-ceramic composite material gas spreading layer used for hydrogen fuel cell and preparation method thereof

A gas diffusion layer and fuel cell technology, which is applied to fuel cell parts, battery electrodes, circuits, etc., can solve the problems of reducing gas mass transfer, affecting gas distribution, and reducing fuel cell performance, achieving uniform and effective diffusion, improving The effect of operating efficiency and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

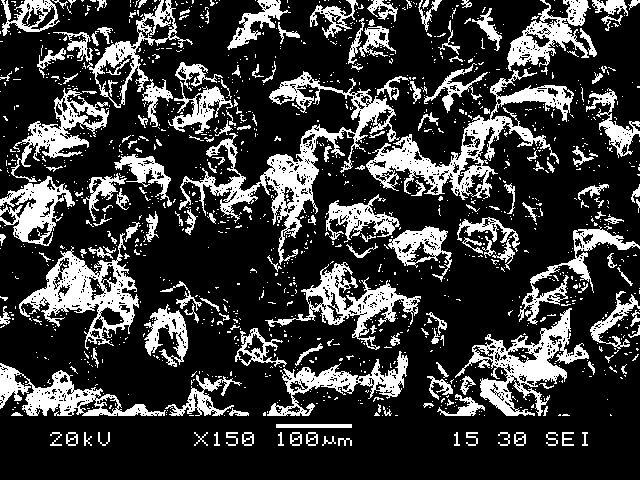

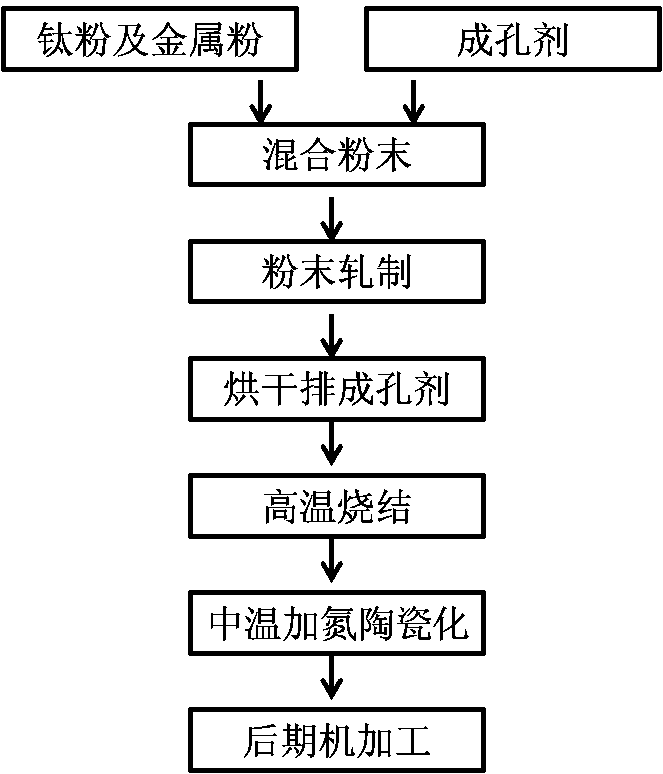

[0024] Raw materials: titanium powder, 500 mesh, purity > 99% Ti; ammonium bicarbonate powder, purity > 99%.

[0025] 1. Roughly grind the ammonium bicarbonate powder with a mortar, and process the ground powder with an ultrafine pulverizer. The obtained powder should be a 400-mesh micropowder.

[0026] 2. Mix titanium powder and ammonium bicarbonate micropowder according to the predetermined weight ratio, 2 kg of titanium powder and 500 g of ammonium bicarbonate powder in a three-dimensional mixer, and the mixing time is 30-45 minutes.

[0027] 3. Pass the mixed powder of the obtained titanium powder and ammonium bicarbonate micropowder through a 60-mesh sieve to remove agglomerates.

[0028] 4. Using a powder rolling mill, adjust the distance between the rolls, and roll the sieved powder into a billet strip with a predetermined thickness of 1 mm. The transverse thickness difference is less than 0.05 mm within 20 cm, and the longitudinal thickness difference is no more t...

Embodiment 2

[0036] Raw materials: titanium powder, 500 mesh, purity > 99%; aluminum powder, 500 mesh, purity > 99%, ammonium bicarbonate powder, purity > 99%.

[0037] 1. Roughly grind the ammonium bicarbonate powder with a mortar, and process the ground powder with an ultrafine pulverizer. The obtained powder should be a 400-mesh micropowder.

[0038] 2. Mix titanium powder and ammonium bicarbonate powder according to the predetermined weight ratio, 2 kg of titanium powder, 50 grams of aluminum powder, and 800 grams of ammonium bicarbonate powder in a three-dimensional mixer, and the mixing time is 30-45 minutes.

[0039] 3. Pass the mixed powder of the obtained titanium powder and ammonium bicarbonate micropowder through a 60-mesh sieve to remove agglomerates.

[0040] 4. Use the powder rolling mill to adjust the distance between the rolls, and roll the sieved powder into a billet strip with a predetermined thickness of 0.5 mm. The transverse thickness difference is less than 0.03 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com