An adsorbent for removing hexafluoropropylene in octafluorocyclobutane and its preparation method

A technology of octafluorocyclobutane and hexafluoropropene is applied in the field of octafluorocyclobutane purification, which can solve the problems of slow progress of synthesis and purification technology, and achieve the effects of firm and stable bonding, uniform growth and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

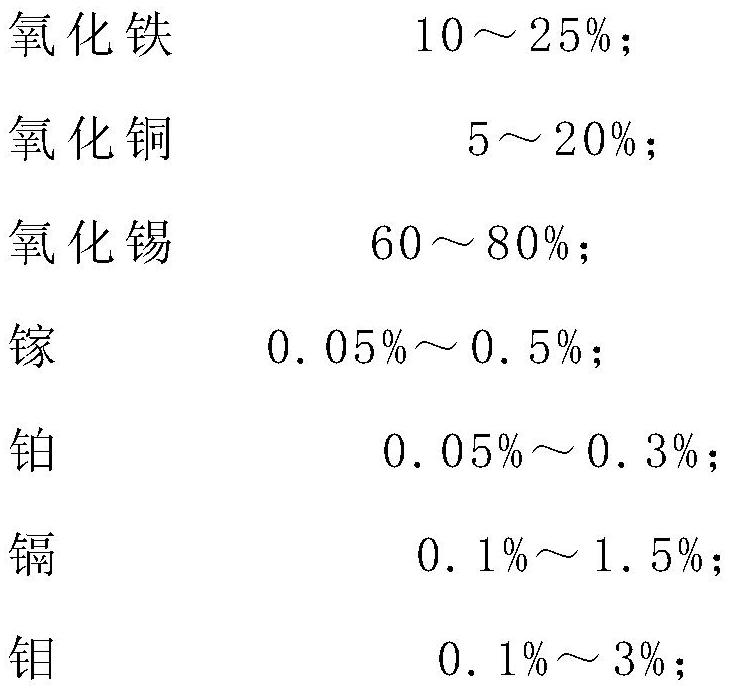

[0034] A preparation method for an adsorbent for removing hexafluoropropylene in octafluorocyclobutane, comprising the steps of:

[0035] (1) Add the salt solution of iron oxide, copper oxide and tin oxide into the hydrothermal kettle, and stir evenly;

[0036] (2) Add salt solutions of gallium, platinum, cadmium and molybdenum to the above-mentioned hydrothermal kettle for doping modification;

[0037] (3) Add wire mesh packing into the above-mentioned hydrothermal kettle, put the above-mentioned hydrothermal kettle with metal mesh filler into the drying oven, and react the solution in the above-mentioned hydrothermal kettle at a hydrothermal treatment temperature of 120°C for 60 minutes;

[0038] (4) Take the above-mentioned hydrothermal kettle out of the above-mentioned drying oven, and cool it at room temperature, and the modified iron oxide, copper oxide, and tin oxide nanoparticles will grow on the above-mentioned wire mesh filler;

[0039] Wherein, after step (1) (2), ...

Embodiment 2

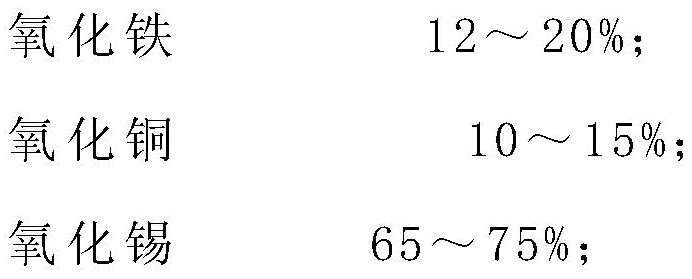

[0041] A preparation method of an adsorbent for removing hexafluoropropylene in octafluorocyclobutane, said preparation method comprising the steps of:

[0042] (1) Add the salt solution of iron oxide, copper oxide and tin oxide into the hydrothermal kettle, and stir evenly;

[0043] (2) adding salt solutions of gallium, platinum, cadmium and molybdenum into the hydrothermal kettle for doping modification;

[0044] (3) Add wire mesh packing into the hydrothermal kettle, put the hydrothermal kettle with the metal mesh filler into the drying oven, and the solution in the hydrothermal kettle is at a hydrothermal treatment temperature of 135°C Reaction 55min;

[0045] (4) Take the hydrothermal kettle out of the drying oven, cool it at room temperature, and the modified iron oxide, copper oxide, and tin oxide nanoparticles will grow on the wire mesh filler;

[0046] Wherein, after step (1) (2), the filling degree of the salt solution in the hydrothermal kettle with iron oxide, co...

Embodiment 3

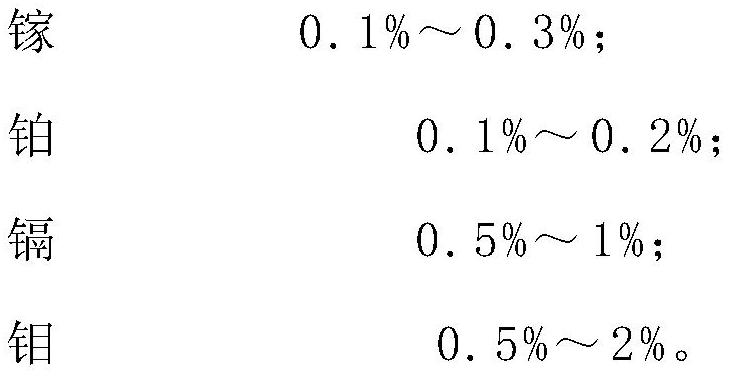

[0048] A preparation method of an adsorbent for removing hexafluoropropylene in octafluorocyclobutane, said preparation method comprising the steps of:

[0049] (1) Add the salt solution of iron oxide, copper oxide and tin oxide into the hydrothermal kettle, and stir evenly;

[0050] (2) adding salt solutions of gallium, platinum, cadmium and molybdenum into the hydrothermal kettle for doping modification;

[0051] (3) Add wire mesh packing into the hydrothermal kettle, put the hydrothermal kettle with the metal mesh filler into the drying oven, and the solution in the hydrothermal kettle is under the hydrothermal treatment temperature of 150°C Reaction 50min;

[0052] (4) Take the hydrothermal kettle out of the drying oven, cool it at room temperature, and the modified iron oxide, copper oxide, and tin oxide nanoparticles will grow on the wire mesh filler;

[0053] Wherein, after step (1) (2), the filling degree of the salt solution in the hydrothermal kettle with iron oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com