Method for preparing light nano porous ceramics

A technology of nano-micropores and ceramics, applied in the direction of nano-structure manufacturing, nano-technology, nano-technology, etc., to achieve the effects of environmental purification, high porosity, and good sound-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

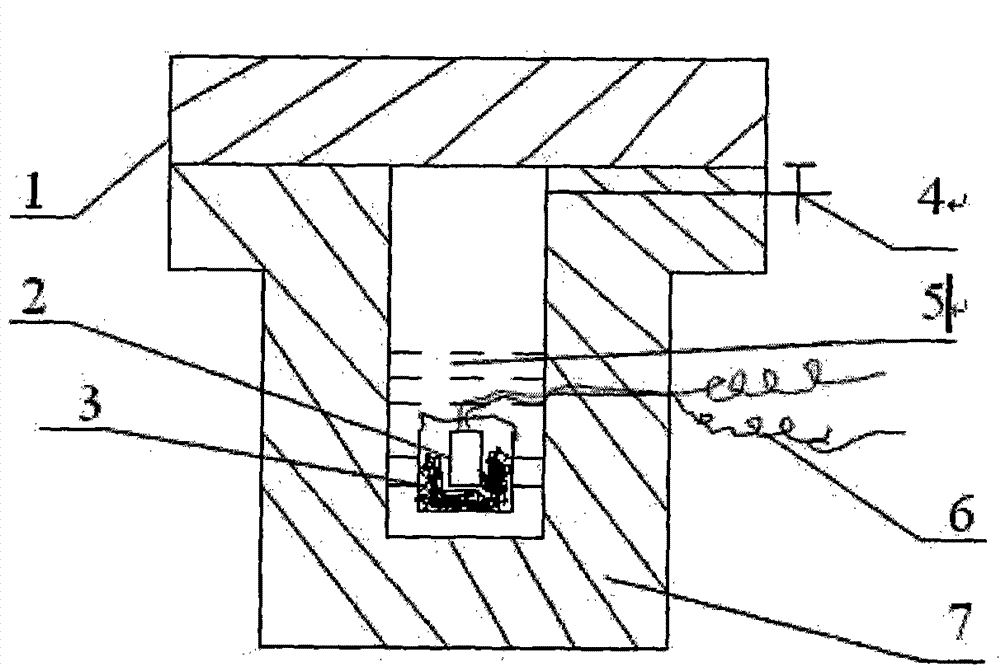

Image

Examples

Embodiment 1

[0030] In a volume of 1M 3 Inject 0.4M into the cartridge 3 Water is used as protection and cooling medium, with 7 parts of explosives (TNT / RDX mass ratio is 70 / 30), 40 parts of aluminum oxide content is 19%, the waste ceramics that silicon oxide content is 74%, 30 parts of waste sludge, and 23 parts The clay is crushed and mixed, packaged with a 8# detonator in a plastic bag and suspended in the cylinder, ignited and detonated, and the product after the explosion is collected and passed through a 100-mesh sieve to remove impurities such as metal wires and tape fragments, and heated in a single phase at 850 °C Pressing and sintering to obtain a density of 0.44kg / m 3 , The porosity is 65%, the nano-microporous ceramics with a pore size of 600nm, and the compressive strength is 8.2MPa.

Embodiment 2

[0032] In a volume of 2M 3 Inject 0.8M into the cartridge 3 Water is used as protection and cooling medium, with 15 parts of explosives (TNT / RDX mass ratio is 30 / 70), 25 parts of waste slag with alumina content of 15% and silicon oxide content of 70%, 30 parts of waste sludge, 20 parts of kaolin , 10 parts of clay were crushed and mixed, packaged with a 8# detonator in a plastic bag and suspended in the cylinder, ignited and detonated, and the products after the explosion were collected and passed through a 100-mesh sieve to remove impurities such as metal wires and tape fragments, and placed at 950 ° C Single-phase hot pressing sintering to obtain a density of 0.32kg / m 3 , Nano-microporous ceramics with a pore size of 20nm, and a compressive strength of 3.4MPa.

Embodiment 3

[0034] In a volume of 10M 3 Inject 4M into the cartridge 3 Water is used as protection and cooling medium, with 1 part of explosive (TNT / RDX mass ratio is 50 / 50), 50 parts of aluminum oxide content is 16%, silicon oxide content is the waste ceramics of 66%, 25 parts of waste slag, 24 parts of long Crushed and mixed with stones, sealed with a plastic bag of 8# detonator and suspended in the barrel, ignited and detonated, collected and passed through a 100-mesh sieve to remove impurities such as metal wires and tape fragments. Heat in single phase at 1150 °C Pressing and sintering to obtain a density of 0.60kg / m 3 , Nano-microporous ceramics with a pore size of 150nm, and a compressive strength of 15.0MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com