Hard carbon negative electrode material for sodium ion battery based on phenolic resin and its preparation method and application

A sodium-ion battery and carbon negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as limiting the application of graphite, achieve stable cycle performance, adjustable pore size distribution, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This example is used to illustrate the preparation method of the hard carbon negative electrode material for sodium ion batteries based on phenolic resin of the present invention.

[0048] figure 1 The preparation method of the sodium ion battery hard carbon negative electrode material based on phenolic resin provided by the embodiment of the present invention, its steps are as follows figure 1 shown, including:

[0049] Step 110, mixing the liquid phenolic resin and ethanol in a volume ratio of 2:1-8:1, and stirring evenly;

[0050] Specifically, the stirring method is preferably mechanical stirring. The time of mechanical stirring can be determined according to the ratio of selected phenolic resin and ethanol. The mixing ratio of liquid phenolic resin and ethanol can be selected in the range of 2:1-8:1 as required.

[0051] Wherein, the phenolic resin includes one or more mixtures of phenol-formaldehyde resin, resorcinol-formaldehyde resin, p-diphenol-formaldehyde...

Embodiment 2

[0063] Mix liquid phenolic resin and ethanol at a volume ratio of 2:1 and stir evenly; transfer the mixture of phenolic resin and ethanol to a reaction kettle, and perform hydrothermal treatment at 180°C for 4 hours to cure the phenolic resin; The resin was taken out and mechanically ground into powder; then the powder was put into a tube furnace, and the temperature was raised to 1550°C at a heating rate of 3°C / min, and the raw material was subjected to high-temperature treatment for 2 hours under the protection of argon to make it Cracking, carbonization; finally cooling to room temperature, taking out the material to obtain a hard carbon material with the following microstructure characteristics.

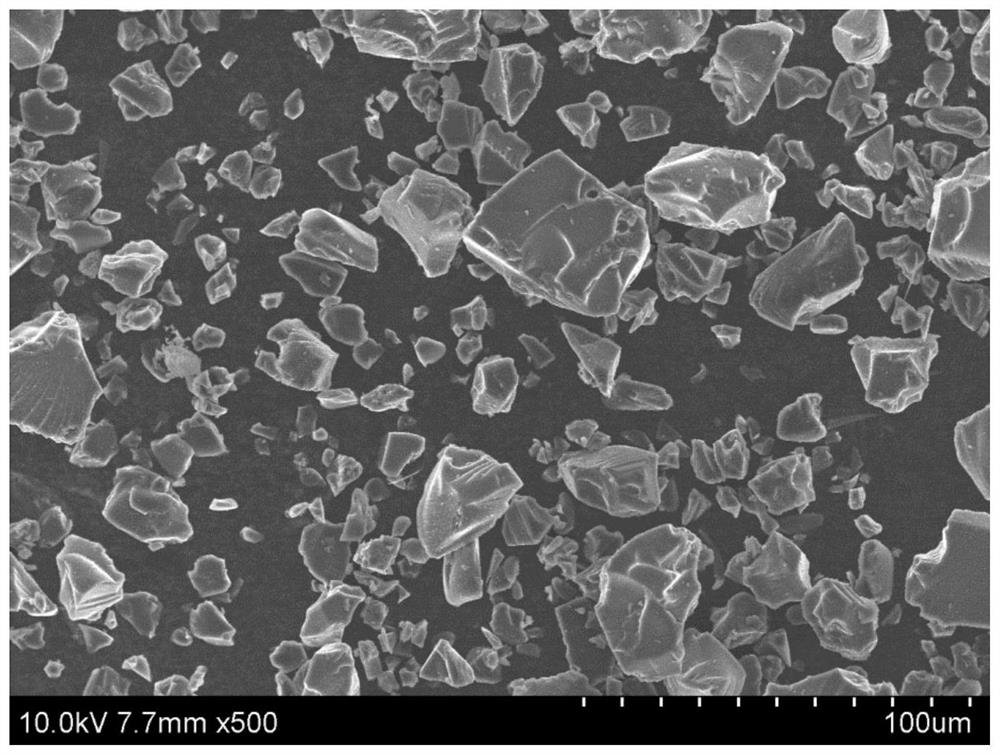

[0064] Figure 2a The photo of the surface morphology of the cured phenolic resin powder particles prepared for this example shows that fine cracks appear on the surface of the cured phenolic resin, forming holes. Figure 2b The SEM image of the hard carbon material prepared for...

Embodiment 3

[0069] Mix the liquid phenolic resin and ethanol at a volume ratio of 8:1, and stir evenly; transfer the mixture of the phenolic resin and ethanol to a reaction kettle, and perform hydrothermal treatment at 180°C for 4 hours to cure the phenolic resin; The resin was taken out and mechanically ground into powder; then the powder was put into a tube furnace, and the temperature was raised to 1550°C at a heating rate of 3°C / min, and the raw material was subjected to high-temperature treatment for 2 hours under the protection of argon to make it Cracking, carbonization; finally cooling to room temperature, taking out the material to obtain a hard carbon material with the following microstructure characteristics.

[0070] Image 6 The SEM image of the hard carbon material prepared for this example shows that the macroscopic appearance is irregular and massive, and the particle diameter is between 50-200 μm. Its XRD pattern sees Figure 7 . It can be seen from the XRD spectrum th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com