Porous carbon material and preparation method thereof

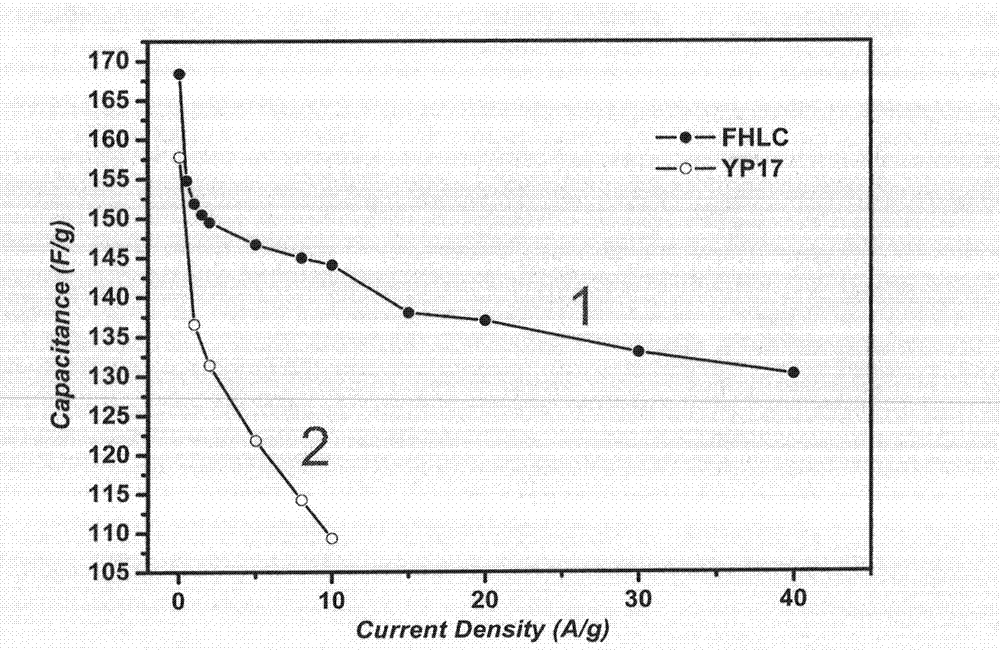

A technology of porous carbon materials and adsorption materials, which is applied in the field of preparation of porous carbon materials to achieve the effects of high adsorption capacity, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

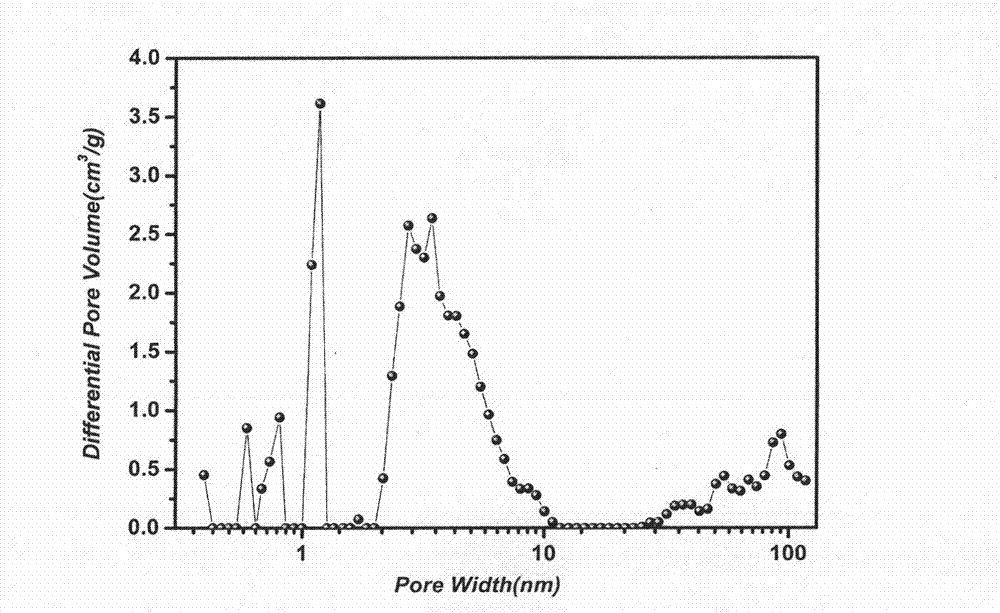

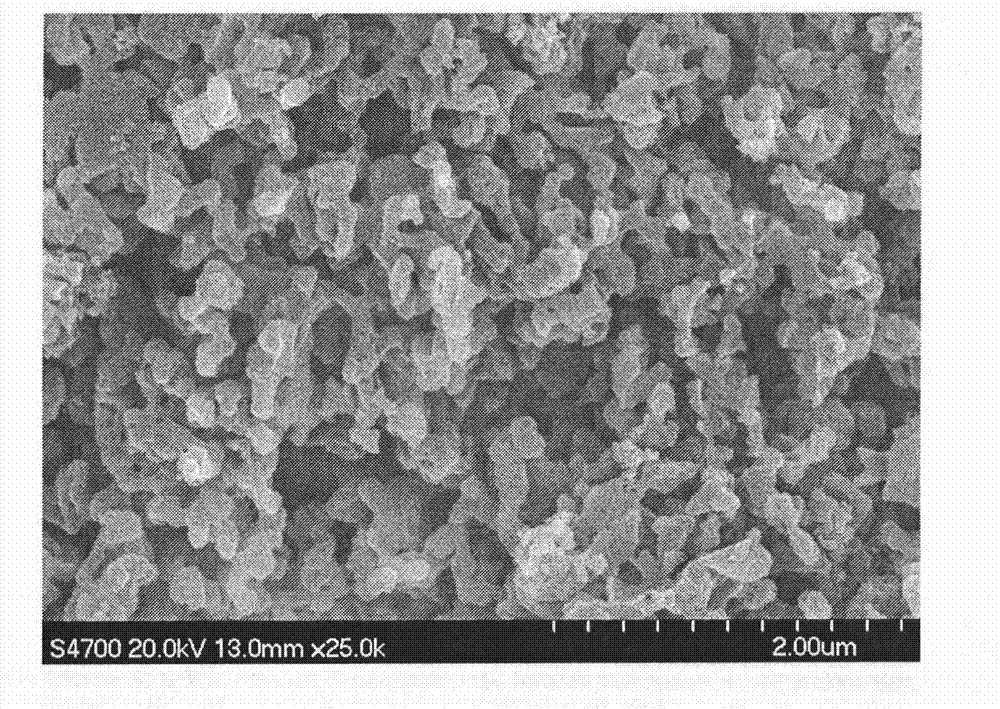

Embodiment 1

[0018] Example 1: (1) Dry and dry the cleaned fish scales at 120°C for 3 hours, then place them in a muffle furnace at 330°C for 6 hours for pre-carbonization; Mix evenly at a ratio of 1:1, raise the temperature to 950°C at a heating rate of 2-10°C / min in a tubular electric furnace under nitrogen protection, and keep it for 1h for activated carbonization. (3) Activate the carbonized product, cool it naturally to room temperature under the protection of nitrogen, treat it with 2mol / L HCl solution to remove the inorganic salts, wash it with deionized water until neutral, and dry it at 120°C to obtain a hierarchical porous carbon material. Its BET specific surface area reaches 2273m 2 g -1 , total pore volume 2.74cm 3 g -1 , with an average pore diameter of 4.47nm. The three-dimensional distribution of the pore length (see figure 1 , figure 2 ), the pore size is mainly micropores less than 2nm, mesopores 2-10nm and macropores greater than 50nm.

Embodiment 2

[0019] Example 2: Pre-carbonization is the same as step (1) of the embodiment, the pre-carbonized fish scales and potassium hydroxide are mixed evenly in a ratio of 1:1, and then kept at 600° C. for 1 h under the protection of nitrogen to activate carbonization and cool naturally. The obtained carbonized product was removed with 2mol / L HCl solution to remove inorganic salts, rinsed with deionized water until neutral, and dried at 120°C to obtain a hierarchically porous carbon material. Its BET specific surface area reaches 1047m 2 g -1 , total pore volume 0.53cm 3 g -1 , with an average pore diameter of 9.74nm. The pores are distributed in three levels, mainly micropores (less than 2nm), mesoporous (3-10nm, 30-50nm) and macropores (greater than 50nm).

Embodiment 3

[0020] Embodiment 3: pre-carbonization is the same as embodiment step (1), the fish scale after pre-carbonization and potassium carbonate mass fraction are mixed uniformly, wherein the fish scale after carbonization and potassium carbonate mass ratio are 1: 3, wait for fully After mixing evenly, dry in an oven at 110°C. Afterwards, it was kept at 700°C for 1 hour under the protection of nitrogen for activated carbonization, and cooled naturally. The obtained carbonized product was removed with 2mol / L HCl to remove inorganic salts, rinsed with hot deionized water until neutral, and dried at 120°C to obtain a hierarchically porous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com