Mesoporous magnesium oxide material and preparation method thereof

A technology of mesoporous magnesium oxide and magnesium nitrate, applied in the direction of magnesium oxide, can solve the problems of high synthesis cost, low porosity, and low yield, and achieve the problems of overcoming many pretreatment steps, improving synthesis efficiency, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 1 g of glucose to 25 mL of water, and stir for 5 minutes at room temperature to obtain an aqueous solution of glucose;

[0022] (2) 5g of magnesium nitrate was added to the aqueous glucose solution obtained in step (1), and stirred for 5 minutes at room temperature to obtain an aqueous solution of magnesium nitrate and glucose;

[0023] (3) heat-treating the aqueous solution obtained in step (2) at 100° C. for 24 hours, evaporating water molecules in the solution, and obtaining a mixture of magnesium nitrate and glucose;

[0024] (4) The mixture obtained in step (3) was heat-treated at 500° C. for 2 hours to obtain a mesoporous magnesium oxide material; the product mass was 0.786 g.

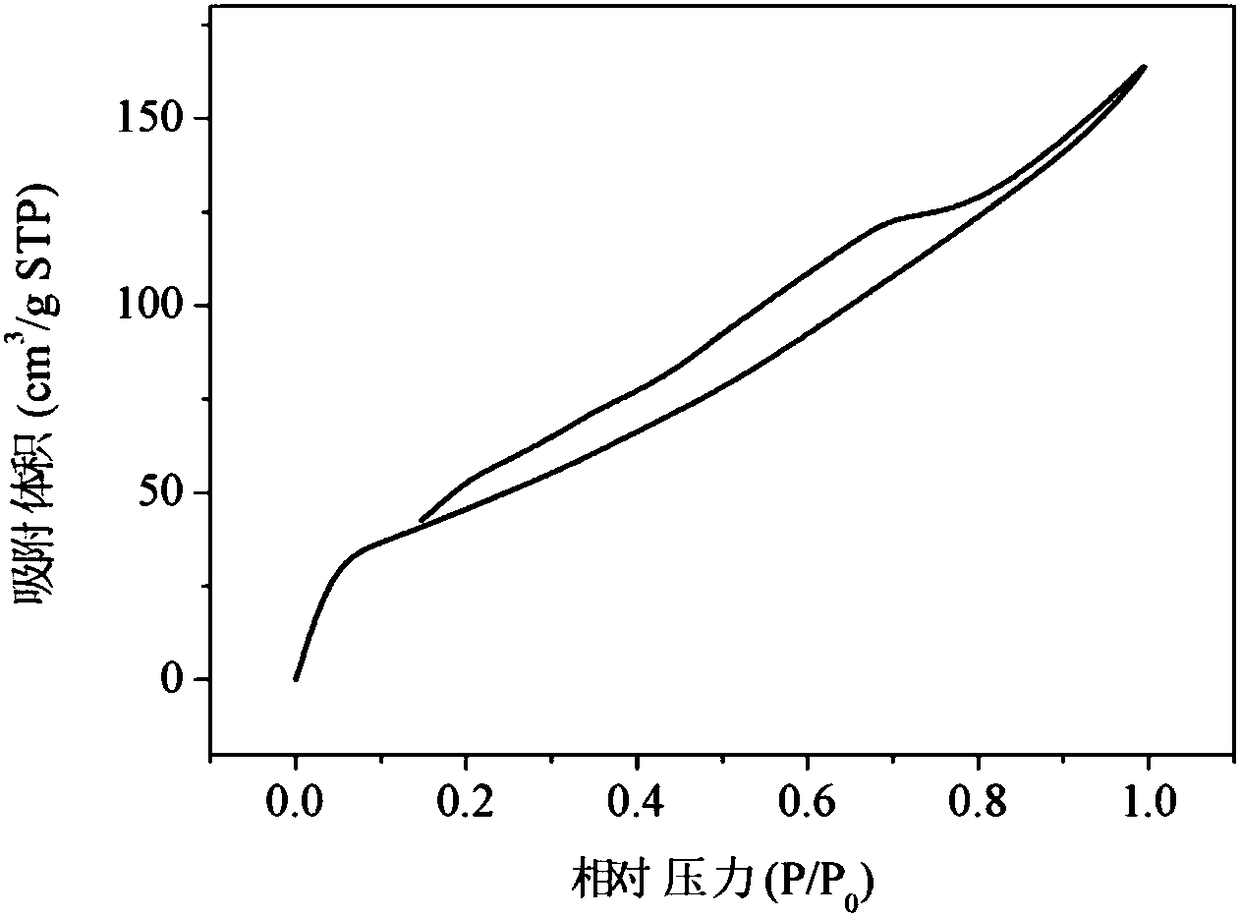

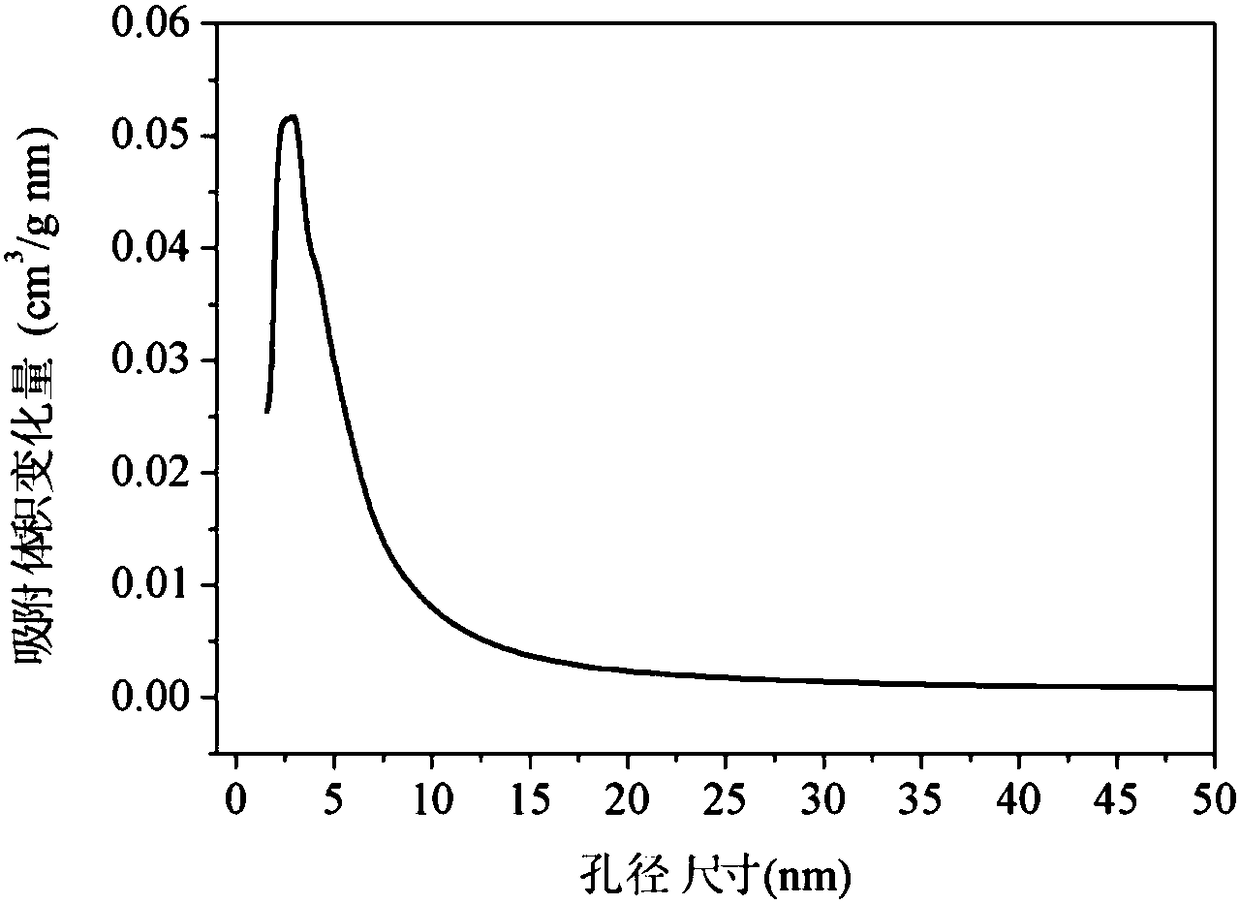

[0025] The prepared mesoporous magnesium oxide material has a three-dimensional porous structure with a pore size of 2 nm and a pore volume of 0.5 cm 3 / g, BET specific surface area is 100m 2 / g.

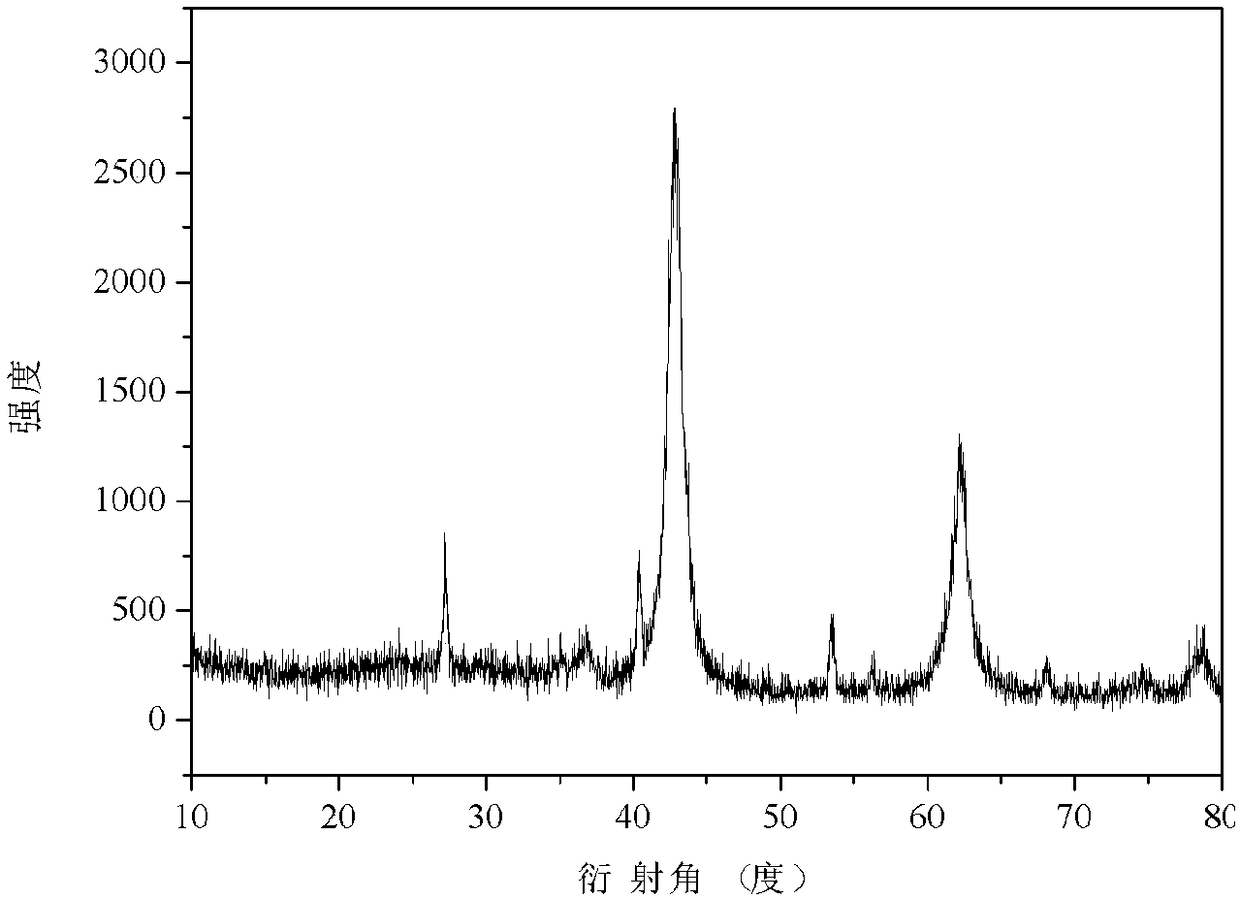

[0026] The wide-angle X-ray diffraction spectrum of the mesoporous magnesium oxid...

Embodiment 2

[0031] (1) Add 2.5 g of glucose to 50 mL of water, and stir for 10 minutes at room temperature to obtain an aqueous solution of glucose;

[0032] (2) 3.75g of magnesium nitrate was added to the aqueous glucose solution obtained in step (1), and stirred for 5 minutes at room temperature to obtain an aqueous solution of magnesium nitrate and glucose;

[0033] (3) heat-treating the aqueous solution obtained in step (2) at 100° C. for 24 hours, evaporating water molecules in the solution, and obtaining a mixture of magnesium nitrate and glucose;

[0034] (4) The mixture obtained in step (3) was heat-treated at 500° C. for 2 hours to obtain a mesoporous magnesium oxide material; the product mass was 0.590 g.

[0035] The prepared mesoporous magnesium oxide material has a three-dimensional porous structure with a pore size of 4 nm and a pore volume of 0.6 cm 3 / g, BET specific surface area is 150m 2 / g.

Embodiment 3

[0037] (1) Add 2.5 g of glucose to 25 mL of water, and stir for 5 minutes at room temperature to obtain an aqueous solution of glucose;

[0038] (2) 2.5g of magnesium nitrate was added to the aqueous glucose solution obtained in step (1), and stirred for 5 minutes at room temperature to obtain an aqueous solution of magnesium nitrate and glucose;

[0039] (3) heat-treating the aqueous solution obtained in step (2) at 110° C. for 36 hours, evaporating water molecules in the solution, and obtaining a mixture of magnesium nitrate and glucose;

[0040] (4) The mixture obtained in step (3) was heat-treated at 550° C. for 3 hours to obtain a mesoporous magnesium oxide material; the product mass was 0.393 g.

[0041] The prepared mesoporous magnesium oxide material has a three-dimensional porous structure with a pore size of 5 nm and a pore volume of 0.8 cm 3 / g, BET specific surface area is 180m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com