Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Zinc phosphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

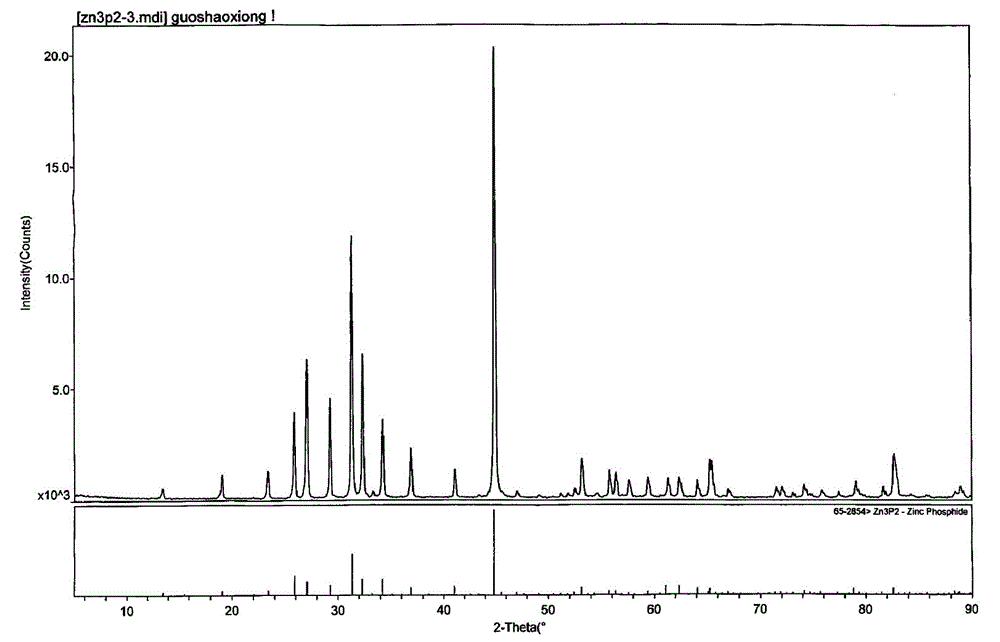

Zinc phosphide (Zn3P2) is an inorganic chemical compound. It is a grey solid, although commercial samples are often dark or even black. It is used as a rodenticide. Zn3P2 is a semiconductor with a direct band gap of 1.5 eV and may have applications in photovoltaic cells.

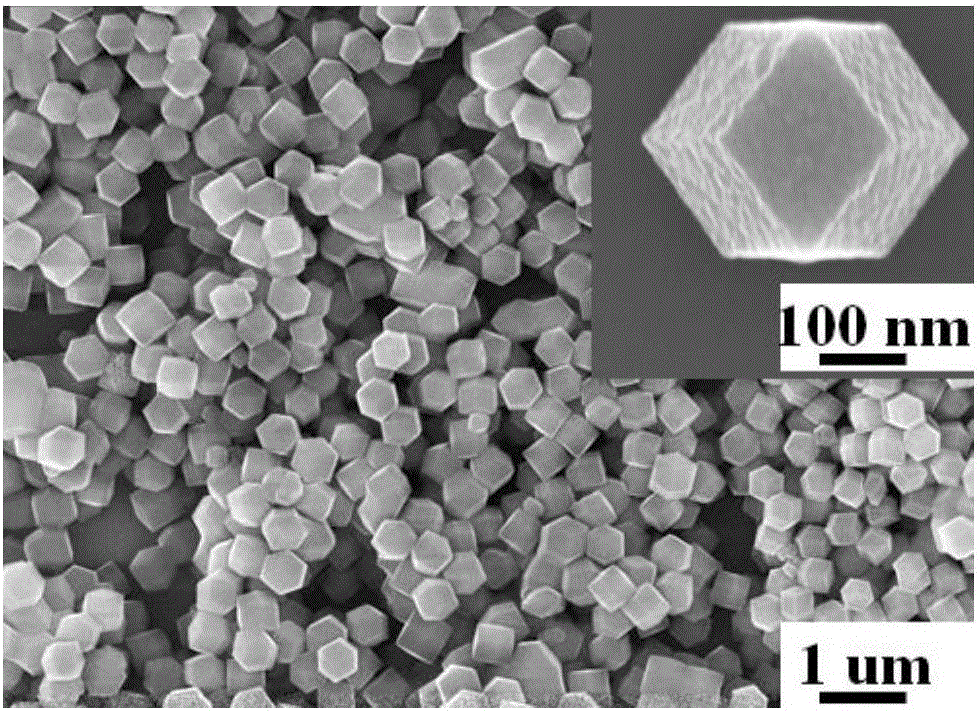

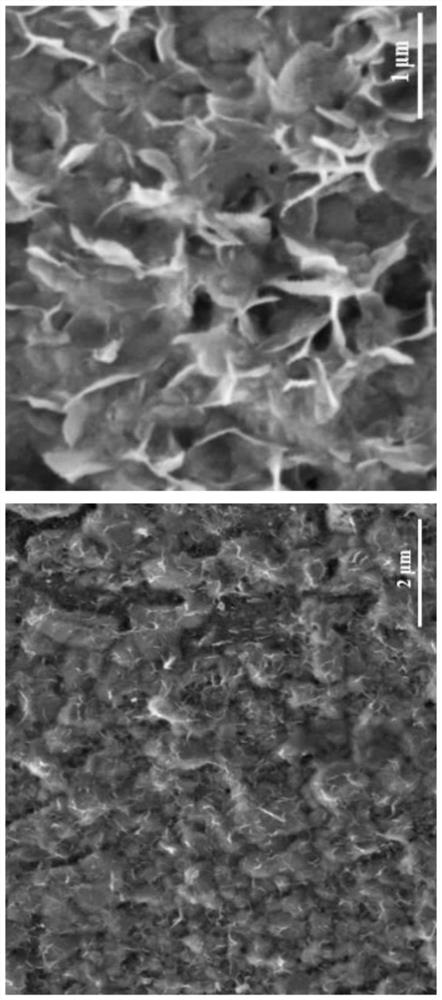

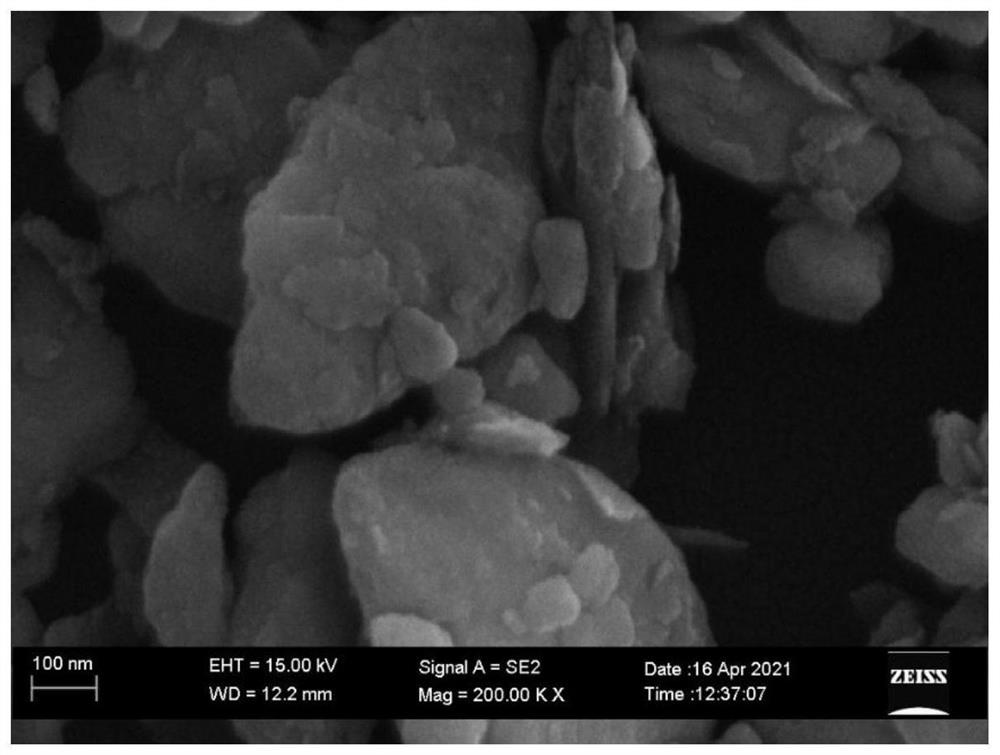

Method for preparing zinc phosphide/cobalt phosphide heterojunction photocatalyst based on MOFs template

InactiveCN106311294AImprove photocatalytic hydrogen production performanceFully exposedPhysical/chemical process catalystsHeterojunctionPtru catalyst

The invention provides a method for preparing a zinc phosphide / cobalt phosphide heterojunction photocatalyst based on an MOFs template and belongs to the technical field of preparation of photocatalytic materials. ZIF-ZnCo is used as a template, and the zinc phosphide / cobalt phosphide heterojunction photocatalyst with a porous structure is formed by conducting oxidation and phosphating treatment on the template. The original framework structure characteristics of a precursor MOFs are kept based on the catalyst, active catalysis sites are fully exposed, meanwhile the catalyst promotes separation of photoproduced electron holes and improves an photo-response behavior through a good synergistic effect, and therefore shows excellent water photolysis hydrogen-production performance.

Owner:BEIJING UNIV OF TECH

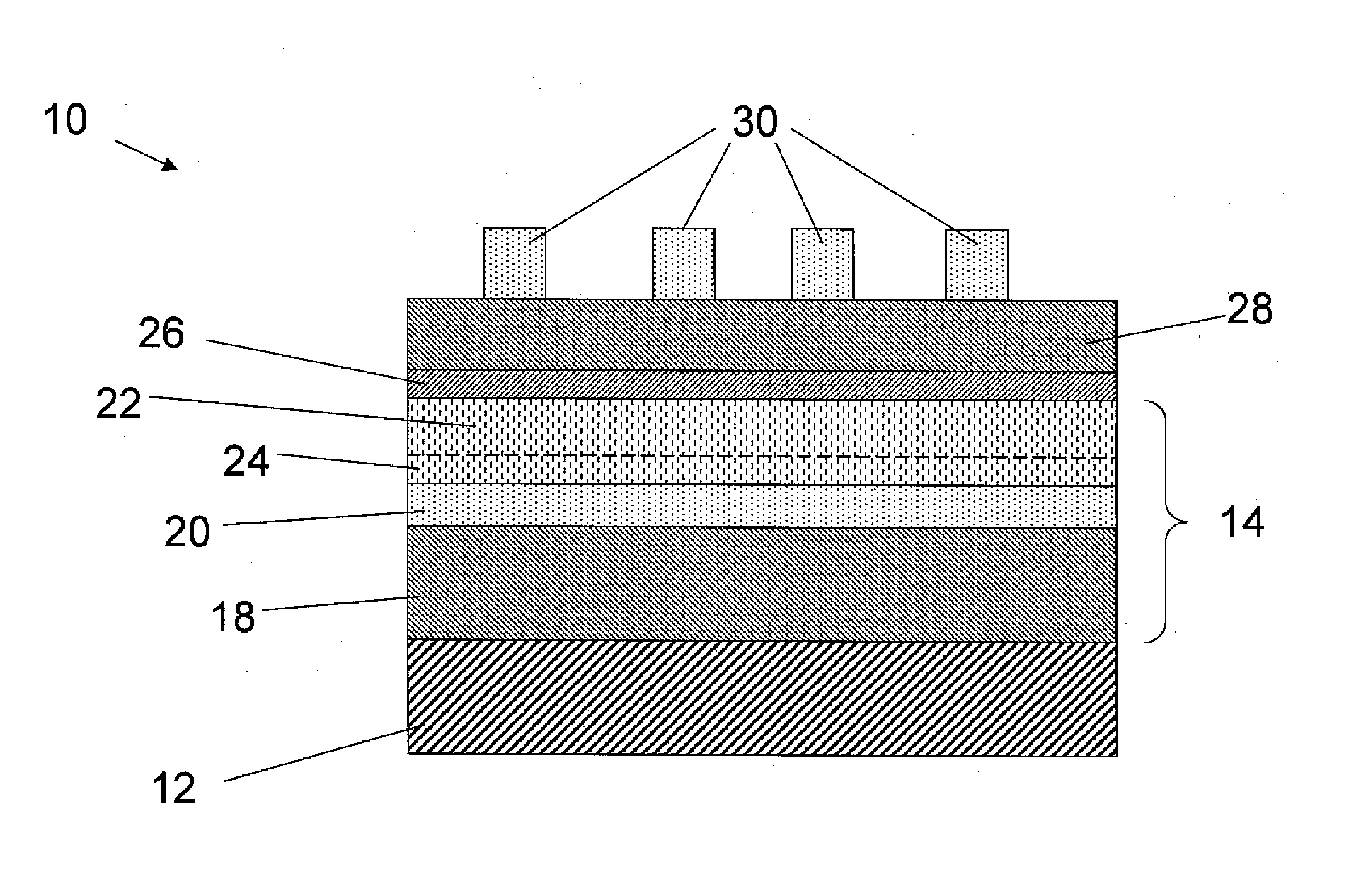

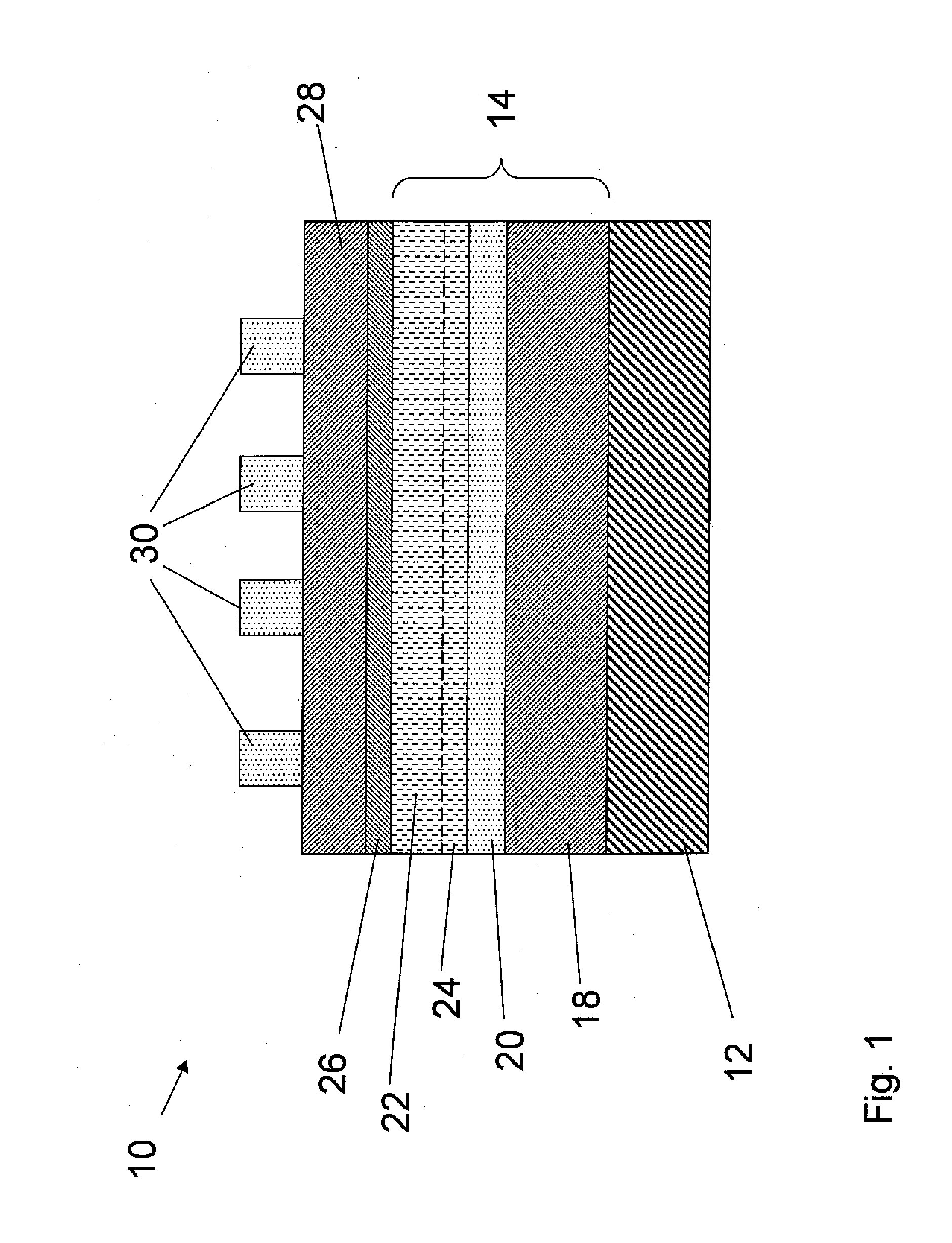

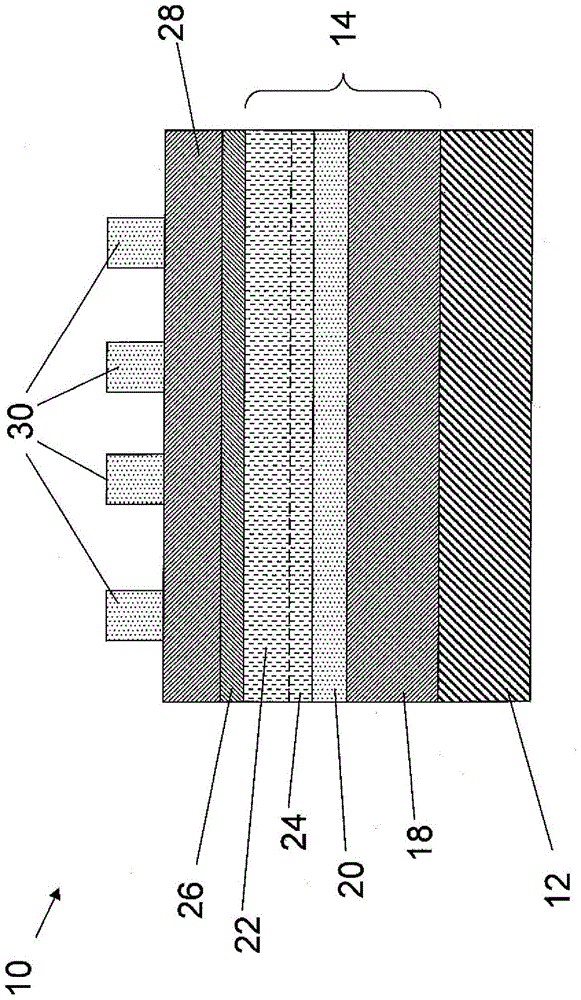

Method of making photovoltaic devices with reduced conduction band offset between pnictide absorber films and emitter films

InactiveUS20160071994A1Reduces conduction bandQuality improvementSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringAlloy

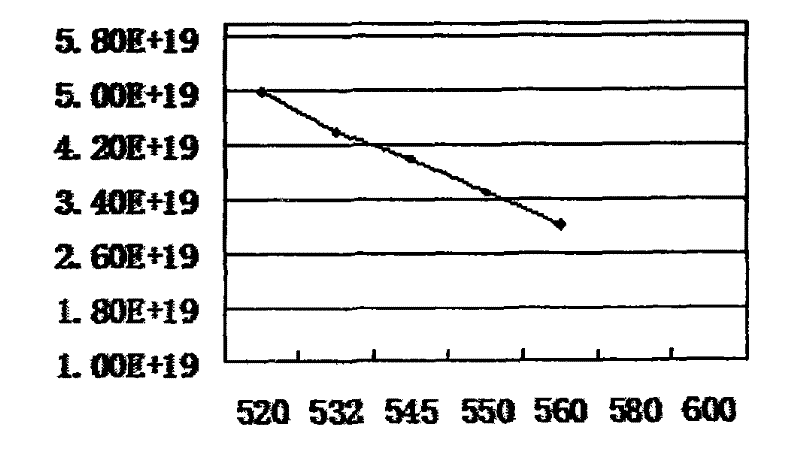

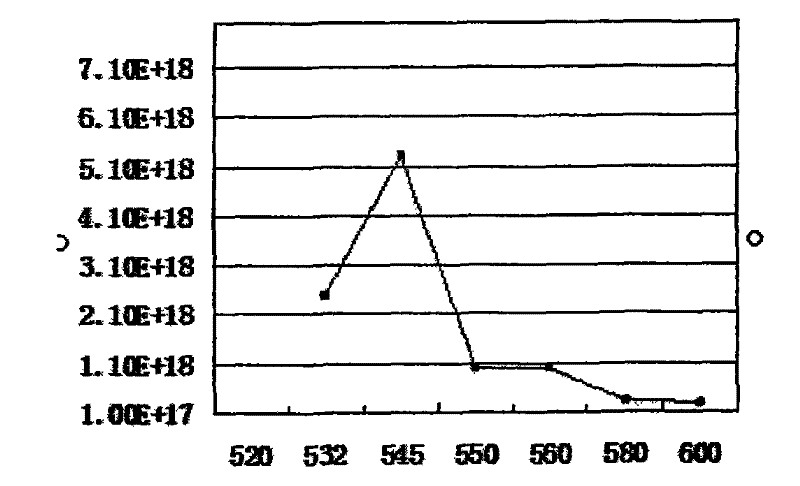

The principles of the present invention are used to reduce the conduction band offset between chalcogenide emitter and pnictide absorber films. Alternatively stated, the present invention provides strategies to more closely match the electron affinity characteristics between the absorber and emitter components. The resultant photovoltaic devices have the potential to have higher efficiency and higher open circuit voltage. The resistance of the resultant junctions would be lower with reduced current leakage. In illustrative modes of practice, the present invention incorporates one or more tuning agents into the emitter layer in order to adjust the electron affinity characteristics, thereby reducing the conduction band offset between the emitter and the absorber. In the case of an n-type emitter such as ZnS or a tertiary compound such as zinc sulfide selenide (optionally doped with Al) or the like, an exemplary tuning agent is Mg when the absorber is a p-type pnictide material such as zinc phosphide or an alloy of zinc phosphide incorporating at least one additional metal in addition to Zn and optionally at least one non-metal in addition to phosphorus. Consequently, photovolotaic devices incorporating such films would demonstrate improved electronic performance.

Owner:CALIFORNIA INST OF TECH +1

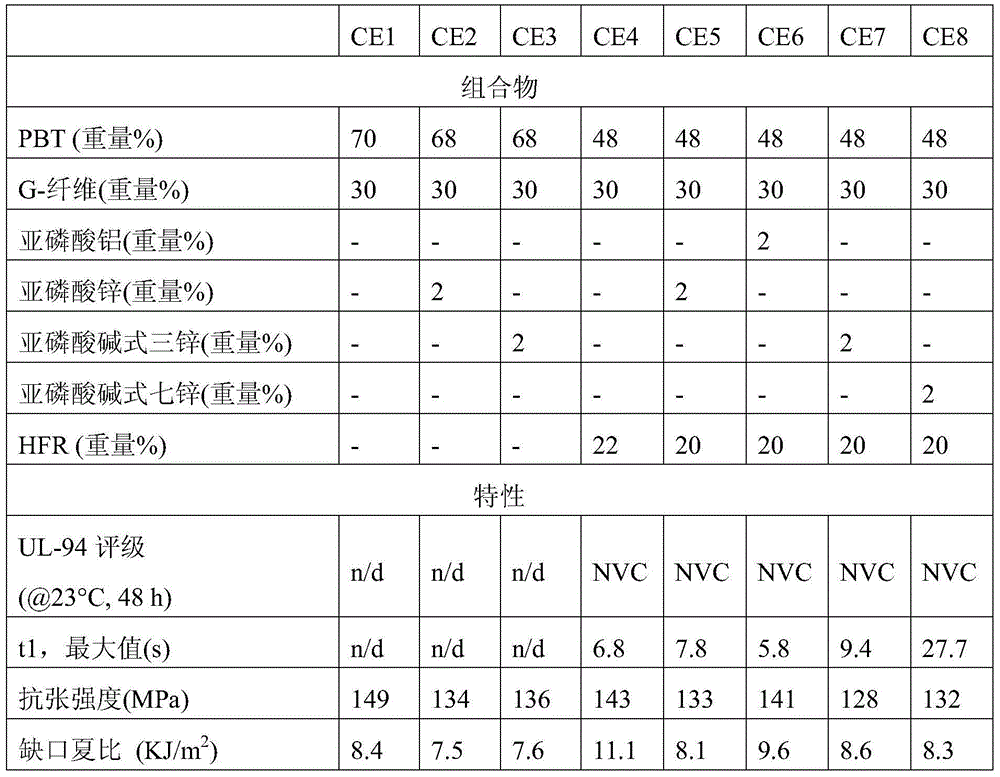

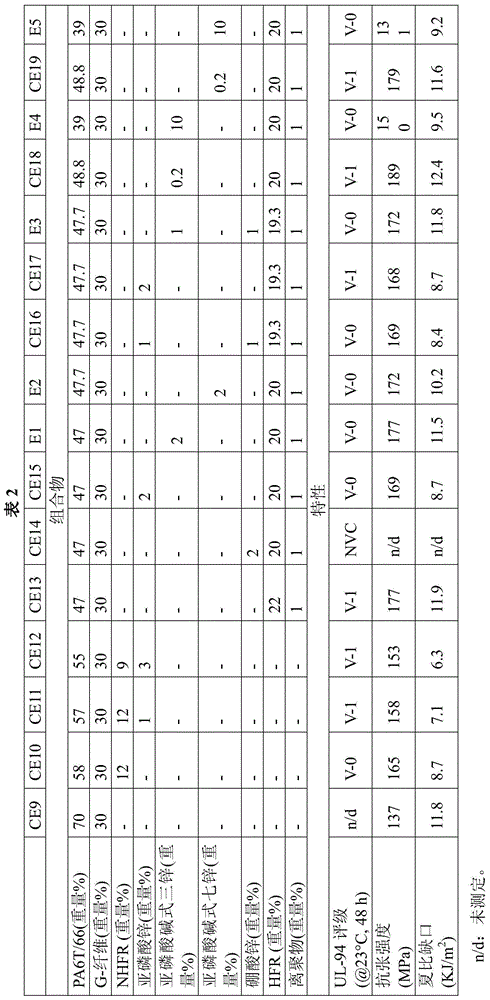

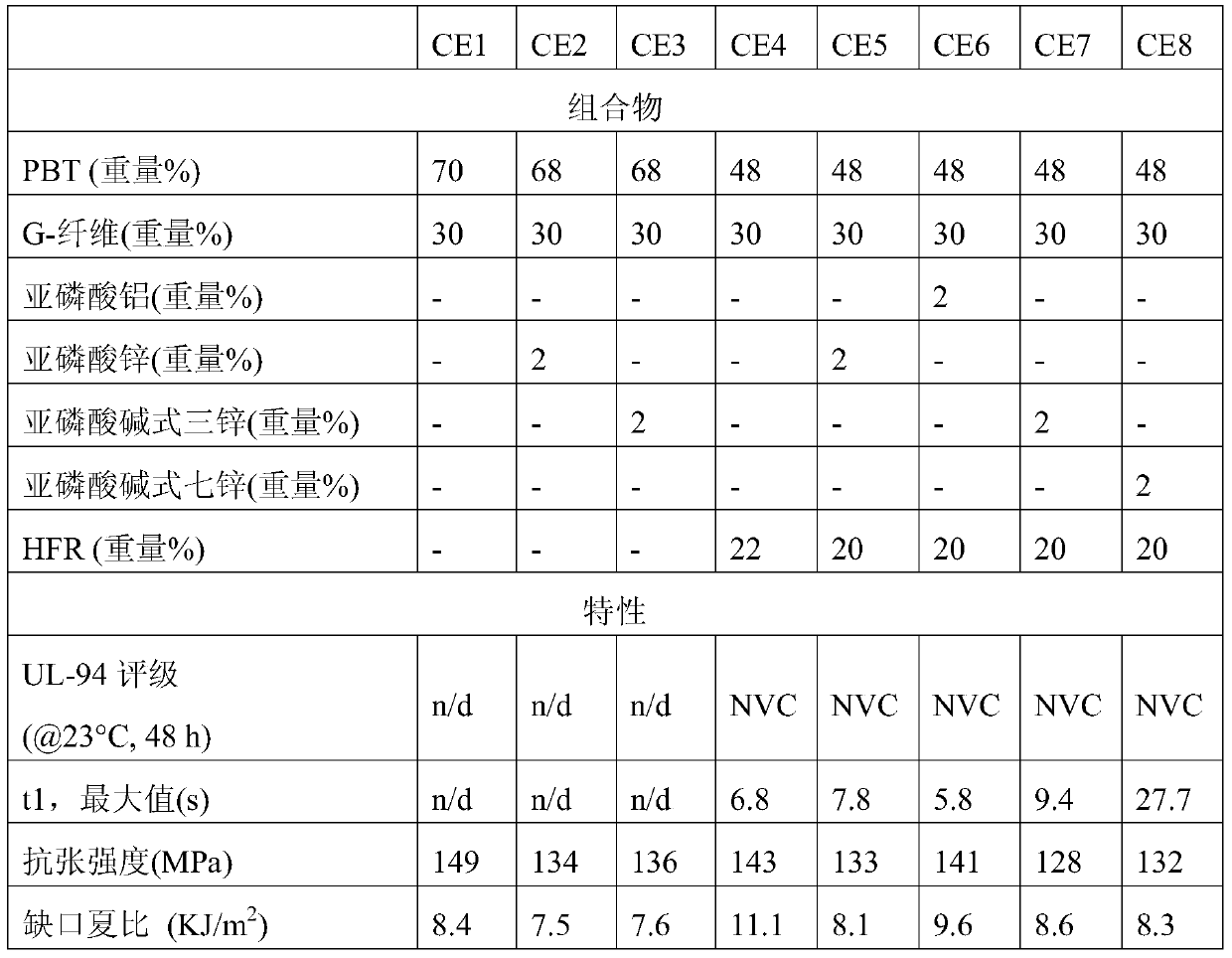

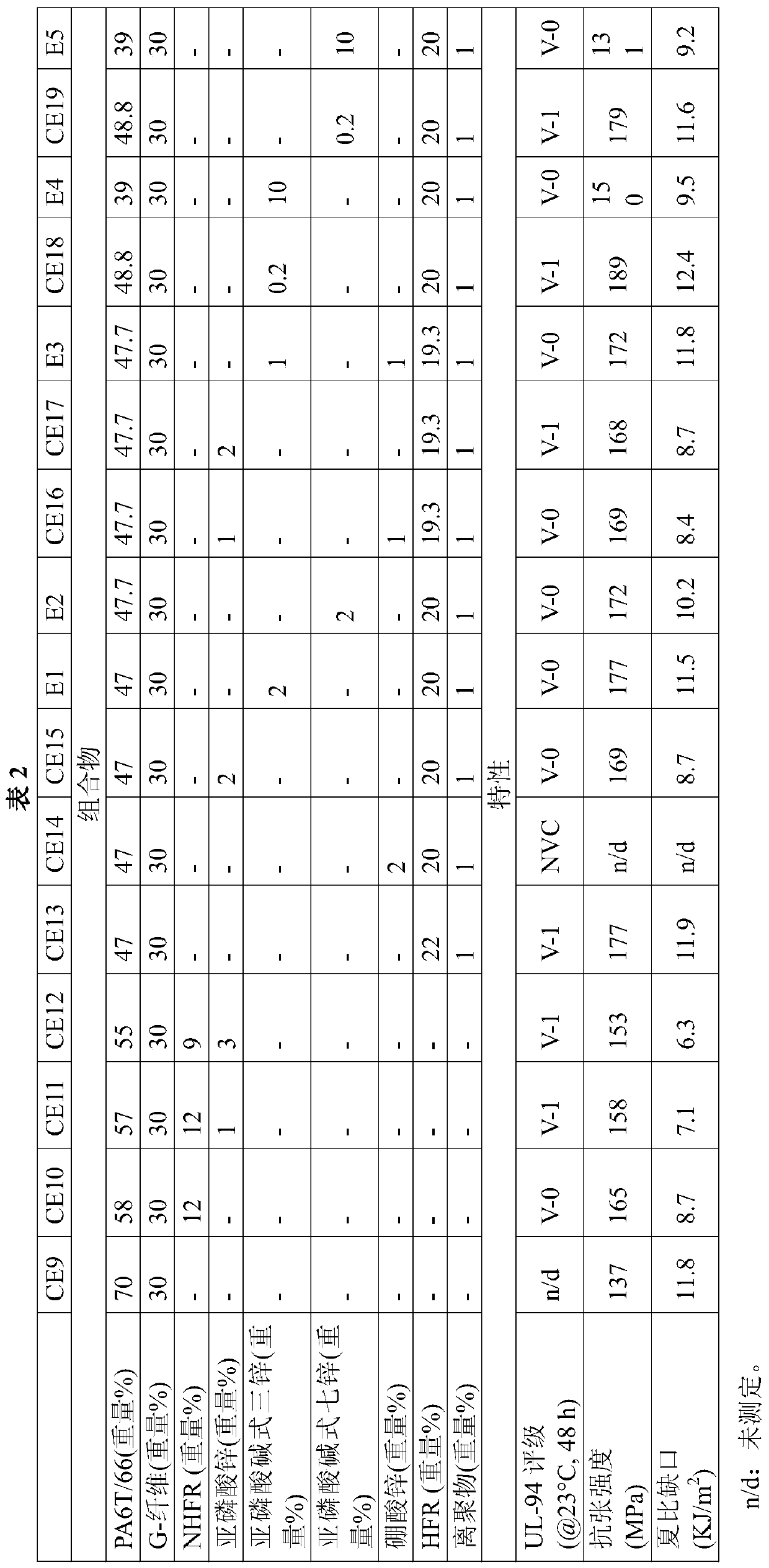

Flame retardant polyamide composition

The present invention relates to a flame retardant polyamide composition comprising(a)at least one polyamide;(b)about 8 to 35 wt% of at least one halogen-containing flame retardant;(c)at least one of about 0.3 to 12 wt% basic zinc phosphite represented by the formula xZnO.ZnHPO3, wherein x is a number from 1 / 2 to 10; and optionally(d)up to about 60 wt% of glass fiber, and the total weight percentage of all components included in the composition is 100 weight%.

Owner:EI DU PONT DE NEMOURS & CO

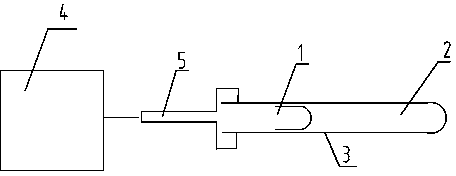

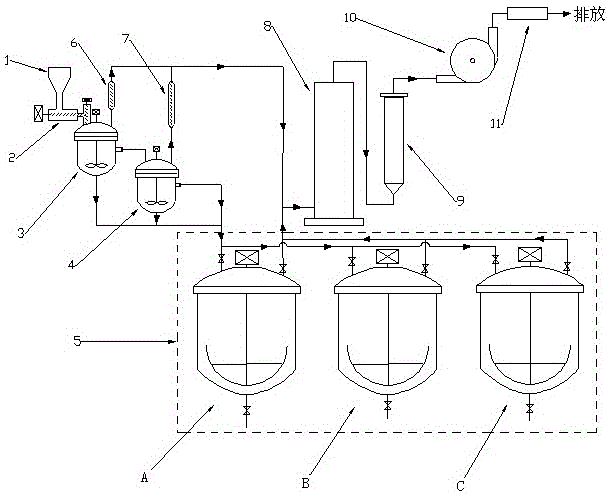

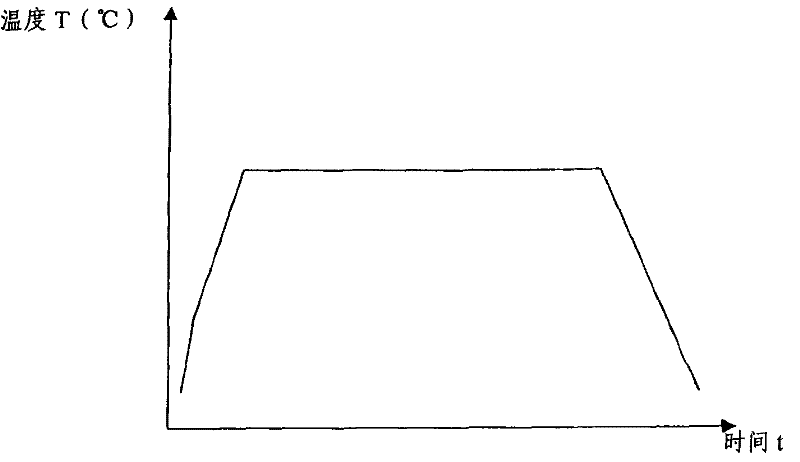

Preparation method of high-purity zinc phosphide

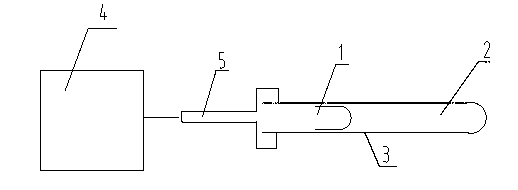

The invention discloses a preparation method of high-purity zinc phosphide, which comprises the following steps of: 1) quartz tube pretreatment; 2) dosing; 3) tube sealing; 4) high-temperature synthesis; and 5) product treatment. According to the invention, high-purity phosphorus and high-purity zinc are directly combined to produce high-purity zinc phosphide, the main reaction process is carried out after the temperature reaches the melting point of zinc, the reaction is actually a steam reaction, and the method is an element direct synthesis method; the requirements for the form of raw materials are not very strict; the raw material is not processed, and the requirement for high purity is met; the pressure in a tube is controlled through temperature control operations such as slow heating, constant temperature, slow cooling and the like; the phosphorus steam pressure in the quartz tube is successfully controlled through length allocation of a heating area and a condensation area for synthesizing a quartz tube, and safe synthesis of a large amount of zinc phosphide is realized; and relatively high yield of a product is realized by controlling the length of the condensation area and the heating area, and the product is applied to the application fields of photoelectric device manufacturing, diffusion sources, nano materials and the like.

Owner:峨嵋半导体材料研究所

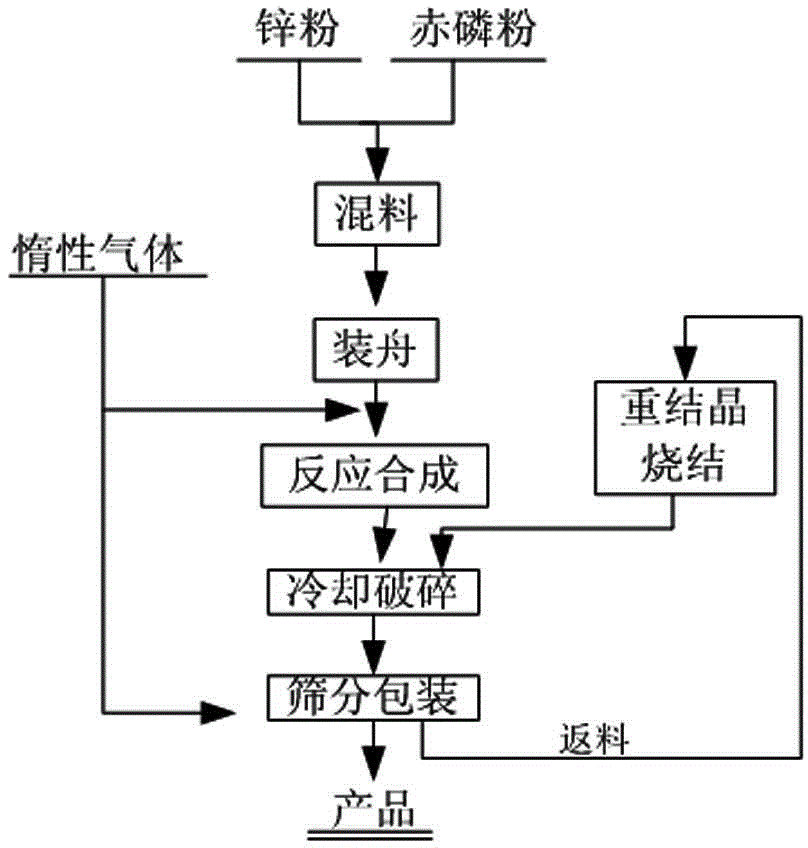

Preparation method of zinc phosphide

The invention relates to a preparation method of zinc phosphide. The invention belongs to a production method of chemical materials and in particular relates to a preparation method of tetragonal system high-purity zinc phosphide. The preparation method of zinc phosphide comprises the following steps: firstly, uniformly mixing metal zinc powder with red phosphorus powder in mass ratio of (3.1-3.3):1, placing mixture into a high-purity graphite boat, then placing the high-purity graphite boat into a smelting furnace while protective gas is introduced until pressure is 90-115KPa, and sealing the smelting furnace; secondly, slowly heating and warming at a speed of 0.5-35 DEG C / min, and carrying out synthetic reaction at the temperature of 100-900 DEG C, so that blocky zinc phosphide is obtained. The zinc phosphide obtained by adopting the preparation method is tetragonal system Zn3P2, product composition phase is uniform, purity is high, flow is short, a production technology is simple, and industrialization can be realized.

Owner:云南锡业研究院有限公司研究设计院

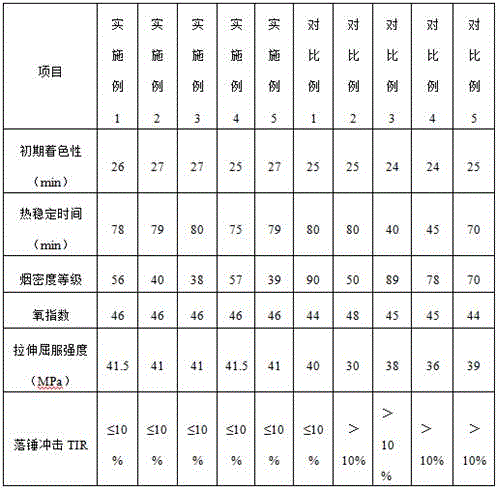

Calcium-zinc composite stabilizer and preparation method thereof

The invention relates to a calcium-zinc composite stabilizer and a preparation method thereof. The calcium-zinc composite stabilizer consists of the following raw materials in percentage by weight: 20%-60% of alkaline calcium-zinc phosphite, 5%-30% of calcium-zinc silicate, 10%-50% of hydrotalcite or hydrotalcite-like compounds, 5%-30% of metal hydroxide, 1%-3% of a surfactant, 5%-30% of an auxiliary stabilizer, and 5%-30% of a lubricant. The calcium-zinc composite stabilizer and the preparation method thereof have the characteristics that the stability is good, the resistance to vulcanization pollution is achieved, the use amount is low, the heat stability of the calcium-zinc composite stabilizer is superior to that of the traditional lead-salt composite stabilizer, the weather resistance is good, the mold cleaning period is long, and the physical properties of products are excellent; waste water, waste gas and waste residues are not generated in production; no dust is generated in use of the stabilizer; the production cost is low; the raw materials are easily available; the calcium-zinc composite stabilizer can widely substitute for the traditional lead-salt composite stabilizer and an organic tin stabilizer; the economic, social and environmental benefits are remarkable.

Owner:JIANGSU LIANMENG CHEM

A heat-resisting environmental-friendly polyvinyl chloride material

A heat-resisting environmental-friendly polyvinyl chloride material is disclosed. The material comprises following components by weight: 65-80 parts of polyvinyl chloride, 20-35 parts of nitrile butadiene rubber, 5-15 parts of methyl methacrylate-butadiene-styrene copolymer, 2-8 parts of chlorinated polyethylene, 0.5-1.5 parts of stearic acid, 1-2.5 parts of zinc phosphite stearate, 0.5-1.5 parts of calcium stearate, 0.2-2 parts of zinc nitrilotiracetate, 1-2.5 parts of acetyl tributyl citrate, 2-8 parts of butyl epoxystearate, 2-6 parts of pentaerythritol, 2-5 parts of oxooctadecyl benzoyl methane, 0.5-2.5 parts of recycled phenolic resin, 5-15 parts of a modified composite filler, 0.5-2 parts of polyethylene wax and 2-7 parts of a silane coupling agent. The material is good in heat resistance and waterproofness, excellent in flame retardance and good in environmental protection performance.

Owner:ANHUI GUANGYUAN TECH DEV

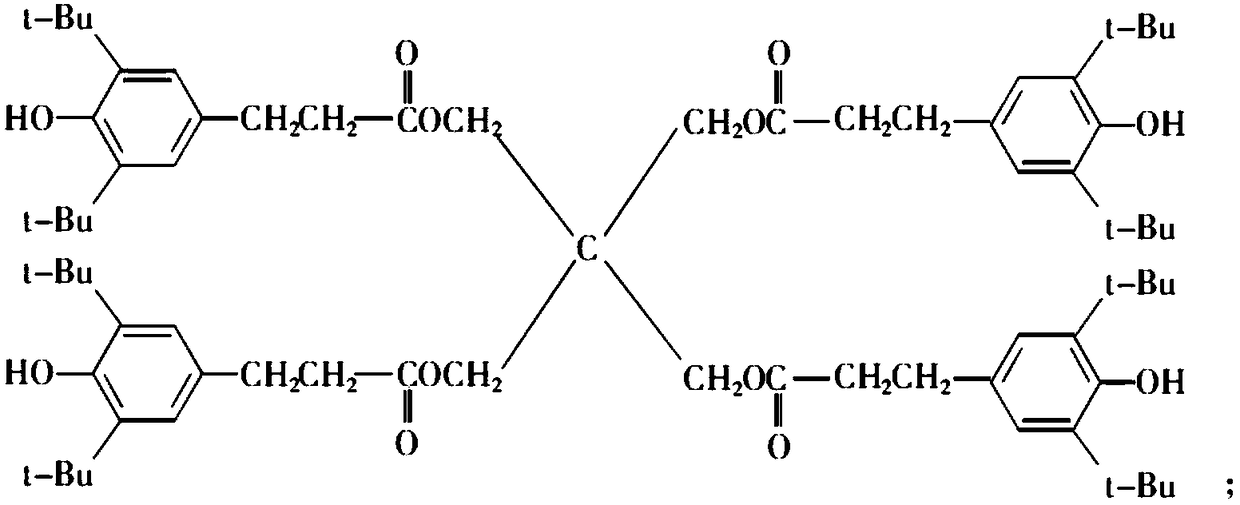

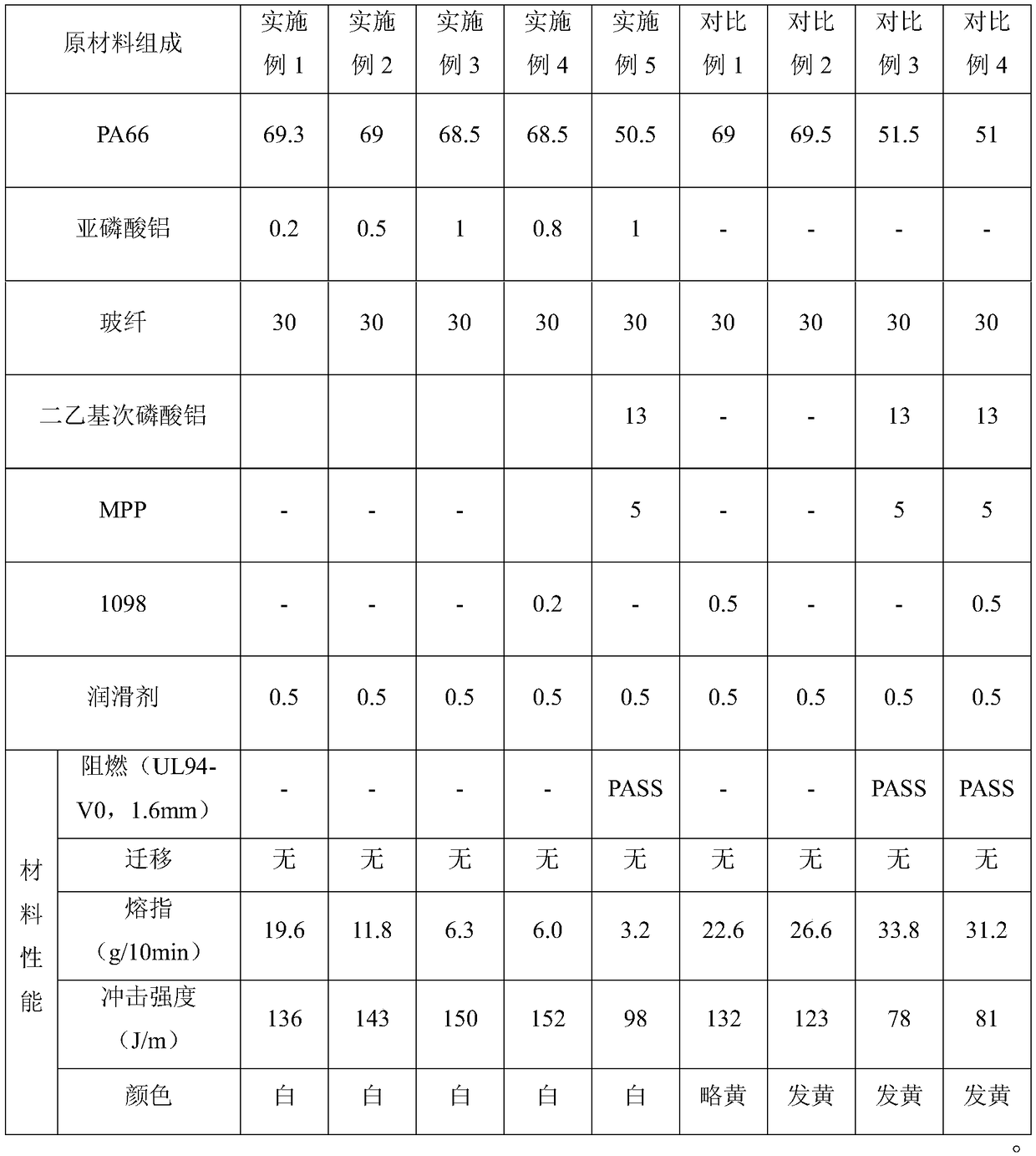

Method for improving high-temperature heat stabilization of thermoplastic polymers or composites thereof by inorganic metal phosphite

InactiveCN109082115AProtection from temperature effectsOvercome the defects of pyrolysis and discolorationDecompositionThermosetting polymer

The invention discloses a method for improving high-temperature heat stabilization of thermoplastic polymers or composites thereof by inorganic metal phosphite. The method includes adding the inorganic metal phosphite into a raw material, wherein the inorganic metal phosphite is selected from at least one of aluminum phosphite, zinc phosphite, calcium phosphite and magnesium phosphite, and the adding amount of the inorganic metal phosphite accounts for 0.1-2% of the total weight of the thermoplastic polymers or the composites thereof. The method has the advantages that cross-linking, decomposition, degradation, discoloration and other problems of the thermoplastic polymers or the composites thereof are avoided under the joint action of the high temperature and the shearing force, and various properties of the materials are maintained.

Owner:JIANGSU LISIDE NEW MATERIAL +1

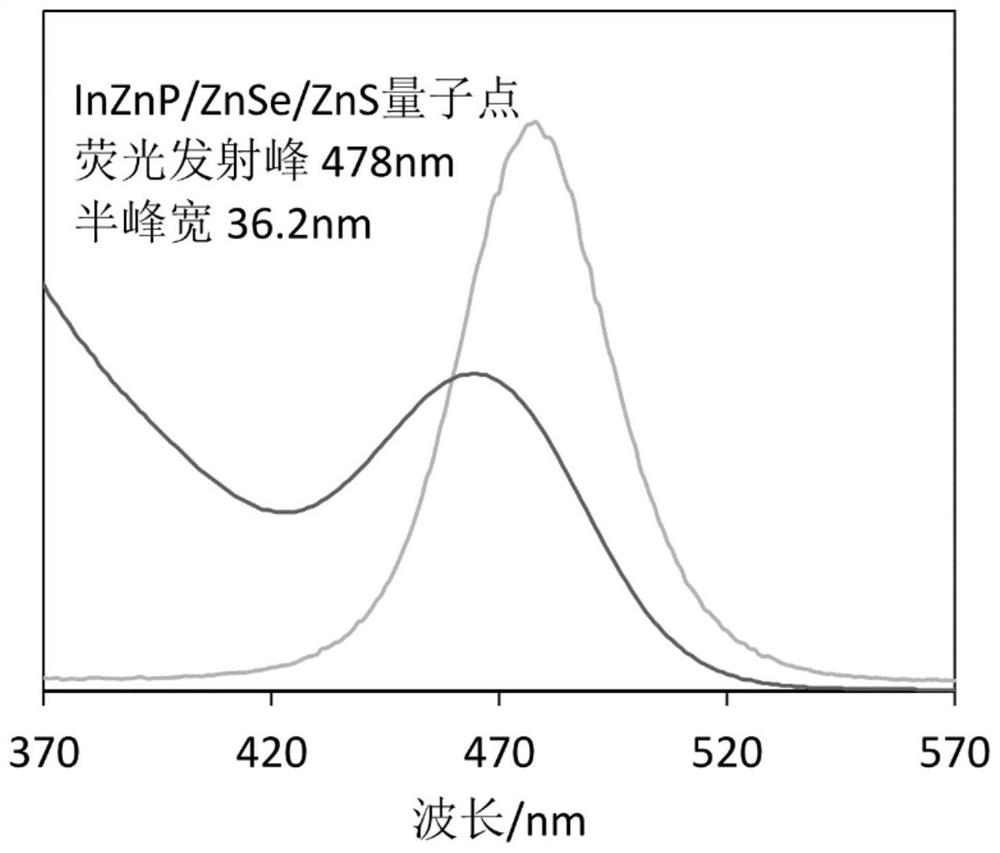

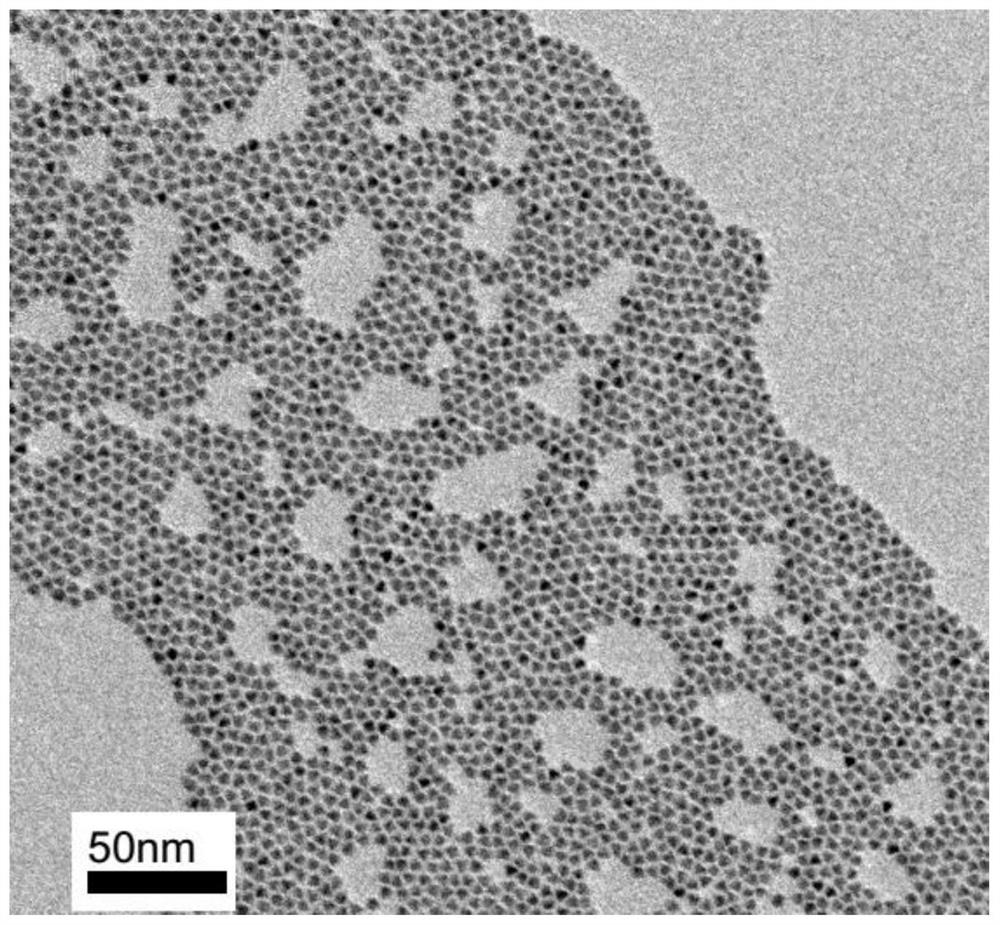

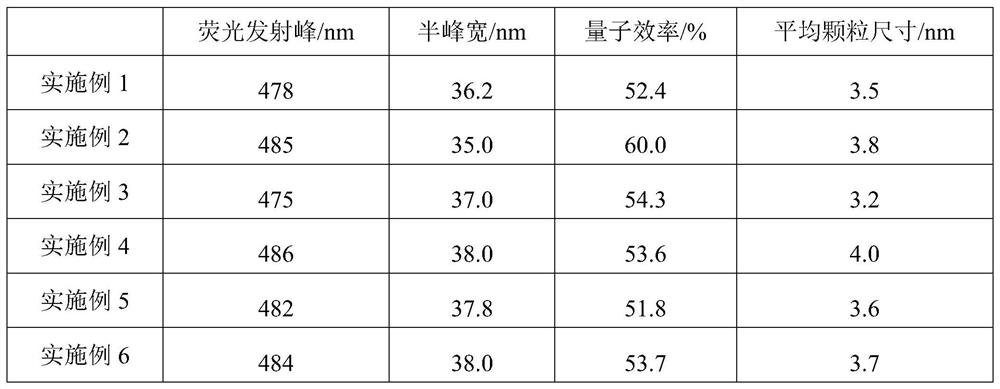

Blue light cadmium-free quantum dot, preparation method thereof and quantum dot photoelectric device

ActiveCN111849483AOptimizing the band structureSmall sizeMaterial nanotechnologySolid-state devicesIndiumCarboxylic acid

The invention discloses a blue light cadmium-free quantum dot, a preparation method thereof and a quantum dot light-emitting device. The preparation method of the cadmium-free quantum dot comprises the following steps that S1, an indium precursor, a first ligand and a solvent are mixed to prepare an indium-first ligand solution, the first ligand is a long-chain carboxylic acid ligand with the carbon number being 10-18, and the ratio of the amount of substance of carboxylate radicals of the first ligand to the amount of substance of indium ions of the indium precursor is (1: 2)-(5: 2); S2, short-chain zinc salt and a second ligand are added into the indium-first ligand solution to form a cation-mixed ligand solution, and at least part of the short-chain zinc salt and the second ligand are bonded through coordination bonds; S3, a phosphorus precursor is added into the cation-mixed ligand solution to react to obtain a solution containing indium zinc phosphide quantum dots. The InZnP quantum dot core with small size and few defects is prepared by introducing the short-chain zinc salt in the nucleation process of the quantum dot, and the introduction of the Zn element also optimizes theenergy band structure of the quantum dot so that the quantum dot with the luminescence range of 470-490nm is obtained.

Owner:NANJING TECH CORP LTD

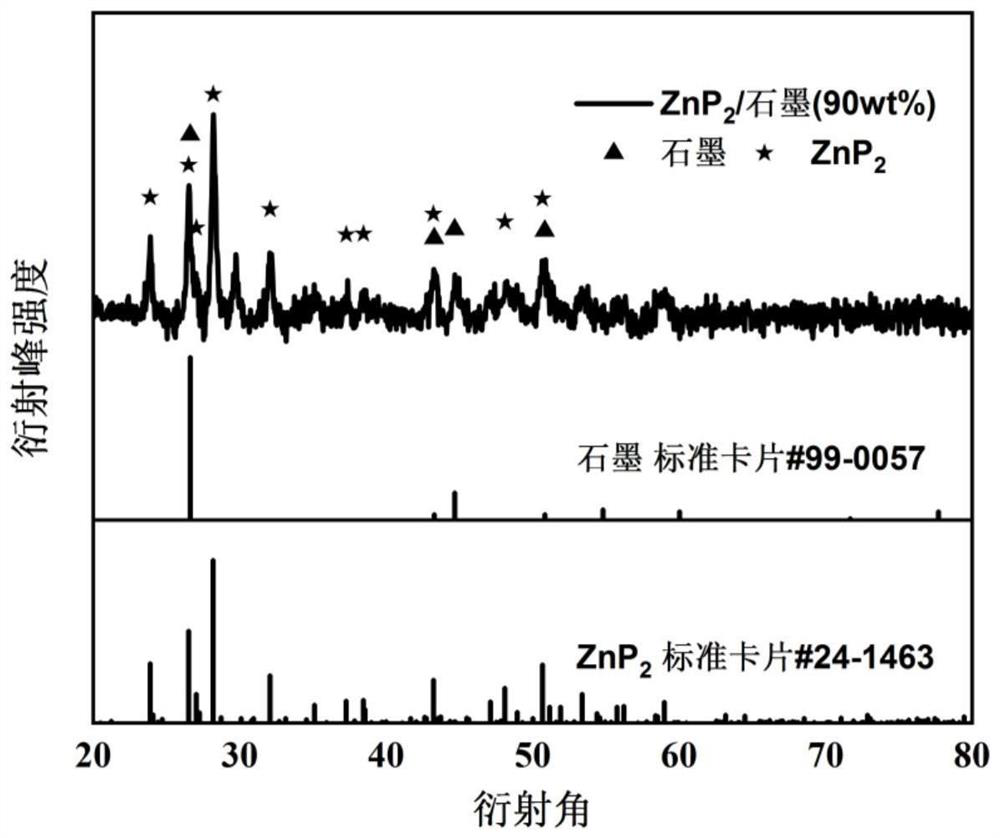

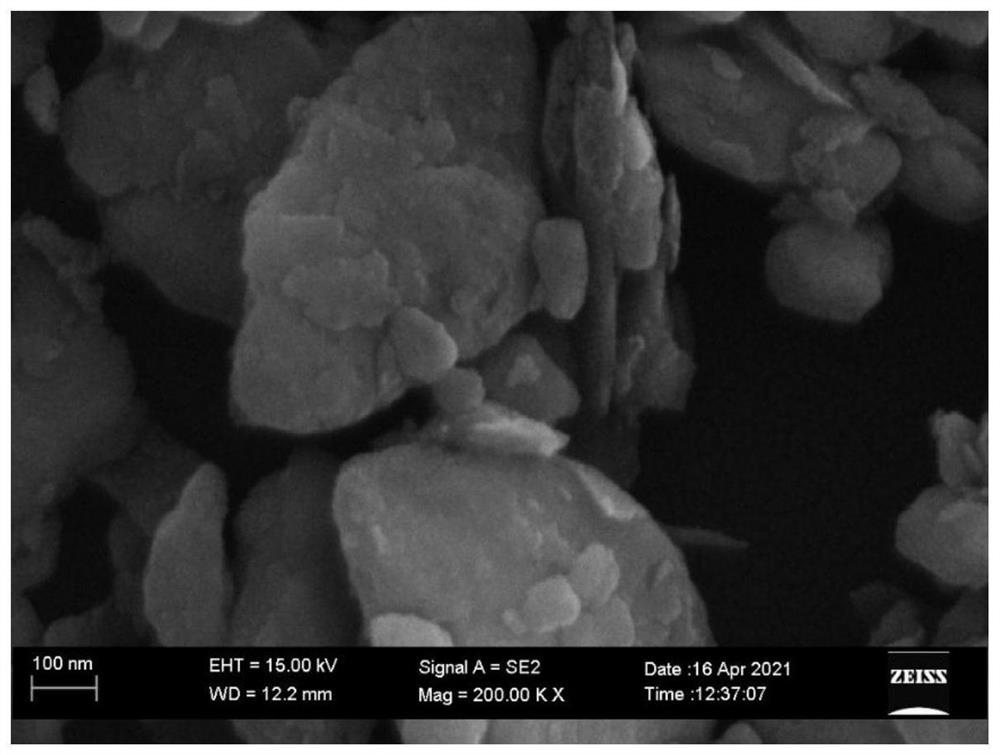

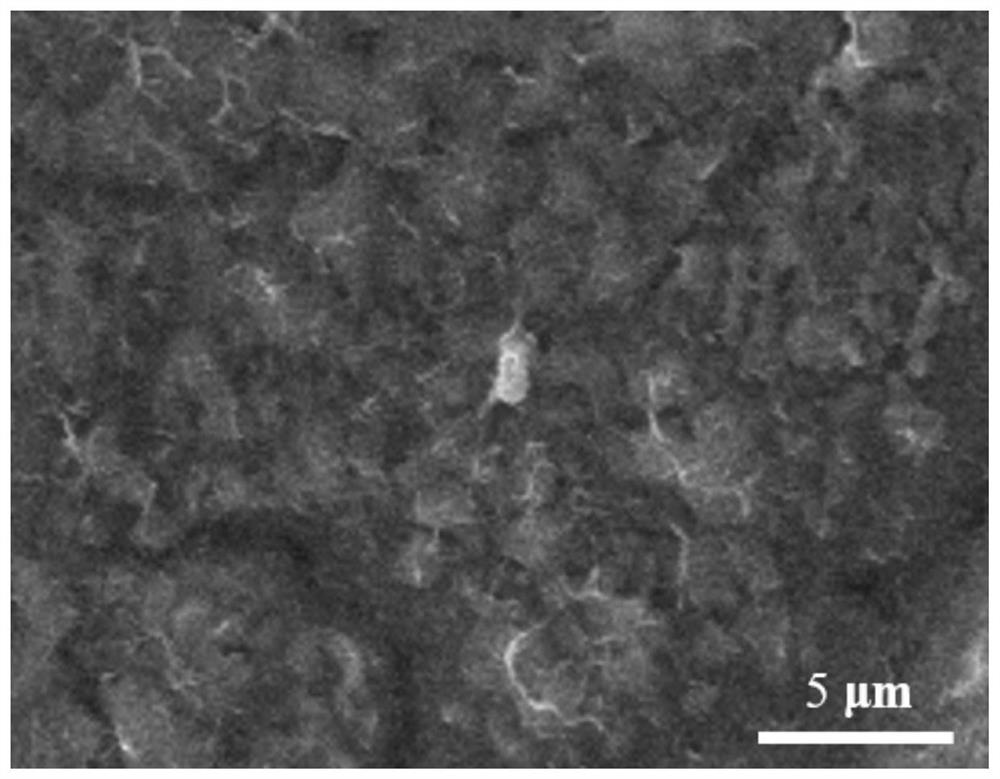

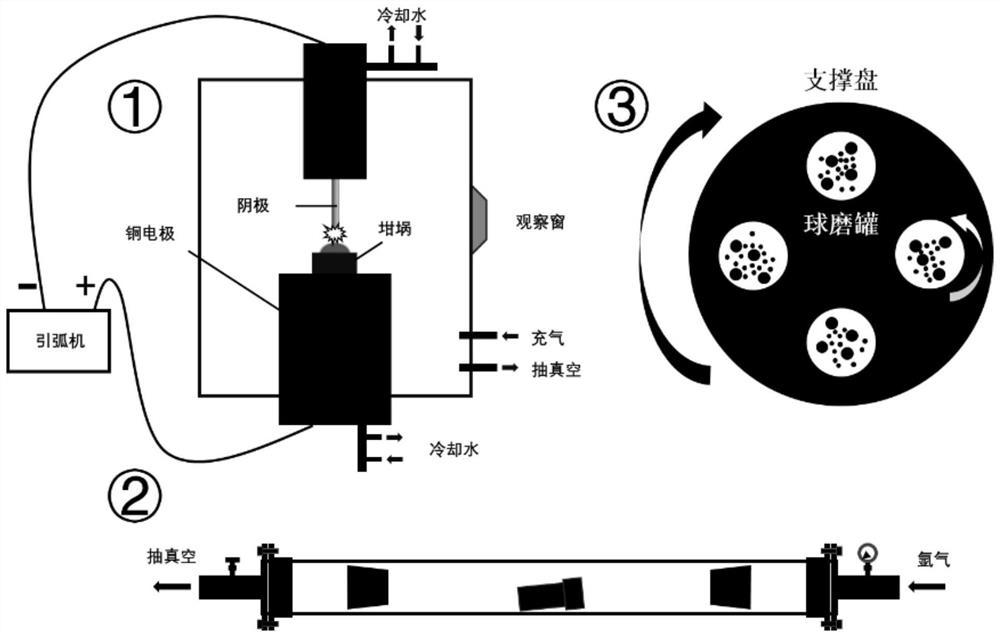

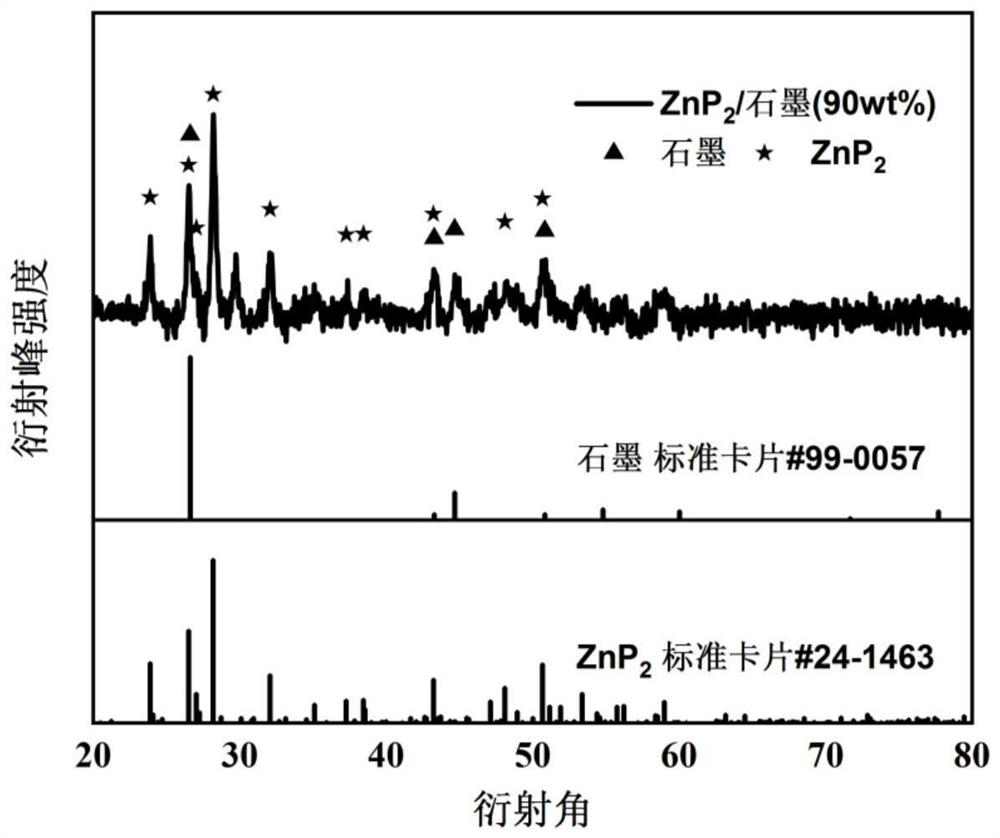

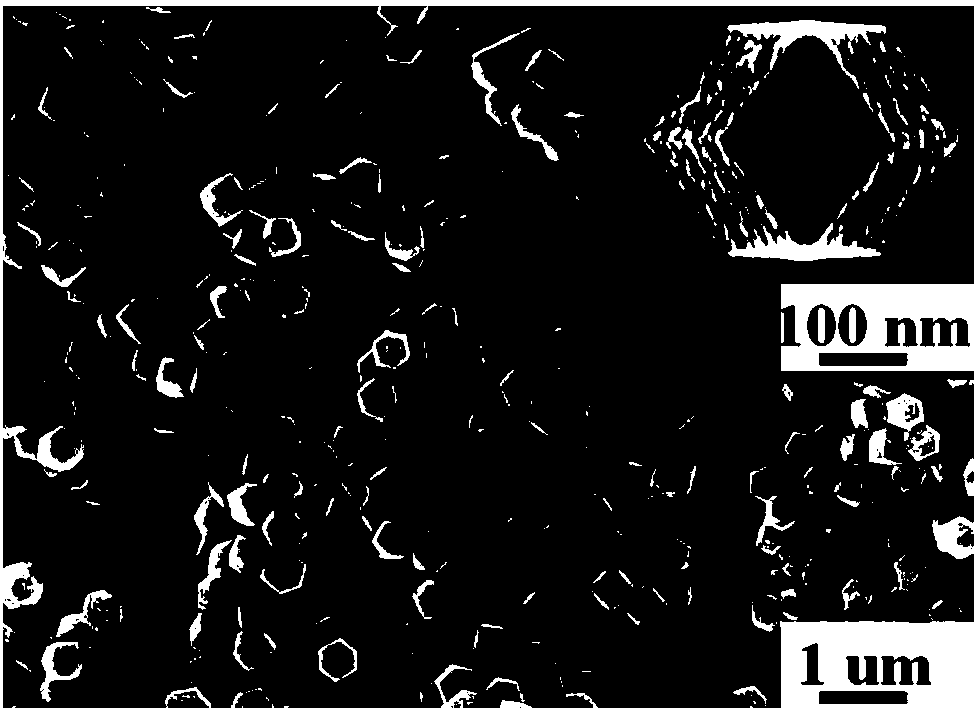

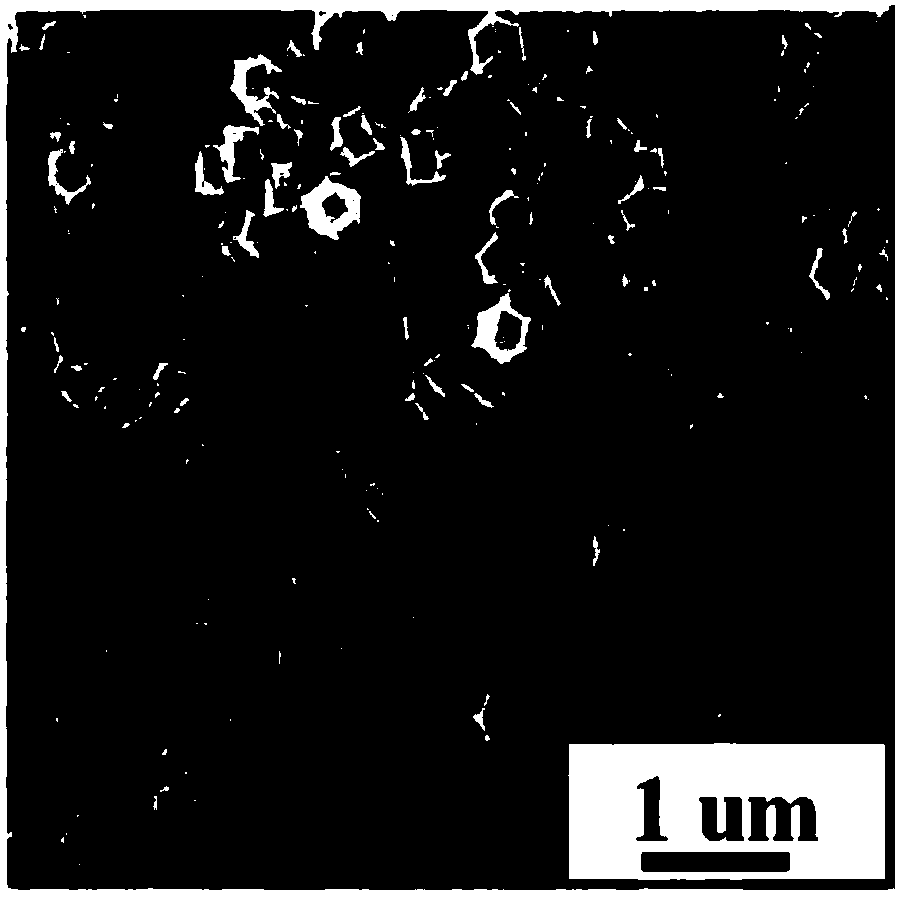

Preparation method and application of carbon-coated zinc diphosphide composite material prepared by three-step method

ActiveCN113422031AReduce manufacturing costImproved magnification performanceCell electrodesSecondary cellsZinc nanoparticlesBattery cell

The invention relates to a preparation method and an application of a carbon-coated zinc phosphide composite material prepared by a three-step method, and belongs to the technical field of lithium ion batteries. The invention aims to solve the problems of a low yield of zinc diphosphide and poor cycle performance when the zinc diphosphide is used as a lithium ion battery negative electrode material. The preparation method comprises the following steps: firstly, evaporating a zinc block into a nano zinc powder based on a direct-current arc plasma method; then synthesizing a zinc diphosphide powder by using the nano zinc powder and phosphorus through a high-temperature solid-phase reaction method; and finally, preparing the carbon-coated zinc diphosphide composite material through a mechanical ball milling method. The method is low in synthesis temperature, short in period, low in cost and high in yield. After a lithium ion battery prepared from the composite material circulates for 200 circles under the current density of 200mA / g, the reversible cycle specific capacity is 629mAh / g.

Owner:DALIAN UNIV OF TECH

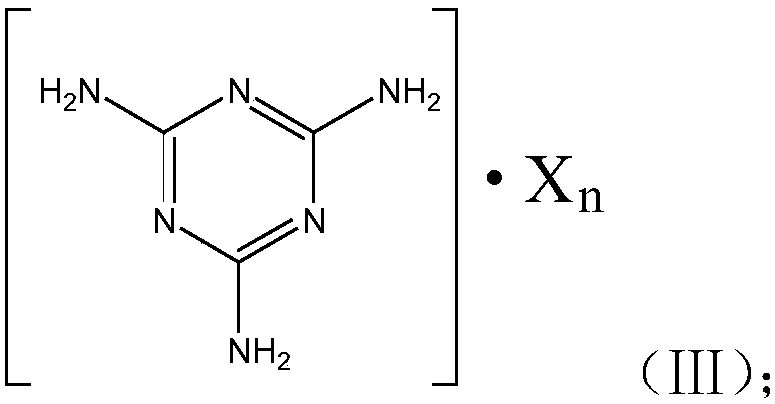

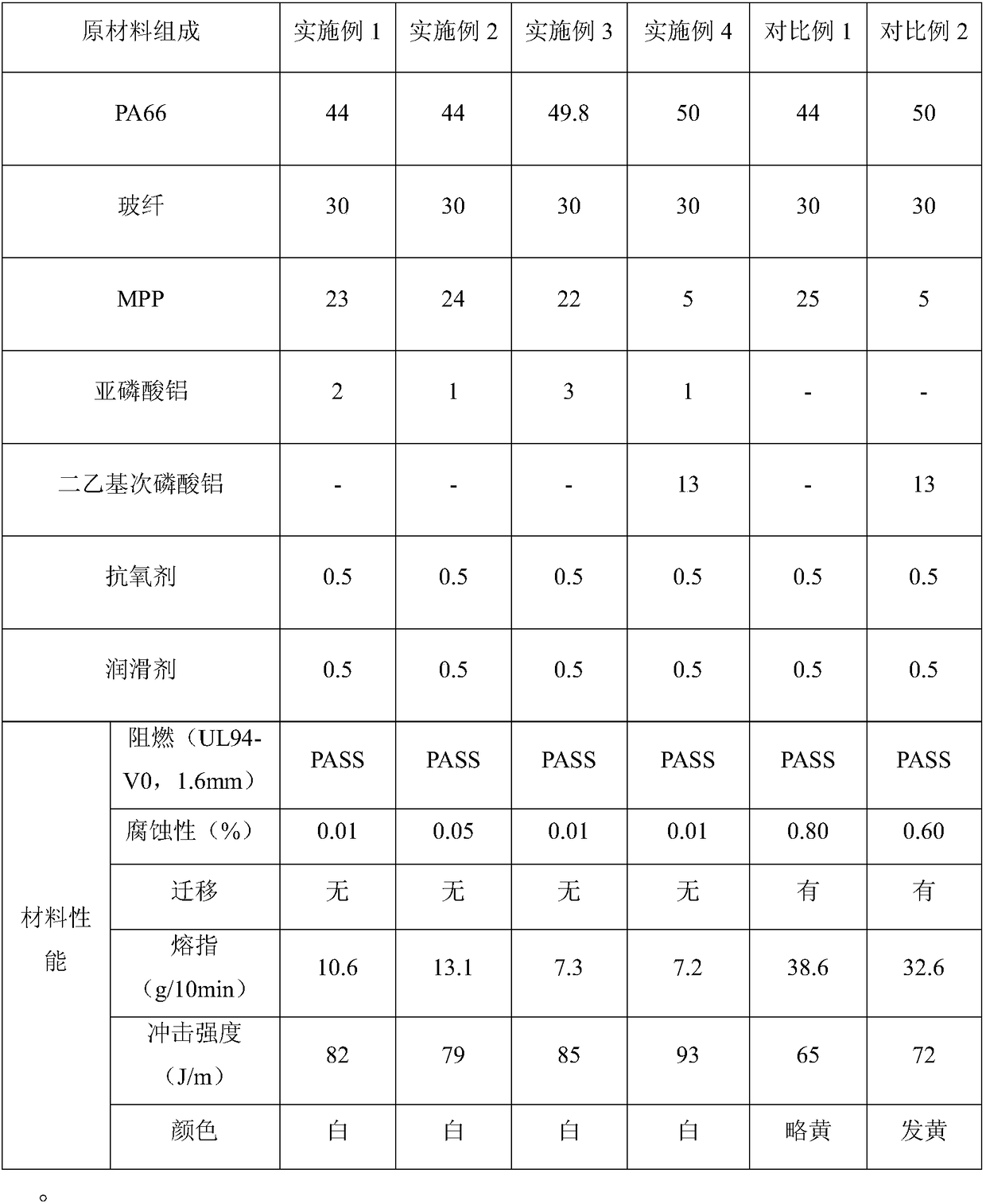

Method for improving high-temperature thermal stabilization of melamine derivative flame retardant by utilizing inorganic metal phosphate, and product and application of melamine derivative flame retardant

InactiveCN108912676AHigh thermal decomposition temperatureGuaranteed performanceMagnesium phosphateDecomposition

The invention discloses a method for improving high-temperature thermal stabilization of a melamine derivative flame retardant by utilizing an inorganic metal phosphite. An inorganic metal phosphate is added into raw materials, wherein the inorganic metal phosphate is at least one selected from aluminum phosphite, zinc phosphite, calcium phosphite and magnesium phosphate, and based on the total weight of the melamine derivative flame retardant, the addition amount of the inorganic metal phosphite is 0.1-40%. Through the method disclosed by the invention, the melamine derivative has a high thermal decomposition temperature, and disadvantages of decomposition, degradation of a matrix polymer, migration, equipment corrosion and the like of the flame retardant are avoided. Meanwhile, performance of the flame retardant is maintained, the flame retardant synergy of the flame retardant with other the flame retardants is improved, and the application field of the flame retardant is expanded.

Owner:JIANGSU LISIDE NEW MATERIAL +1

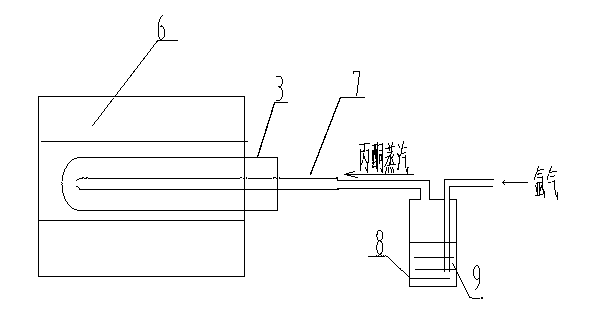

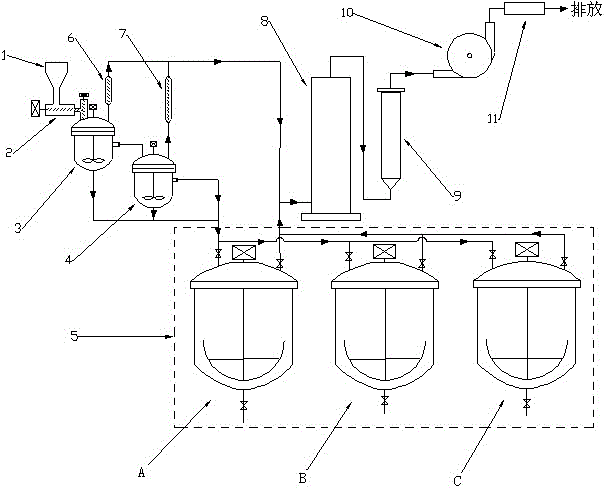

Safe production technique for manufacturing high-purity phosphine on large scale

InactiveCN104058375AAvoid pollutionAvoid corrosionChemical industryHydrogen phosphidesEthylic acidEngineering

The invention discloses a safe production technique for manufacturing high-purity phosphine on large scale. Aluminum phosphide and deionized water or zinc phosphide and acetic acid used as raw materials are subjected to sealed solid feeding, negative-pressure three-stage cascade reactor reaction, low-temperature low-pressure trapping purification, tail gas oxidation trivalent phosphorus removal, and absorption of phosphorus pentoxide by alkali liquor and activated charcoal under closed reaction conditions. The technique can simultaneously satisfy the four requirements of capability of large-scale industrial manufacturing from laboratories to industrialization, control on the virulent phosphine in air in the production workshop and surrounding environment to be lower than allowable concentration, no intricate corrosion problem in equipment, and high product purity, and provides a safe and reliable production technique for industrial production.

Owner:李达刚 +3

Preparation method of high-purity zinc phosphide

The invention discloses a preparation method of high-purity zinc phosphide, comprising the following steps: 1) quartz tube pretreatment, 2) batching, 3) tube sealing, 4) high-temperature synthesis, 5) product treatment, the invention uses high-purity phosphorus and high-purity Zinc direct conversion and production of high-purity zinc phosphide, the main reaction process occurs after the temperature reaches the melting point of zinc, actually belongs to the reaction between steam, belongs to the direct synthesis of elements, the requirements for the form of raw materials are not very strict, and the raw materials have not been processed , to meet the requirements of high purity, the present invention controls the internal pressure of the tube through temperature control operations such as slow temperature rise, constant temperature, and slow temperature drop, and distributes the length of the heating area and condensation area of the synthetic quartz tube to successfully control the phosphorus vapor pressure in the quartz tube to achieve a large amount of The safe synthesis of zinc phosphide; through the control of the length of the condensation area and the heating area, a higher yield of the product is achieved. The product is used in the application fields of optoelectronic device production, diffusion source, and nanomaterials.

Owner:峨嵋半导体材料研究所

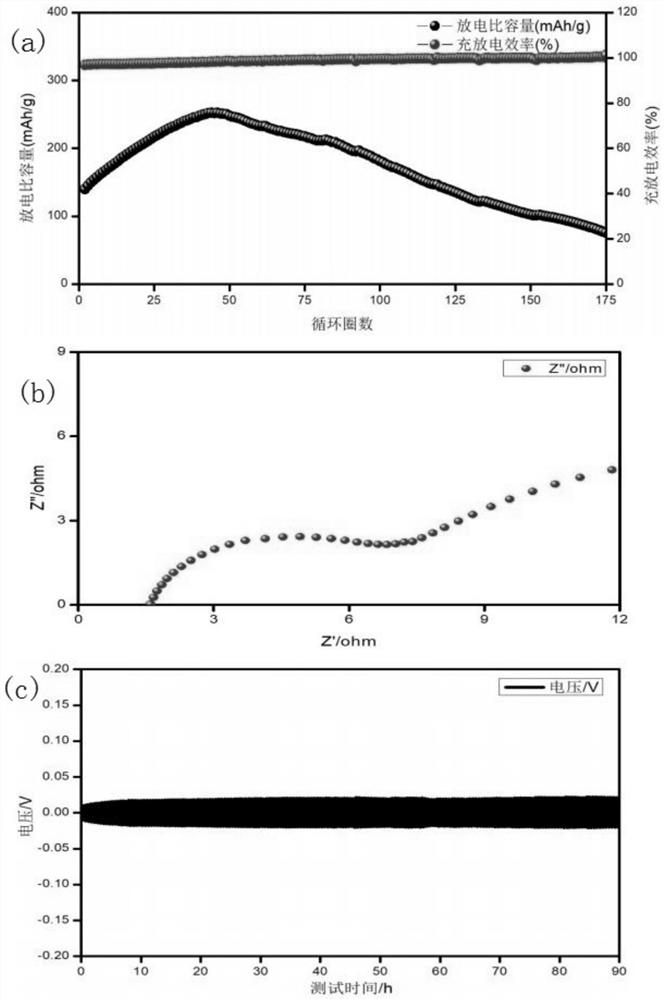

Aqueous zinc ion battery negative electrode material with functional protection layer and preparation method of aqueous zinc ion battery negative electrode material

PendingCN114824236AIncrease dosageFast transferElectrode manufacturing processesSecondary cellsElectrochemical responseElectrical battery

The invention belongs to the technical field of preparation of zinc ion battery electrode materials, and particularly relates to an aqueous zinc ion battery negative electrode material with a functional protection layer and a preparation method of the aqueous zinc ion battery negative electrode material. Zinc sulfate heptahydrate, sodium phosphite, stannous chloride dehydrate, boric acid, sodium sulfate, disodium ethylene diamine tetraacetate and deionized water are mixed to form an electroplating solution, and tin-doped zinc phosphide is uniformly deposited on a zinc sheet through an electrodeposition method to form the coating (Zn (at) Sn-ZnP). According to the invention, the Sn-ZnP functional protection layer is constructed on the surface of the metal zinc negative electrode, and P is inserted into a Zn lattice to form the ZnP protection layer through an economical and efficient electro-deposition method, so that the rapid transfer of Zn < 2 + > is facilitated, and the electrochemical reaction energy barrier in the Zn electroplating / stripping process is reduced; and meanwhile, the ZnSn alloy formed by electro-deposition can effectively inhibit the hydrogen evolution reaction of a zinc electrode and the generation of irreversible byproducts, so that the cycle life of the battery is prolonged.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

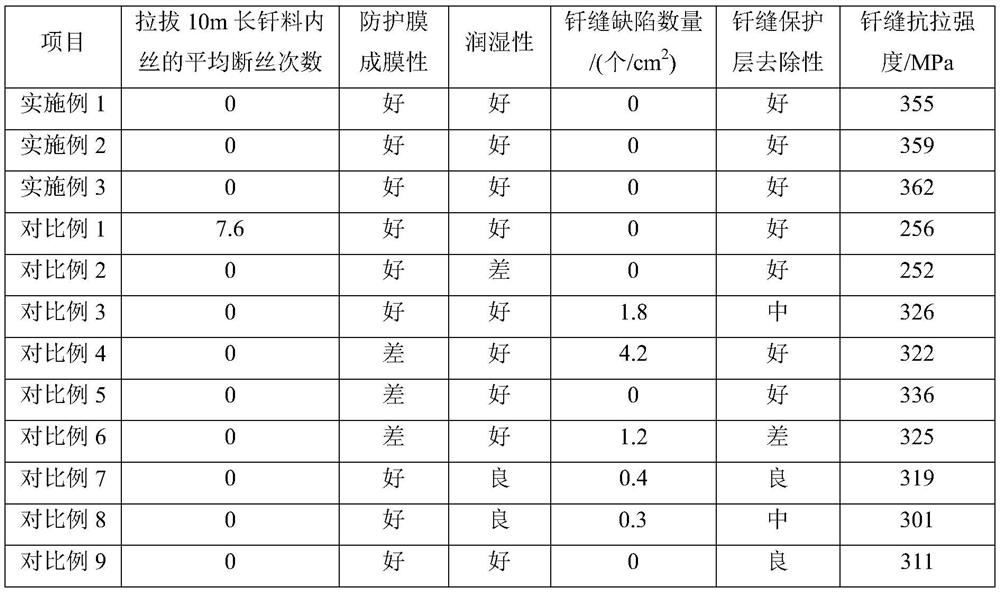

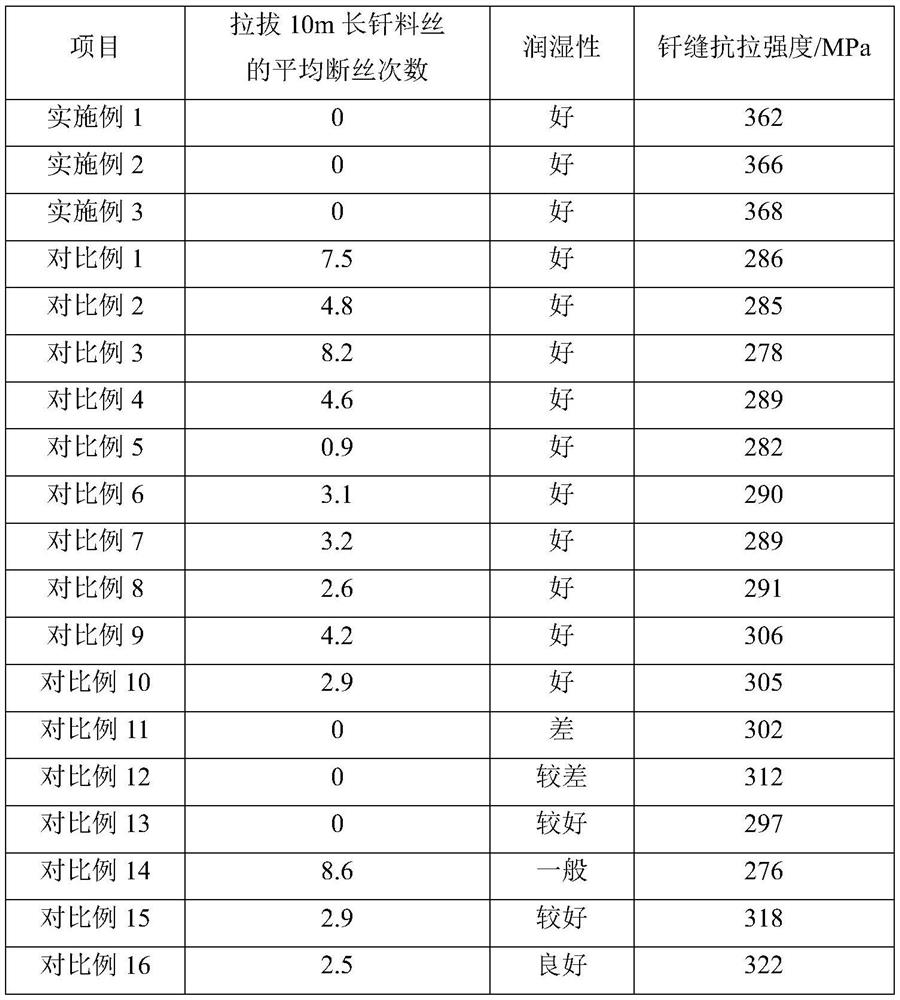

Copper-based brazing filler metal capable of accurately controlling using amount of brazing flux and good in brazing seam protection effect

ActiveCN113102915AImprove wetting abilityImprove liquidityWelding/cutting media/materialsSoldering mediaFirming agentSilicon dioxide

The invention belongs to the field of welding materials, and particularly relates to copper-based brazing filler metal capable of accurately controlling the using amount of brazing flux and good in brazing seam protection effect. The copper-based brazing filler metal comprises a round or oval copper-based brazing filler metal inner wire and a protective film; the protective film is prepared from 10%-12% of zinc phosphide powder, 5%-7% of kyanite powder, 3%-5% of glass fibers, 2.5%-3.5% of nano silicon dioxide powder, 10%-12% of boric anhydride powder and 20%-25% of potassium fluoborate powder which are all treated by the aid of a coupling agent, 5.5%-6.5% of a curing agent and the balance epoxy resin. In the preparation process, the wire breakage phenomenon is avoided, the wettability of the brazing filler metal is high during brazing, and gaps between workpieces to be welded can be effectively filled; during brazing, the using amount of the brazing flux can be accurately controlled, and the problem that the using amount of the brazing flux is not enough during brazing or a large amount of the brazing flux is left after brazing is solved; during brazing, the protection effect on brazing seams is good, the protection layer is easy to remove, the brazing seams have few defects, and the strength is high.

Owner:ZHENGZHOU UNIV

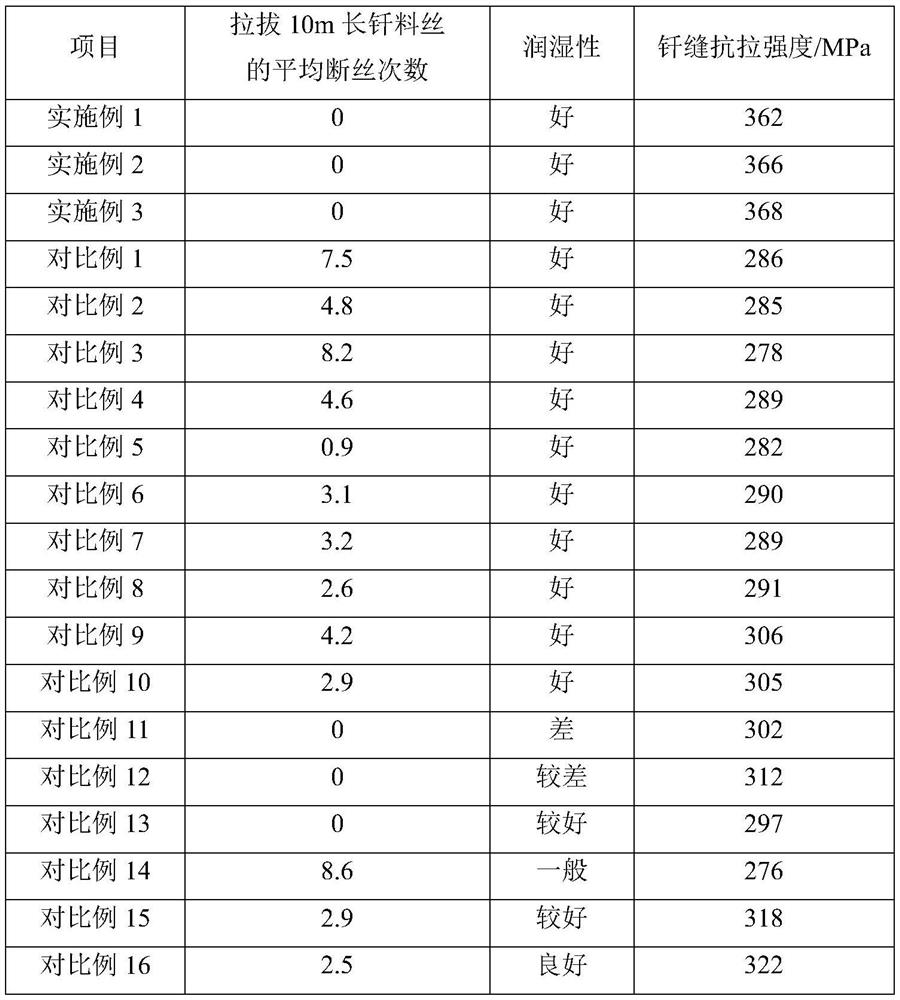

Copper-based flux-cored solder wire easy to prepare, high in wettability and high in soldering seam strength

ActiveCN113245746AImprove toughnessImprove plasticityWelding/cutting media/materialsSoldering mediaIndiumPotassium fluoride

The invention belongs to the field of a welding material, and particularly relates to a copper-based flux-cored solder wire easy to prepare, high in wettability and high in soldering seam strength. The copper-based flux-cored solder wire comprises outer skin and flux core powder; the flux core powder comprises 5%-8% of nano hexagonal boron nitride, 8%-12% of nano zinc carbonate, 16%-20% of zinc phosphide, 25% of borax, 18% of boric acid, 7% of potassium fluoride and the balance of tin powder; the outer skin contains 8%-12% of silver, 1.2%-2.5% of indium, 1.5%-2.2% of antimony and the balance of copper; and the mass of the flux core powder accounts for 25%-32% of the total mass of the flux-cored solder wire. According to the invention, no brittle phase exists in the outer skin; the nano hexagonal boron nitride with high lubricity is contained in the flux core powder; wires are not broken in the drawing process, and the copper-based flux-cored solder wire is easy to prepare; the wettability of brazing filler metal can be enhanced through the existence of phosphorus after zinc phosphide in the flux core powder is molten during brazing and the stirring effect of overflow of carbon dioxide; the nano hexagonal boron nitride and decomposed nano zinc oxide can effectively improve the strength of a brazing seam, and a brazing flux does not need to be matched during brazing.

Owner:ZHENGZHOU UNIV

Preparation method and application of carbon-coated zinc diphosphide composite material prepared by three-step method

ActiveCN113422031BReduce manufacturing costImproved magnification performanceCell electrodesSecondary cellsElectrical batteryZinc nanoparticles

The invention relates to a preparation method and application of a carbon-coated zinc diphosphide composite material prepared by a three-step method, and belongs to the technical field of lithium ion batteries. The purpose is to solve the problems of low yield of zinc diphosphide and poor cycle performance as negative electrode material of lithium ion battery. The preparation method is as follows: first, based on the DC arc plasma method, the zinc block is evaporated into nano-zinc powder; then, zinc diphosphide powder is synthesized by high-temperature solid-state reaction method using nano-zinc powder and phosphorus; finally, carbon-coated powder is prepared by mechanical ball milling. Zinc phosphide composite. The method has low synthesis temperature, short period, low cost and high yield. The lithium ion battery prepared by the composite material of the present invention has a reversible cycle specific capacity of 629mAh / g after 200 cycles at a current density of 200mA / g.

Owner:DALIAN UNIV OF TECH

Copper-based flux-cored solder wire with easy preparation, strong wettability and high braze joint strength

ActiveCN113245746BImprove toughnessImprove plasticityWelding/cutting media/materialsSoldering mediaIndiumPotassium fluoride

The invention belongs to the field of welding materials, in particular to a copper-based flux-cored brazing material wire which is easy to prepare, has strong wettability and high brazing seam strength, and comprises outer skin and flux-core powder; the flux-core powder contains nano-hexagonal boron nitride 5%-8 %, nano zinc carbonate 8%-12%, zinc phosphide 16%-20%, borax 25%, boric acid 18%, potassium fluoride 7%, the balance is tin powder; the outer skin contains silver 8%-12%, indium 1.2%-2.5%, antimony 1.5%-2.2%, and the balance is copper; the quality of the core powder accounts for 25%-32% of the total mass of the core solder wire. There is no brittle phase in the outer skin of the present invention, and there is nano-hexagonal boron nitride with strong lubricity in the drug core powder, which is uninterrupted in the drawing process and easy to prepare. The stirring effect of the carbon dioxide escape can enhance the wettability of the solder, and the nano-hexagonal boron nitride and the decomposed nano-zinc oxide can effectively improve the strength of the brazing seam, and no flux is needed during brazing.

Owner:ZHENGZHOU UNIV

Taxus chinensis planting method based on seed collecting planting

The invention provides a taxus chinensis planting method based on seed collecting planting. The method comprises the steps of S1, planting environment selection: a farmland with the slope smaller than20 degrees, a deep and thick soil layer, a loosened structure, abundant humus and excellent drainage is selected; S2, seed collecting treatment: ripe fruits on a ripe taxus chinensis tree are removed, put into a basin to be rubbed and cleaned until seed coats are broken, the rubbing cleaning is stopped after 50% of a seed kernel is exposed, and the ripe fruits are placed in a shady place to be dried by air for spare use; S3, seedling bed preparation: pits are dug, the pit depth is 25-35 mm, the pit diameter is 35-45 mm, and the spacing between the adjacent pits is 2.0-2.5 m; S4, planting: a greenhouse is constructed, bunch planting is conducted on the seeds to plant the seeds in the dug pits, the seeds are covered with 1-2 cm of fine earth, thorough watering is conducted, an agriculturalmembrane covers the seeds, the four sides of the agricultural membrane are tightly pressed by mud, zinc phosphide is prepared into a toxic bait to prevent rat plague; S5, young seedling transplanting:when small seedlings grow to the state with 3-4 leaves, transplanting is conducted according to the plant spacing of 15-20 cm and the row spacing of 25-30 cm; S6, nursing management; S7, transplanting forestation: when the young seedlings grow to the height of 30-50 cm, transplanting forestation is conducted in spring; S8, forestry nursing.

Owner:华容县新发农业开发有限公司

A safe production process for large-scale production of high-purity phosphine trihydrogen

InactiveCN104058375BAvoid pollutionAvoid corrosionChemical industryHydrogen phosphidesEthylic acidCorrosion

The invention discloses a safe production process for large-scale production of high-purity phosphine trihydrogen. Aluminum phosphide and deionized water or zinc phosphide and acetic acid are used as raw materials, and sealed solid feed is used under closed reaction conditions. , Negative pressure three-stage series reactor reaction, low-temperature and low-pressure capture and purification, tail gas oxidation to remove trivalent phosphorus, and lye and activated carbon to absorb phosphorus pentoxide, which can simultaneously meet the requirements of large-scale production from the laboratory to industrialization Industrial manufacturing, control of the highly toxic substance phosphine trihydrogen in the atmosphere of the production workshop and the surrounding environment is lower than the allowable concentration, the equipment has no corrosion problems that are difficult to overcome, and the four requirements of high product purity provide a safe and reliable production for industrial production. craft.

Owner:李达刚 +3

Novel foliar fertilizer for promoting generation of SOD in rice

InactiveCN108299063AReduce usageGrowth-promoting SOD contentFertilising methodsOrganic fertilisersFoliar fertilizationManganese

The invention discloses a novel foliar fertilizer for promoting the generation of SOD in rice. The novel foliar fertilizer is characterized in that the novel foliar fertilizer adopts iron manganese phosphite, copper zinc phosphite, potassium citrate, calcium nitrate, borax, urea and sodium phosphite as main components, the fertilizer is applied in the heading stage and the grain filling stage ofrice in a foliar fertilization manner, and the SOD content in grown rice is equal to or more than 30 U / mg.

Owner:杨洋

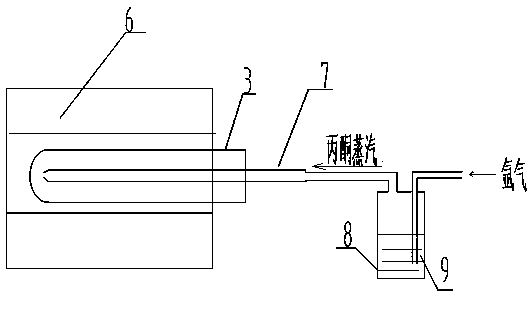

Graded zinc diffusing method based on MOCVD (Metal-Organic Chemical Vapor Deposition) system for producing chip of indium-gallium-arsenic photoelectric detector

ActiveCN101567407BIncrease the carrier concentrationImprove responsivenessFinal product manufactureChemical vapor deposition coatingIndiumGallium

The invention relates to a graded zinc diffusing method based on an MOCVD system for producing the chip of an indium-gallium-arsenic photoelectric detector. The method comprises the following steps: asemiconductor wafer which does not form an InGaAs PIN structure of a PN junction is cleaned and blown to dry by high-purity nitrogen; an MOCVD reaction chamber is heated up, depressurized and cleaned; the semiconductor wafer is placed in the reaction chamber; the pressure of the reaction chamber is set; diffusion taking a zinc phosphide compound which is formed by zinc methide (DMZn) and phosphorane (PH3) at high temperature as a diffusion source is conducted with the presence of catalytic reaction and the shielding gas; after the completion of the diffusion, the gas is turned off, the reaction chamber is cooled down and filled with nitrogen and has a pressure rise; and the wafer which undergoes the diffusion is taken out of the reaction chamber. As the diffusion rules of zinc in InP material and InGaAs material have great difference, the graded diffusion method is adopted. With the method, both the InP layer and the InGaAs layer can have rather high current carrier concentration, good interface, rather good homogeneity, technique repeatability, high response and precise control and can be manufactured on a large scale.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

Method of fabricating photovoltaic devices with reduced conduction band shift between pnictide absorber and emitter films

InactiveCN104364910BQuality improvementReduce conduction band offsetPhotovoltaic energy generationSemiconductor devicesZinc selenideEngineering

Owner:DOW GLOBAL TECH LLC +1

Flame retardant polyamide composition

The present invention relates to a flame retardant polyamide composition comprising: (a) at least one polyamide; (b) about 8-35% by weight of at least one halogen-containing flame retardant; (c) about 0.3-12% by weight % of at least one zinc hydroxyphosphite represented by the following formula: xZnO.ZnHPO3, wherein x is a number from 1 / 2 to 10; and optionally (d) up to about 60% by weight of glass fibers contained in The total weight percentages of all components in the composition add up to 100% by weight.

Owner:EI DU PONT DE NEMOURS & CO

A copper-based solder that can accurately control the amount of flux and has a good protection effect on the brazing seam

ActiveCN113102915BImprove wetting abilityImprove liquidityWelding/cutting media/materialsSoldering mediaFirming agentFluoboric acid

The invention belongs to the field of welding materials, in particular to a copper-based solder that can accurately control the amount of flux and has a good protective effect on the brazing seam, including a circular or oval copper-based solder inner wire and a protective film. The protective film includes: Zinc phosphide powder 10%‑12%, kyanite powder 5%‑7%, glass fiber 3%‑5%, nano silicon dioxide powder 2.5%‑3.5%, boric anhydride powder 10%‑12%, potassium fluoroborate Powder 20%-25%, the above substances are treated with coupling agent, there is also 5.5%-6.5% curing agent, and the balance is epoxy resin. In the preparation process of the present invention, there will be no wire breakage, and the solder has strong wettability during brazing, which can effectively fill the gaps between the workpieces to be welded; the amount of brazing flux can be precisely controlled during brazing, which solves the problem of brazing Insufficient dosage or too much flux residue after brazing; the protection effect on the brazing seam is good during brazing and the protective layer is easy to remove, the brazing seam has fewer defects and high strength.

Owner:ZHENGZHOU UNIV

Environmentally friendly flame-retardant polyvinyl chloride composition for drain pipe and preparation method thereof

The invention relates to an environmentally friendly flame-retardant polyvinyl chloride composition for a drain pipe and a preparation method thereof. The environmentally friendly flame-retardant polyvinyl chloride composition for a drain pipe comprises, by mass, 100 parts of polyvinyl chloride, 2 to 10 parts of a compound zinc-based flame-retardant heat stabilizer, 1 to 5 parts of a lubricant, 0 to 15 parts of an impact modifier, 0.5 to 5 parts of a pigment and 0 to 60 parts of a filler. The compound zinc-based flame-retardant heat stabilizer comprises, by mass, 100 parts of zinc phosphite, 10 to 30 parts of a synergistic stabilizer, 10 to 15 parts of tripentaerythritol phosphite, 35 to 70 parts of nano-hydrotalcite and 15 to 40 parts of halloysite. The drain pipe prepared from the environmentally friendly flame-retardant polyvinyl chloride composition retains the mechanical properties of the pipe, has excellent flame retardancy and smoke suppression performances, provides convenience for production of a building drain pipe having high fire safety and satisfies requirements on comprehensive lead-free development of a PVC pipe.

Owner:GUANGDONG LIANSU TECH INDAL

A method for constructing zinc phosphide/cobalt phosphide heterojunction photocatalyst based on mofs template

InactiveCN106311294BImprove photocatalytic hydrogen production performanceFully exposedPhysical/chemical process catalystsElectron holeHeterojunction

A method of constructing zinc phosphide / cobalt phosphide heterojunction photocatalyst based on MOFs template, which belongs to the technical field of photocatalytic material preparation. Using ZIF‑ZnCo as a template, a zinc phosphide / cobalt phosphide heterojunction catalyst with a porous structure was constructed by oxidizing and phosphating it. Based on the fact that the catalyst maintains the original skeletal structure characteristics of the precursor MOFs and fully exposes the active catalytic sites, the catalyst promotes the separation of photogenerated electron holes and improves the photoresponse behavior through good synergy, so it exhibits excellent Photo-splitting water hydrogen production performance.

Owner:BEIJING UNIV OF TECH

Calcium-zinc composite stabilizer and preparation method thereof

Owner:JIANGSU LIANMENG CHEM

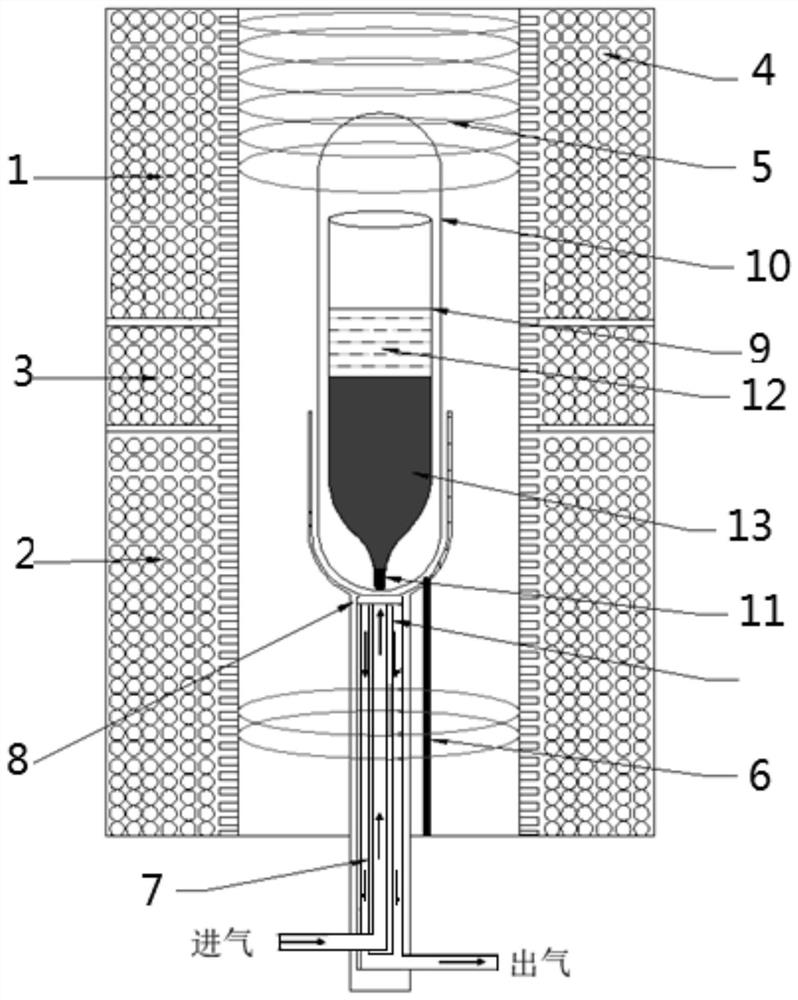

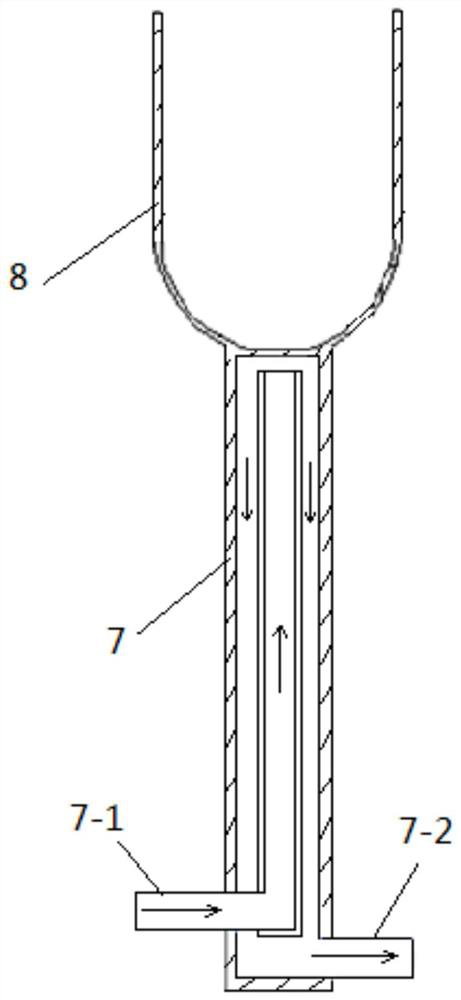

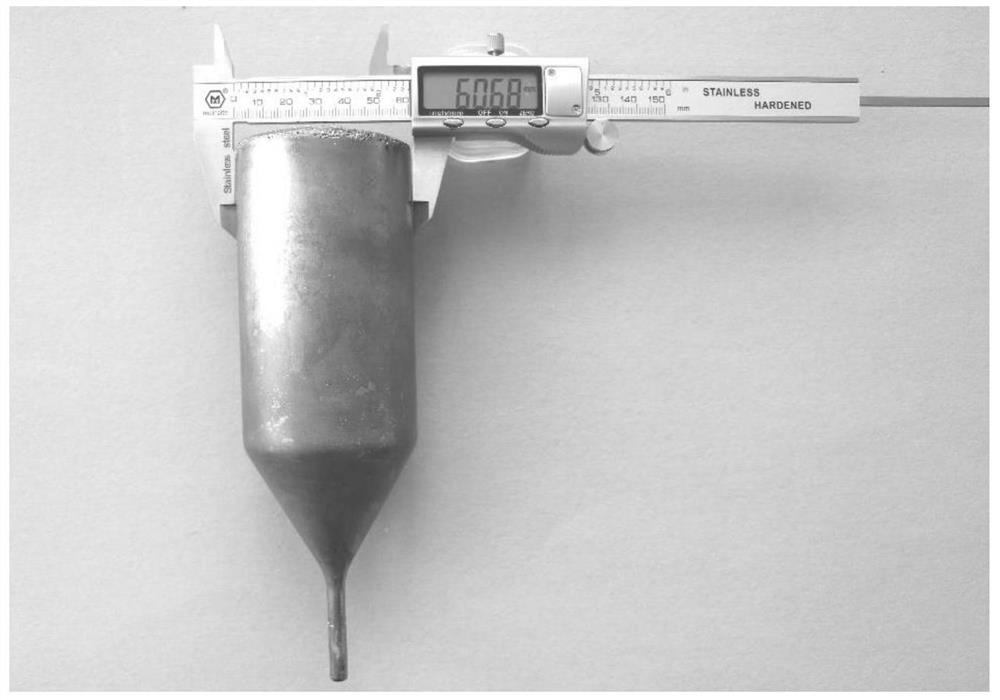

A method for growing large-sized germanium-zinc phosphide crystals with increased heat transfer

ActiveCN110042461BQuality improvementImprove cooling effectPolycrystalline material growthFrom frozen solutionsPhysical chemistryPolycrystalline material

Owner:HARBIN INST OF TECH

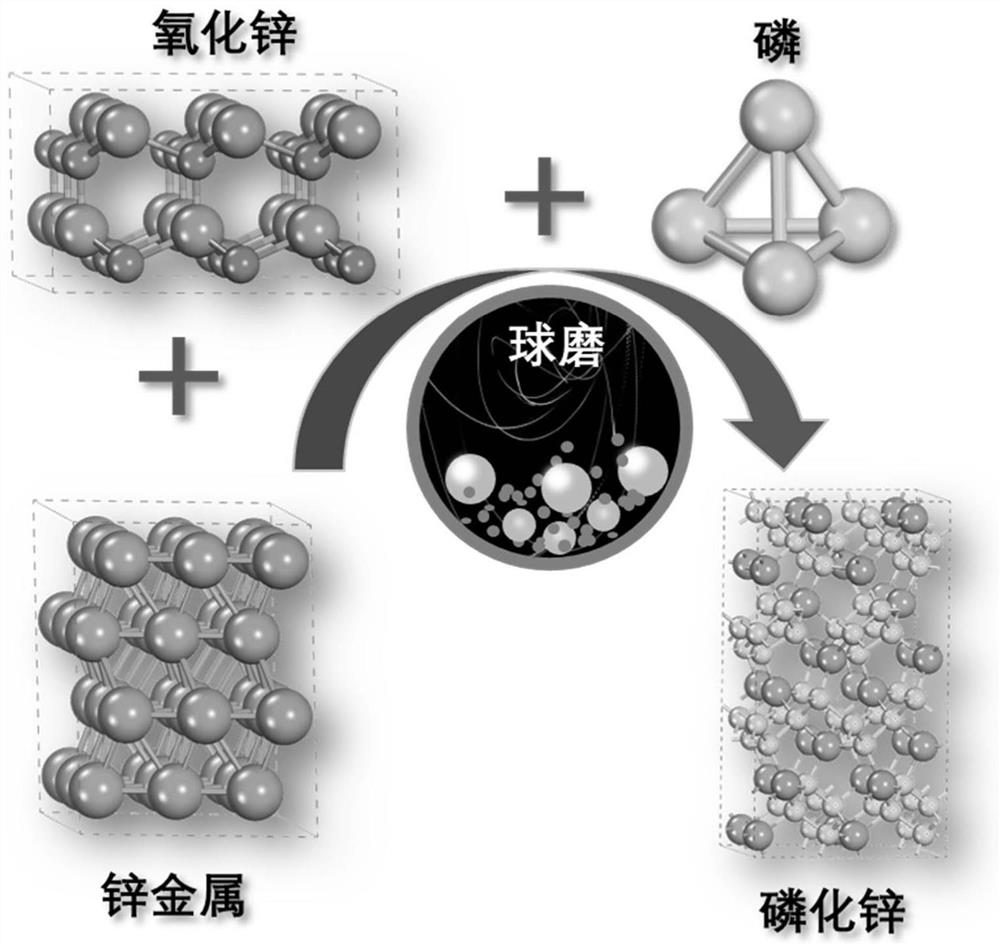

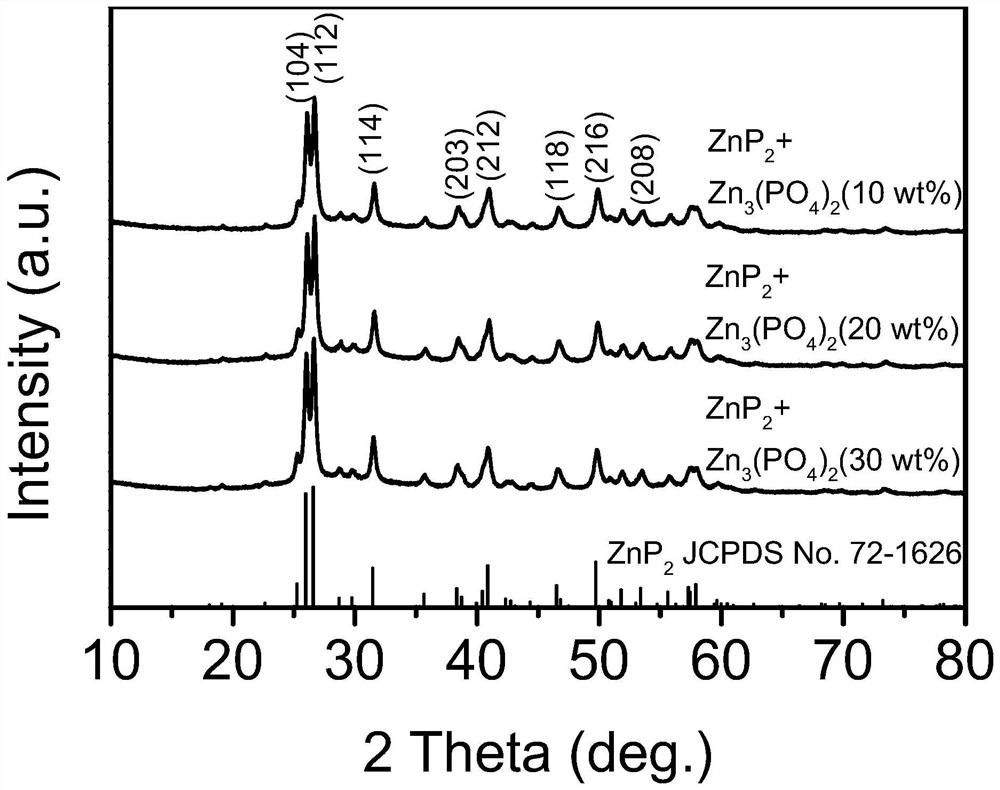

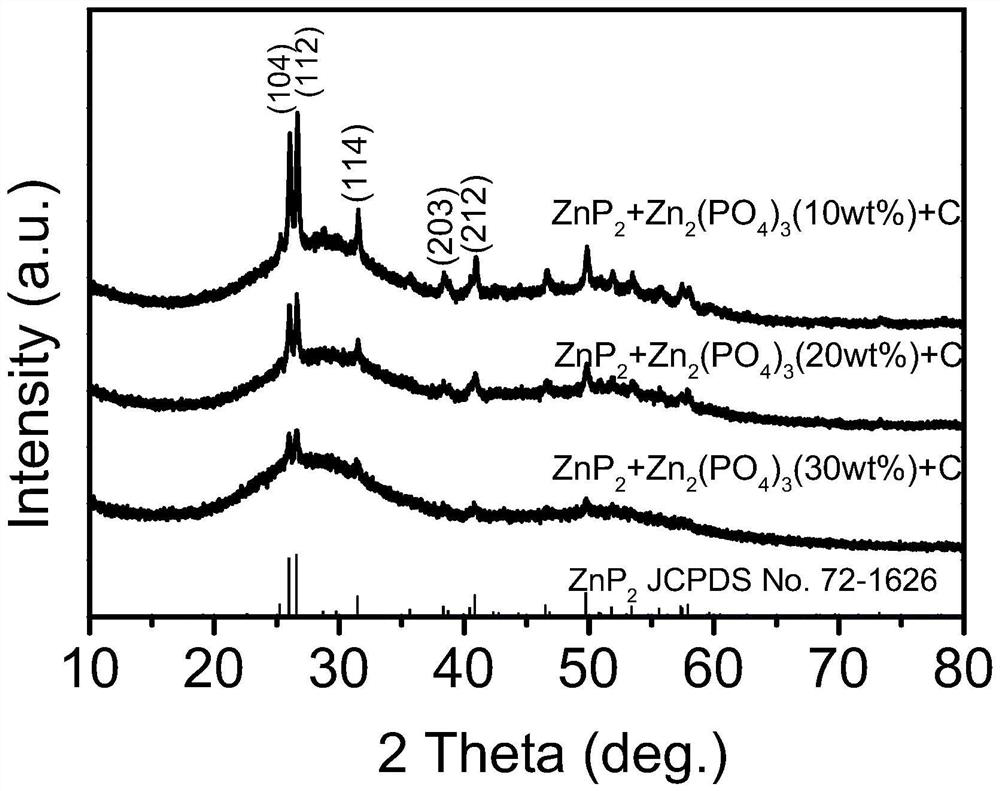

Zinc phosphide material, zinc phosphide composite material and preparation method and application thereof

PendingCN114655941ABuffer volume expansionIncrease profitCell electrodesSecondary cellsZinc phosphatePotassium ions

The invention discloses a zinc phosphide material, a zinc phosphide composite material and a preparation method and application thereof. The zinc phosphide composite material is doped with amorphous zinc phosphate. The preparation method of the zinc phosphide material comprises the following step: ball-milling a mixture of metal zinc, zinc oxide and phosphorus to obtain the zinc phosphide material. By doping zinc phosphate in zinc phosphide, volume expansion of active zinc phosphide in the charging and discharging process can be buffered, the utilization rate of the zinc phosphide material as a potassium ion negative electrode material is increased, and the cycling stability of the electrode material is improved. Through one-step ball milling, the raw materials are subjected to an oxidation-reduction reaction, and zinc phosphate is formed in situ while zinc phosphide is generated. Other post-treatment is not needed, and large-scale production and use are facilitated. In addition, a carbon material is mixed and added into the zinc phosphide material to form a composite material which is used as an active material of the negative electrode material of the potassium ion battery, so that the phenomenon that the conductivity is reduced due to the existence of zinc phosphate can be compensated.

Owner:UNIVERSITY OF MACAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com