Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about "Hydrogen phosphides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

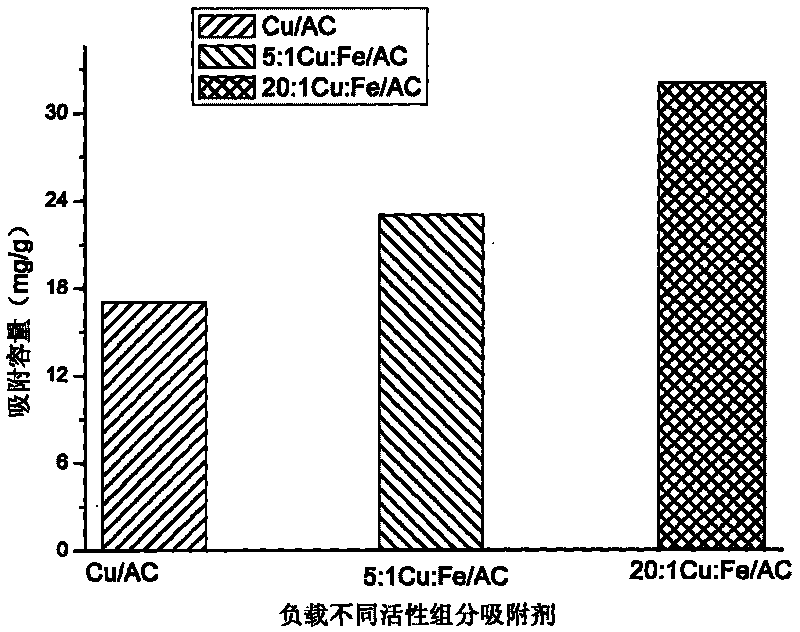

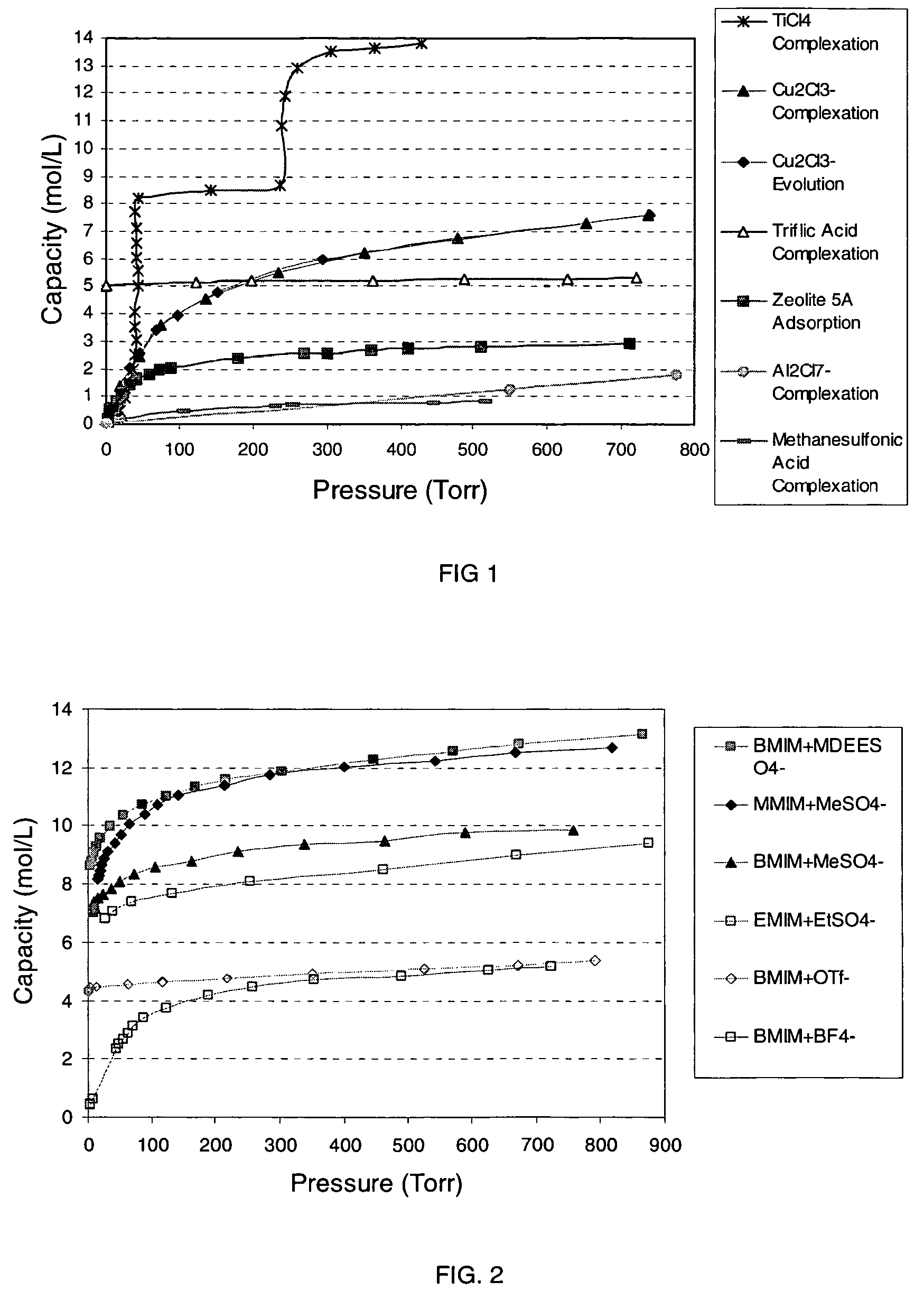

Ionic liquid based mixtures for gas storage and delivery

InactiveUS20060060817A1Oxygen/ozone/oxide/hydroxideLiquid degasificationChemical reactionIonic liquid

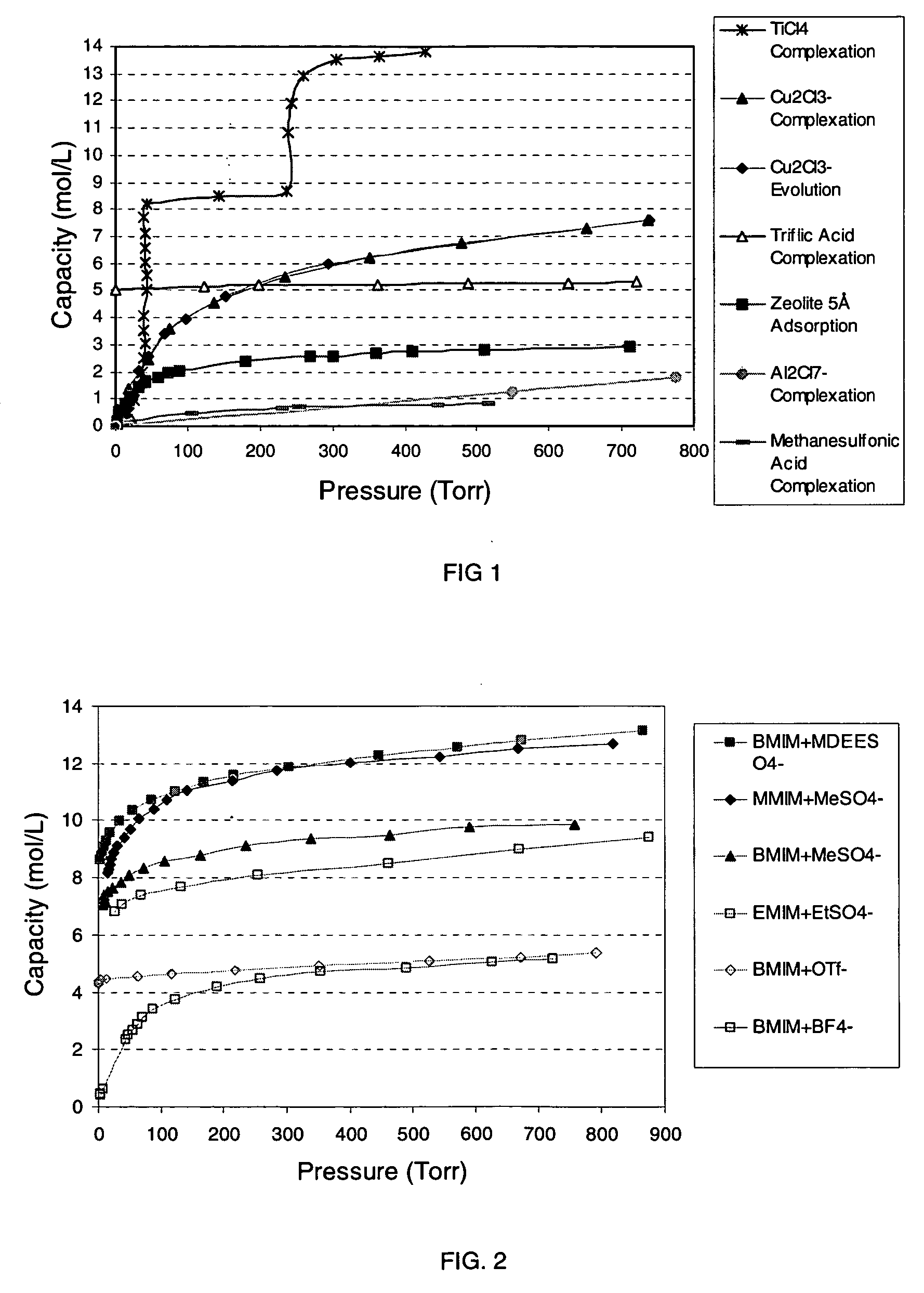

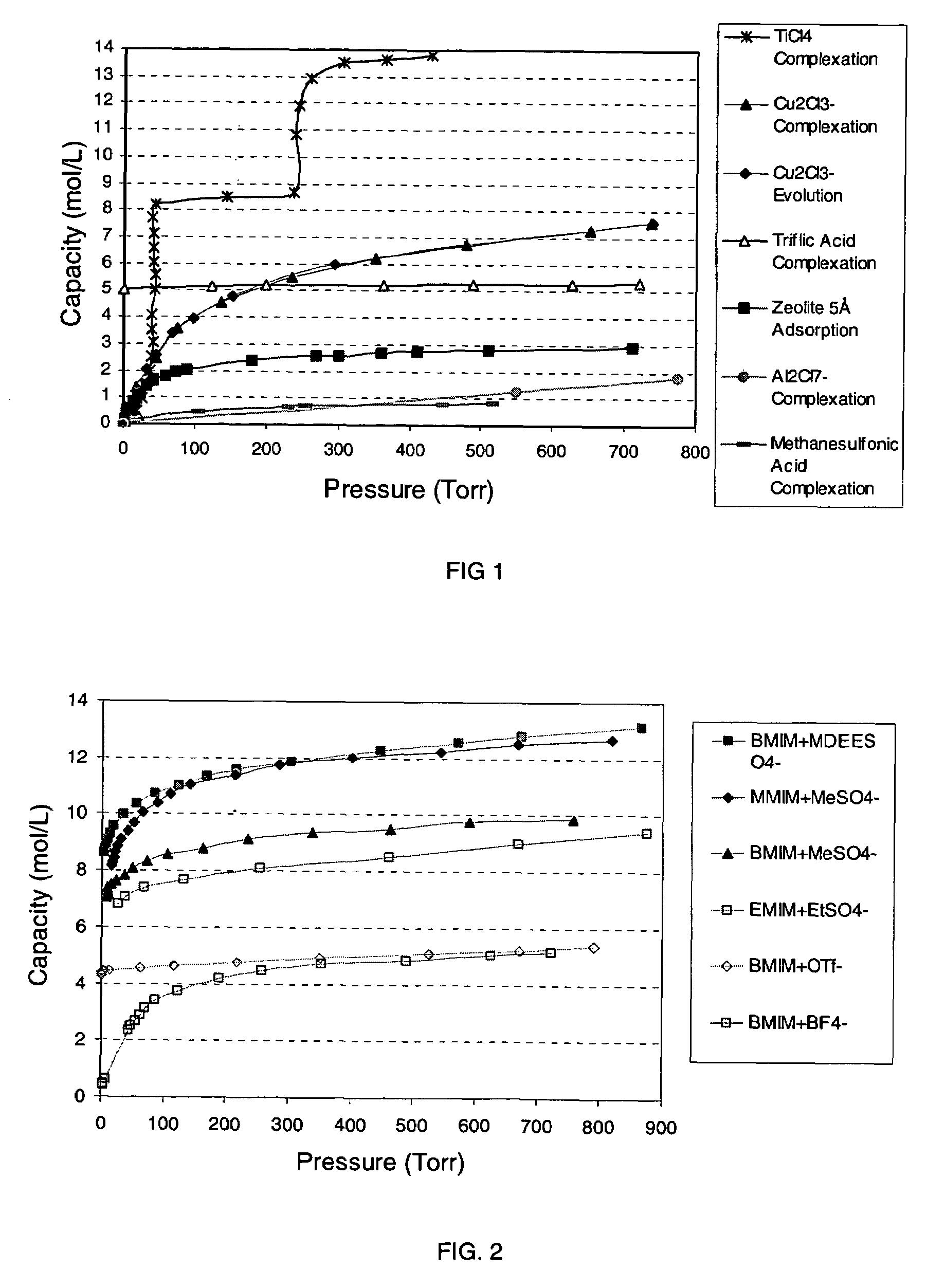

A mixture and method for the storage and delivery of at least one gas are disclosed herein. In one aspect, there is provided a mixture for the storage and delivery of at least one gas comprising: an ionic liquid comprising an anion and a cation; and at least one gas that is disposed within and is reversibly chemically reacted with the ionic liquid. In another aspect, there is provided a method for delivering at least one gas from a mixture comprising an ionic liquid and at least one gas comprising: reacting the at least one gas and the ionic liquid to provide the mixture and separating the at least one gas from the mixture wherein the at least one gas after the separating step is substantially the same as the at least one gas prior to the reacting step.

Owner:VERSUM MATERIALS US LLC

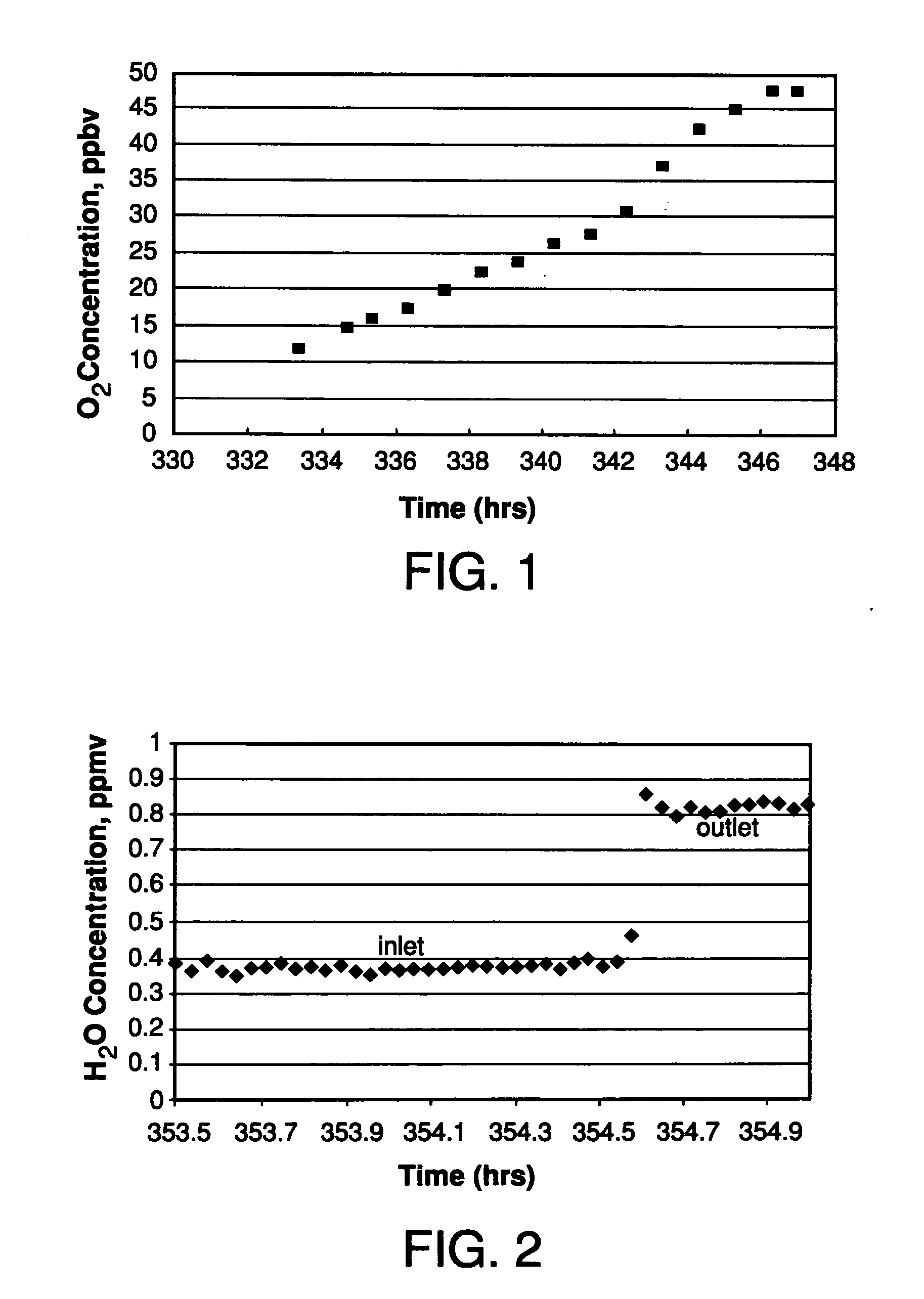

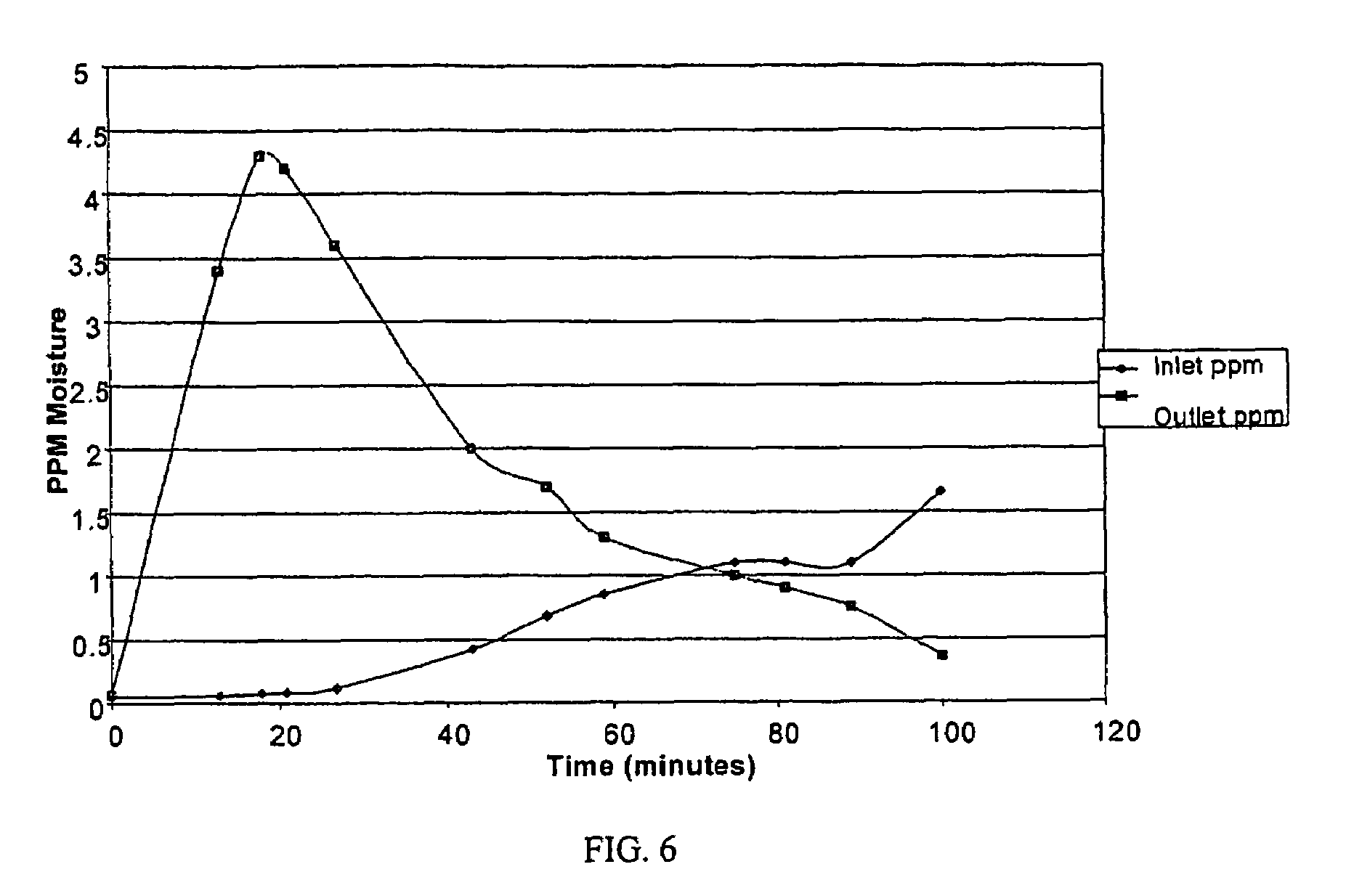

Purification of hydride gases

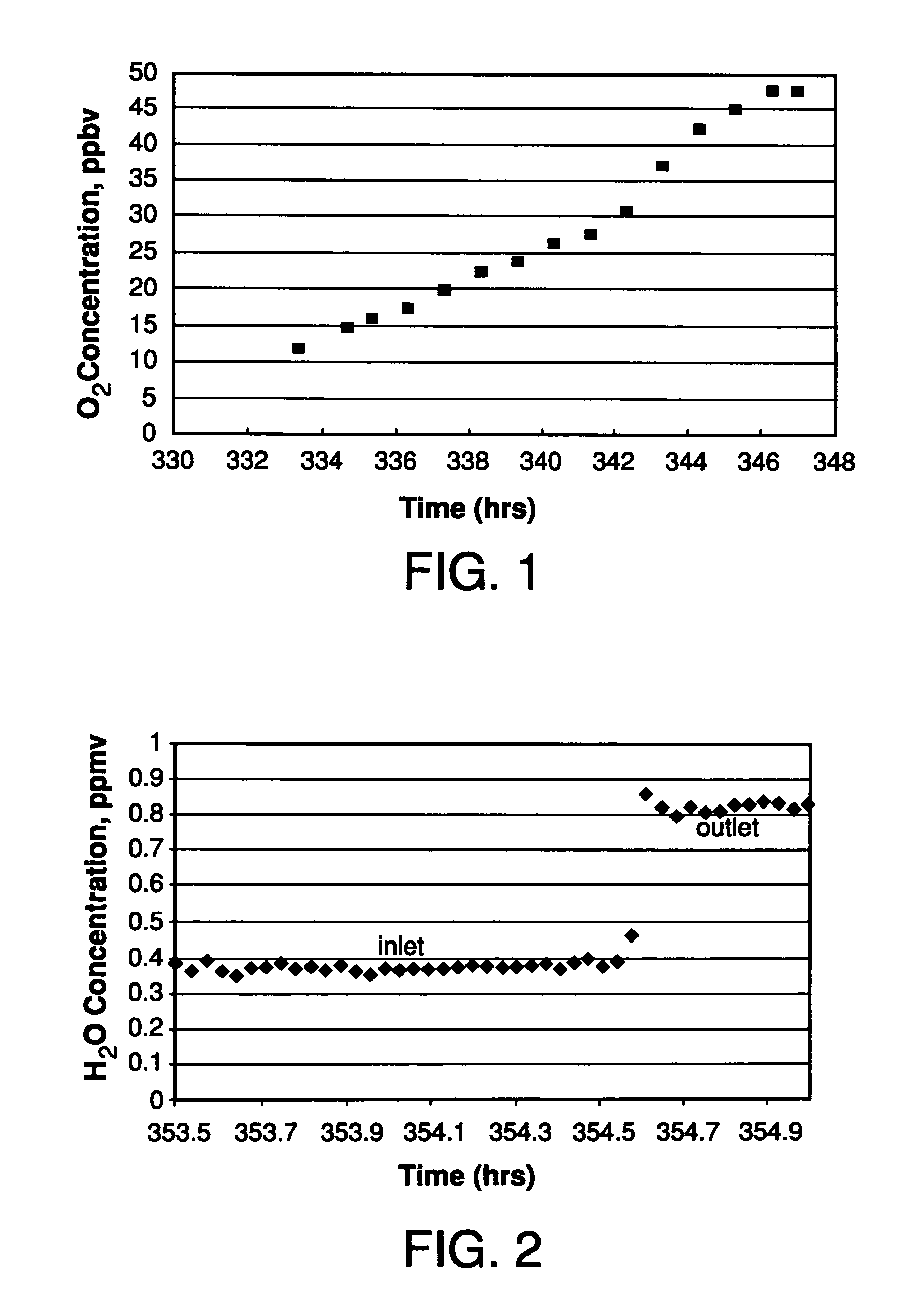

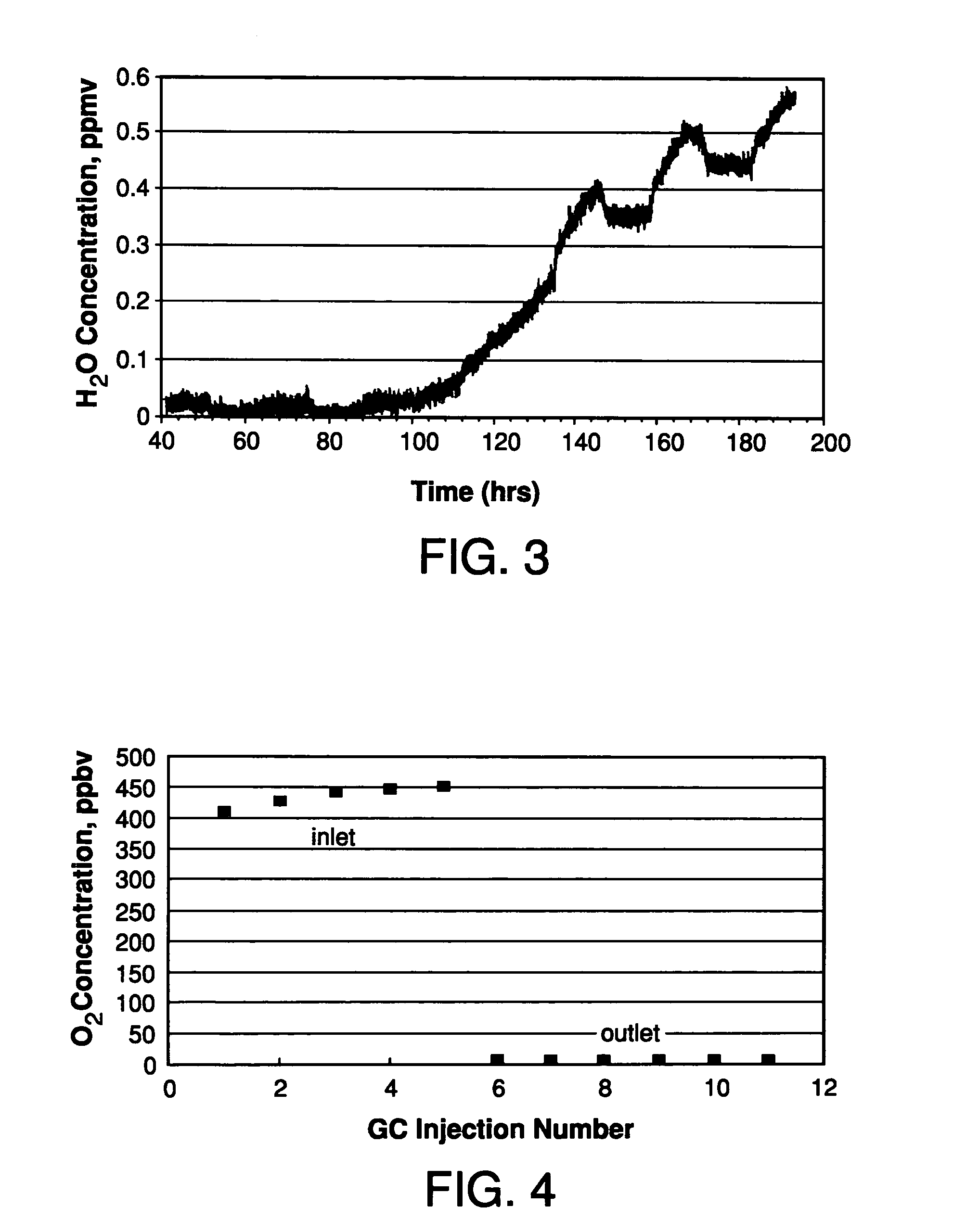

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

Ionic liquid based mixtures for gas storage and delivery

A mixture and method for the storage and delivery of at least one gas are disclosed herein. In one aspect, there is provided a mixture for the storage and delivery of at least one gas comprising: an ionic liquid comprising an anion and a cation; and at least one gas that is disposed within and is reversibly chemically reacted with the ionic liquid. In another aspect, there is provided a method for delivering at least one gas from a mixture comprising an ionic liquid and at least one gas comprising: reacting the at least one gas and the ionic liquid to provide the mixture and separating the at least one gas from the mixture wherein the at least one gas after the separating step is substantially the same as the at least one gas prior to the reacting step.

Owner:VERSUM MATERIALS US LLC

Purification of hydride gases

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

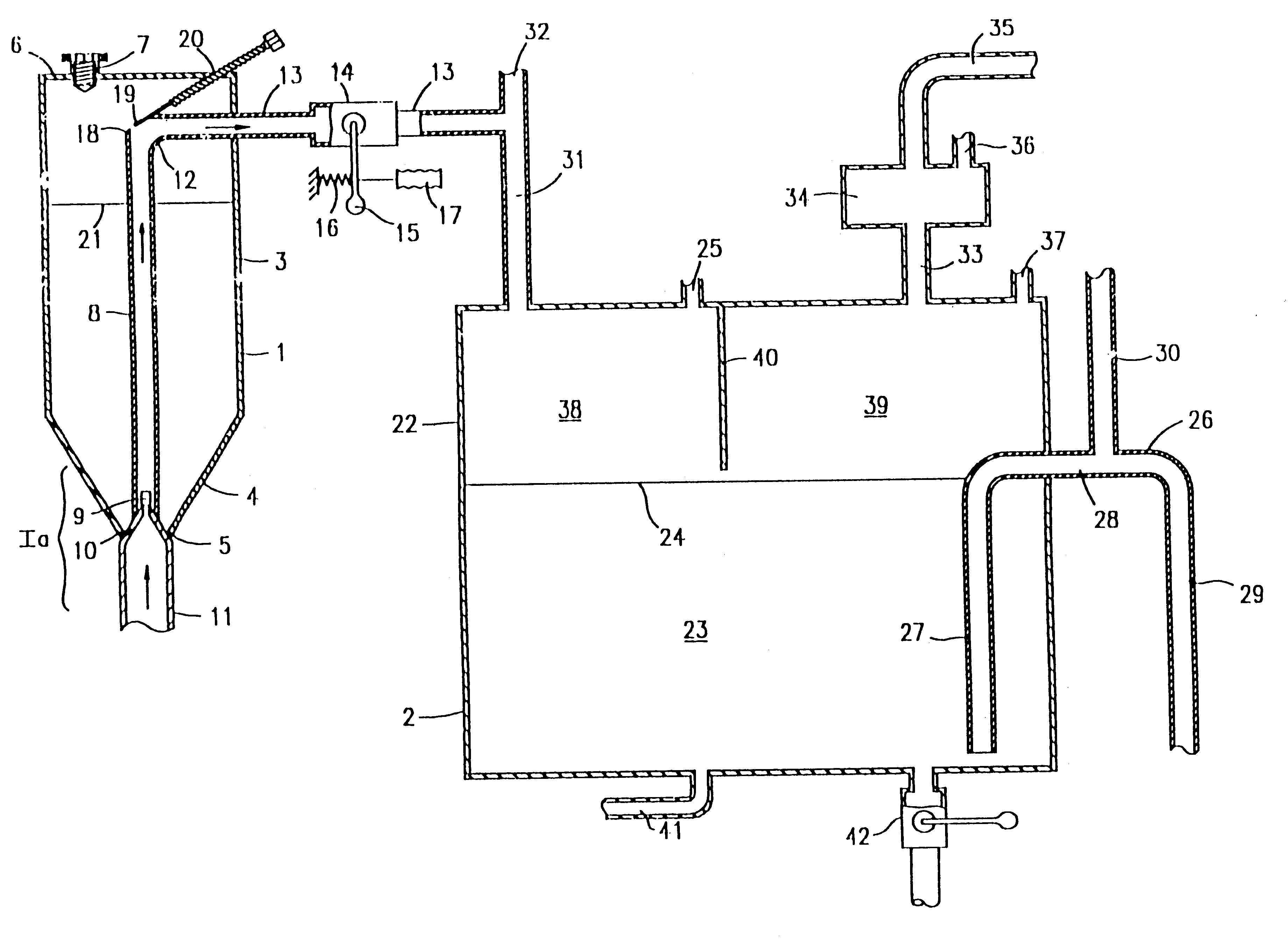

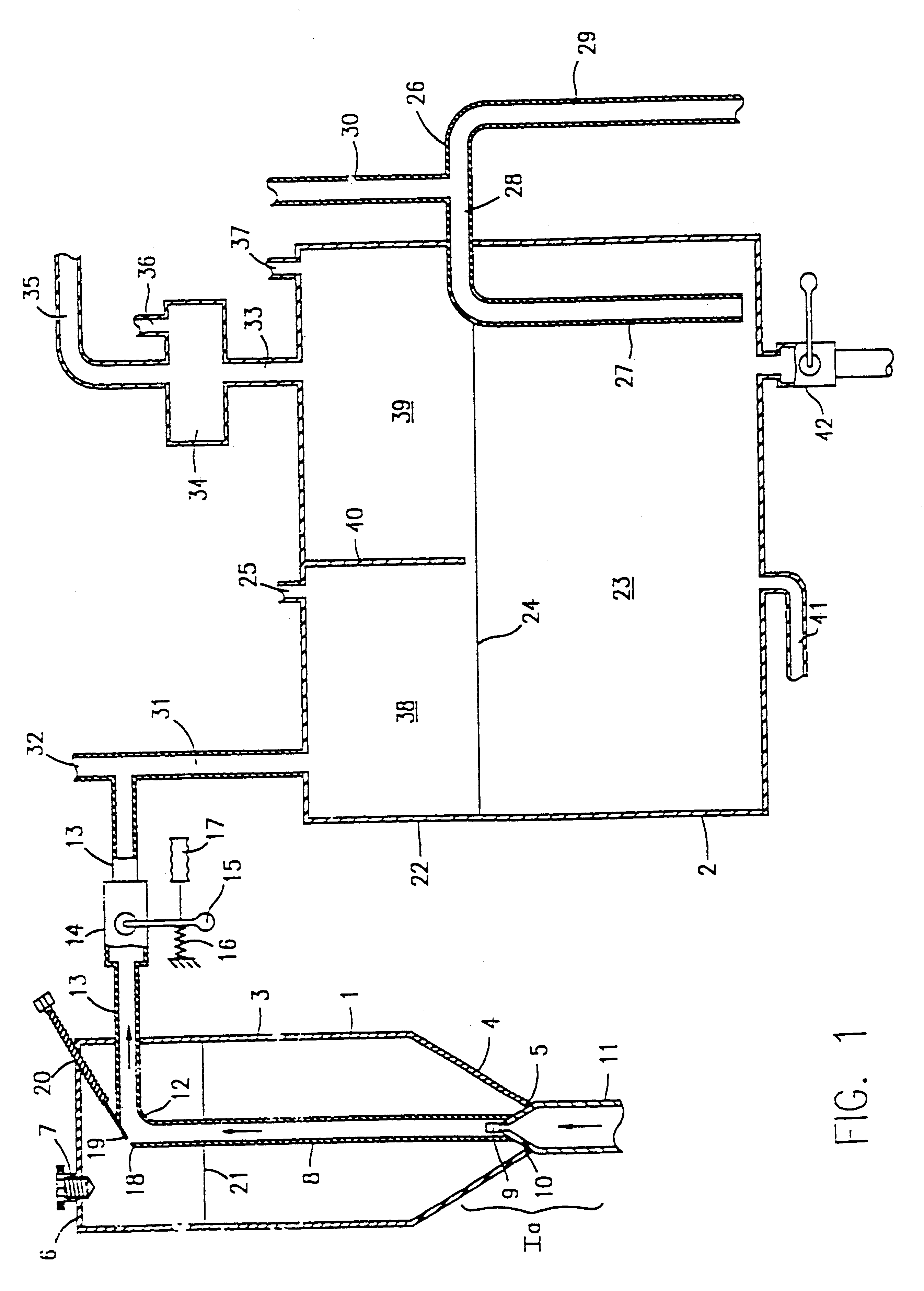

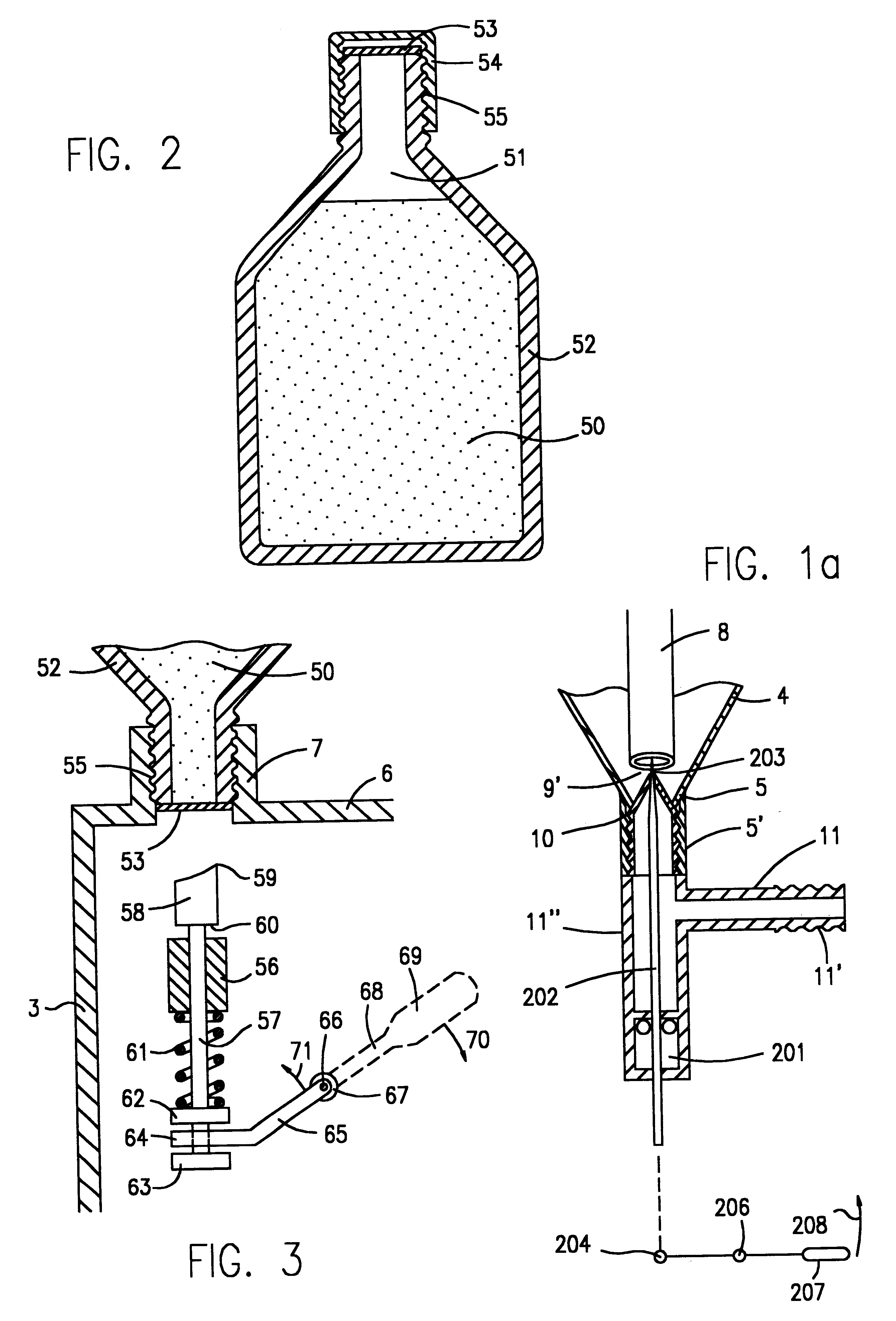

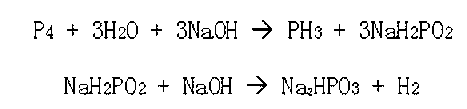

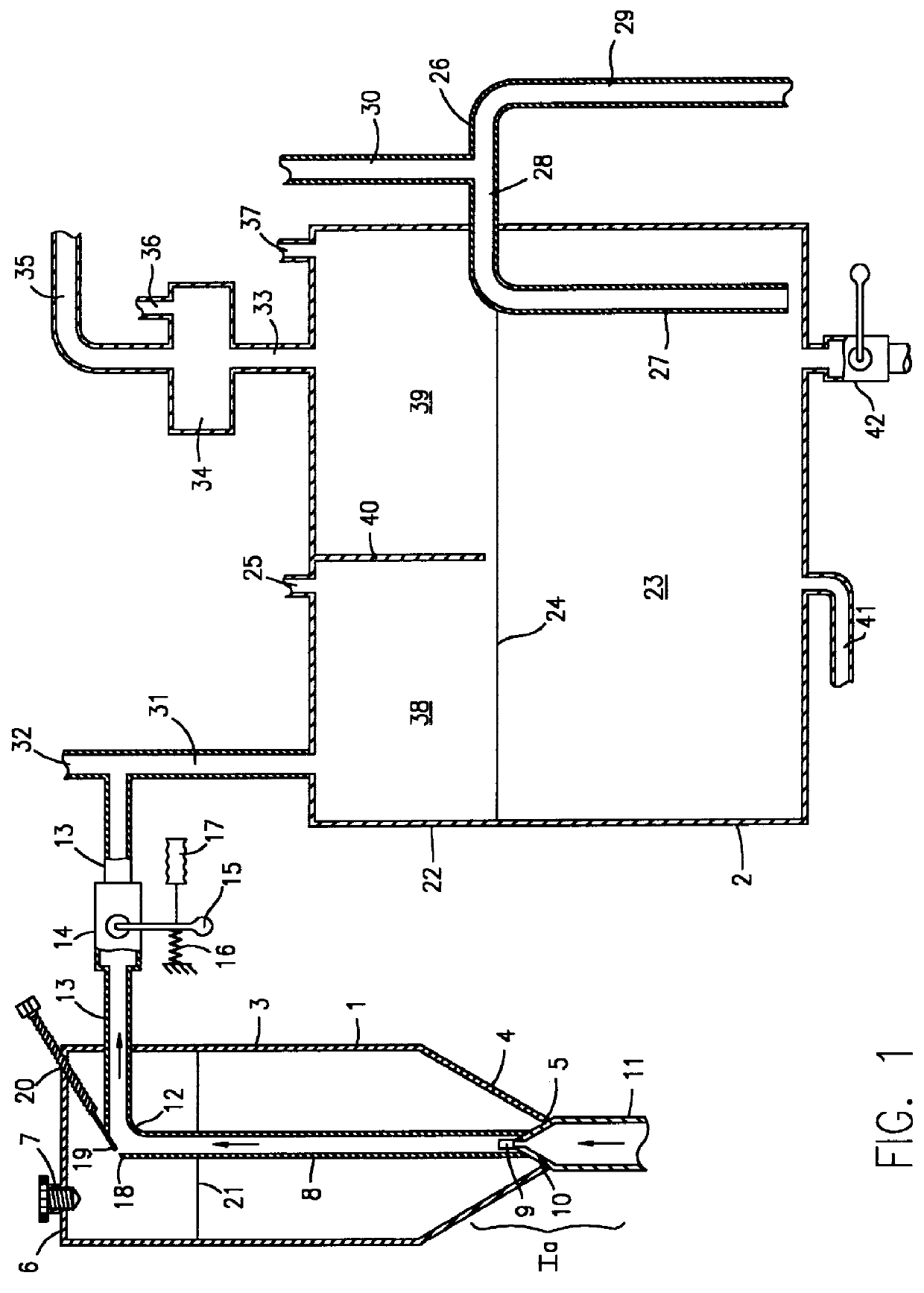

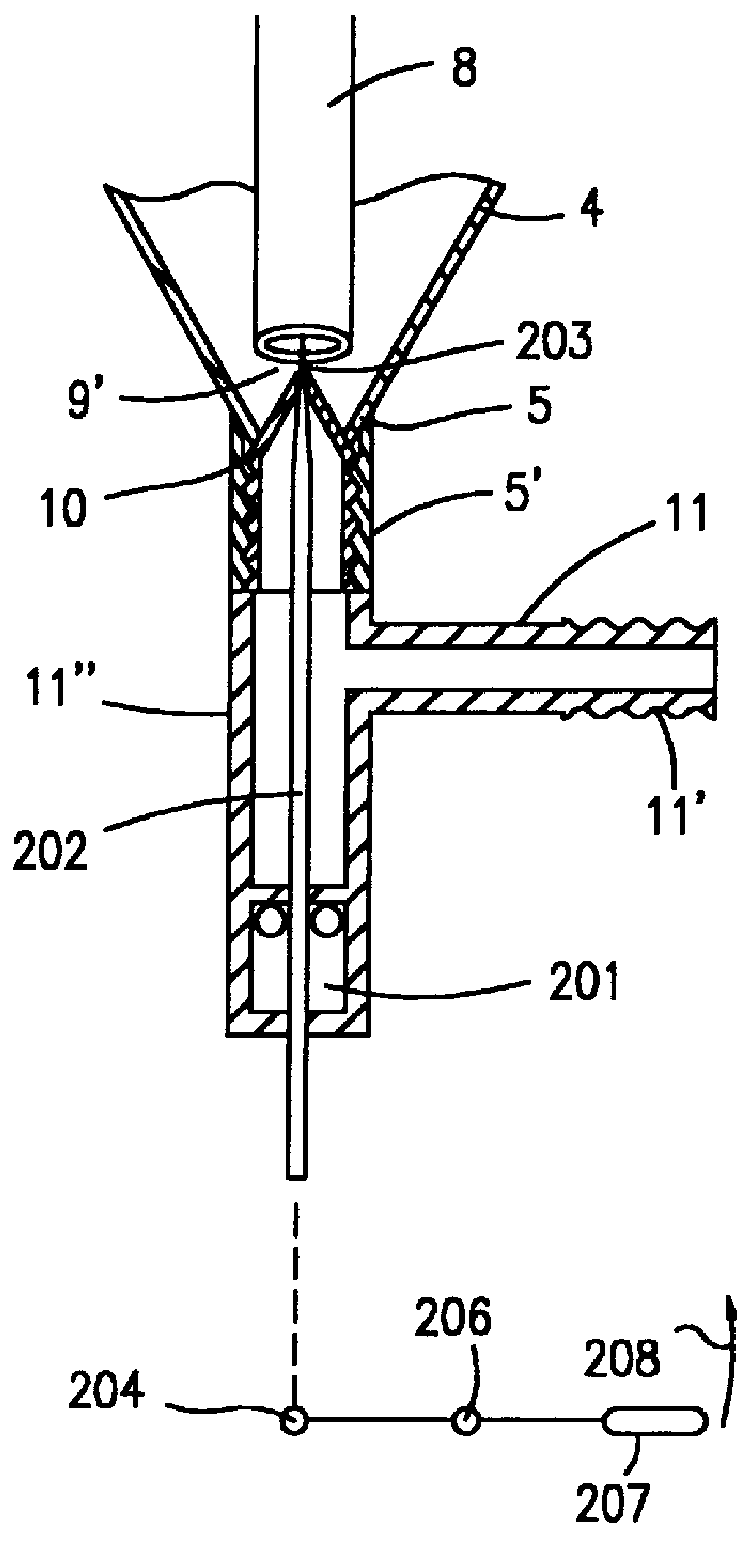

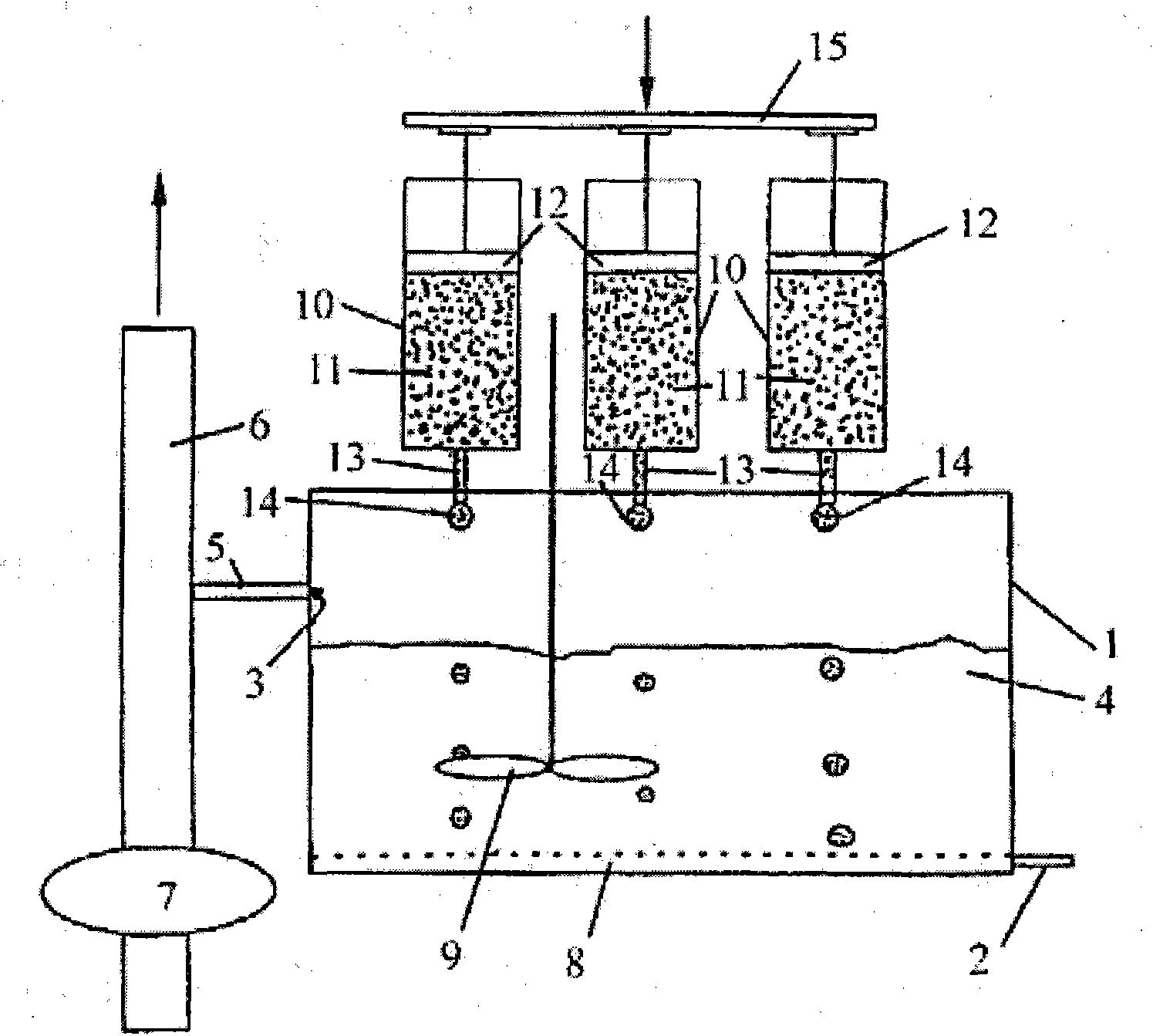

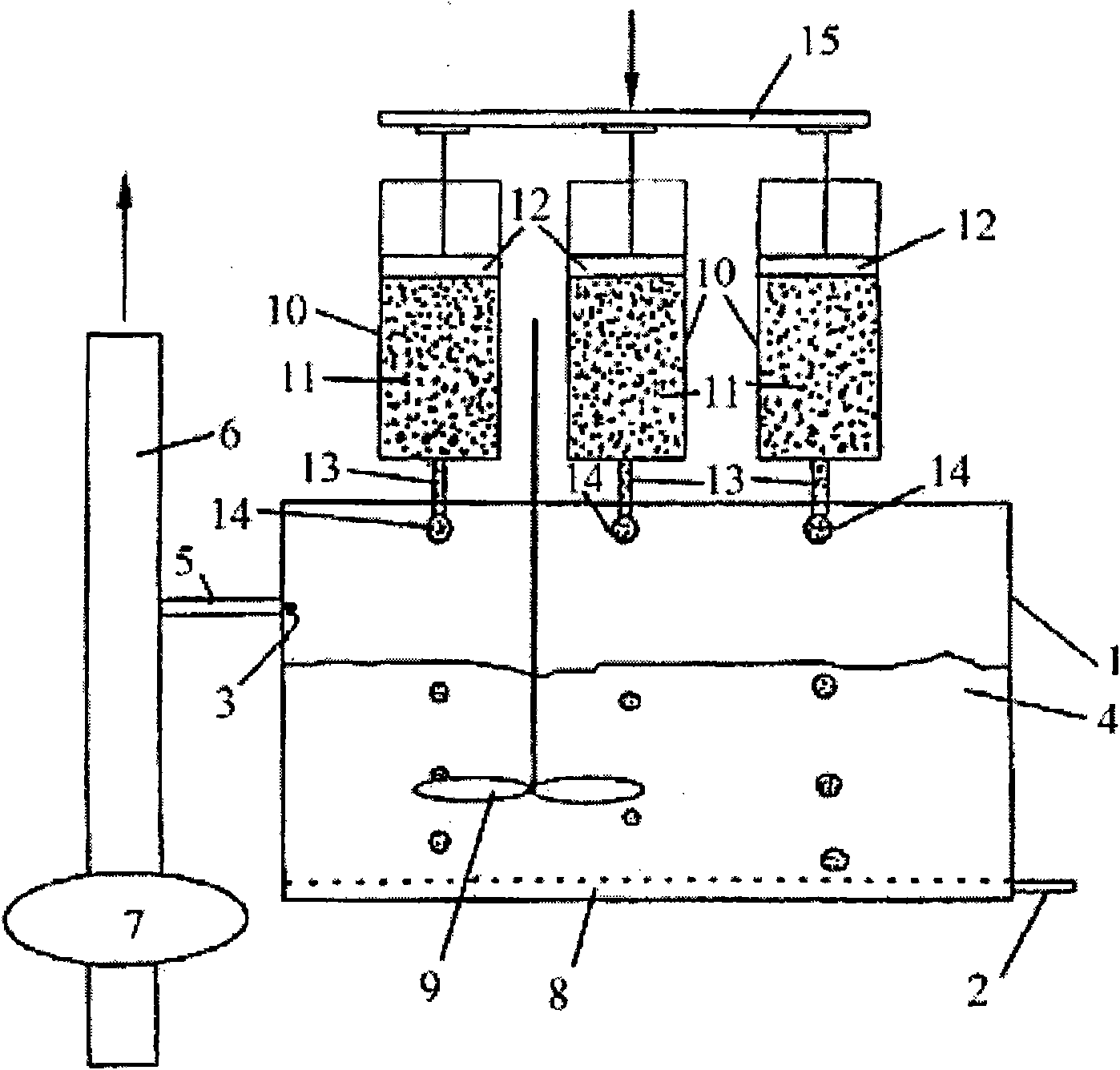

Phosphine generator for producing phosphine-containing gas

InactiveUS6315965B1Promote safe productionImprove storage characteristicsBiocideMixing methodsParticulatesLiquid water

A process and apparatus is disclosed for generating a mixture of phosphine and diluent gas(es). A hydrolysable metal phosphide, preferably magnesium phosphide, is released directly into liquid water under an atmosphere of gas inert to phosphine and in a free-flowing particulate form, composed of loose metal phosphide particles. The generated mixture of phosphine and inert carrier gas, e.g. CO2, is used as such or is diluted into a gas mixing chamber with air to a concentration below the ignitability limit before being used in fumigation. Using argon as a carrier gas the phosphine mixture is suitable for semiconductor doping.

Owner:DECH DE CHILE

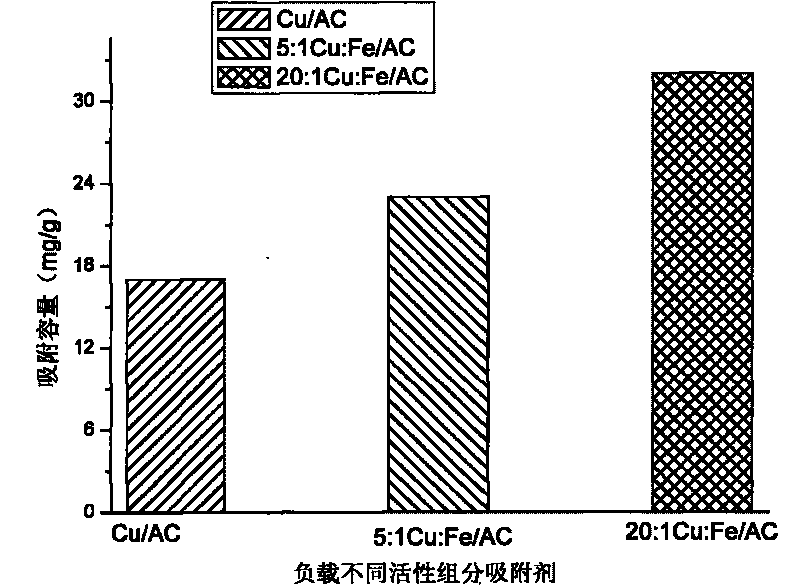

Copper and iron-loaded modified activated carbon absorbent and method for preparing same

InactiveCN101695651ASimple methodEasy to operateOther chemical processesDispersed particle separationSorbentCoal

The invention discloses a copper and iron-loaded modified active carbon absorbent and a method for preparing the same. The copper and iron-loaded modified active carbon absorbent is characterized by: taking conventional coal-based activated carbon as a carrier of the absorbent, wherein the carrier is loaded with an oxide of copper and iron two transition metals as an active component; and the mol ratio of the copper to the iron in the oxide is 5-20:1. The method for preparing the copper and iron-loaded modified active carbon absorbent is simple, strong in operability, moderate in reaction condition and easy in implementation, improves purification efficiency, reduces the purification cost, and can realize the dephosphorization of waste gas and the reclamation of wastes after saturated absorption. The invention also discloses the method for preparing the copper and iron-loaded modified active carbon absorbent.

Owner:KUNMING UNIV OF SCI & TECH

Device for removing phosphor from phosphor-containing organic wastewater and producing hydrogen phosphide

ActiveCN104828938AAvoid the problem of low phosphorus removal efficiencyHigh purityWater contaminantsTreatment with anaerobic digestion processesSequencing batch reactorElectricity

The invention discloses a device for removing phosphor from phosphor-containing organic wastewater and producing hydrogen phosphide. The device comprises an anaerobic reactor, a microbial fuel cell and a microbial electrolytic bath; the water outlet pipe of the anaerobic reactor is connected to the anode water inlet pipe of the microbial fuel cell; the anode water outlet pipe of the microbial fuel cell is connected to the water inlet pipe of the microbial electrolytic bath; and the electricity output terminal of the microbial fuel cell is connected to the power supply port of the microbial electrolytic bath. The organic wastewater is introduced into the anaerobic sequencing batch reactor, the organic phosphor and occluded phosphor in organic wastewater are converted into phosphate through the metabolism of microbes, and then the wastewater is processed by the microbial fuel cell and microbial electrolytic bath. In the prior art, the phosphor removing efficiency is very low because the microbial anaerobic process is taken as the main process of hydrogen phosphide production, and the provided device solve the problem mentioned above.

Owner:SOUTH CHINA UNIV OF TECH

Ionic liquid based mixtures for gas storage and delivery

InactiveUS7563308B2Reduce solubilityIncrease temperatureOxygen/ozone/oxide/hydroxideLiquid degasificationChemical reactionCompound (substance)

A mixture and method for the storage and delivery of a gas are disclosed herein. In one aspect, there is provided a mixture comprising: an ionic liquid comprising an anion and a cation, at least a portion of the gas that is disposed within and reversibly chemically reacted with the ionic liquid, and optionally an unreacted gas. In another aspect, there is provided a method for delivering a gas from a mixture comprising an ionic liquid and one or more gases comprising: reacting at least a portion of the gas with the ionic liquid to provide the mixture comprising a chemically reacted gas and an ionic liquid and separating the chemically reacted gas from the mixture wherein the chemically reacted gas after the separating step has substantially the same chemical identity as the chemically reacted gas prior to the reacting step.

Owner:VERSUM MATERIALS US LLC

Method for purifying phosphine by-product and application method of phosphine by-product

ActiveCN101638224AHigh value-added utilizationReduce manufacturing costDispersed particle separationLiquid/solution decomposition chemical coatingAqueous sodium hydroxideGas passing

The invention relates to a method for purifying a phosphine by-product in a process of producing sodium hypophosphite, and a method for synthesizing trialkyl phosphine by using the phosphine by-product. The method for purifying the phosphine by-product comprises the following steps that: 1) phosphine tail gas produced in a sodium hypophosphite reactor is drawn out from a tail gas exhaust port at the upper end of the reactor, and then naturally passes through a water seal tank by means of the pressure produced by a water seal in the water seal tank; 2) the gas passing through the water seal tank enters a water seal purifier filled with sodium hydroxide aqueous solution for purification; and 3) the phosphine gas purified by the purifier enters a gas-water separator to carry out gas-water separation so as to obtain a dried gas. The method provided by the invention realizes high added value utilization of the phosphine by-product, and greatly reduces the production cost of the trialkyl phosphine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame retardant polymer compositions comprising stabilized hypophosphite salts

InactiveUS20130324646A1Improve flame retardant performanceGroup 5/15 element organic compoundsConductive materialPolymer scienceGram

A flame retardant polymer composition is described. The composition includes at least one polymer and a hypophosphite salt, wherein the hypophosphite salt is heat stabilized so that when it is heated for 3 hours at 298° C. under a flow of argon flushing at rate 58 mL / min, it generates less than 0.5 mL of phosphine per gram of hypophosphite salt. The flame retardant polymer composition can also include at least one additive that improves the flame retardant properties of the composition.

Owner:RHODIA OPERATIONS SAS +1

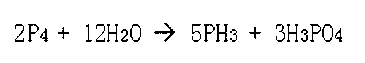

Phosphine preparation method

InactiveCN103253640AHigh yieldReduce manufacturing costHydrogen phosphidesPhosphorous acidPhosphinic Acids

The present invention relates to a phosphine preparation method, which comprises the steps that: yellow phosphorus generates phosphine, hypophosphite and phosphite under an alkali effect, an inorganic acid is adopted to treat the hypophosphite and the phosphite to obtain a mixture of hypophosphorous acid and phosphorous acid, and the obtained mixing acid is subjected to pyrolysis to produce phosphine and a by-product phosphoric acid. According to the method, the by-products of the whole process are the sodium salt and phosphoric acid so as to reduce waste emission, substantially increase the yield of phosphine, and increase the highest yield by 50-68% compared with the highest yield of the conventional alkali process.

Owner:江苏先锋生物基技术研究中心有限公司

Passivating treatment process of electronic grade arsenic hydride, hydrogen phosphide and mixture gas steel cylinder

ActiveCN106185850ANo reduction in purityArsenic/antimony hydridesSolid state diffusion coatingVacuum pumpingMetallurgy

The invention relates to a passivating treatment process of a super-high-purity arsenic hydride, hydrogen phosphide and mixture gas steel cylinder. The process comprises the following steps that a first steel cylinder to be subjected to passivating treatment is heated and baked at a high temperature of 100 to 200 DEG C; the first steel cylinder is subjected to vacuum pumping treatment through an exhaust fan; the first steel cylinder is continuously subjected to heating and baking treatment at a high temperature of 100 to 200 DEG C; when the first steel cylinder is pumped into a vacuum state, scavenging and replacement are performed; the first steel cylinder is subjected to vacuum pumping treatment through the exhaust fan, and the first steel cylinder is continuously subjected to heating and baking treatment at a high temperature of 100 to 200 DEG C; when the first steel cylinder is pumped into a vacuum state, the inner wall is passivated; the first steel cylinder is subjected to vacuum pumping treatment through a gas pumping-back device; extracted arsenic hydride and hydrogen phosphide gas is recovered to a gas recovery steel cylinder.

Owner:HEFEI ZHENGFAN ELECTRONICS MATERIAL

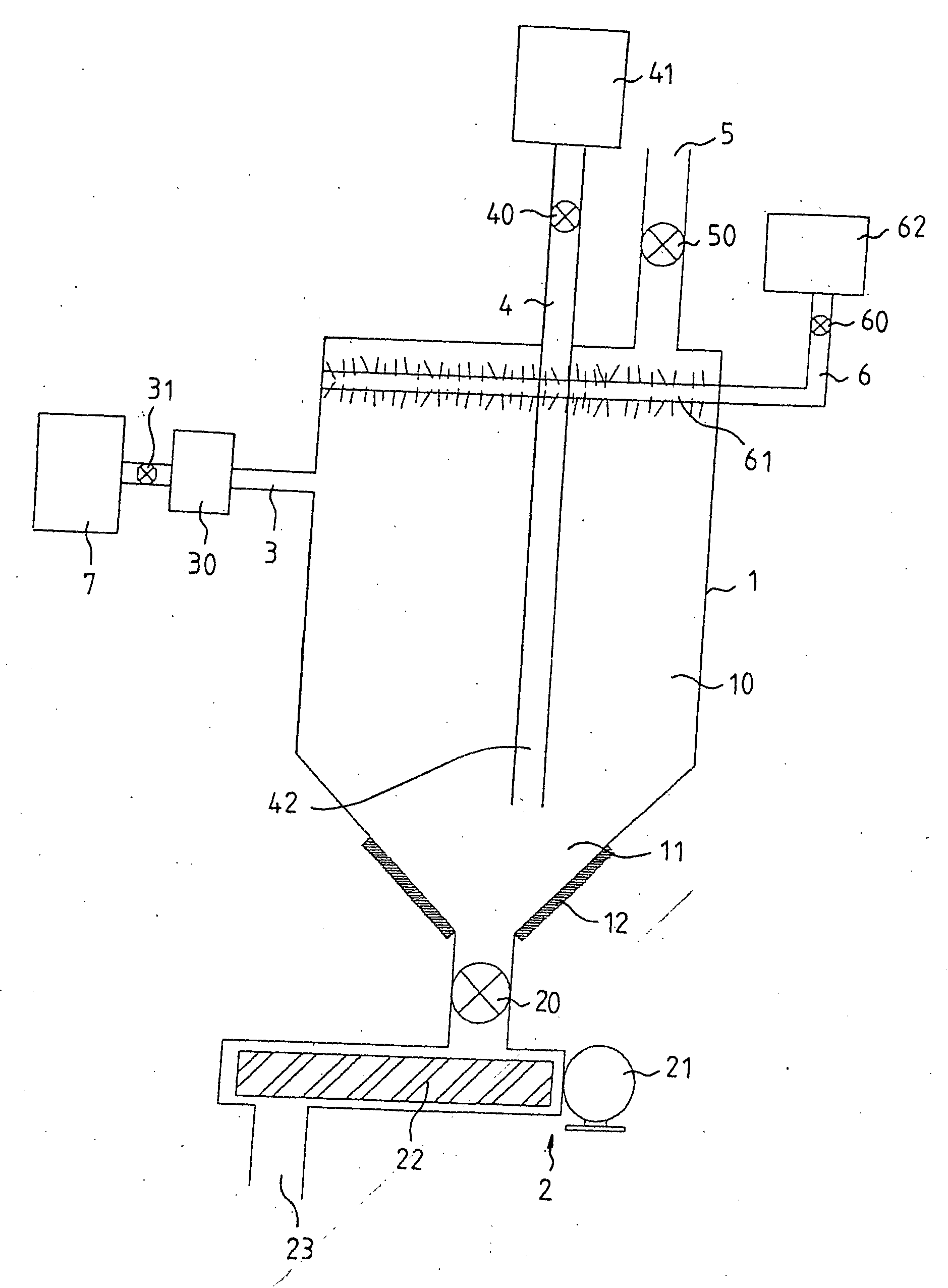

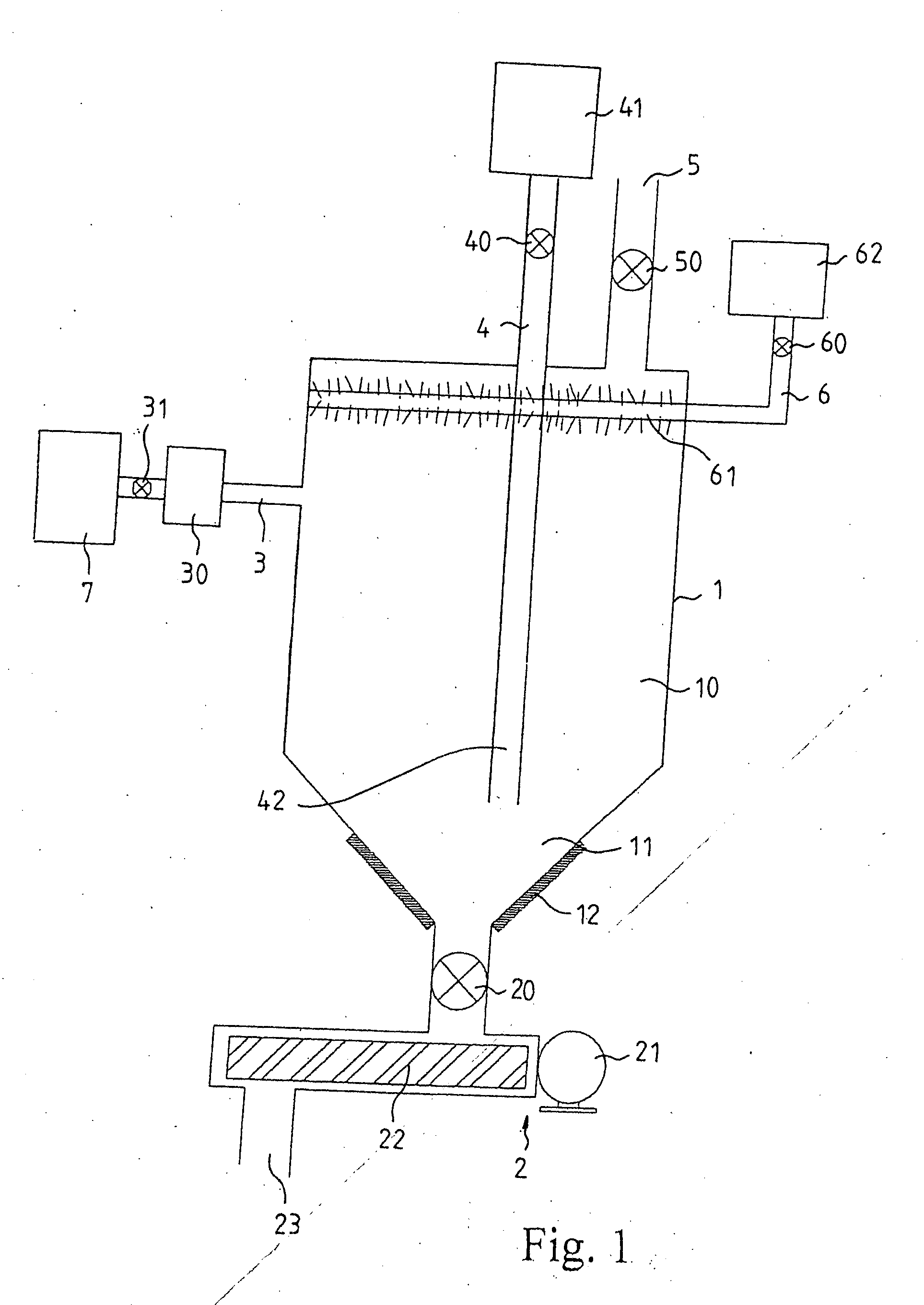

Process and apparatus for producing phosphine-containing gas

InactiveUS6027667APromote safe productionImprove storage characteristicsBiocideGroup 5/15 element organic compoundsParticulatesLiquid water

A process and apparatus is disclosed for generating a mixture of phosphine and diluent gas(es). A hydrolyzable metal phosphide, preferably magnesium phosphide, is released directly into liquid water under an atmosphere of gas inert to phosphine and in a free-flowing particulate form, composed of loose metal phosphide particles. The generated mixture of phosphine and inert carrier gas, e.g. CO2, is used as such or is diluted into a gas mixing chamber with air to a concentration below the ignitability limit before being used in fumigation. Using argon as a carrier gas the phosphine mixture is suitable for semiconductor doping.

Owner:DECH DE CHILE

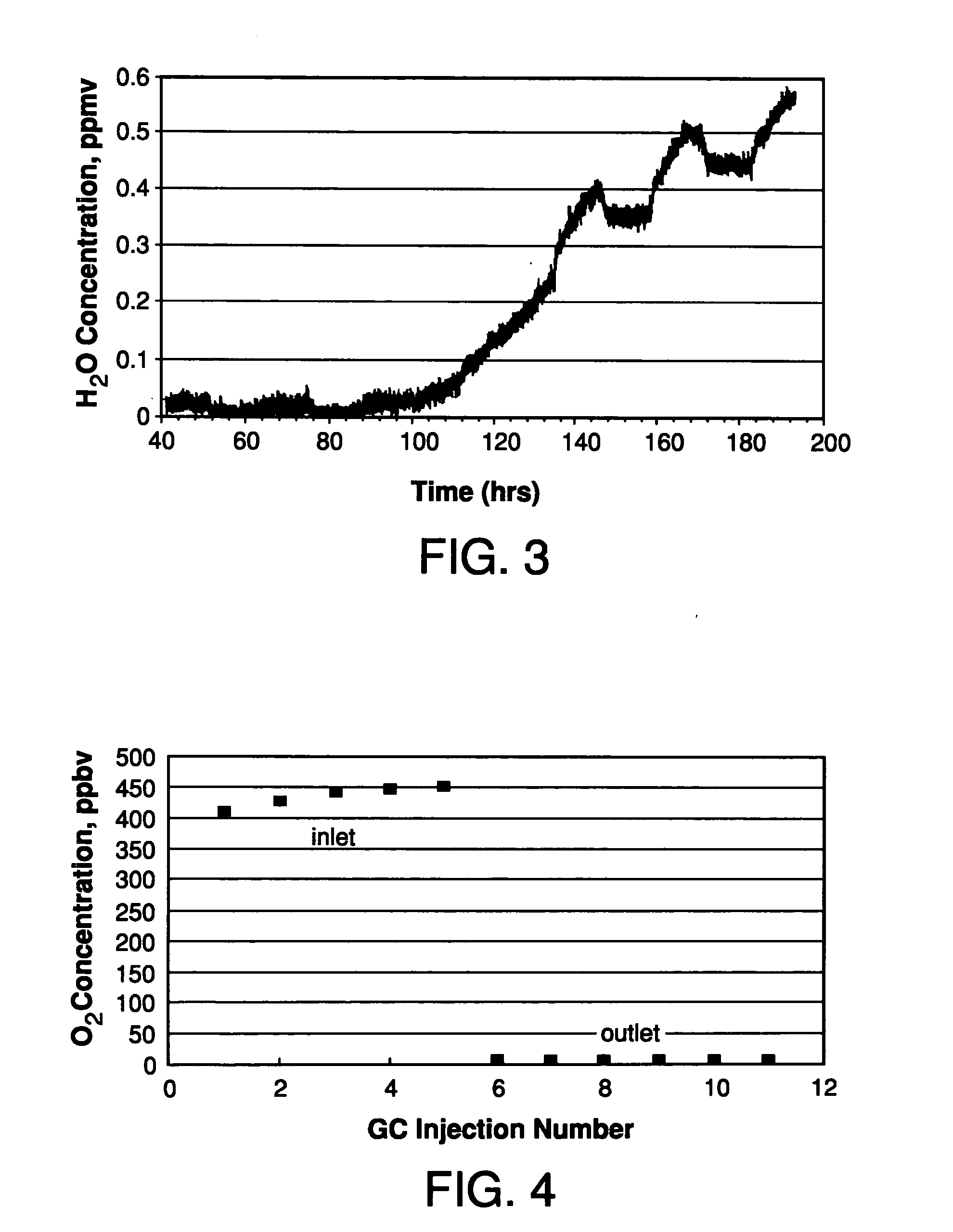

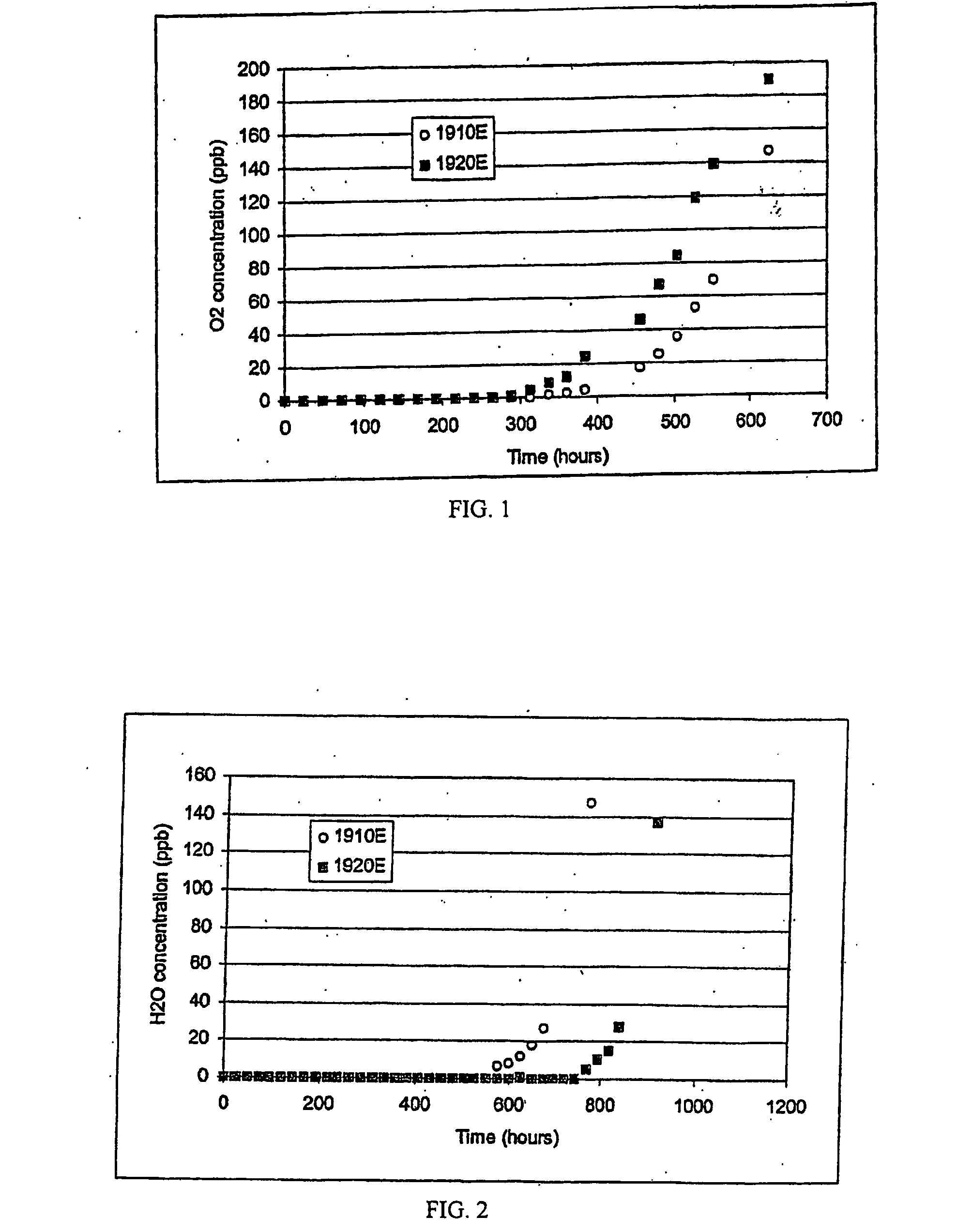

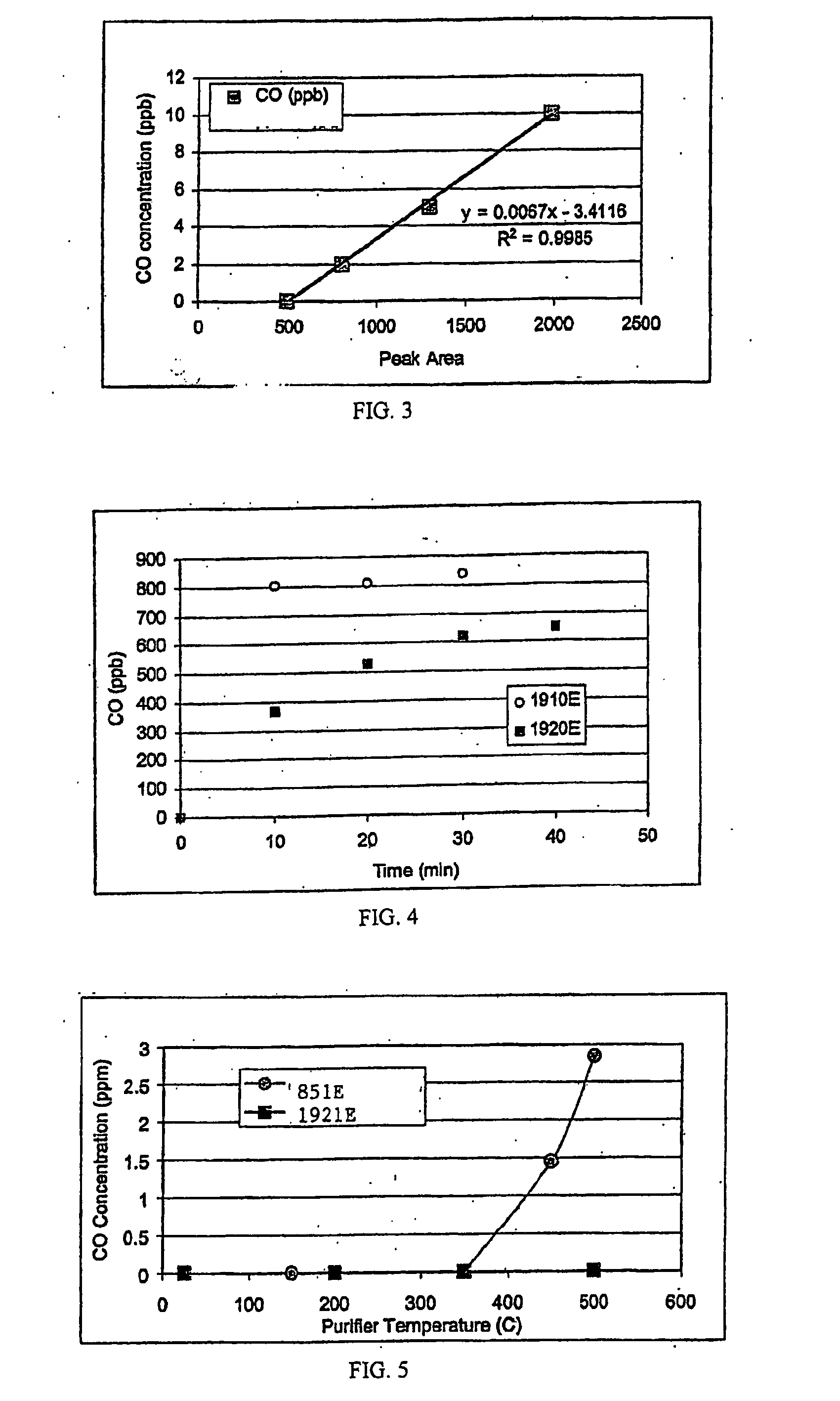

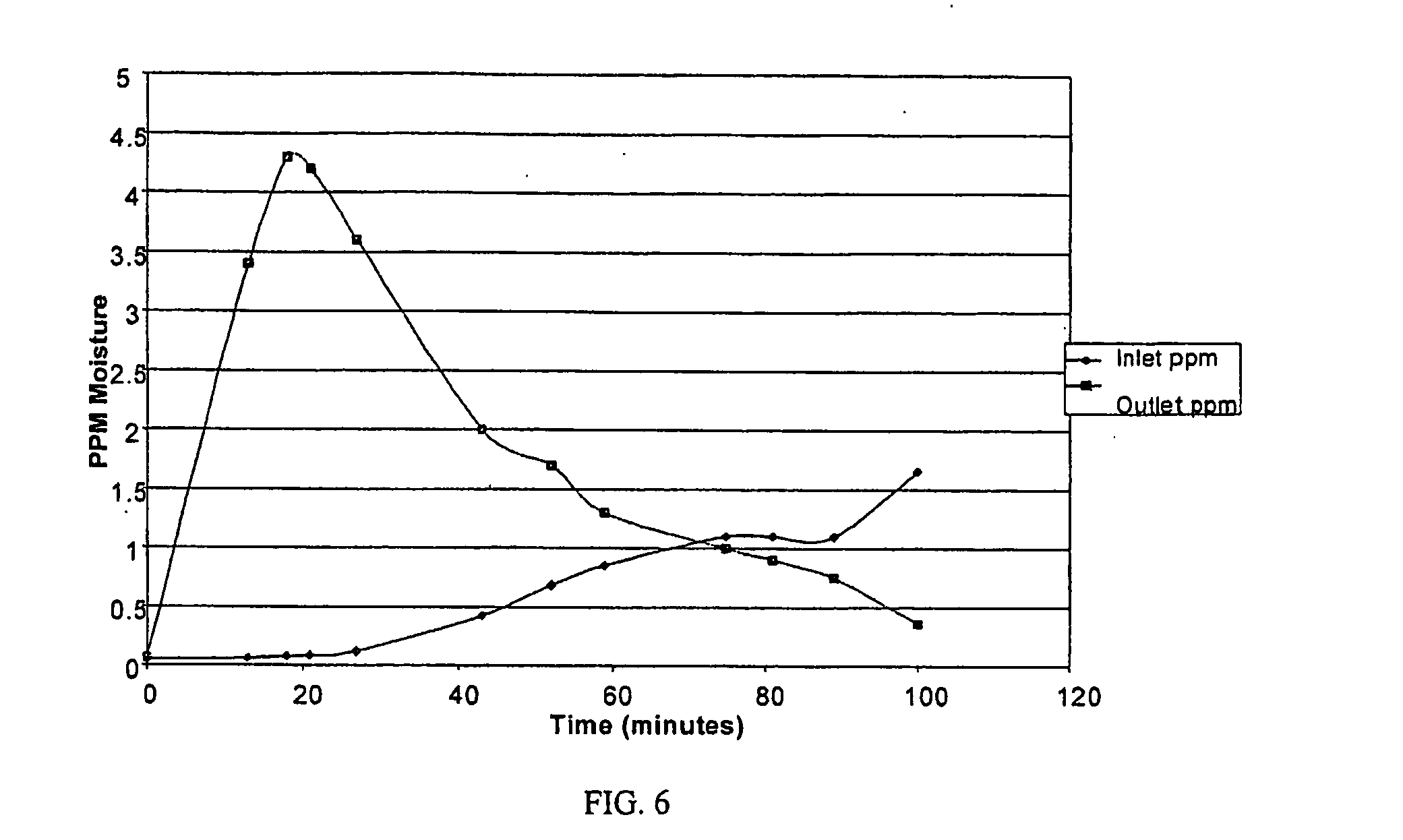

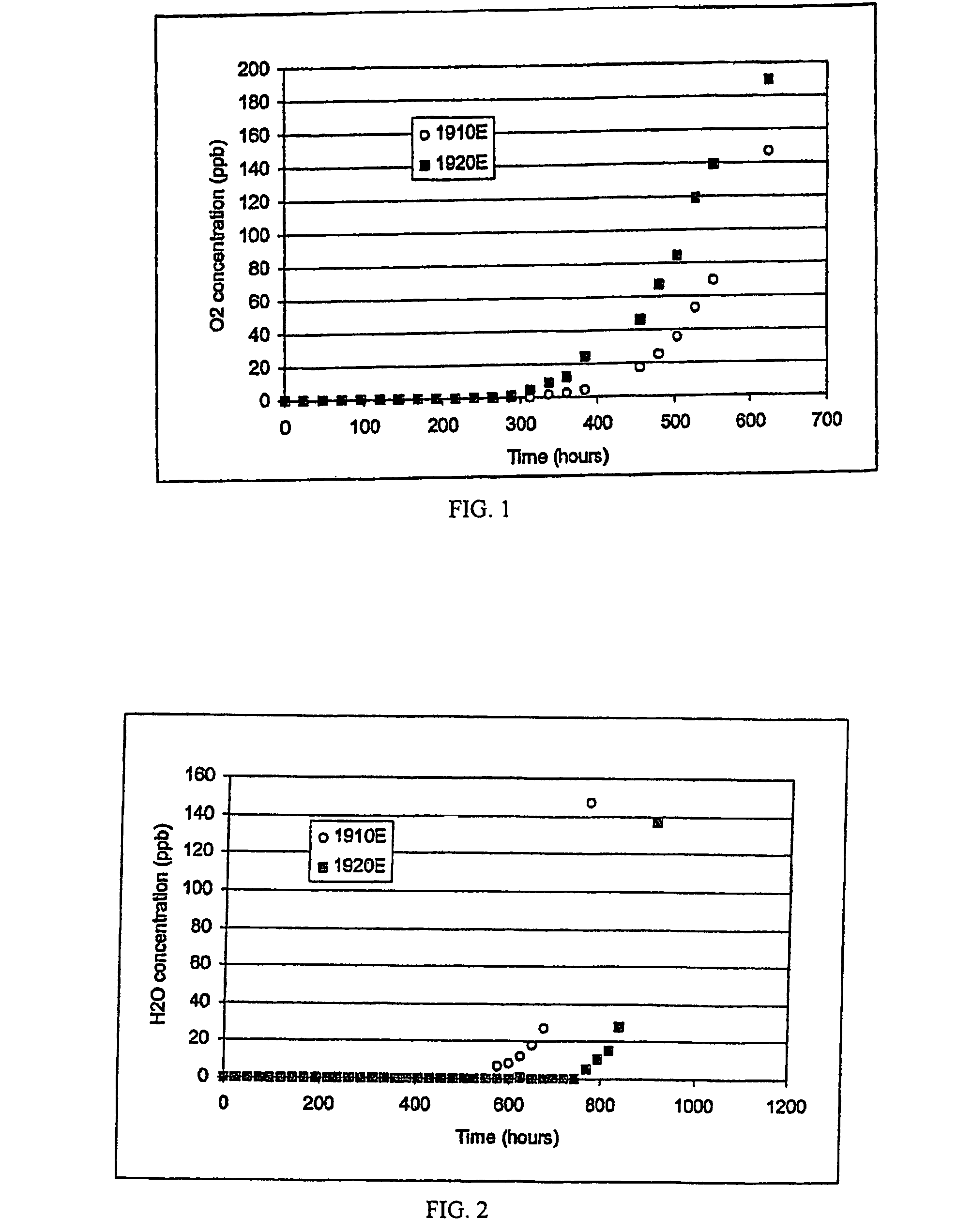

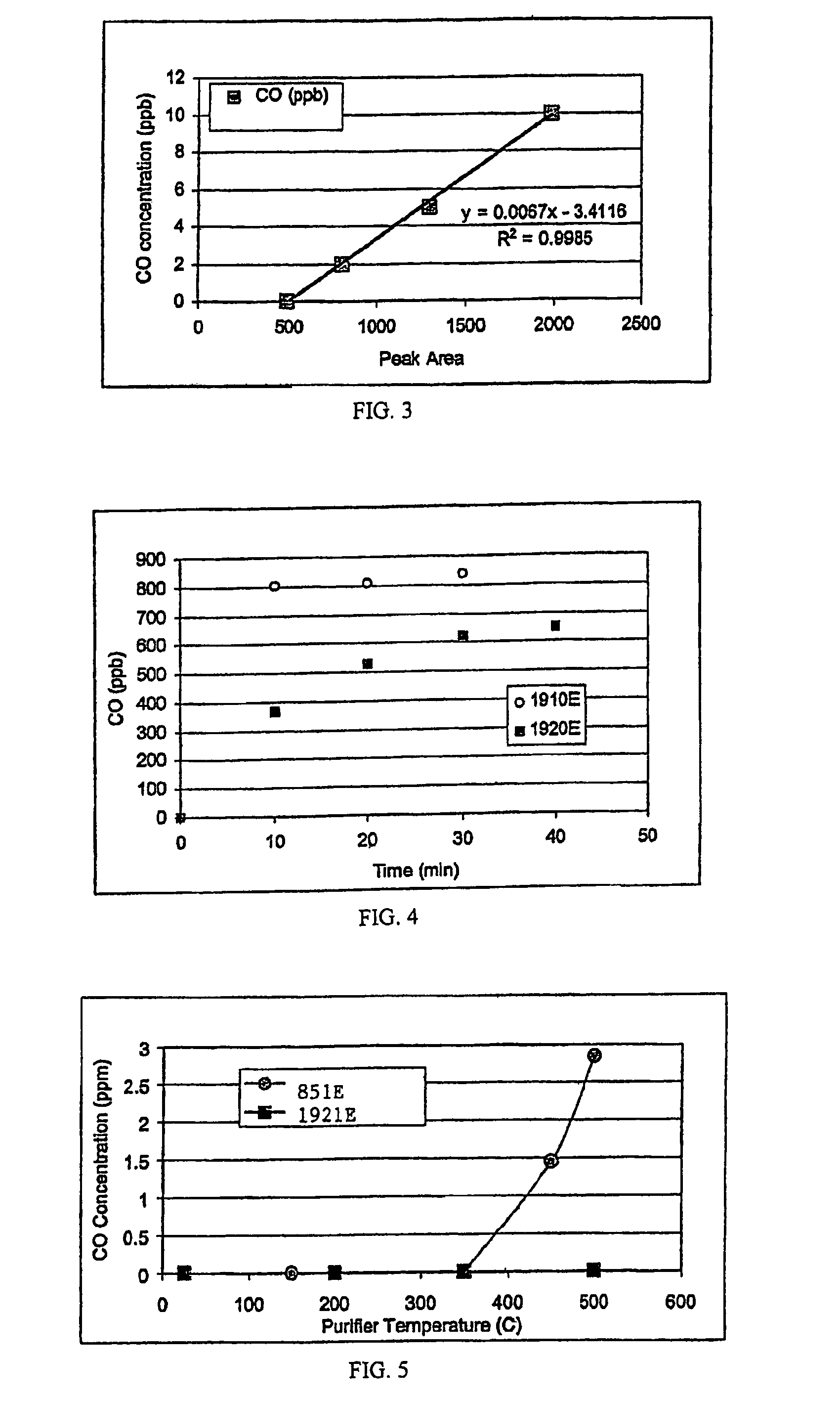

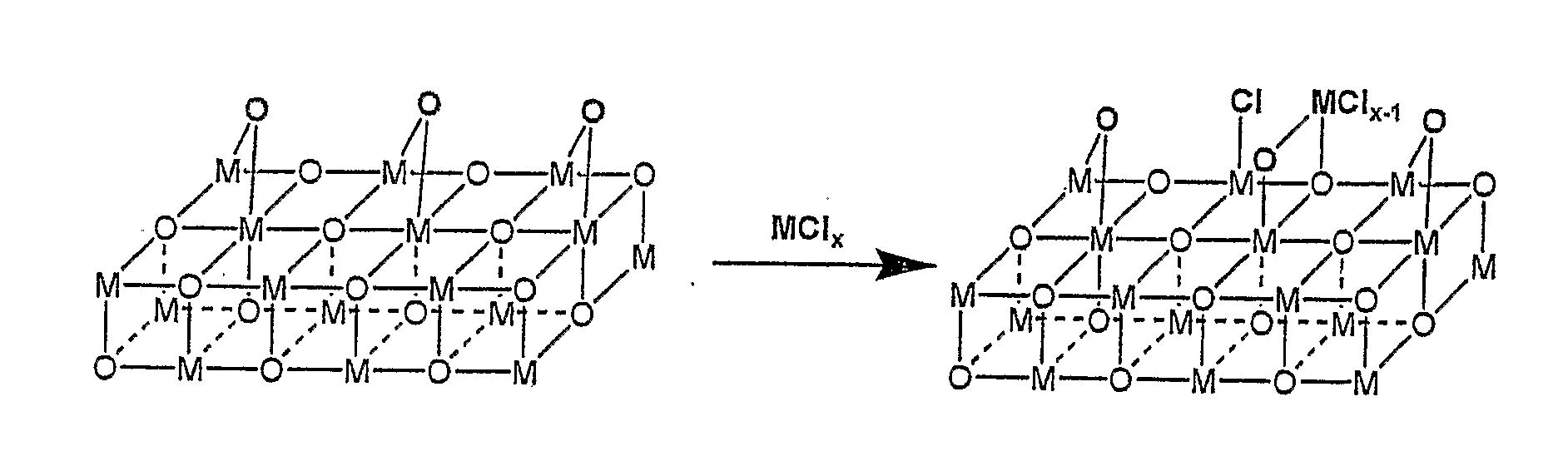

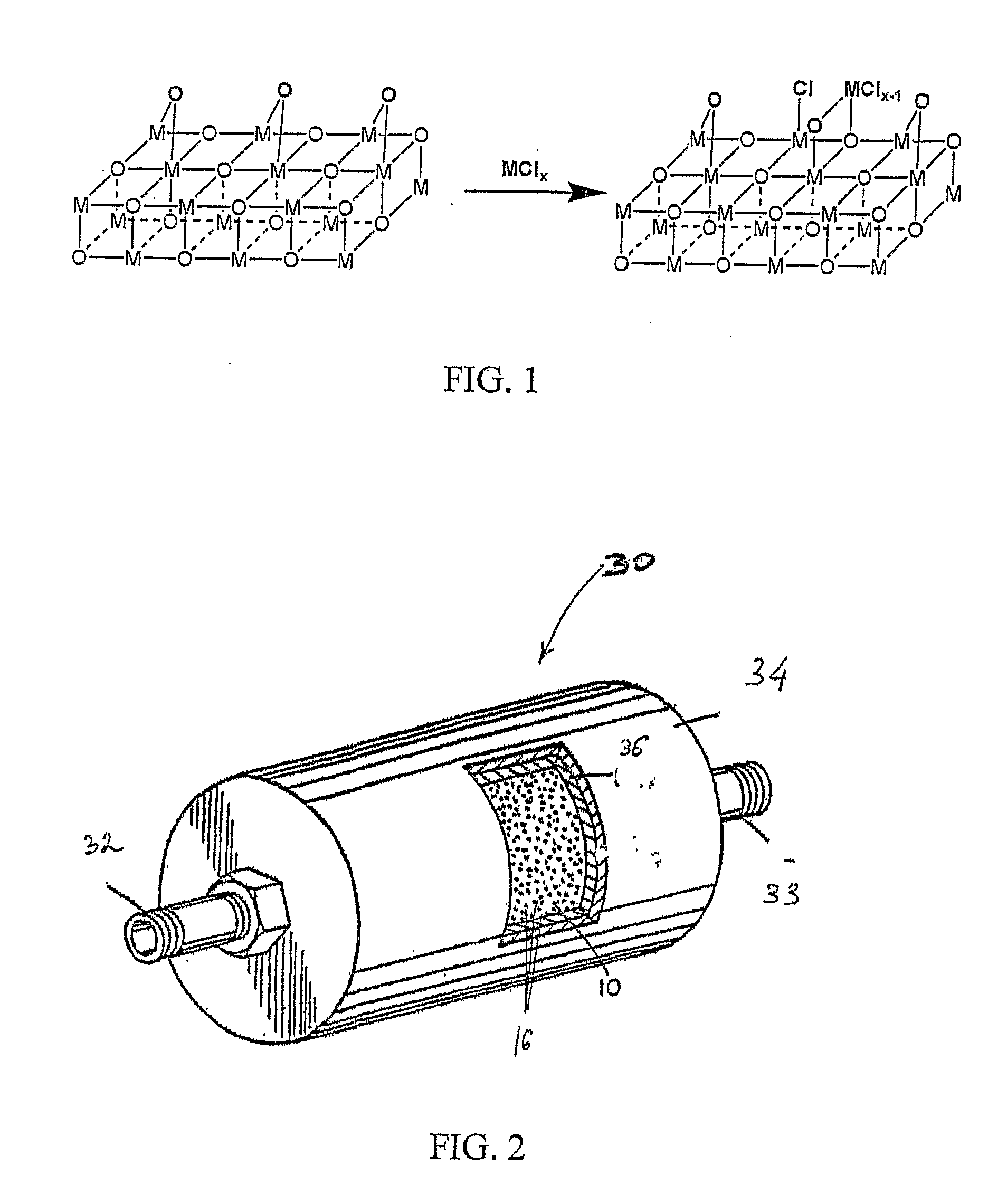

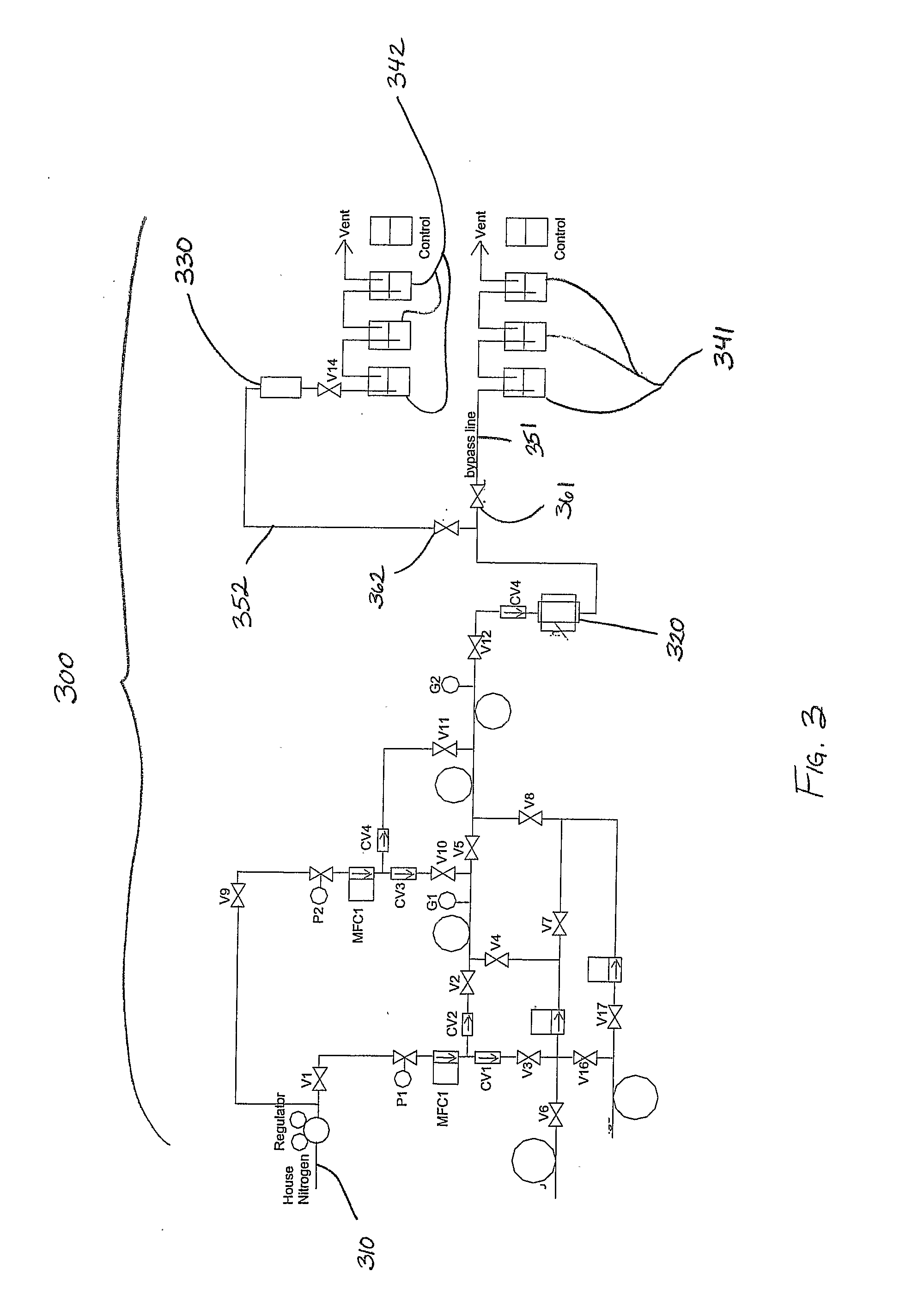

Hydride gas purification for the semiconductor industry

ActiveUS20060188420A1Increase capacityOrganic chemistryNitrogen compoundsRare-earth elementLanthanide

Owner:MYKROLIS CORP +1

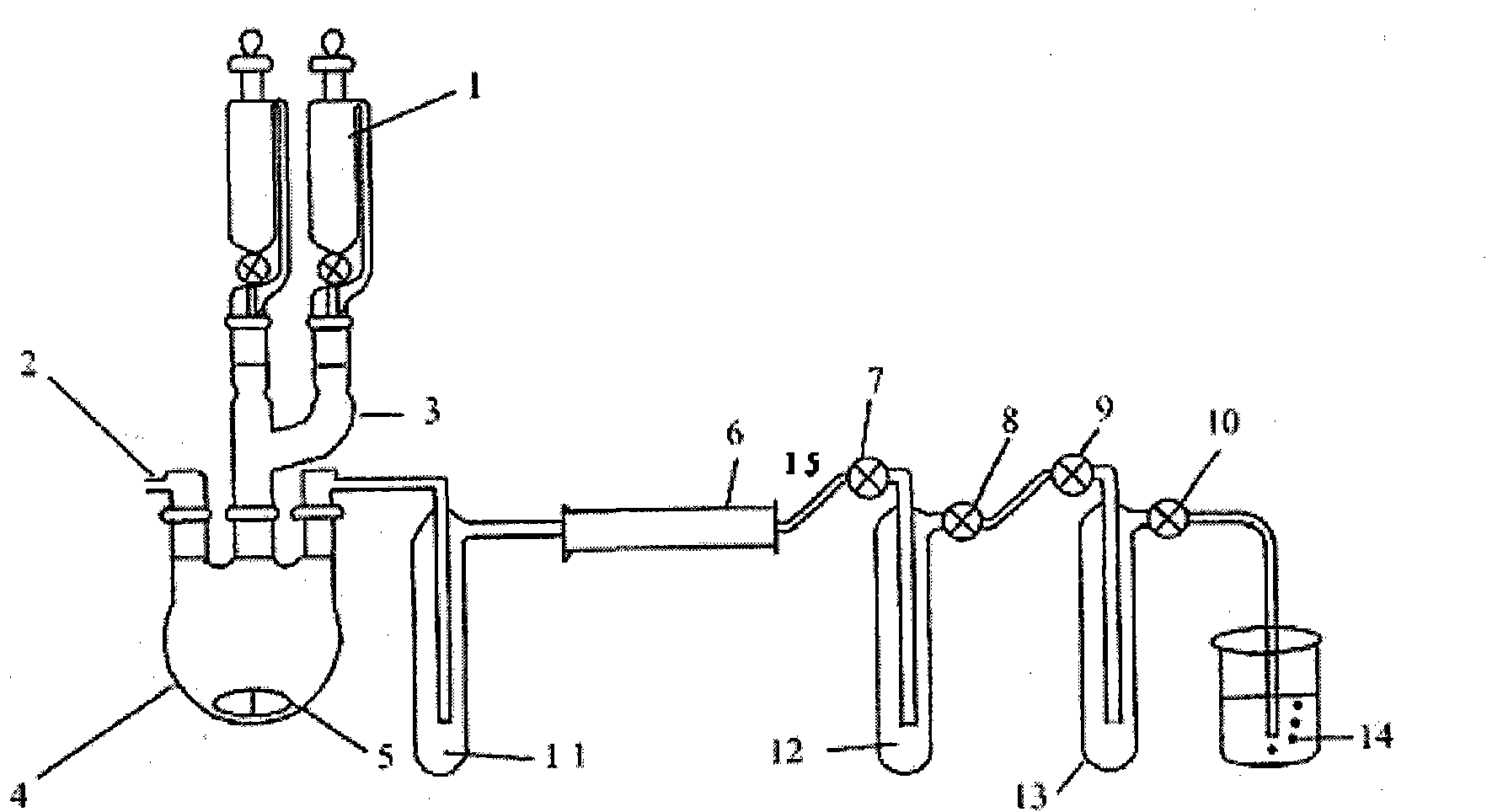

Phosphine fast-generating device and the method used by the device

InactiveUS20050255025A1Avoid dangerChemical/physical/physico-chemical processesLiquid-gas reaction processesNitrogenPhosphoric acid

A phosphine fast-generating device comprises a tank; a reaction chamber formed in the tank; an agent input opening installed at an upper side of the reaction chamber; a nitrogen injection system, a high pressure spraying system and a phosphine purifying system connected to the upper side of the reaction chamber; a pressure reduction chamber connected to the phosphine purifying system; the pressure reduction chamber being retained in a negative pressure so that when the phosphine passes through the phosphine purifying system, the phosphine will be purified and thus the phosphine is sucked in the pressure reduction chamber. Moreover, a phosphine fast-generating method for generating phosphine in the phosphine fast-generating device is also disclosed.

Owner:CHEN HUNG YI

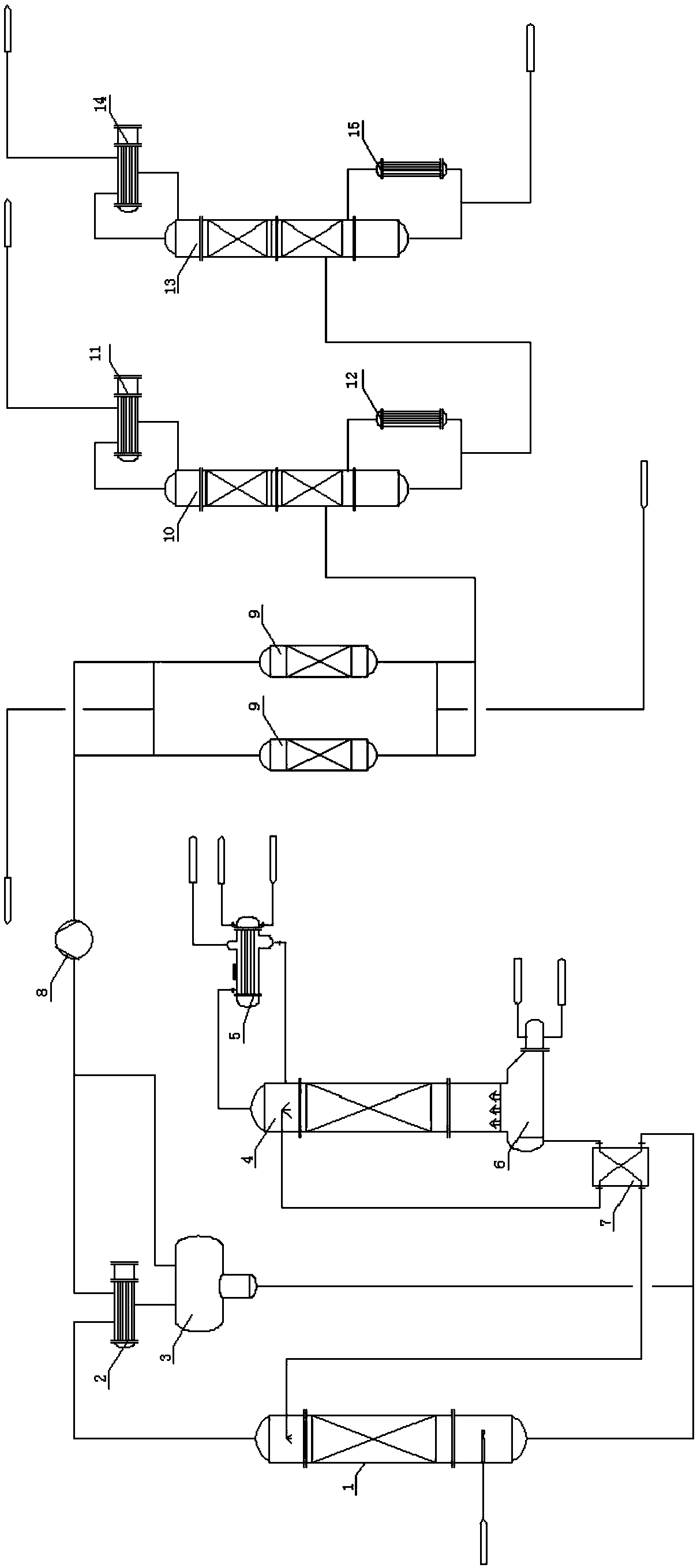

Electronic grade phosphorane purification system and processing method

The invention discloses an electronic grade phosphorane purification system. The electronic grade phosphorane purification system comprises an absorbing tower, a compressor, an adsorption system, a light removal rectifying tower, and a heavy removal rectifying tower. The invention also discloses an electronic grade phosphorane processing method. The method comprises the following steps: a phosphorane raw material is introduced in the tower from bottom of the absorbing tower, realizes counter-current contacting with absorption liquid from down to up, and the whole hydrogen sulfide and carbon dioxide accounting for 10-40% of that of total amount are absorbed; gas at the top of the absorbing tower is compressed through a compressor and is introduced to the adsorption system, and passes through an adsorbent layer for absorbed dehydration from up to down; the gas through the absorbed dehydration is introduced to the light removal rectifying tower for rectification, a light component is discharged from the top of the light removal rectifying tower to a condenser at the top of the light removal rectifying tower, a heavy component is introduced to the heavy removal rectifying tower for rectification, the light component is discharged from the top of the tower and is discharged to the condenser at top of the heavy removal rectifying tower, and noncondensable gas at the top of the condenser is a phosphorane finished product. The phosphorane purification system takes amine liquid as absorption liquid, and the purity of the obtained phosphorane is greatly increased, which can achieve 7N.

Owner:南京佳华科技股份有限公司

Modified adsorbent for purifying low-concentration phosphine and preparation method thereof

InactiveCN101564678AAchieve dephosphorizationHigh adsorption activityOther chemical processesHydrogen phosphidesNickel saltSorbent

The invention discloses a preparation method of transitional metal ion Ni modified adsorbent for purifying low-concentration phosphine, without the need of adding accelerating agents such as noble metal (AgO) and high-contamination noble metal (HgO and CdO) and the like, and application thereof. The preparation method is characterized in that one of general adsorbents is taken as a carrier, soluble nickel salts are taken as active components, and the general absorbent is taken as a carrier; as the nickel salts as the active components are loaded on the general absorbent, when the Ni ion modified adsorbent is used for adsorbing waste gas containing phosphine, the waste gas is adsorbed by the surface of the modified adsorbent; waste gas dephophorization can be realized after the adsorption is saturated, and the adsorption activity is higher within the temperature range of 20-90 DEG C, therefore, undoubtedly, the adsorbent of the invention provides a simple and easy way for the purification of waste gas containing phosphine.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing hydrogen phosphide by utilizing phosphorous acid pyrolysis

ActiveCN103318860AReduce energy consumptionReduce corrosionHydrogen phosphidesPhosphorous acidPlatinum

The invention discloses a method for producing hydrogen phosphide by utilizing phosphorous acid pyrolysis. A platinum-carbon catalyst is utilized for pyrolyzing phosphorous acid at 150 DEG C-200 DEG C, so that high-purity hydrogen phosphide is obtained. The method for producing hydrogen phosphide by utilizing phosphorous acid pyrolysis disclosed by the invention is low in reaction temperature, small in energy consumption, high in product yield and lower in corrosion to the device.

Owner:南京韦福化工技术有限公司

Preparation method of phosphine

InactiveCN103342346AHigh yieldReduce manufacturing costPhosphoric acidHydrogen phosphidesPhosphorous acidPhosphoric acid

The invention relates to a preparation method of phosphine. The preparation method comprises the following steps of: generating phosphine, hypophosphite and phosphite from yellow phosphorus under the action of a base, processing the hypophosphite and the phosphite by using an inorganic acid to obtain a mixture of hypophosphorous acid and phosphorous acid, and performing pyrolysis on the mixed acid to generate the phosphine and a byproduct, namely phosphoric acid. During the whole technological process of the preparation method, the byproducts, namely a sodium salt and the phosphoric acid are produced, the emission of wastes is reduced, and the yield of the phosphine is greatly improved by 50-68.3% in comparison with the highest yield of a traditional base method process.

Owner:南京宏福高端膦技术研发中心有限公司

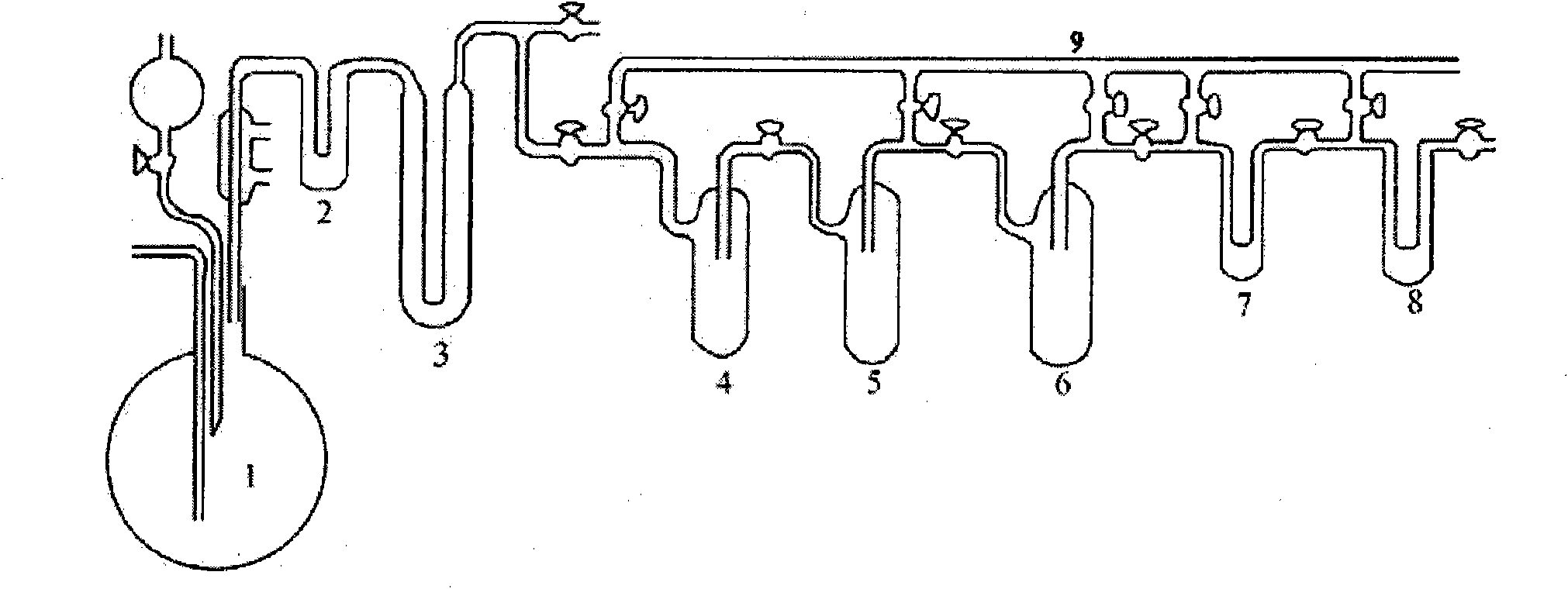

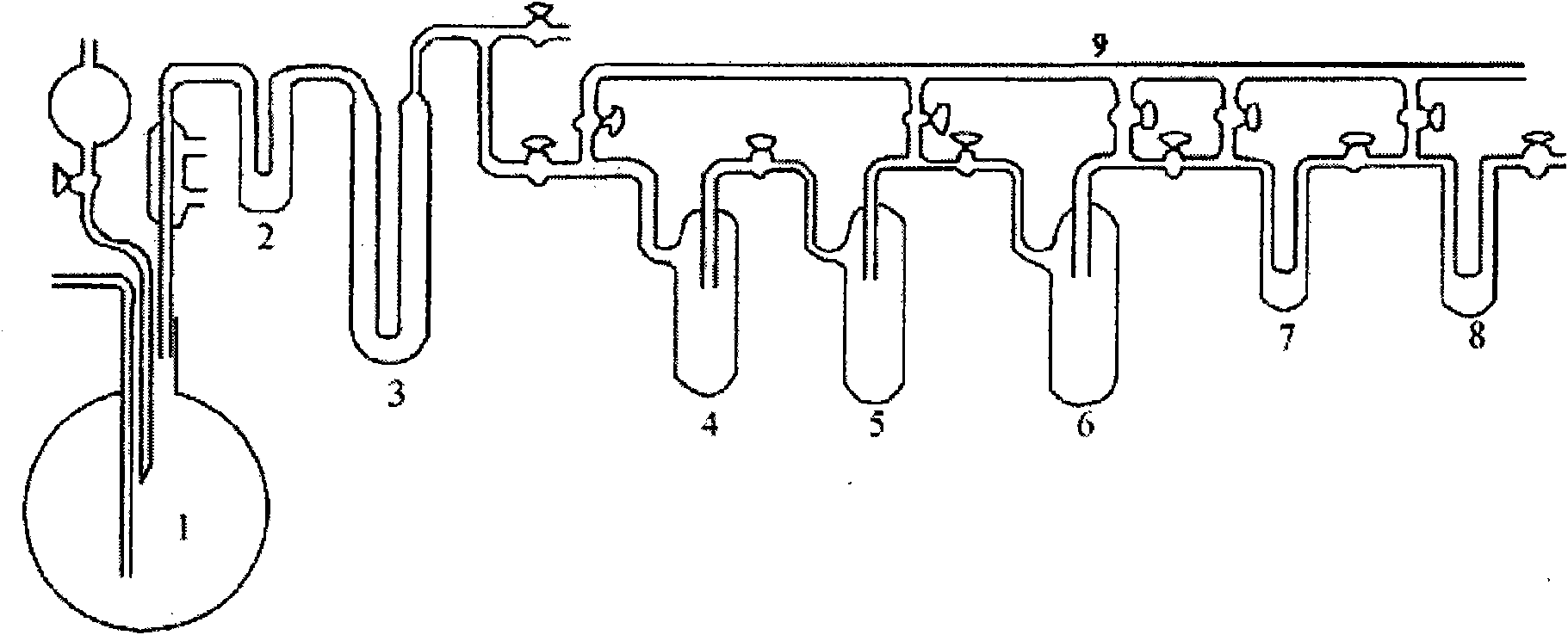

Technique for preparing phosphine by heating white phosphorous placed into potassium hydroxide solution

InactiveCN101955172AIdeal preparation technologyReasonable designHydrogen phosphidesPotassium hydroxidePhysical chemistry

The invention discloses a technique for preparing phosphine by heating white phosphorous placed into potassium hydroxide, mainly composed of a generating bottle, a first cold trap, a drying tube, a second cold trap, a third cold trap, a fourth cold trap, a fifth cold trap and a sixth cold trap which are assembled into a whole by virtue of connecting pipelines according to system function. The invention has reasonable design and use convenience, thus being an ideal phosphine preparation process technology.

Owner:TIANJIN TAIYUAN INDAL GAS

Technology for preparing phosphine by reacting aluminium phosphide with sulfuric acid

InactiveCN101955170AIdeal preparation technologyReasonable designHydrogen phosphidesPhospholanNitrogen

The invention discloses technology for preparing phosphine by reacting aluminium phosphide with sulfuric acid. In the technology, the upper end of an integrated flask is connected and provided with a constant-pressure charging hopper through a connection pipe and also connected and provided with a nitrogen inlet pipe; an electromagnetic heating stirrer is arranged on inner bottom of the flask; and a KOH drying pipe, a piston 1, a piston 2, a piston3, a piston 4, a catcher 1, a catcher 2 and a catcher 3 are sequentially connected through a connection pipe. The technology has the advantages of reasonable design and convenient use and is ideal technology for preparing phosphine.

Owner:TIANJIN TAIYUAN INDAL GAS

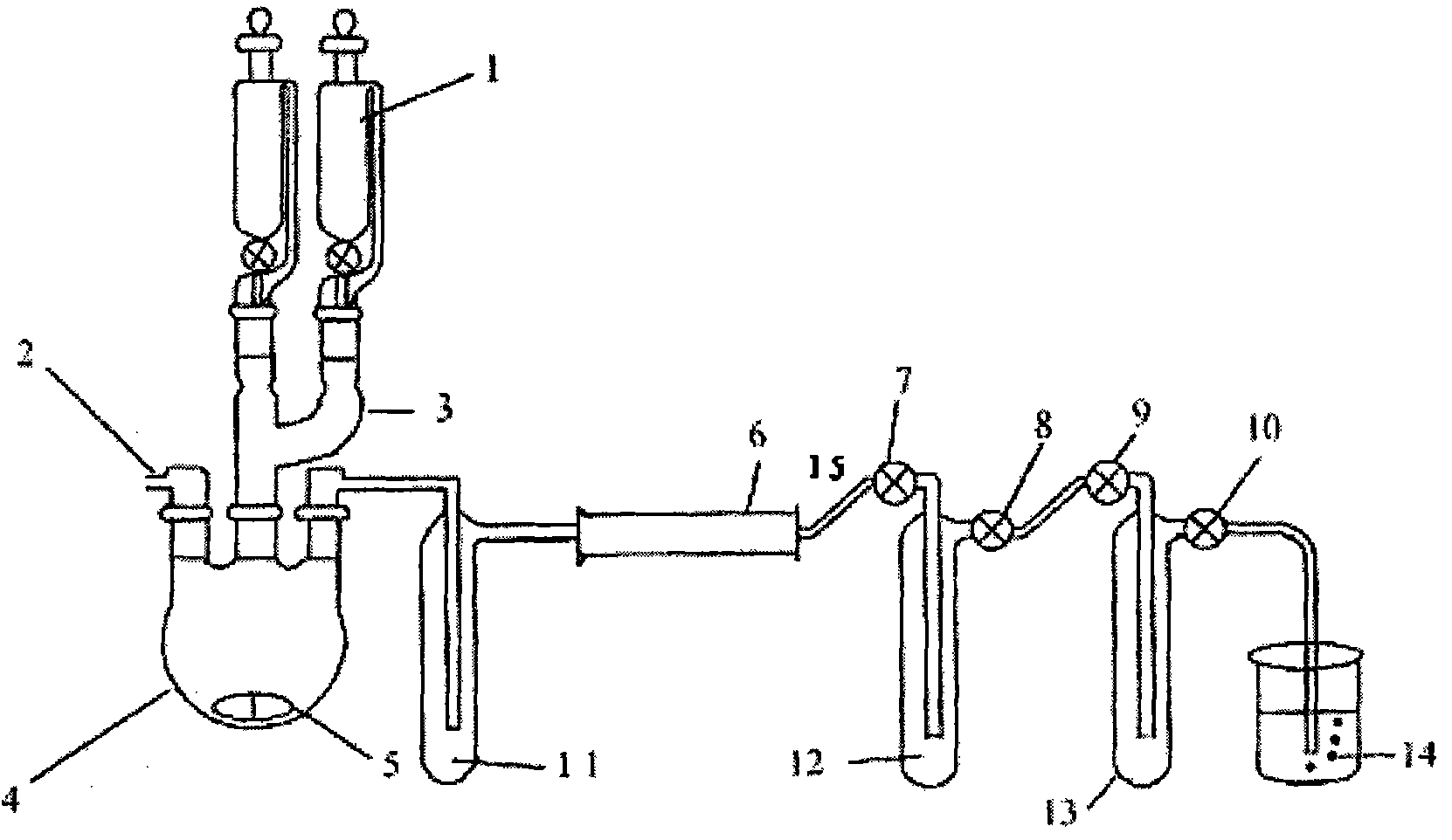

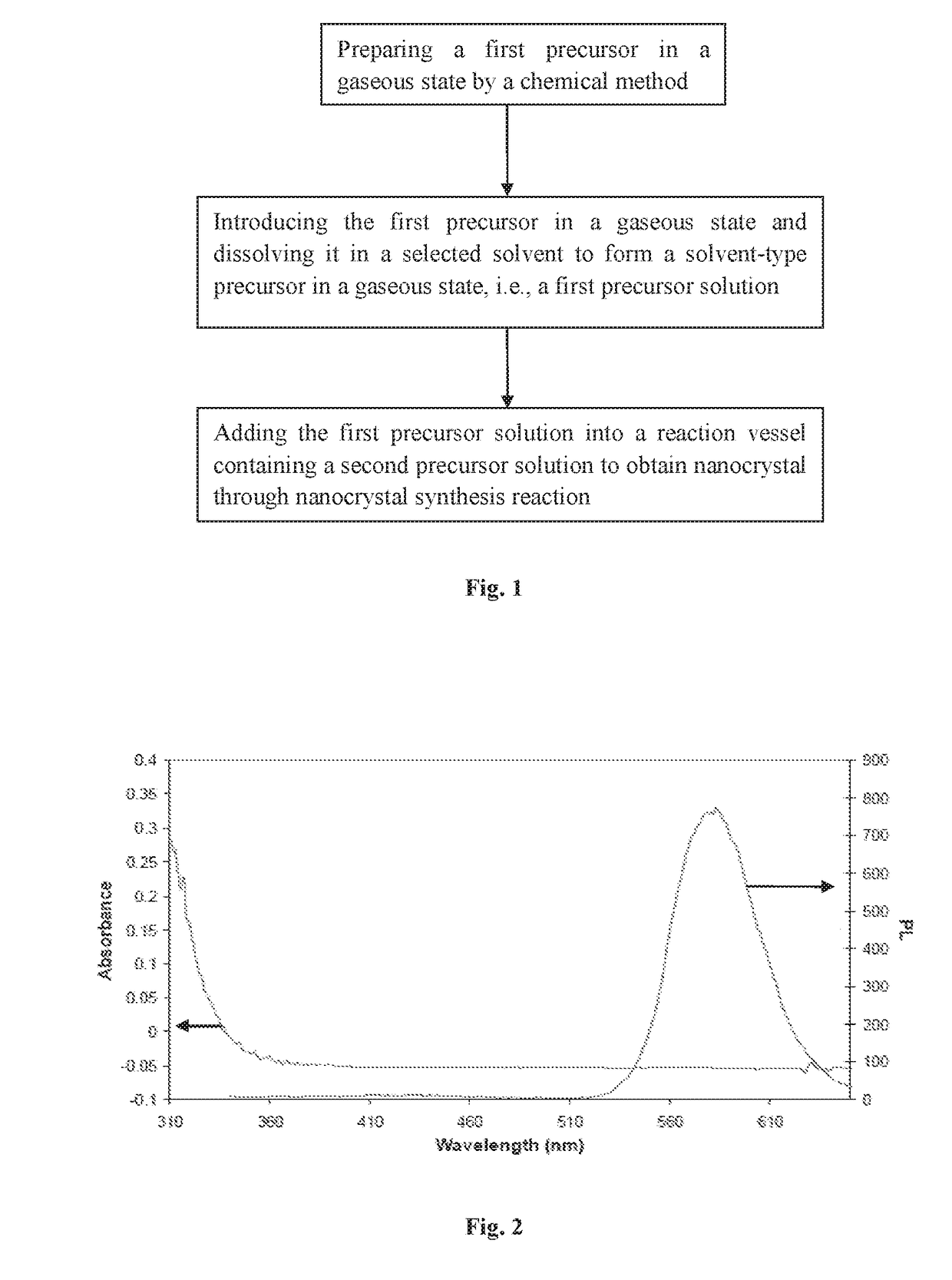

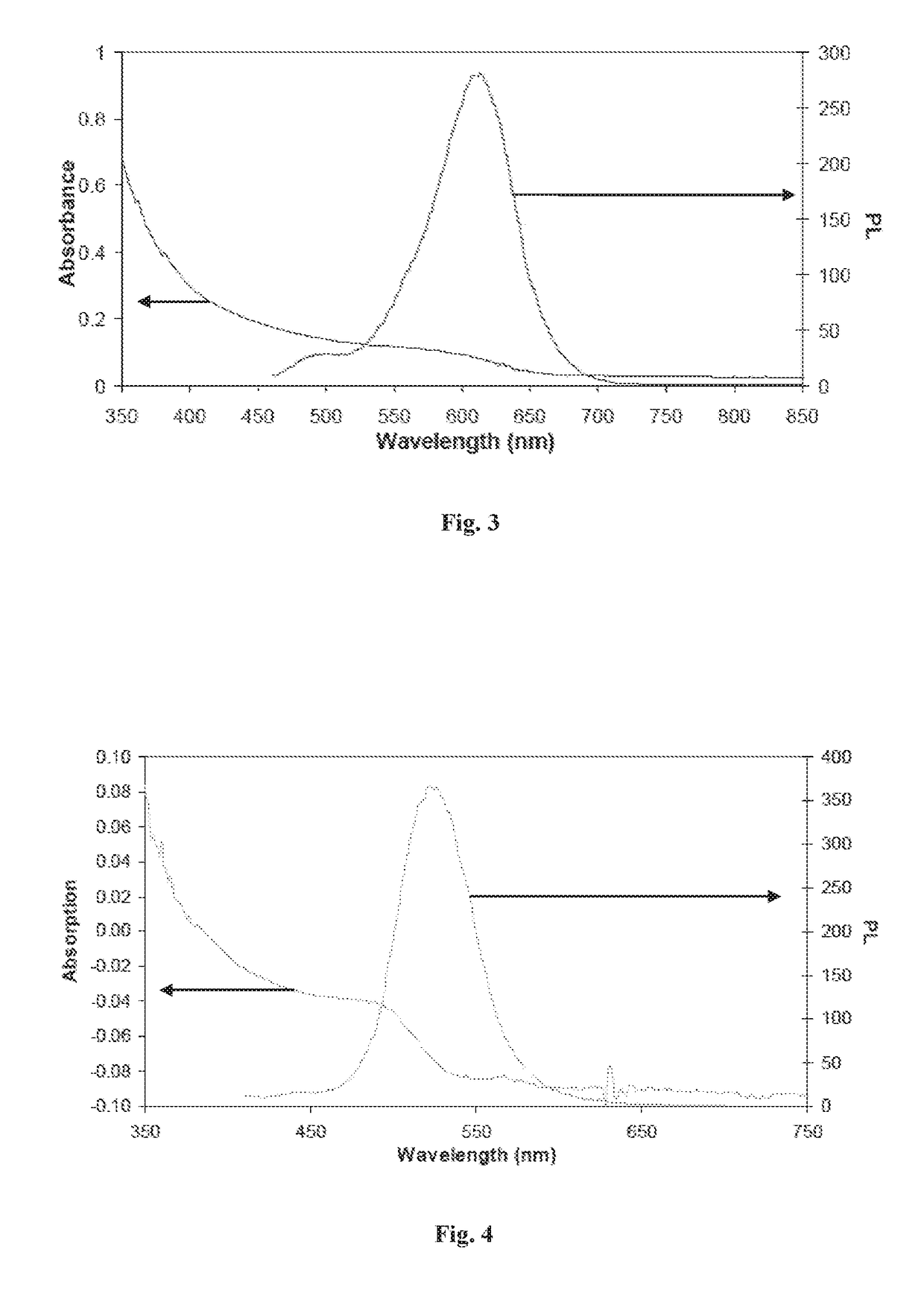

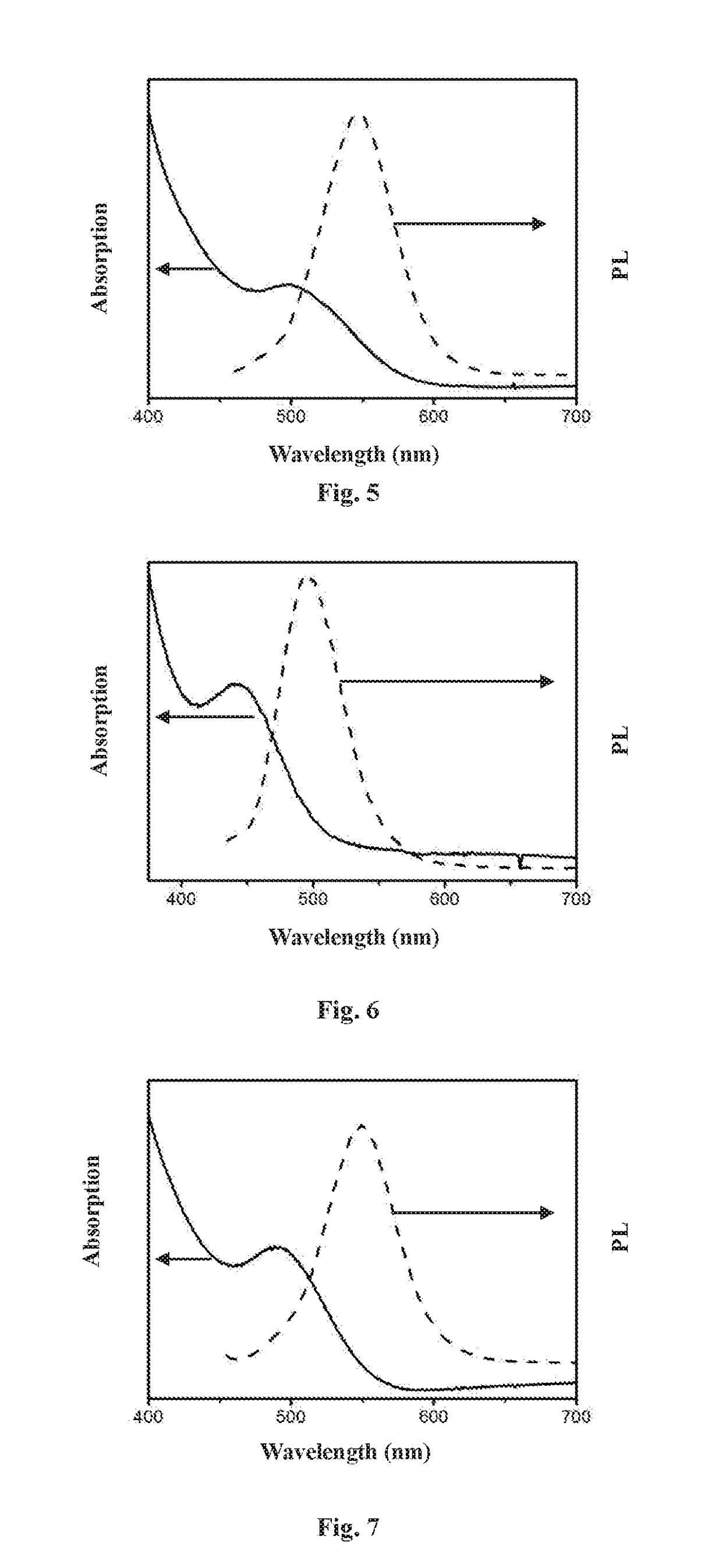

Nanocrystal preparation method, nanocrystals, and apparatus for preparing and storing dissolved gas

ActiveUS20190055126A1Small peak widthHigh Luminescence Quantum YieldMaterial nanotechnologyMicroballoon preparationLuminescence quantum yieldChemical reaction

A nanocrystal preparation method comprises the following steps: dissolving, in a first selected solvent, a first precursor which is in a gaseous state under normal temperature and normal pressure, to form a first precursor solution; dissolving a second precursor in a second selected solvent to form a second precursor solution, wherein the second precursor is a precursor of a metal element of Group I, Group II, Group III or Group IV; and in an inert gas atmosphere, adding the first precursor solution into a reaction vessel which contains the second precursor solution, wherein the first precursor chemically reacts with the second precursor to generate a nanocrystal. The present invention further discloses a nanocrystal prepared by the above method and an apparatus for preparing and storing a gas-dissolved solution. With the preparation method according to the invention, the amount of the first precursor in a gaseous state can be accurately controlled, the reaction is more uniform and more controllable, and the obtained nanocrystal has uniform volume distribution and a higher luminescent quantum yield.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Technique for preparing phosphine by performing hydrolysis reaction on aluminium phosphide

InactiveCN101955171AIdeal preparation technologyReasonable designHydrogen phosphidesEngineeringHydrolysis

The invention discloses a technique for preparing phosphine by performing a hydrolysis reaction on aluminium phosphide. Particularly, the technique adopts the following technical scheme that: a gas inlet pipe is connected with and installed at the lower end of an integrated reaction chamber; the reaction chamber is connected with a conduit through one end of a gas outlet pipe; the conduit is connected with a fumigant transfer pipe; a fan is connected with and installed on the lower part of the fumigant transfer pipe; the fan is connected with the reaction chamber through the other end of the gas outlet pipe; the upper part of the reaction chamber is connected with a cartridge case through a slim tube; a piston is connected to and installed in the cartridge case; a driving plate is connected with and installed at the upper end of the piston; and a gas distributing plate and a stirrer are connected to and installed in the reaction chamber. The technique has reasonable design, is convenient for use and is an ideal process technique for preparing the phosphine.

Owner:TIANJIN TAIYUAN INDAL GAS

Hydride gas purification for the semiconductor industry

ActiveUS7510692B2Highly efficient gas purification substrateEfficient removalOrganic chemistryNitrogen compoundsRare-earth elementLanthanide

Owner:MYKROLIS CORP +1

Removal Of Metal Contaminants From Ultra-High Purity Gases

InactiveUS20080107580A1Improve production stabilityDefective products are minimizedHydrogen bromideNitrogen compoundsUltra high purityDevice failure

The invention is a method and apparatus for removing metal compounds from ultra-high purity gases using a purifier material comprising a high surface area inorganic oxide, so that the metals do not deposit on a sensitive device and cause device failure.

Owner:ENTEGRIS INC

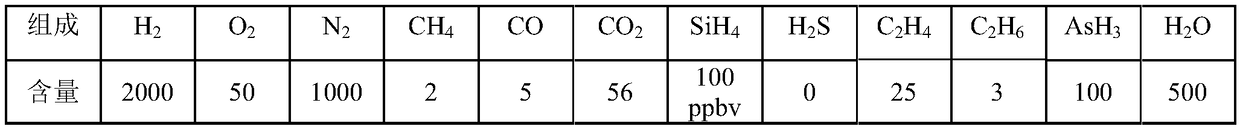

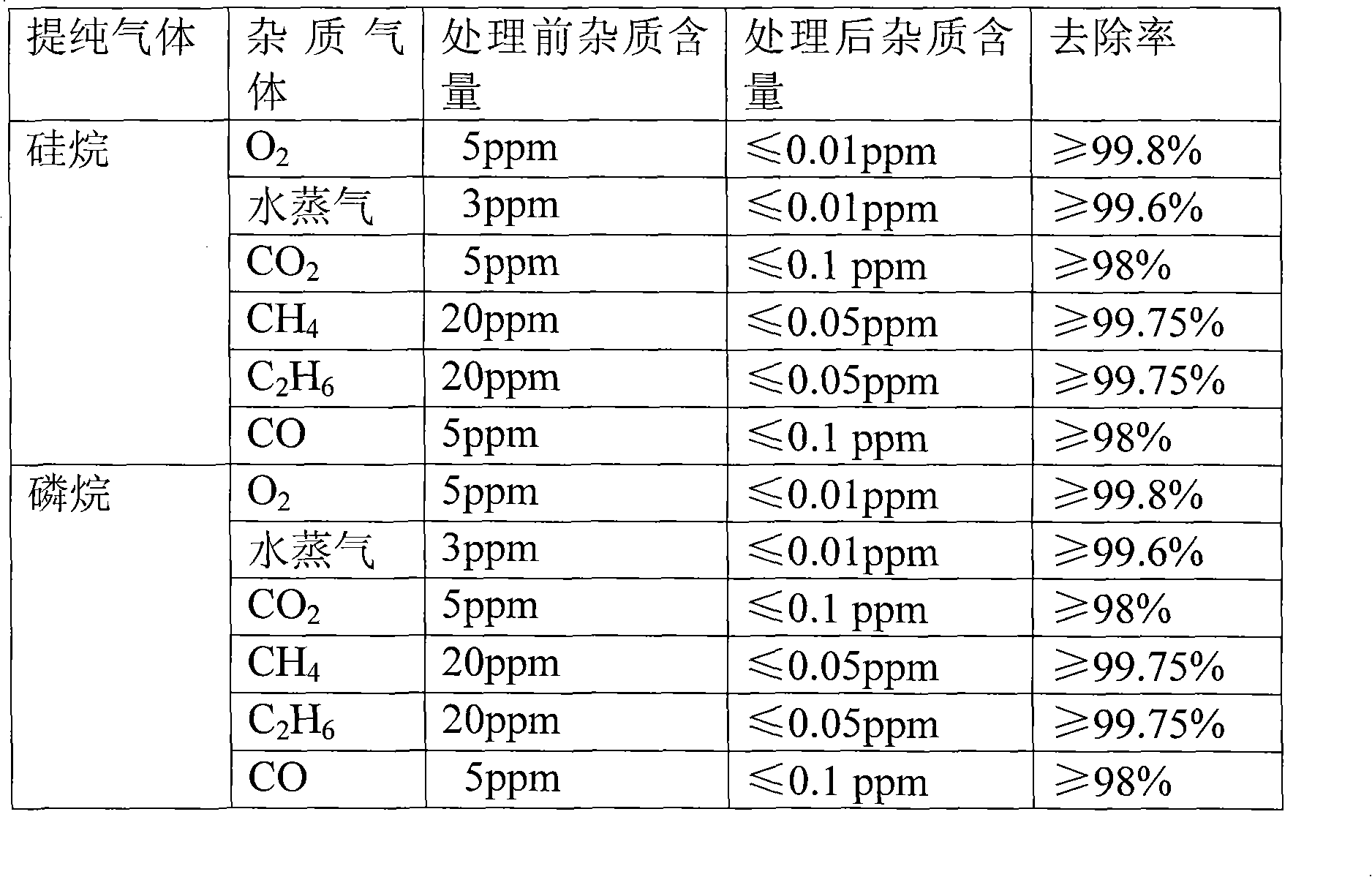

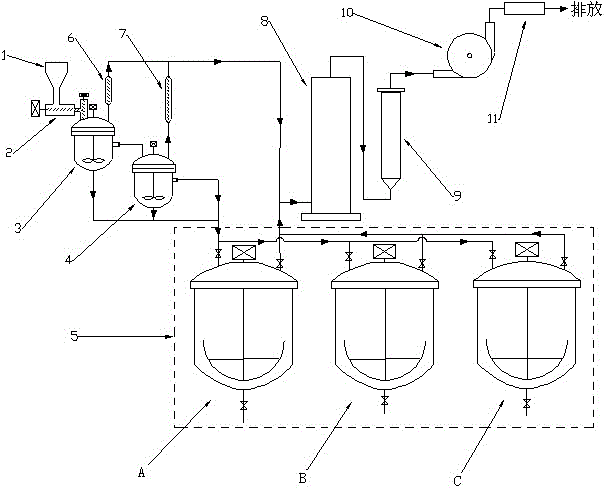

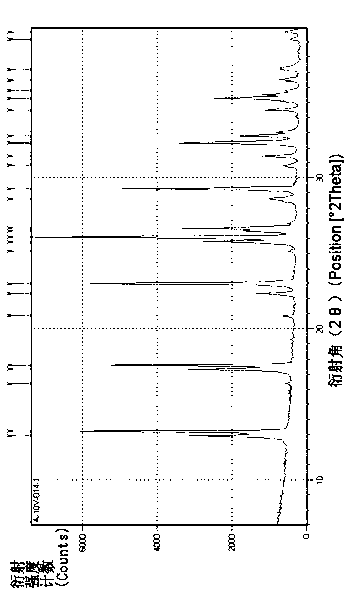

Purification adsorption agent for silicone hydride, phosphorane, arsine or borane gases and preparation method thereof

InactiveCN101342478AHigh removal rateHigh purityOther chemical processesSilicon hydridesMetallic aluminumSorbent

The invention discloses to a refining adsorbent for silane gas, phosphorane gas, arsine gas or borane gas and a preparation method thereof, relating to a gas refining adsorbent and a preparation method. The invention solves the problems that the removal rate of foreign gas in the silane gas, the phosphorane gas, the arsine gas or the borane gas by adopting the prior palladium powder adsorbent is low, thereby needing further assistant decomposition. The refining adsorbent consists of a carrier and a metallic aluminum layer on the surface of the carrier. The preparation method is as follows: in the presence of hydrogen gas, mixed gas of the hydrogen gas and aluminum methide is sprayed on the surface of the carrier in the temperature of 600 to 650 DEG C so as to obtain the refining adsorbent for the silane gas, the phosphorane gas, the arsine gas or the borane gas. Under the condition that the assistant decomposition is not added, the refining adsorbent of the invention is tested to show a result that the removal rate of CO2 is higher than 95 percent; the removal rate of CH4 is higher than 98 percent; the removal rate of C2H6 is higher than 98 percent; the removal rate of O2 is higher than 99.8 percent; the removal rate of CO is higher than 95 percent; and the removal rate of water vapor is higher than 99.6 percent.

Owner:王少志

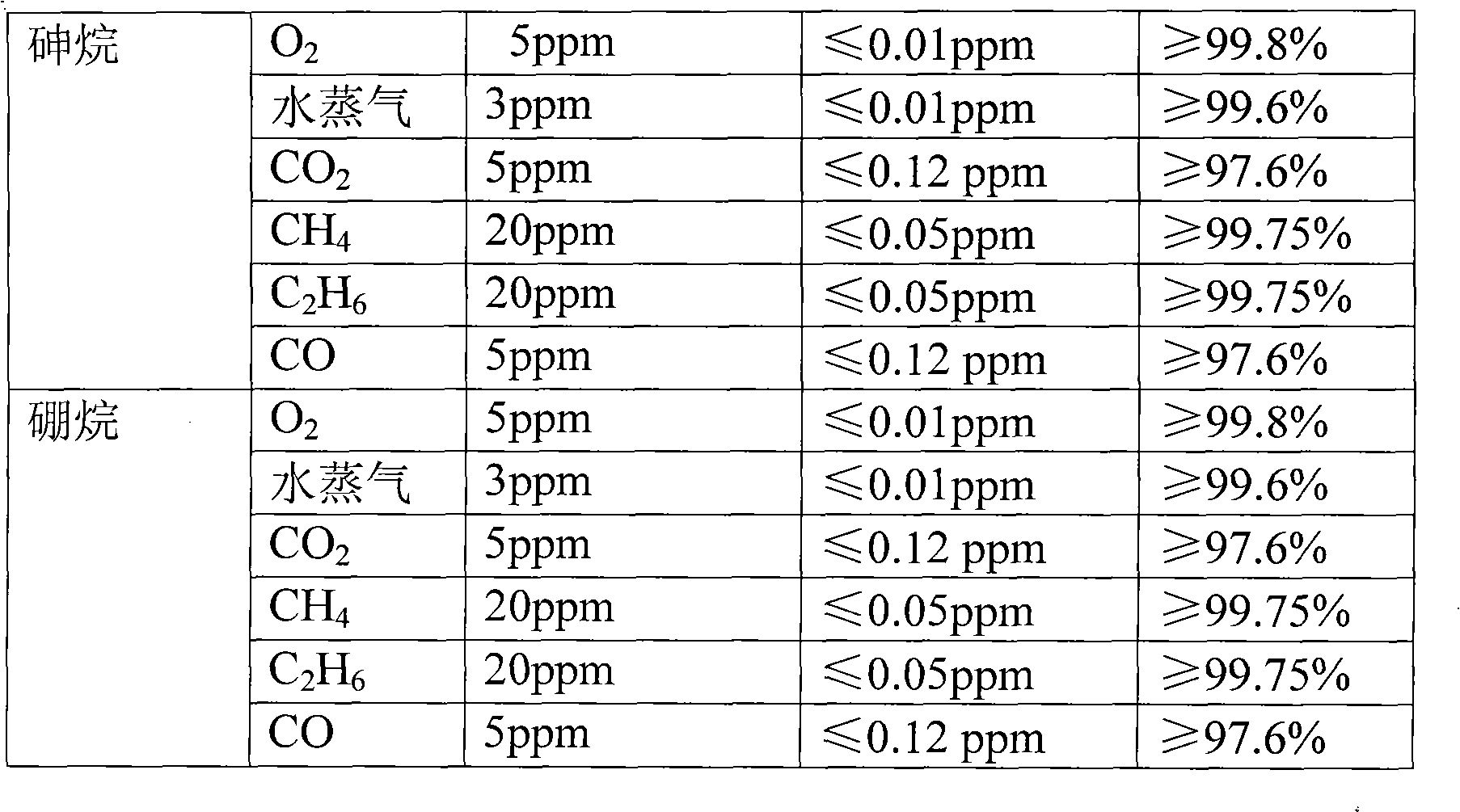

Safe production technique for manufacturing high-purity phosphine on large scale

InactiveCN104058375AAvoid pollutionAvoid corrosionChemical industryHydrogen phosphidesEthylic acidEngineering

The invention discloses a safe production technique for manufacturing high-purity phosphine on large scale. Aluminum phosphide and deionized water or zinc phosphide and acetic acid used as raw materials are subjected to sealed solid feeding, negative-pressure three-stage cascade reactor reaction, low-temperature low-pressure trapping purification, tail gas oxidation trivalent phosphorus removal, and absorption of phosphorus pentoxide by alkali liquor and activated charcoal under closed reaction conditions. The technique can simultaneously satisfy the four requirements of capability of large-scale industrial manufacturing from laboratories to industrialization, control on the virulent phosphine in air in the production workshop and surrounding environment to be lower than allowable concentration, no intricate corrosion problem in equipment, and high product purity, and provides a safe and reliable production technique for industrial production.

Owner:李达刚 +3

Dephosphorization agent for removing PH3 in yellow phosphorus tail gas, preparation method and application thereof

ActiveCN101590354AHigh phosphorus capacityHigh dephosphorization accuracyDispersed particle separationHydrogen phosphidesAccelerantYellow phosphorus

The invention provides a dephosphorization agent for removing PH3 in yellow phosphorus tail gas, a preparation method and application thereof. The dephosphorization agent comprises the following components by weight percent: 1-10 percent of metal salt, 0.1-10 percent of accelerant and the balance of active carbon. The preparation method comprises the following steps: impregnating the metal salt and the accelerant in selected treated active carbon individually or together according to the proportion, drying for 4-30 hours at 25-150 DEG C, and roasting for 2-4 hours at 150-500 DEG C to obtain the dephosphorization agent. The dephosphorization agent is suitable for removing PH3 in various kinds of gas sources, has favorable adaptability for gas sources, can remove PH3 in sulphureous gas, and has the advantages of high phosphorus capacity, simple flow, wide operation window, simple and convenient dephosphorization agent preparation method, and the like.

Owner:DALIAN CATALYTIC ENG TECH

Method for removing phosphate in sewage by photo-catalytic reduction

InactiveCN101597093AEasy to operateLow costWater/sewage treatment by irradiationHydrogen phosphidesPhotocatalytic reactionPhoto catalytic

The invention relates to a method for removing phosphate in sewage, in particular to a method for removing phosphate in sewage by photo-catalytic reduction; the method is characterized in that: the method comprises the following steps: 1) suspended matters in sewage are removed by pre-treatment; and then the sewage after pre-treatment is added in a photo-catalytic reactor according to the proportion of 1 g : (1 to 100g) of the phosphate in sewage after pre-treatment and nanometer semiconductor photo-catalysts, and then the nanometer semiconductor photo-catalysts are added; 2) the mixture in the photo-catalytic reactor is irradiated by a light source and is stirred for 1 to 480 minutes; the stirring operation is kept and hole trapping agents are added in the e photo-catalytic reactor, and the adding amount of the hole trapping agents is 0.01 to 20 times of the mass of the phosphate in the sewage after the pre-treatment, stirring is carried out for 1 to 60 minutes continuously; 3) the stirring is stopped, and the mixed liquid B formed by sewage, nanometer semiconductor photo-catalysts and the hole trapping agents is precipitated for 10 to 120 minutes, then filtration is carried out, and the filter liquid is discharged or recycled. The method has simple process operation and low cost.

Owner:WUHAN UNIV OF TECH

Phosphine and sodium trimetaphosphate preparation method

The invention discloses a phosphine and sodium trimetaphosphate preparation method, wherein a mixture of a sodium salt of trivalent phosphate and a sodium salt of pentavalent phosphate is heated to a temperature of 300-400 DEG C to be subjected to a disproportionation and condensation reaction under nitrogen protection so as to obtain phosphine and sodium trimetaphosphate, wherein a sodium-phosphorus ratio of the mixture is 0.93-0.99, and a ratio (P<III> / P<V>) of trivalent phosphorus atoms to pentavalent phosphorus atoms of the mixture is 1-1.34. With the method, decomposition and oxidation of an intermediate product phosphine produced from the reaction are avoided, the important chemical industry material phosphine is collected, the condensation reaction for sodium trimetaphosphate production is promoted in the presence of the phosphine, the high purity sodium trimetaphosphate is obtained, long chain high molecule weight substance production is avoided, the sodium trimetaphosphate process is shortened, environmental pollution is reduced, production energy consumption is reduced, production cost is reduced, the whole production process and the final product meet food industry requirements, and comprehensive utilization is achieved.

Owner:江苏先锋生物基技术研究中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com