Electronic grade phosphorane purification system and processing method

A processing method and electronic-grade technology, applied in the field of purification systems, can solve the problems of reducing the downstream processing load and affecting the purity of phosphine, and achieve the effect of reducing the gas-liquid contact time and improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

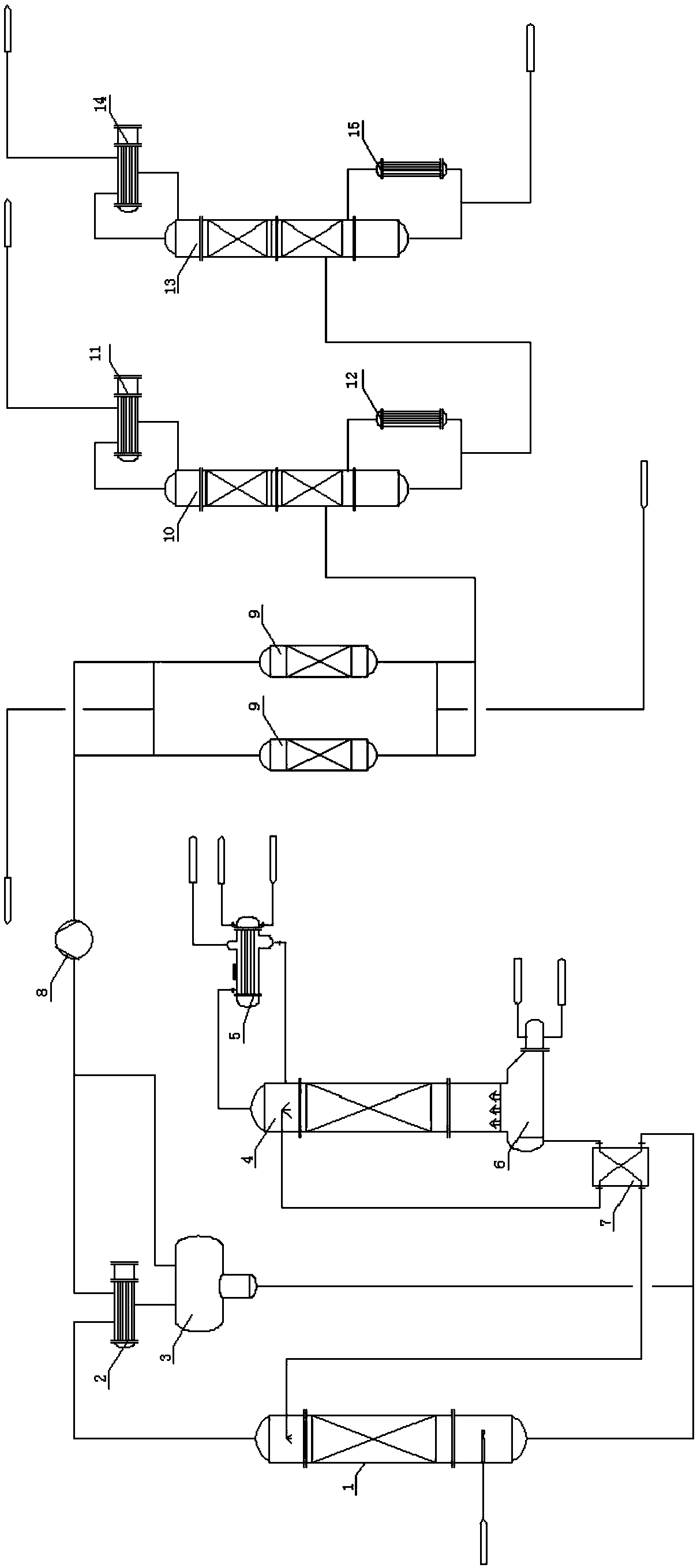

[0035] like figure 1 As shown, a purification system of electronic-grade phosphine includes an absorption tower 1, a condenser 2, a gas-liquid separation tank 3, a desorption tower 4, a desorption tower top condenser 5, a reboiler 6, a heat exchanger 7, Compressor 8, adsorption system, light removal rectification tower 10, light removal rectification tower overhead condenser 11, light removal rectification tower kettle reboiler 12, heavy weight removal rectification tower 13, heavy weight rectification tower Top condenser 14 and reboiler 15 of heavy-removing rectification column tower kettle; Described absorption tower 1 is provided with the lower part air inlet that is used to pass into phosphine raw material, upper absorption liquid inlet, tower bottom liquid outlet, tower top Gas outlet; the top gas outlet of the absorption tower 1 is connected to the condenser 2, the non-condensable gas outlet of the condenser 2 is connected to the air inlet of the compressor 8, and the co...

Embodiment 2

[0056] like figure 1 As shown, a purification system of electronic grade phosphine includes an absorption tower 1, a condenser 2, a compressor 8, an adsorption system, a light removal rectification tower 10, a light removal rectification tower top condenser 11, a light removal rectification tower Distillation column tower kettle reboiler 12, weight-removing rectification tower 13, weight-removing rectification tower overhead condenser 14 and weight-removing rectification tower tower kettle reboiler 15; Described absorption tower 1 is provided with for feeding The lower air inlet of the phosphine raw material, the upper absorption liquid inlet, the liquid outlet at the bottom of the tower, and the gas outlet at the top of the tower; the gas outlet at the top of the absorption tower 1 is connected to the condenser 2, and the non-condensable gas outlet of the condenser 2 It is connected with the air inlet of compressor 8, and the condensate reflux outlet of condenser 2 is connect...

Embodiment 3

[0058] like figure 1 As shown, a purification system of electronic grade phosphine includes an absorption tower 1, a condenser 2, a compressor 8, an adsorption system, a light removal rectification tower 10, a light removal rectification tower top condenser 11, a light removal rectification tower Distillation column tower kettle reboiler 12, weight-removing rectification tower 13, weight-removing rectification tower overhead condenser 14 and weight-removing rectification tower tower kettle reboiler 15; Described absorption tower 1 is provided with for feeding The bottom air inlet and the top gas outlet of the phosphine raw material are filled with zinc oxide or iron oxide in the absorption tower 1; the tower top gas outlet of the absorption tower 1 is connected with the air inlet of the compressor 8; The outlet of the compressor 8 is connected to the inlet of the adsorption system, the adsorption system includes two parallel adsorption towers 9, the adsorption towers 9 are fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com