Blue light cadmium-free quantum dot, preparation method thereof and quantum dot photoelectric device

A quantum dot and blue light technology, applied in the field of blue light cadmium-free quantum dots and their preparation, quantum dot optoelectronic devices, can solve the problems of difficult industrial application, poor nucleation uniformity, poor stability, etc., to control the reaction speed and optimize the uniformity. One degree, the effect of improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing blue cadmium-free quantum dots, which includes the following steps:

[0035] S1, mixing the indium precursor, the first ligand, and the solvent to prepare an indium-first ligand solution, where the first ligand is a long-chain carboxylic acid ligand with 10 to 18 carbons, and the first ligand The ratio of the amount of the carboxylate of the body to the amount of the indium ion of the indium precursor is (1:2) ~ (5:2);

[0036] S2, adding a short-chain zinc salt and a second ligand to the indium-first ligand solution to prepare a cation-mixed ligand solution, wherein at least part of the short-chain zinc salt is coordinated with the second ligand Together

[0037] S3, adding phosphorus precursor to the cation-mixed ligand solution, and obtaining a solution containing indium zinc phosphide quantum dots after the reaction.

[0038] In the present invention, "-" represents the bonding effect of an ionic bond or a coordination bond.

[...

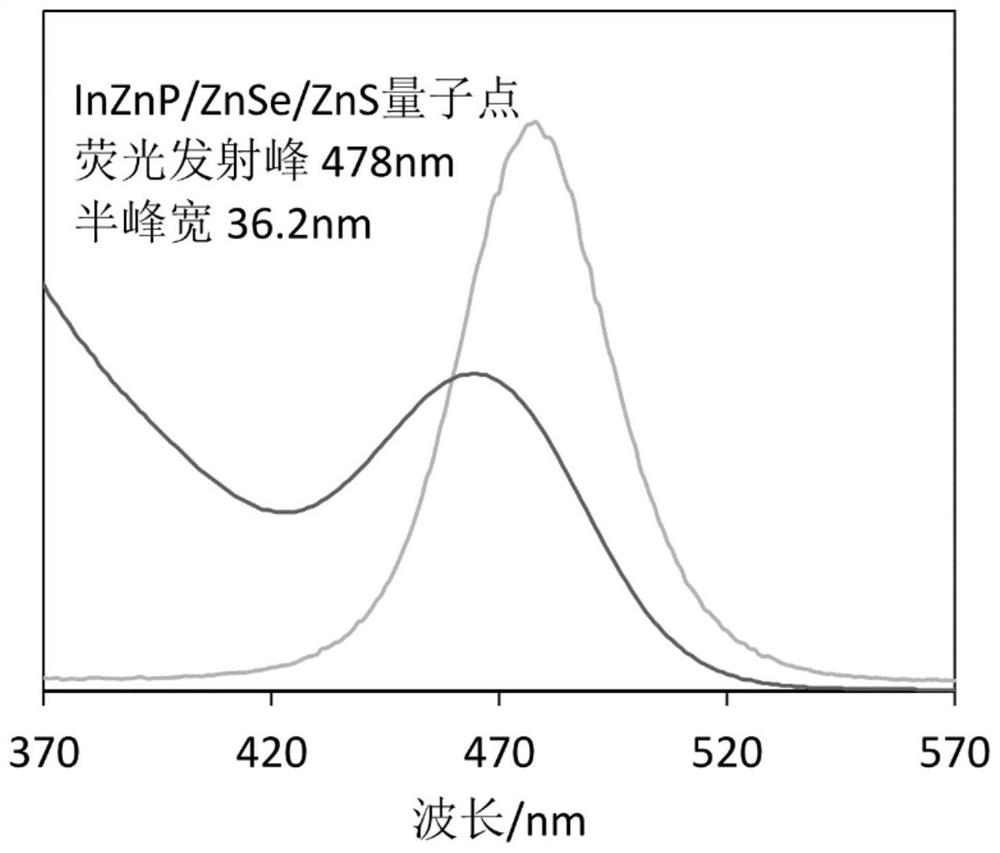

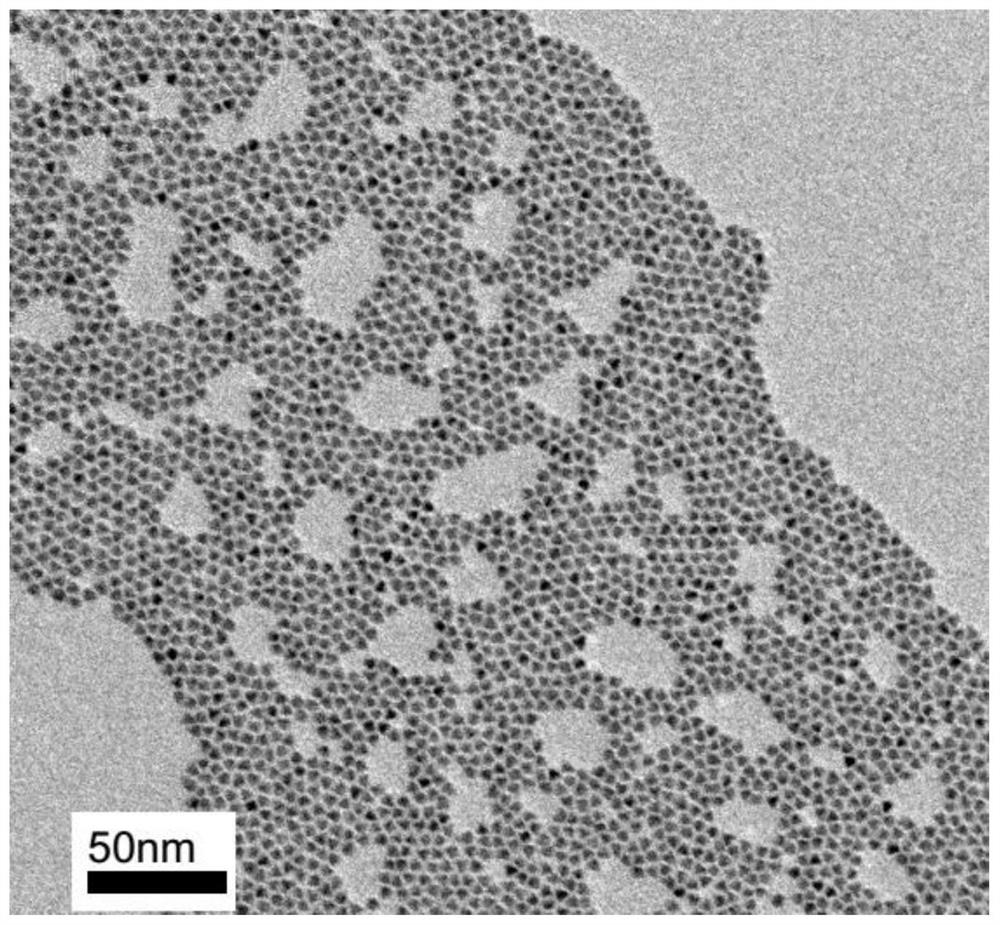

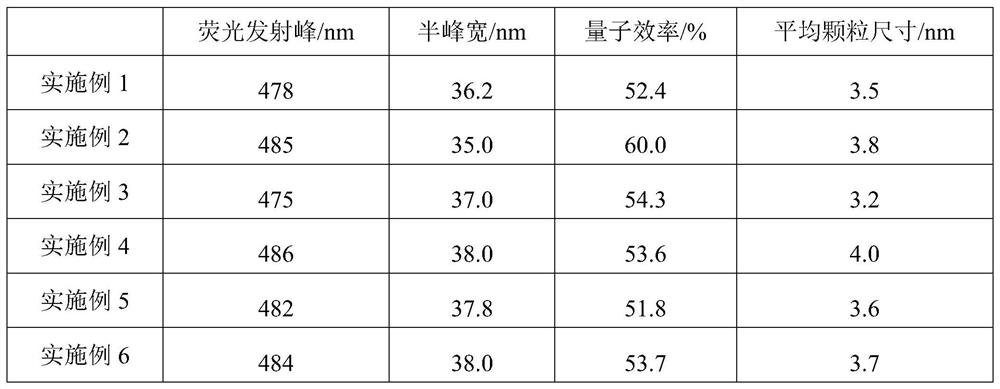

Embodiment 1

[0064] Provide core-shell quantum dots, prepared by the following steps:

[0065] (1) Add 0.3mmol In(Ac) 3 (Indium acetate), 0.3mmol octadecanoic acid and 20mL octadecene were added to a 100mL three-necked flask, and the three-necked flask was placed in N 2 Heat to 180°C under exhaust, and after keeping at 180°C for 30min, add 0.9mmolZn(Ac) 2 (Zinc acetate) and 3.0mmol trioctylamine, react at 180℃ for 10min and then drop to 30℃, quickly inject 0.2mmol TMS-P (tris(trimethylsilyl)phosphine) and 2mL octadecene mixture and then heat up to 300°C, react at 300°C for 5 minutes to obtain a solution containing InZnP quantum dots;

[0066] (2) Keep the reaction temperature at 300℃, add 1.0mmol Zn(OA) to the InZnP quantum dot solution 2 (Zinc oleate), add 0.5mmol Se-TOP (selenium-trioctylphosphine) after reacting for 10min, react at 300℃ for 20min, then add 2.0mmol Zn(OA) to it 2 After reacting for 10 minutes, add 0.8mmol S-TOP (sulfur-trioctyl phosphine), react at 300°C for 30 minutes, and lo...

Embodiment 2

[0070] Provide core-shell quantum dots, prepared by the following steps:

[0071] (1) Add 0.3mmol In(Ac) 3 (Indium acetate), 0.3mmol octadecanoic acid and 20mL octadecene were added to a 100mL three-necked flask, and the three-necked flask was placed in N 2 Heat to 180°C under exhaust, and after keeping at 180°C for 30min, add 0.9mmolZn(Ac) 2 (Zinc acetate) and 3.0mmol trioctylamine, reacted at 180℃ for 10min, and then reduced to 30℃, quickly injected 0.2mmol TMS-P (tris(trimethylsilyl)phosphine) and 2mL octadecene mixture and then heated to 300°C, react at 300°C for 5min, then add 0.2mmol S-TOP (sulfur-trioctylphosphine), react for 5min, to obtain a solution containing InZnP / InZnPS quantum dots;

[0072] (2) Keep the reaction temperature at 300℃, add 1.0mmol Zn(OA) to the InZnP / InZnPS quantum dot solution 2 (Zinc oleate), add 0.5mmol Se-TOP (selenium-trioctylphosphine) after reacting for 10min, react at 300℃ for 20min, then add 2.0mmol Zn(OA) to it 2 After reacting for 10 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com