Quantum dots, preparation method thereof and optoelectronic device

A technology of quantum dots and quantum dot solutions, which is applied in the field of quantum dot luminescent materials, can solve problems such as the difficulty in regulating the composition and structure of quantum dots, and achieve the effects of avoiding self-nucleation, narrowing the half-peak width of fluorescence, and improving the energy band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Since the Cd-free quantum dots in the prior art are difficult to form quantum dots with adjustable composition and structure, in order to improve this situation, in a typical implementation of the present application, a II-III-V-VI quantum dot is provided A preparation method, the preparation method comprising: Step A, preparing the first nanocluster, the second nanocluster and the third nanocluster, wherein the first nanocluster is a III-V nanocluster, and the second nanocluster The clusters are III-II-V nanoclusters, and the third nanoclusters are III-II-VI nanoclusters; step B, mixing the first nanoclusters with a non-coordinating solvent to form the first quantum dot solution; step C, mixing and heating the second nanocluster and the first quantum dot solution to form a second quantum dot solution; step D, mixing and heating the third nanocluster and the second quantum dot solution to form a third quantum dot solution, the third quantum dot solution The third quantu...

Embodiment 1

[0065] (1) The first nanocluster solution: 0.2mmol In(Ac) 3 (Indium acetate), 0.6mmol hexadecanic acid and 6mL ODE (octadecene) join in the 50mL three-necked flask, and this three-necked flask is placed in N 2 Heat to 180°C under exhaust state, keep at 180°C for 30min, then drop to 40°C. Add 0.1 mmol TMS-P (tris(trimethylsilyl)phosphine) and 1 mmol trioctylamine to react for 20 min to form InP nanoclusters, and cool down to room temperature for later use.

[0066] The second nanocluster solution: 0.2mmol In(Ac) 3 (Indium acetate), 0.2mmol Zn(Ac) 2 (zinc acetate), 1.0mmol hexadecanic acid and 6mL ODE (octadecene) were added into a 50mL three-necked flask, and the three-necked flask was heated to 180°C under N2 exhaust state, kept at 180°C for 30min, and then dropped to 60°C. Add 0.1 mmol TMS-P (tris(trimethylsilyl) phosphine) and 5 mmol dioctylamine to react for 20 min to form InZnP nanoclusters, and cool down to room temperature for later use.

[0067] The third nanoclust...

Embodiment 2

[0071] (1) The first nanocluster solution: 0.2mmol In(Ac) 3 (Indium acetate), 0.6mmol hexadecanic acid and 6mL ODE (octadecene) join in the 50mL three-necked flask, and this three-necked flask is placed in N 2 Heat to 180°C under exhaust state, keep at 180°C for 30 minutes, then drop to 60°C. Add 0.04 mmol TMS-P (tris(trimethylsilyl) phosphine) and 1 mmol trioctylamine to react for 20 min to form InP nanoclusters, and cool down to room temperature for later use.

[0072] The second nanocluster solution: 0.2mmol In(Ac) 3 (Indium acetate), 0.1mmol Zn(Ac) 2 (zinc acetate), 0.8mmol hexadecanic acid and 6mL ODE (octadecene) were added into a 50mL three-necked flask, and the three-necked flask was heated to 180°C under N2 exhaust state, and kept at 180°C for 30min, then dropped to 60°C. Add 0.04 mmol TMS-P (tris(trimethylsilyl) phosphine) and 5 mmol dioctylamine to react for 20 min to form InZnP nanoclusters, and cool down to room temperature for later use.

[0073] The third n...

PUM

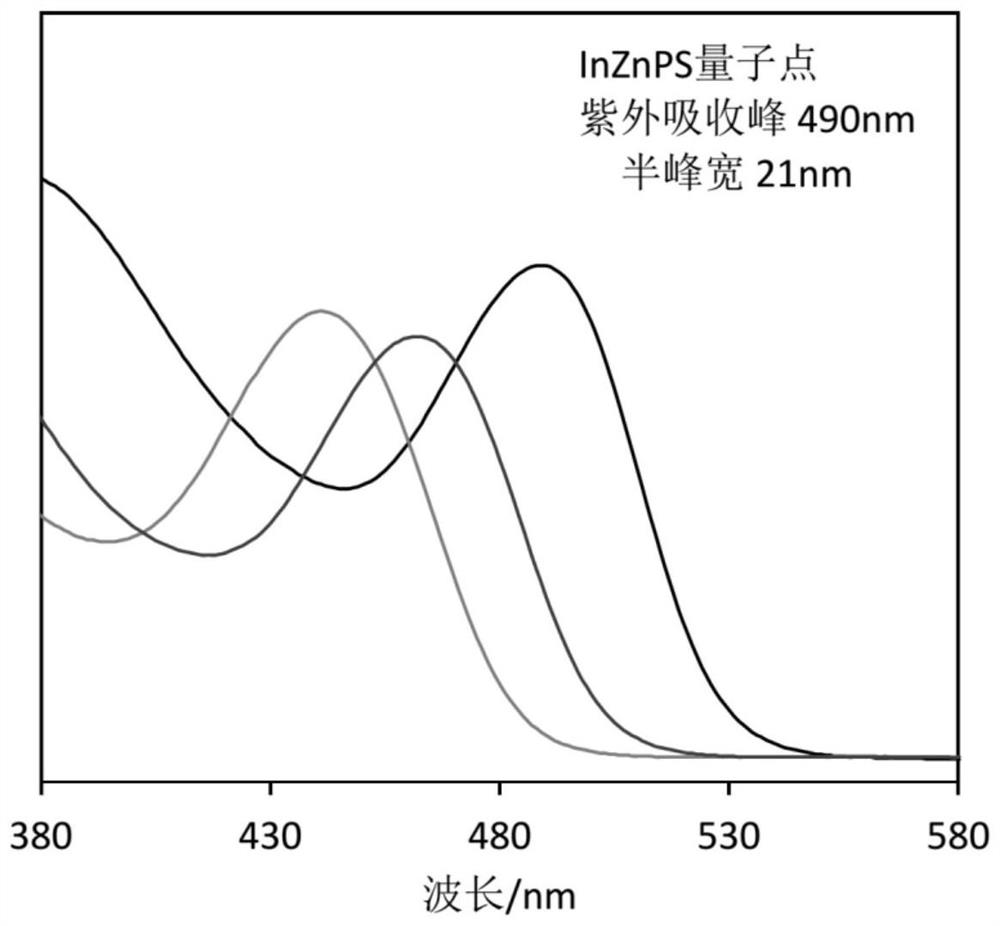

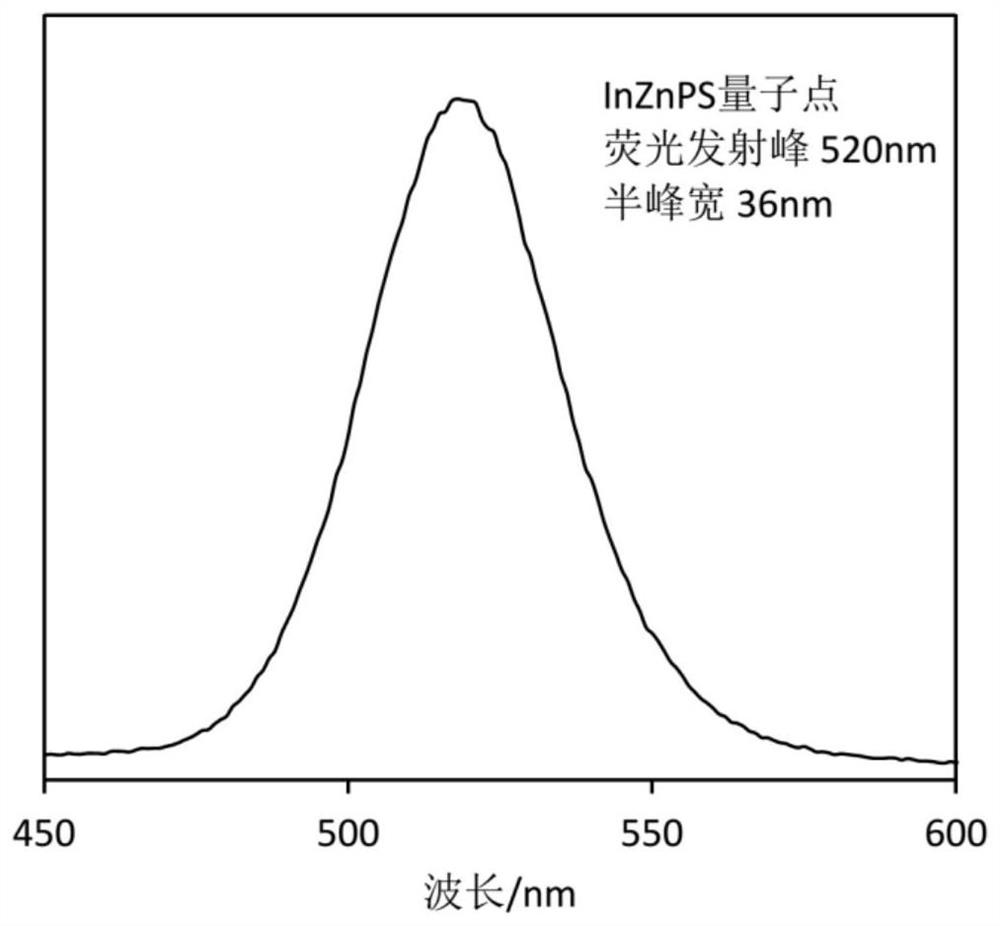

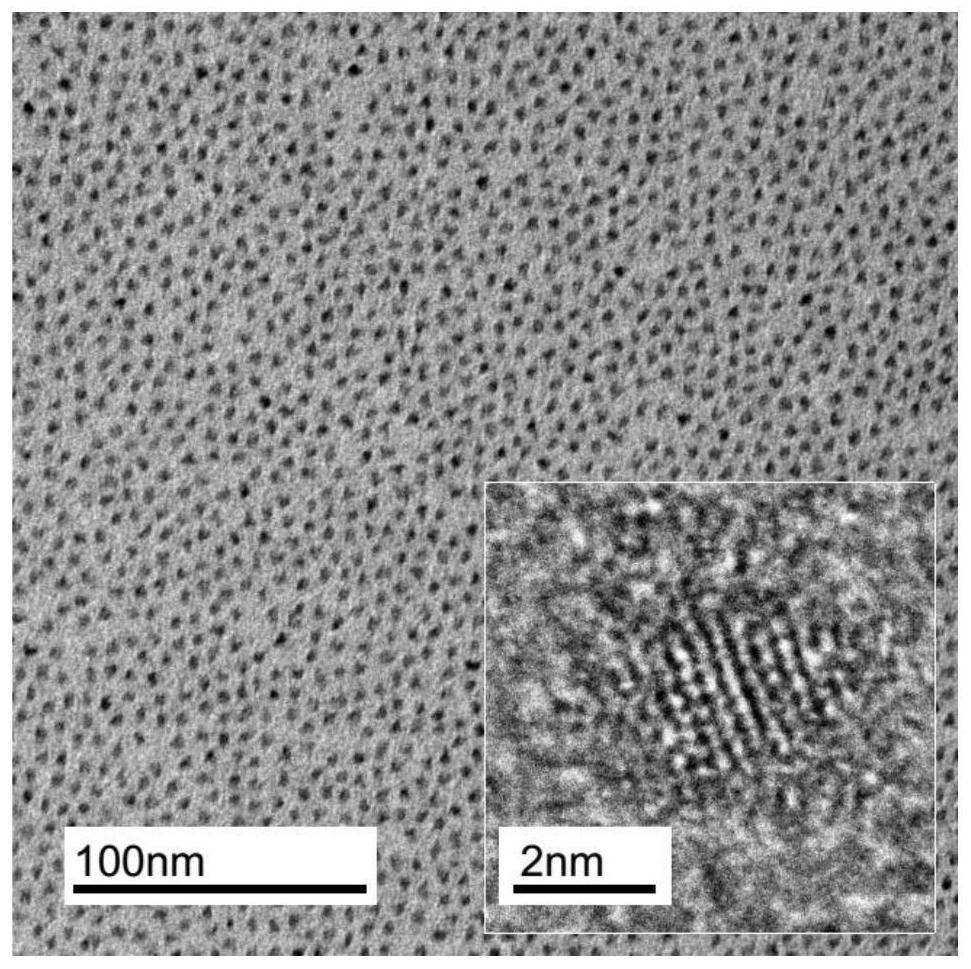

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com