Preparation method of zinc phosphide

A technology of zinc phosphide and metal zinc, which is applied in the field of preparation of tetragonal high-purity zinc phosphide, can solve the problems of low yield, complicated preparation process, uneven composition, etc., and achieve the goal of prolonging the reaction time, increasing the reaction temperature and avoiding damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

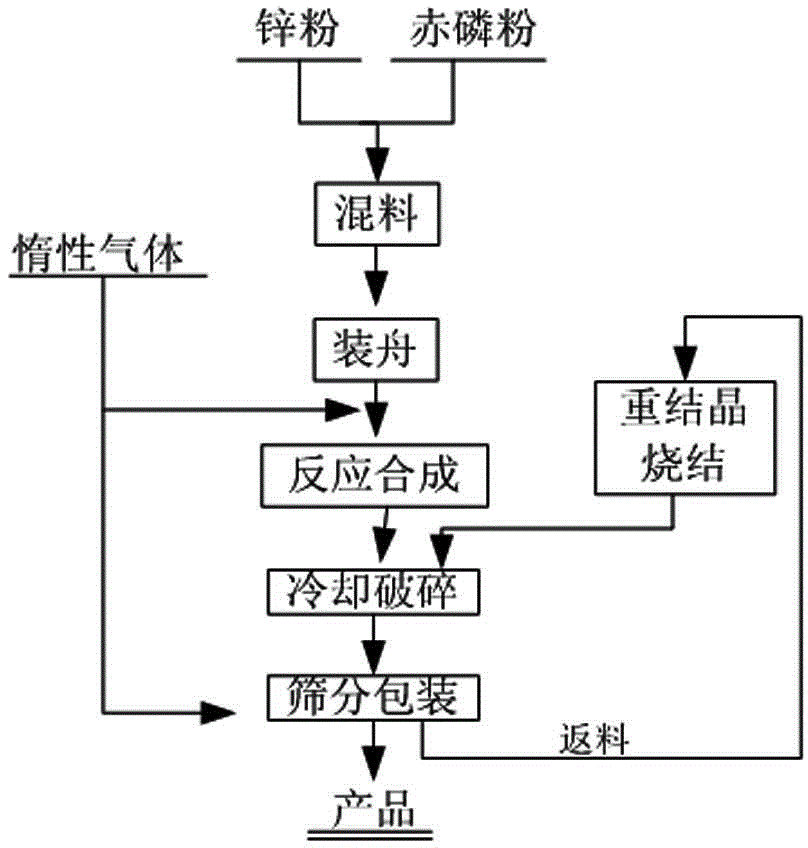

Method used

Image

Examples

Embodiment

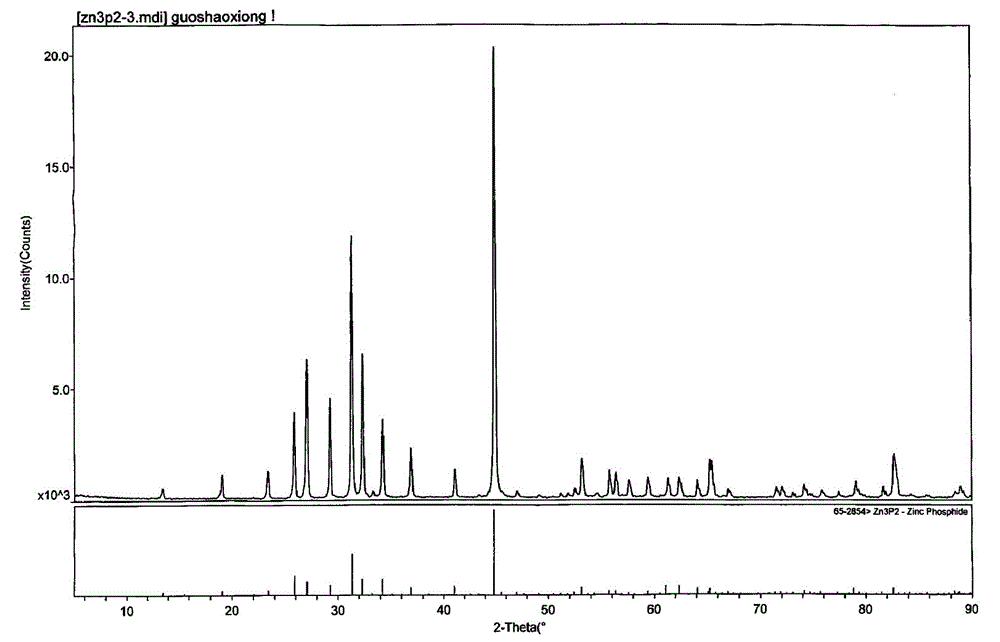

[0018] Example: mix metal zinc powder with a purity of 99.9% and analytically pure red phosphorus powder according to the above mass ratio of 3.1 to 3.3:1, put the mixed powder into a high-purity graphite boat, and then put the mixed The high-purity graphite boat of the raw material is put into a vacuum-capable closed heating reactor. Vacuumize the reactor first, then fill the reactor with inert gas to normal pressure, continue vacuuming after the normal pressure, and then fill the reactor with inert gas to normal pressure. Control the reaction temperature to 100-900°C, and the reaction time to 1-8 hours. After the reaction is completed, cool to room temperature and start the furnace to take the material. Use a crusher to crush the preliminarily obtained massive zinc phosphide to obtain tetragonal zinc phosphide products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com