Aqueous zinc ion battery negative electrode material with functional protection layer and preparation method of aqueous zinc ion battery negative electrode material

A technology of zinc ion battery and negative electrode material, applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of complex equipment and uneven protective layer, achieve uniform zinc electrodeposition, abundant raw materials, and promote rapid ion transport Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

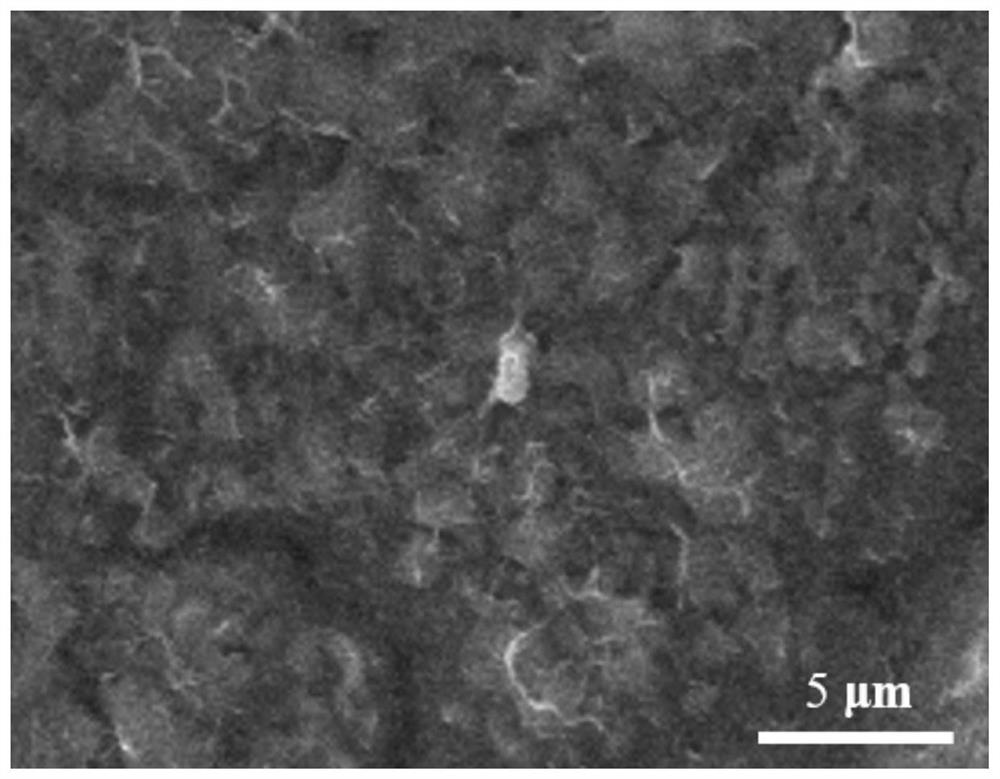

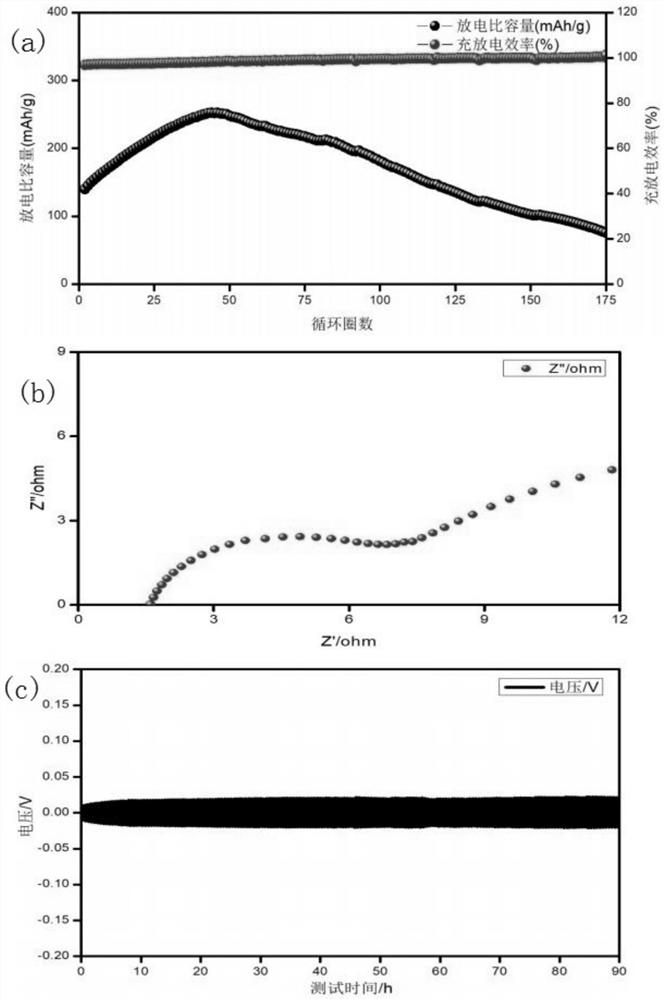

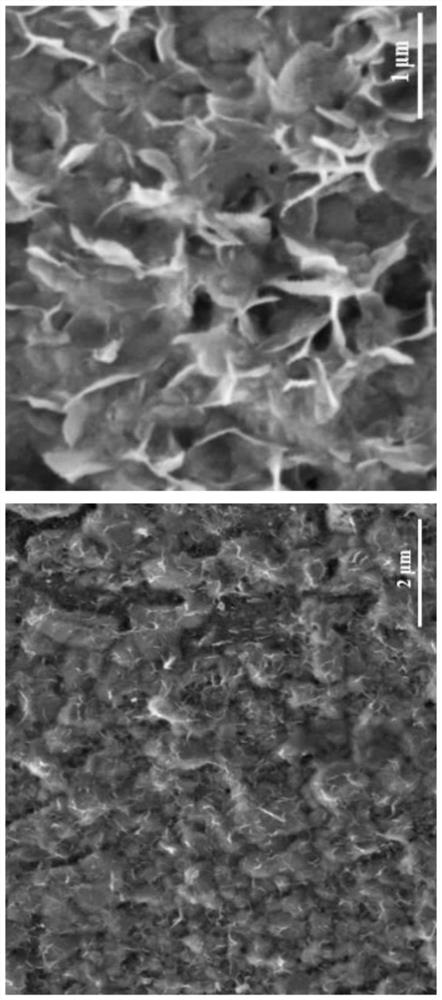

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a negative electrode material for an aqueous zinc ion battery, specifically comprising the following steps:

[0035] 1) Pretreatment of zinc flakes: Cut multiple zinc flakes with a size of 2cm×1cm, soak them in dilute hydrochloric acid with a concentration of 0.3mol / L for 3 minutes, remove the surface oxide film, and use anhydrous ethanol and deionized water for the soaked zinc flakes. Repeated cleaning several times, dry in natural environment, spare.

[0036] 2) Prepare 100mL of 0.4M zinc sulfate heptahydrate (ZnSO 4 ·7H 2 O), 0.1M sodium phosphite (NaH 2 PO 2 ), 0.08M boric acid (H 3 BO 3 ), sodium sulfate (NaSO 4 ), 0.01M stannous chloride dihydrate (SnCl 2 ·2H 2 O), 0.006M sodium ethylenediaminetetraacetate (C 10 H 14N 2 Na 2 O 8 ) as the electroplating solution.

[0037] 3) Using the pretreated zinc sheet in step 1) as the working electrode, using AgCl as the reference electrode and Pt as the counter electrode, placing it in th...

Embodiment 2

[0041] A method for preparing a negative electrode material for an aqueous zinc ion battery, specifically comprising the following steps:

[0042] 1) Pretreatment of zinc flakes: Cut multiple zinc flakes with a size of 2cm×1cm, soak them in dilute hydrochloric acid with a concentration of 0.3mol / L for 3 minutes, remove the surface oxide film, and use anhydrous ethanol and deionized zinc flakes to remove the surface oxide film. Wash with water several times, dry in natural environment, and set aside.

[0043] 2) Prepare 100mL of 0.4M zinc sulfate heptahydrate (ZnSO 4 ·7H 2 O), 0.1M sodium phosphite (NaH 2 PO 2 ), 0.08M boric acid (H 3 BO 3 ), sodium sulfate (NaSO 4 ), 0.01M stannous chloride dihydrate (SnCl 2 ·2H 2 O), 0.006M sodium ethylenediaminetetraacetate (C 10 H 14 N 2 Na 2 O 8 ) as the electroplating solution.

[0044] 3) Using the pretreated zinc sheet in step 1) as the working electrode, using AgCl as the reference electrode and Pt as the counter electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com