Copper-based flux-cored solder wire easy to prepare, high in wettability and high in soldering seam strength

A technology of wettability and solder wire, applied in the field of copper-based flux cored solder wire, can solve the problems of decreased toughness, poor fluidity of solder, and limited effect, so as to enhance wettability, increase fluidity, promote The effect of liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

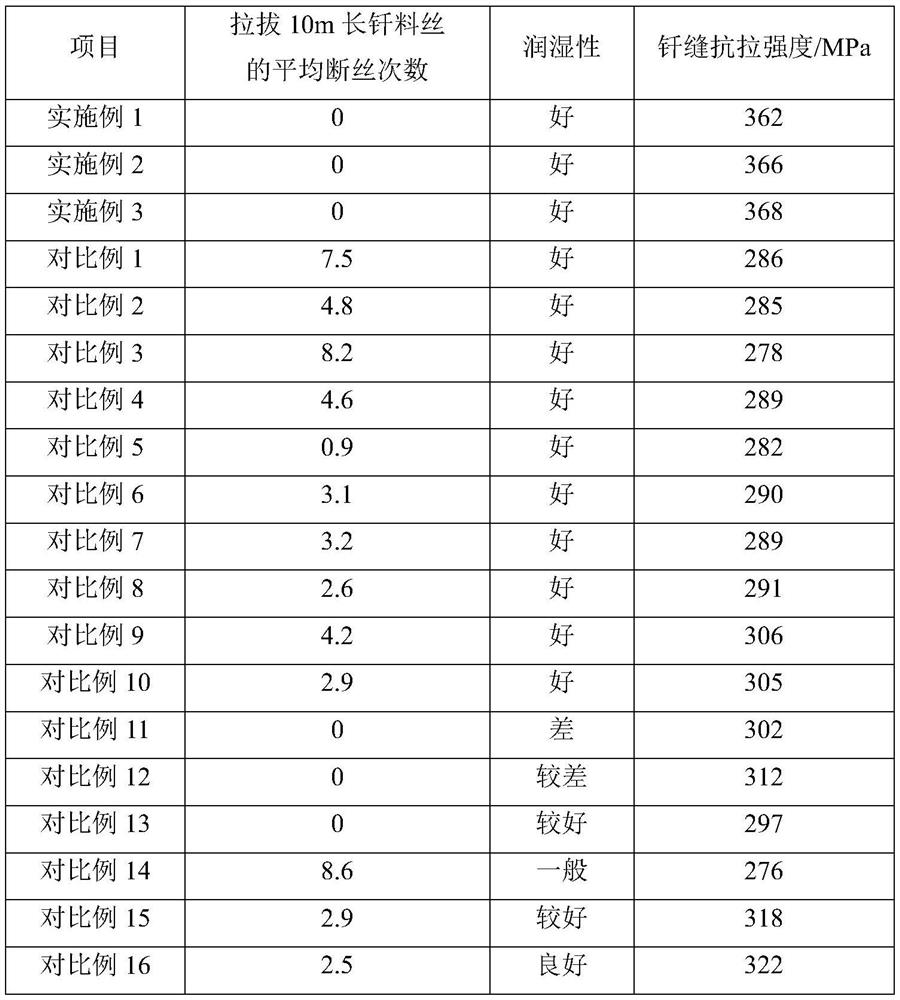

Examples

Embodiment 1

[0031] The preparation of the copper-based flux-cored solder wire described in the present invention, which is easy to prepare, has strong wettability and high brazing seam strength, comprises an outer skin and core powder, the outer skin is in the shape of a circular tube with seams, and the inside is filled with core powder.

[0032] The chemical composition of the drug core powder is calculated by mass percentage: nano-hexagonal boron nitride 5%, nano-zinc carbonate 8%, zinc phosphide 16%, borax 25%, boric acid 18%, potassium fluoride 7%, and the balance is tin pink.

[0033] The chemical composition of the skin is calculated by mass percentage: 8% silver, 1.2% indium, 1.5% antimony, and the balance is copper.

[0034] The mass of the core powder accounts for 25% of the total mass of the core solder wire.

[0035] The particle size of the nanometer hexagonal boron nitride is 30nm-50nm.

[0036] The particle size of the nano-zinc carbonate is 30nm-50nm.

[0037]The partic...

Embodiment 2

[0043] The preparation of the copper-based flux-cored solder wire described in the present invention, which is easy to prepare, has strong wettability and high brazing seam strength, comprises an outer skin and core powder, the outer skin is in the shape of a circular tube with seams, and the inside is filled with core powder.

[0044] The chemical composition of the drug core powder is calculated by mass percentage: nano-hexagonal boron nitride 6.5%, nano-zinc carbonate 10%, zinc phosphide 18%, borax 25%, boric acid 18%, potassium fluoride 7%, and the balance is tin pink.

[0045] The chemical composition of the skin is calculated by mass percentage: 10% silver, 1.8% indium, 1.8% antimony, and the balance is copper.

[0046] The mass of the core powder accounts for 29% of the total mass of the core solder wire.

[0047] The particle size of the nanometer hexagonal boron nitride is 30nm-50nm.

[0048] The particle size of the nano-zinc carbonate is 30nm-50nm.

[0049] The p...

Embodiment 3

[0055] The preparation of the copper-based flux-cored brazing filler metal filament described in the present invention is easy to prepare, has strong wettability and high brazing seam strength, and comprises an outer skin and core powder, the outer skin is in the shape of a seamless tube, and the core powder is filled inside.

[0056] The chemical composition of the drug core powder is calculated by mass percentage: nano-hexagonal boron nitride 8%, nano-zinc carbonate 12%, zinc phosphide 20%, borax 25%, boric acid 18%, potassium fluoride 7%, and the balance is tin pink.

[0057] The chemical composition of the skin is calculated by mass percentage: silver 12%, indium 2.5%, antimony 2.2%, and the balance is copper.

[0058] The mass of the core powder accounts for 32% of the total mass of the core solder wire.

[0059] The particle size of the nanometer hexagonal boron nitride is 30nm-50nm.

[0060] The particle size of the nano-zinc carbonate is 30nm-50nm.

[0061] The part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com