Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "RED MATERIAL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blood tracking system

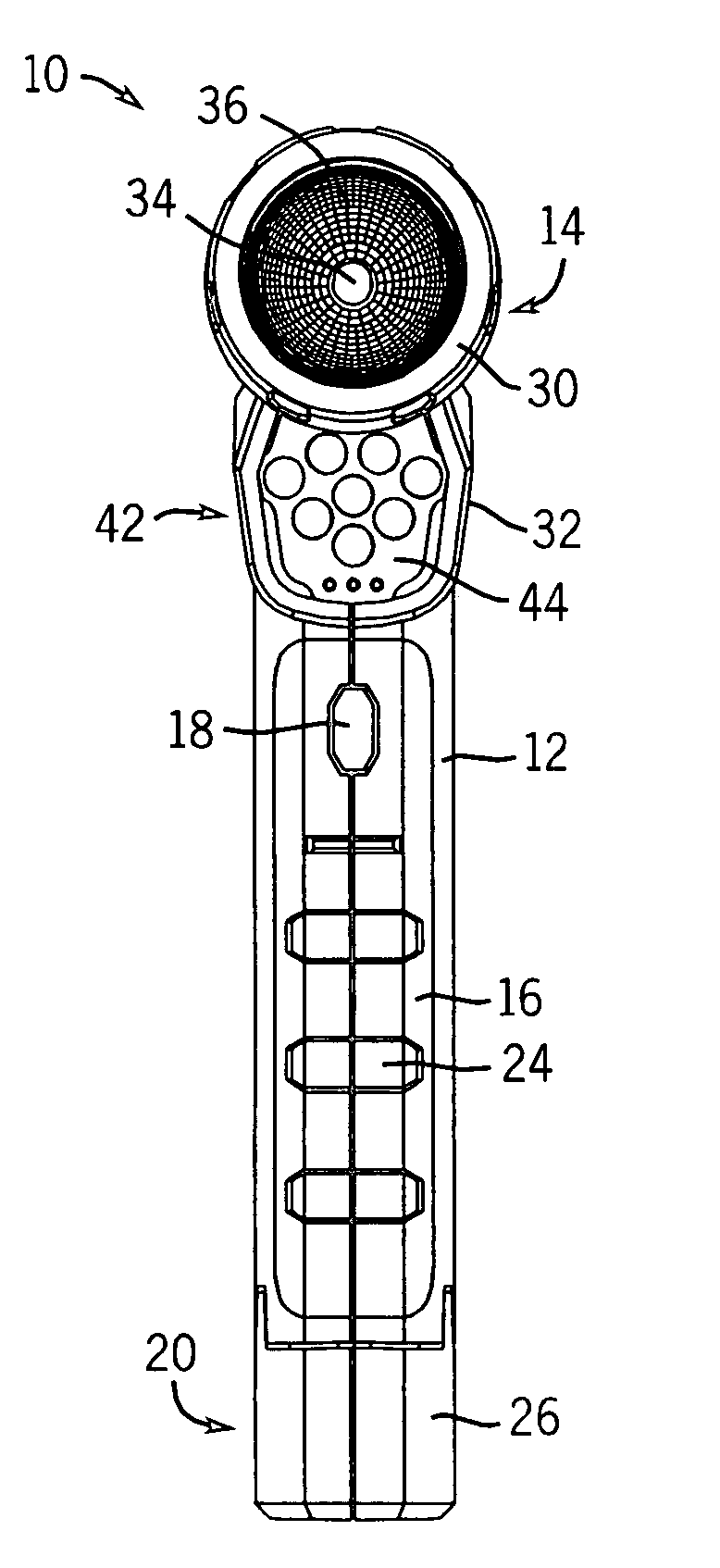

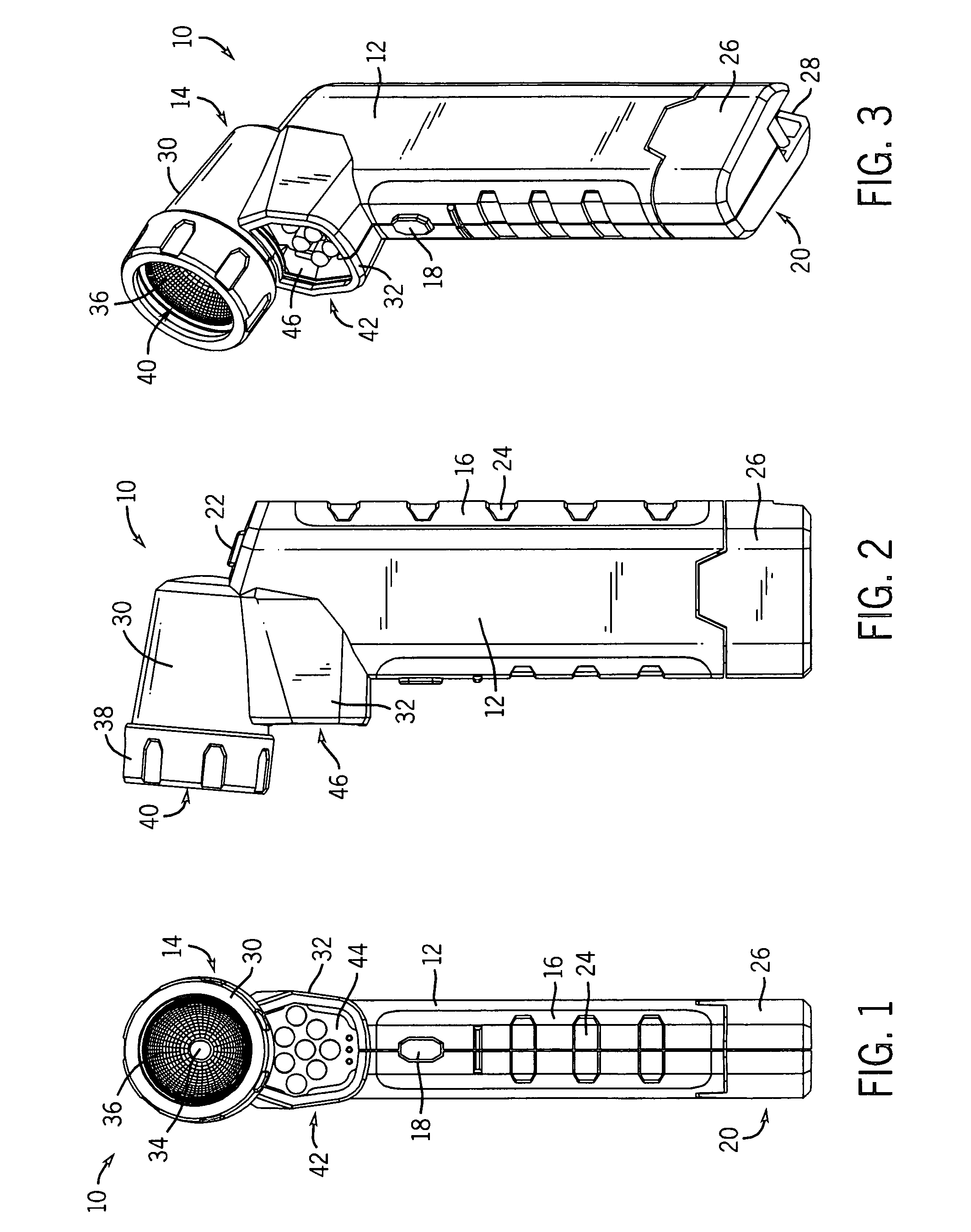

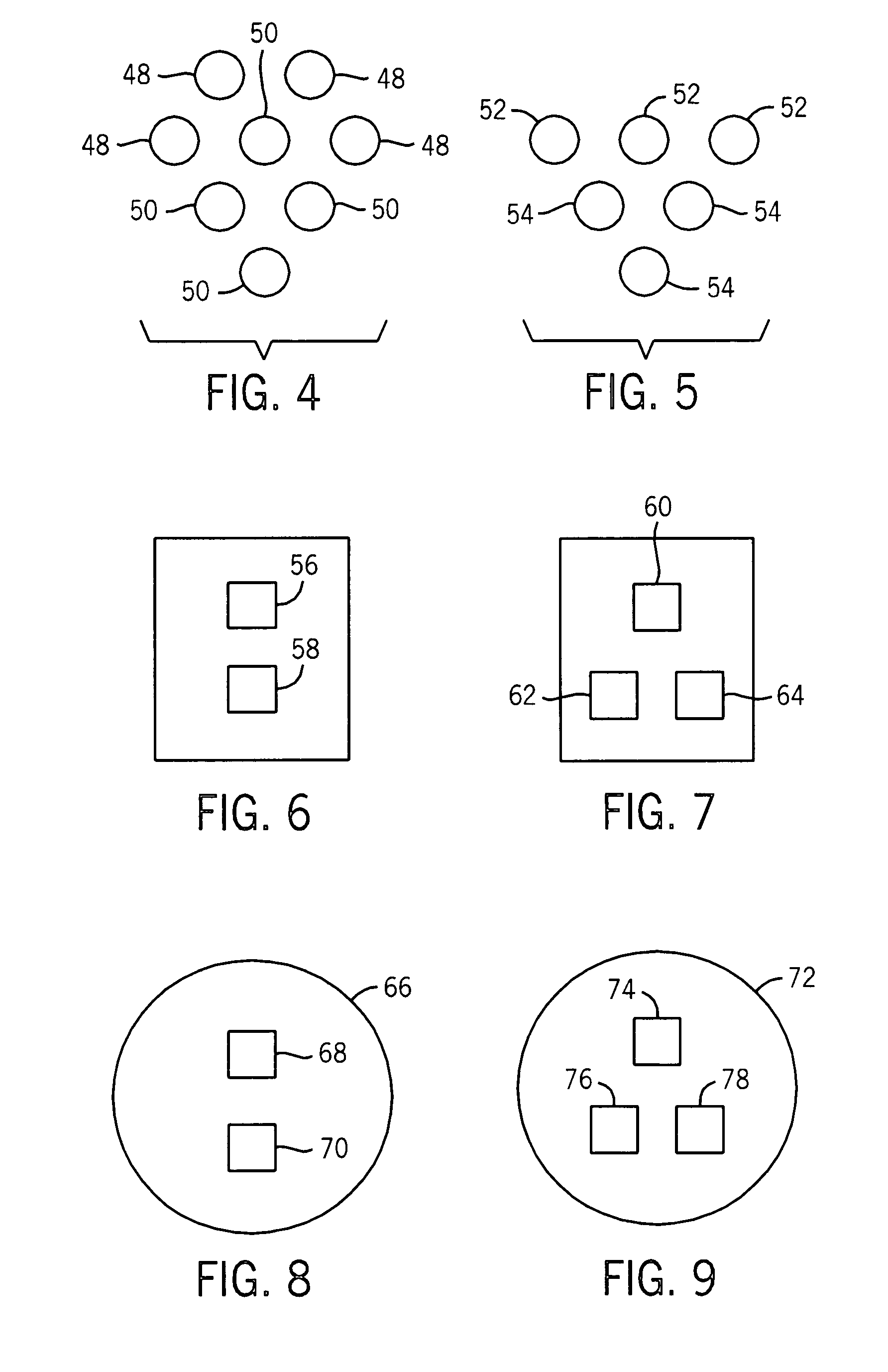

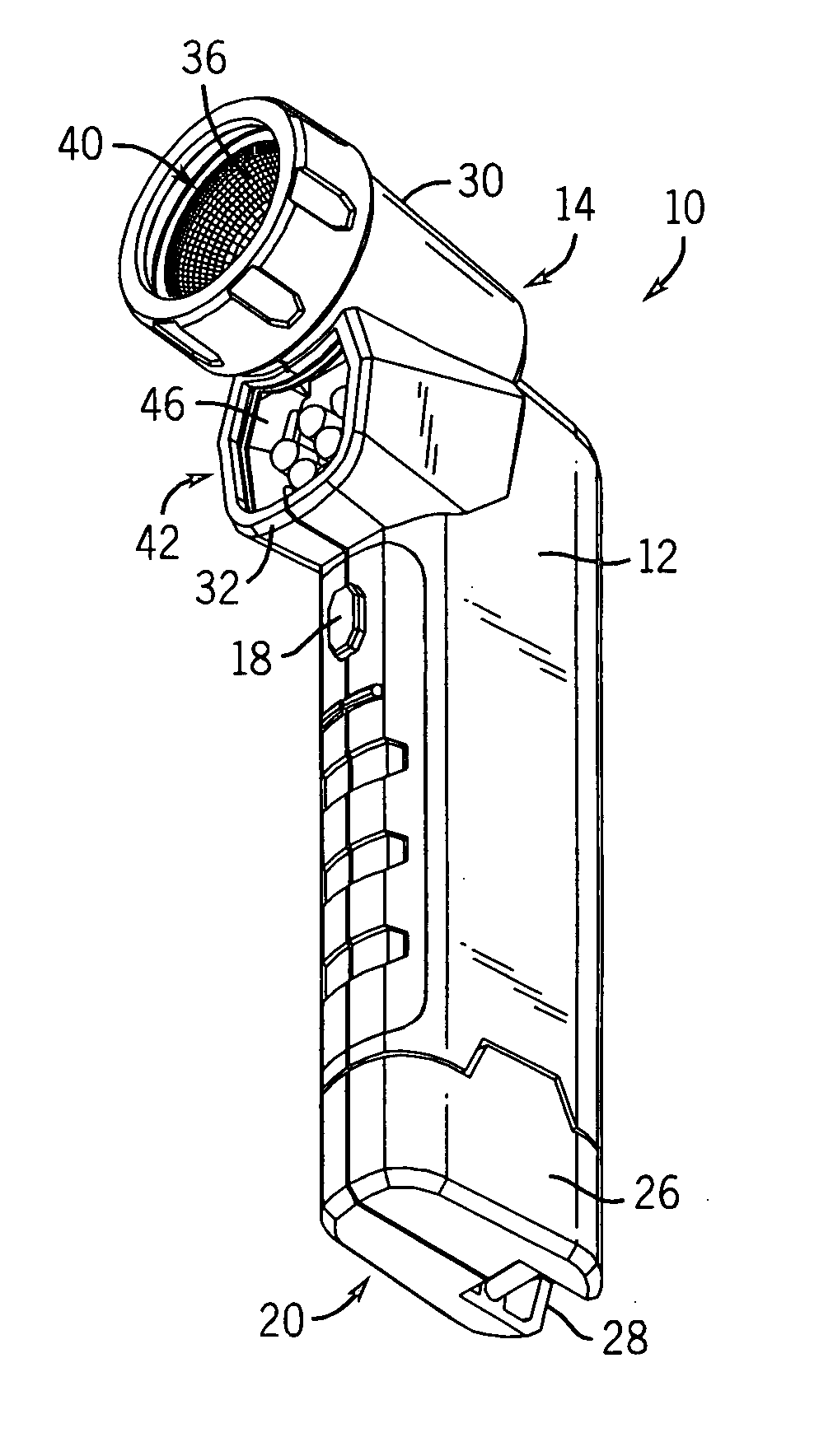

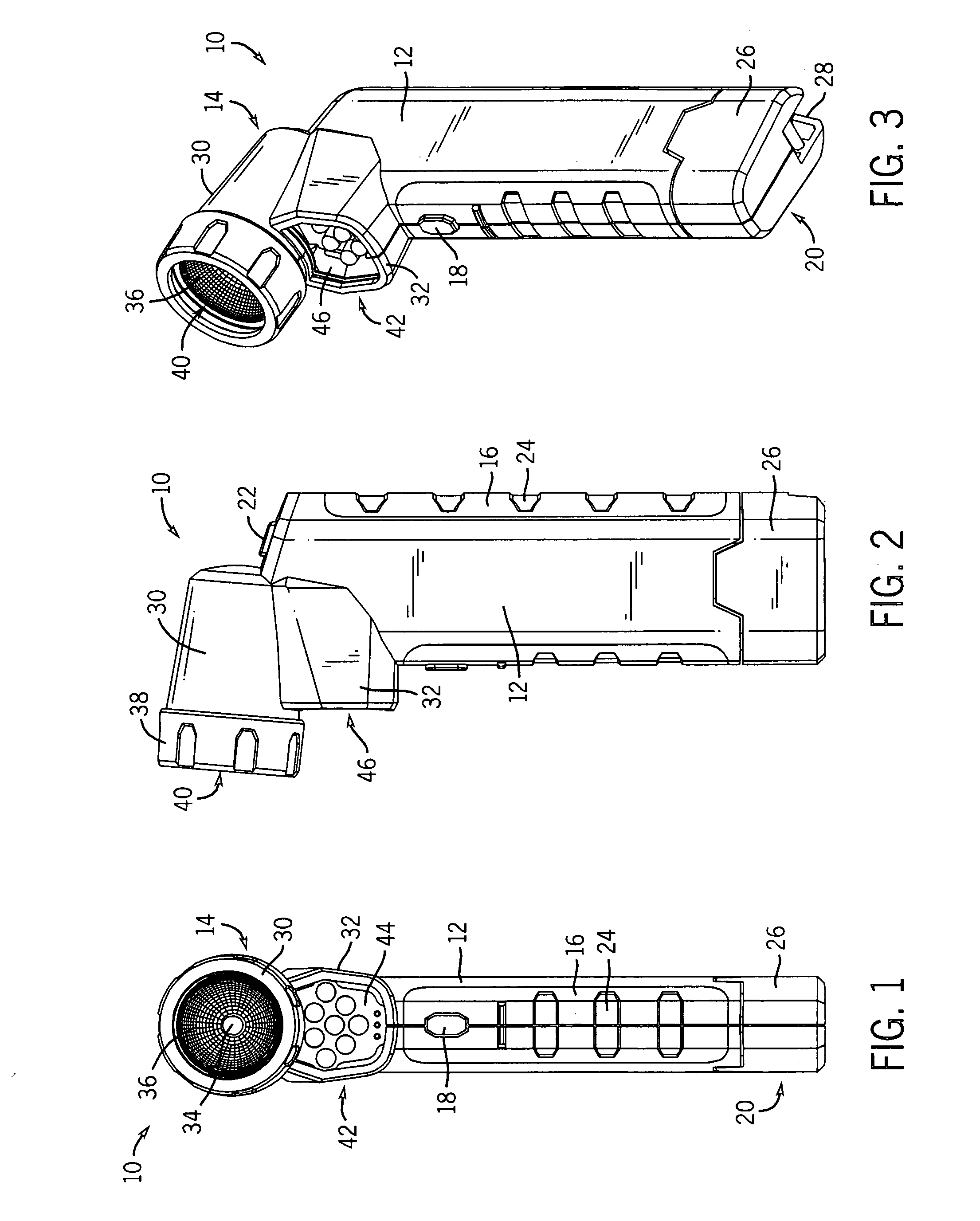

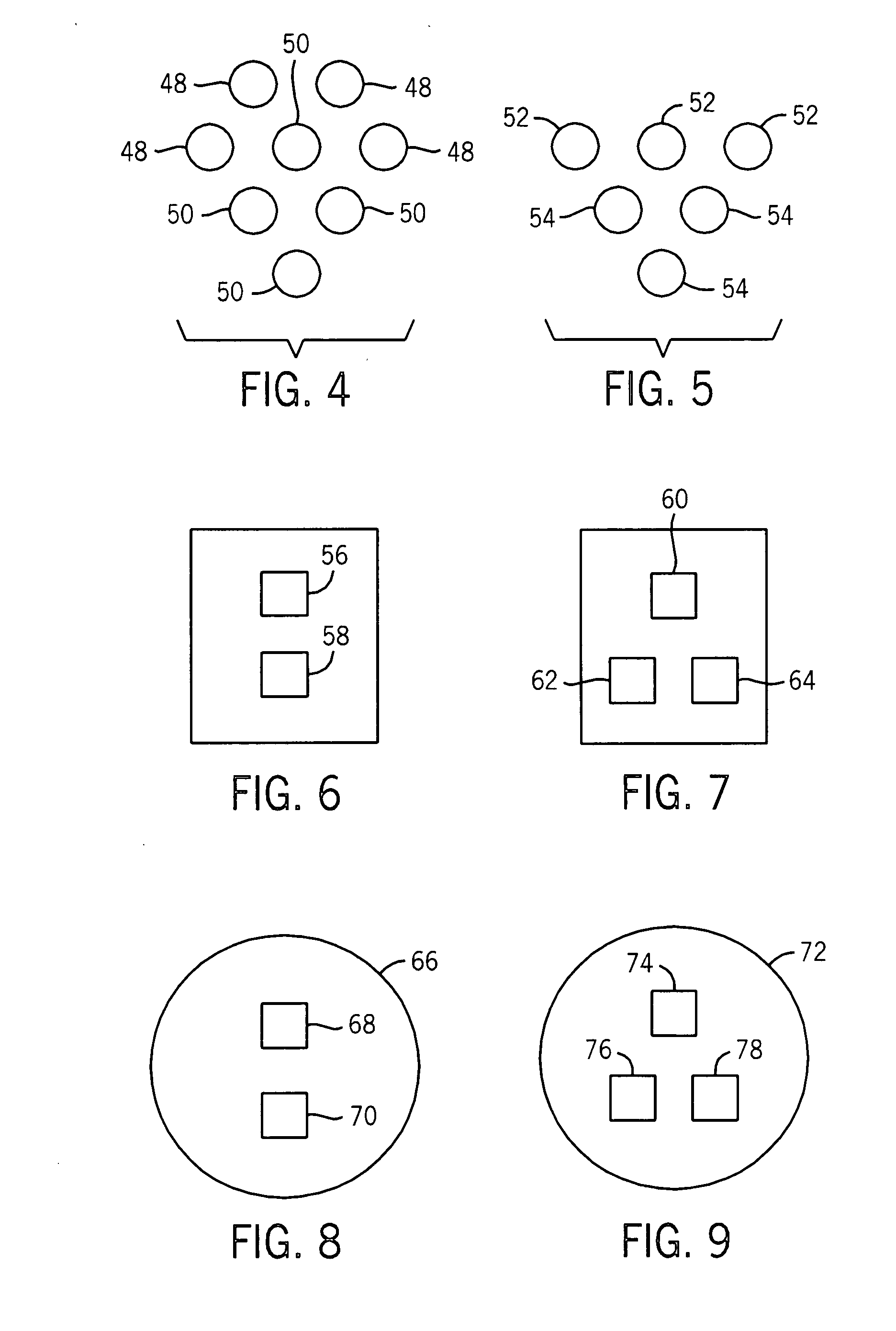

A blood tracking system, comprising a light source comprising a first LED configured to emit light of a first color and a second LED configured to emit light of a second color is disclosed. The light of the first color and the light of the second color are mixed to appear as light of a third color when the first LED and the second LED are activated; and wherein the light of a third color is effective for highlighting blood. A method of highlighting a red material comprising illuminating the red material with both red and blue light is also disclosed.

Owner:OY FISKARS AB

Blood tracking system

A blood tracking system, comprising a light source comprising a first LED configured to emit light of a first color and a second LED configured to emit light of a second color is disclosed. The light of the first color and the light of the second color are mixed to appear as light of a third color when the first LED and the second LED are activated; and wherein the light of a third color is effective for highlighting blood. A method of highlighting a red material comprising illuminating the red material with both red and blue light is also disclosed.

Owner:OY FISKARS AB

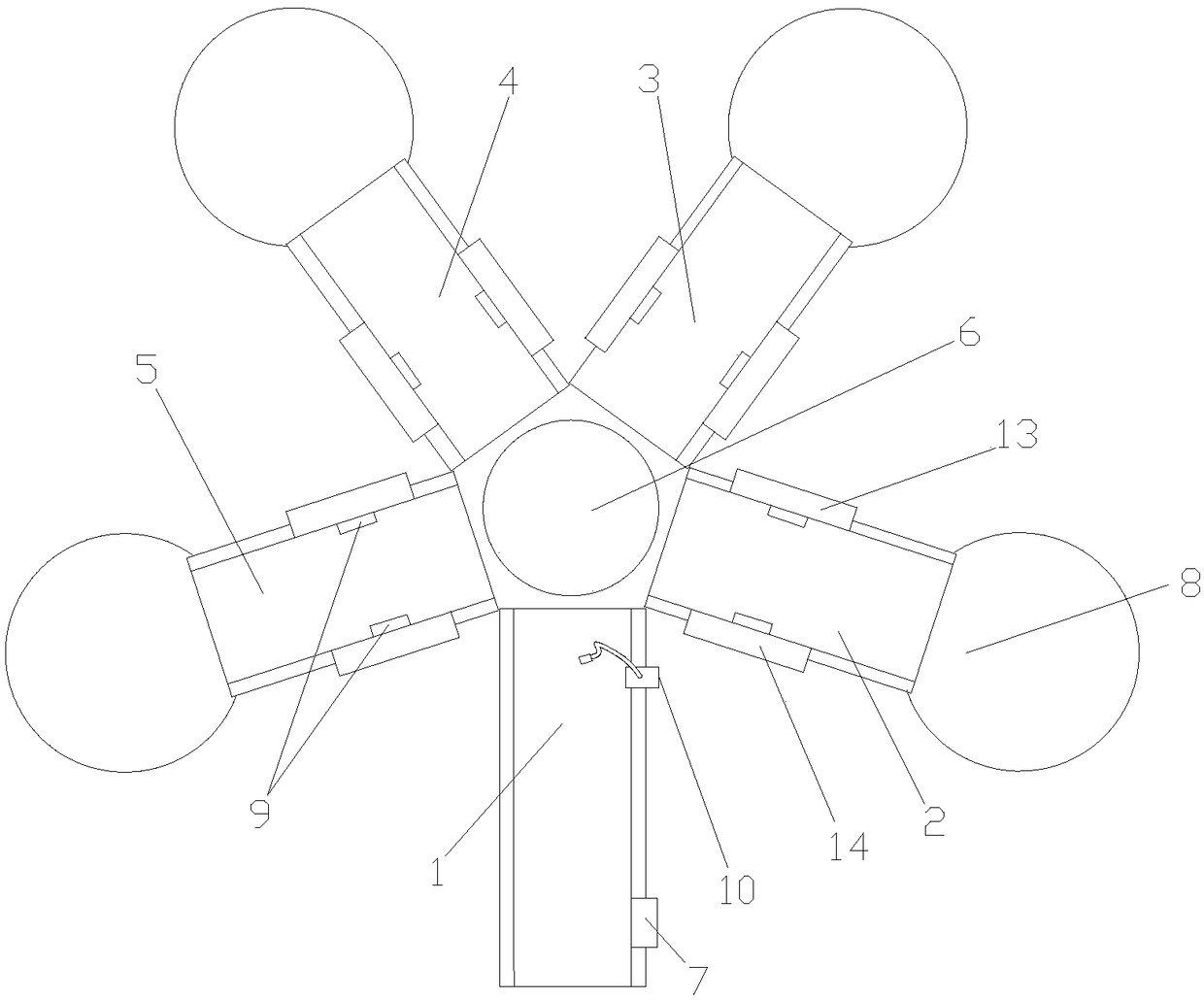

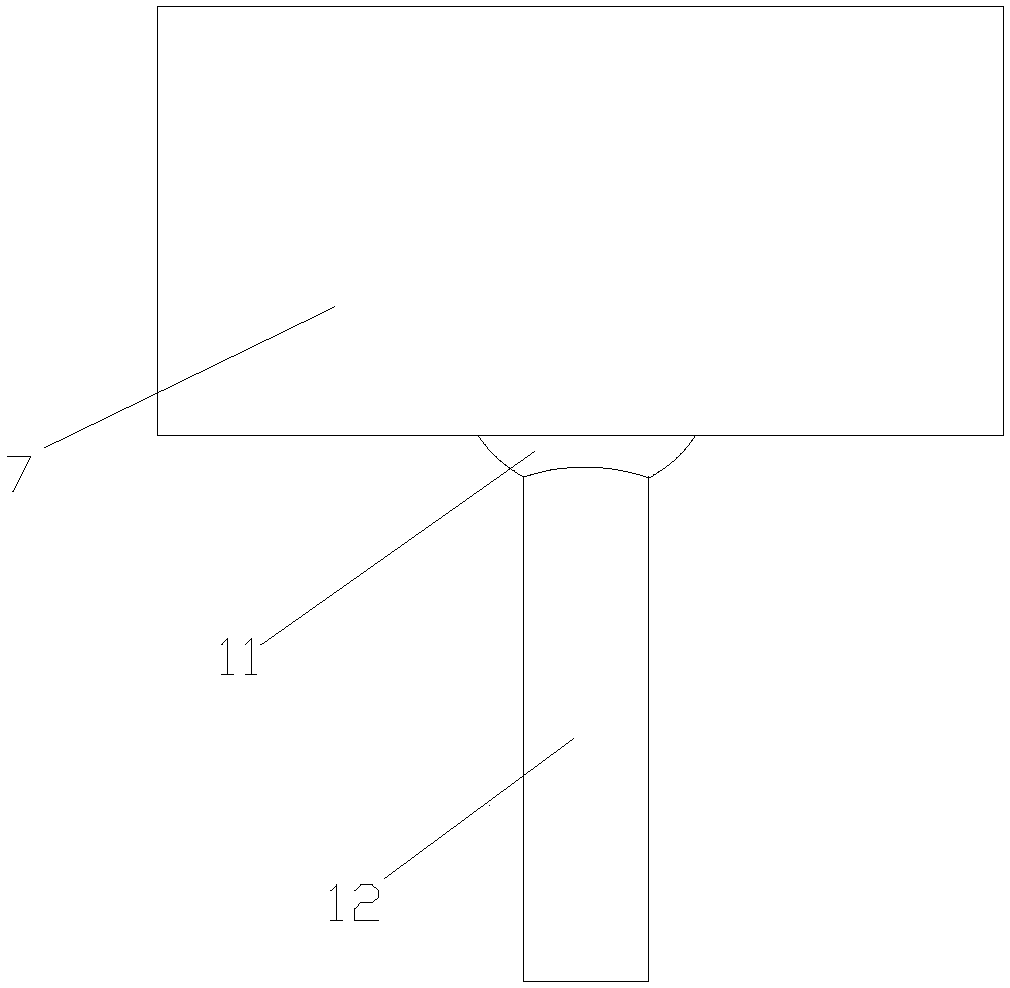

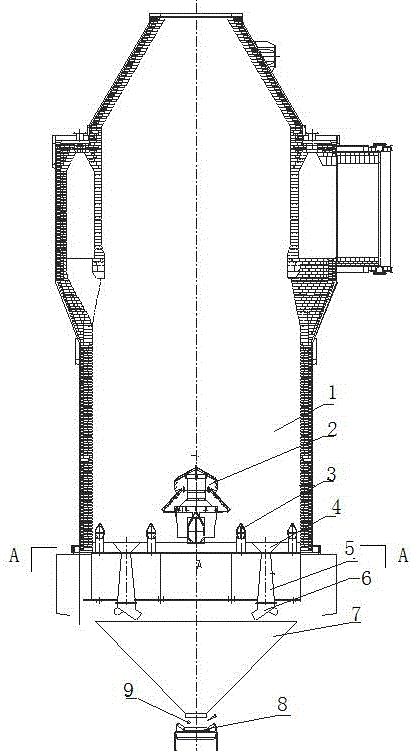

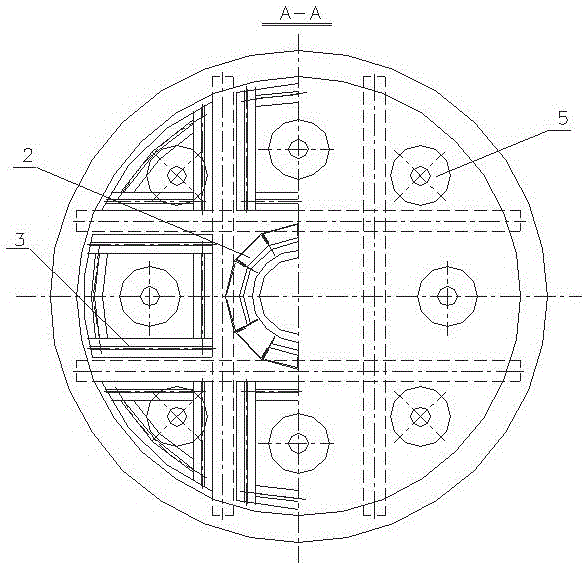

Multi-pipe discharging device of sinter shaft kiln type waste heat recovery system

ActiveCN106123572AAddresses the inherent drawback of having a very limited adjustment rangeSolve the "kiln wall effect"Increasing energy efficiencyHandling discharged materialAir volumeEngineering

The invention relates to a multi-pipe discharging device of a sinter shaft kiln type waste heat recovery system and relates to flow characteristics of sinter, heat exchange characteristics of the sinter and air, out-of-kiln manners of hot air, structural forms of kiln bodies, diameter and height parameters, kiln top material distributing equipment, bottom air distribution devices and the like. A multi-pipe type discharging technology is adopted and matched with air volume adjustment, a kiln wall effect and a center funnel effect are avoided, and the inherent defect that the adjusting range of an adjusting bar manner is very limited is effectively overcome. Due to the efficient cooperation of the discharging technology and the air distribution manner, the comprehensive effects of increasing the air temperature, reducing the air volume and the air resistance and eradicating red material accidents can be achieved.

Owner:江苏垦乐节能环保科技有限公司

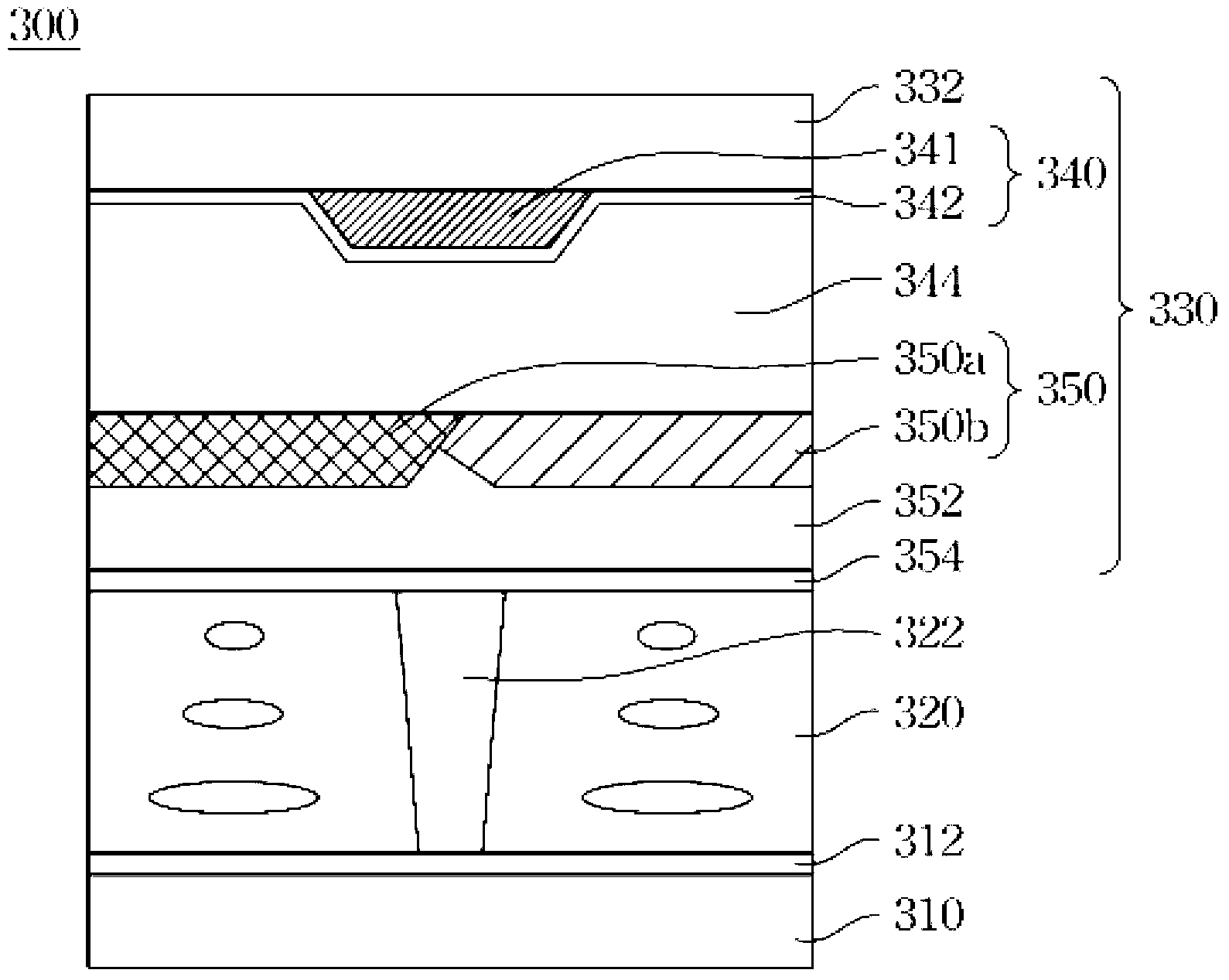

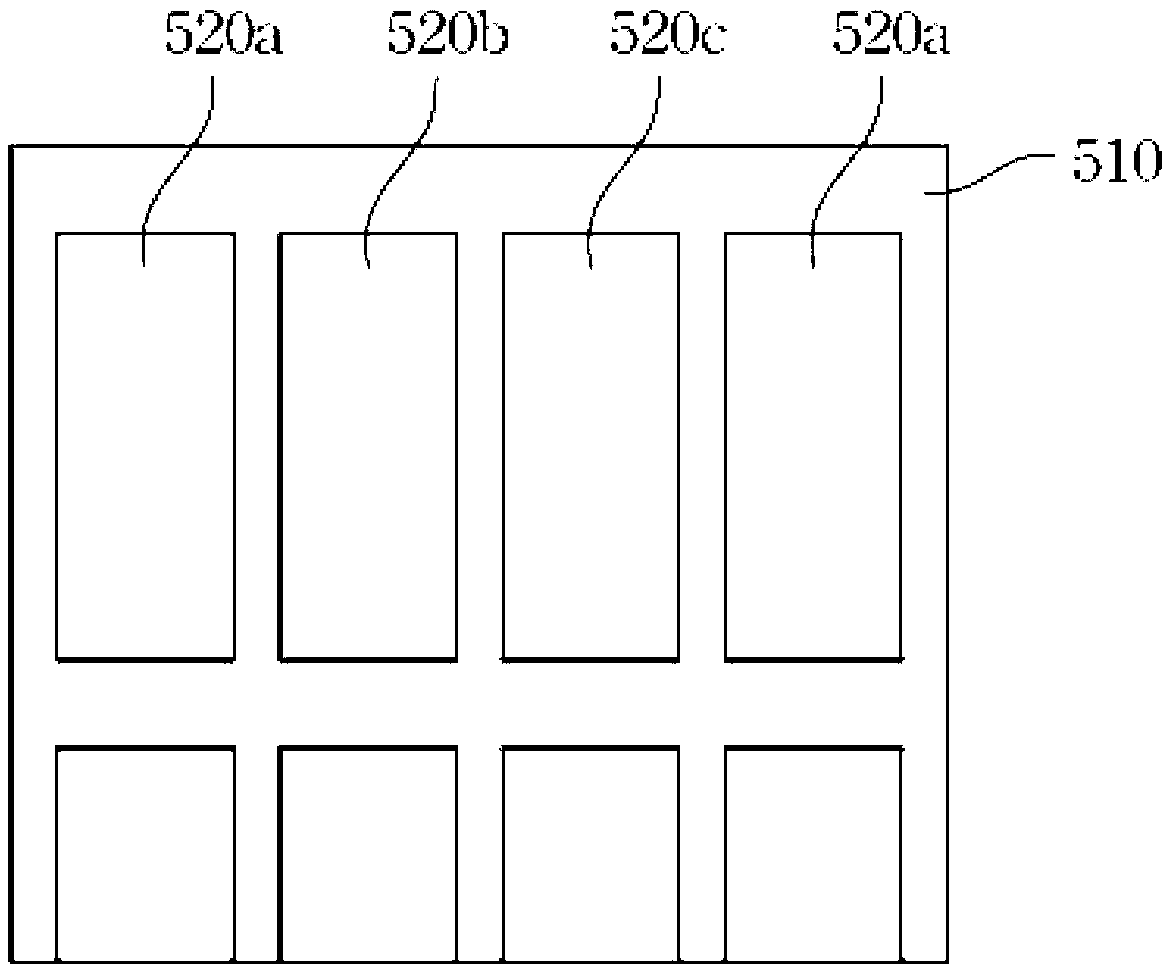

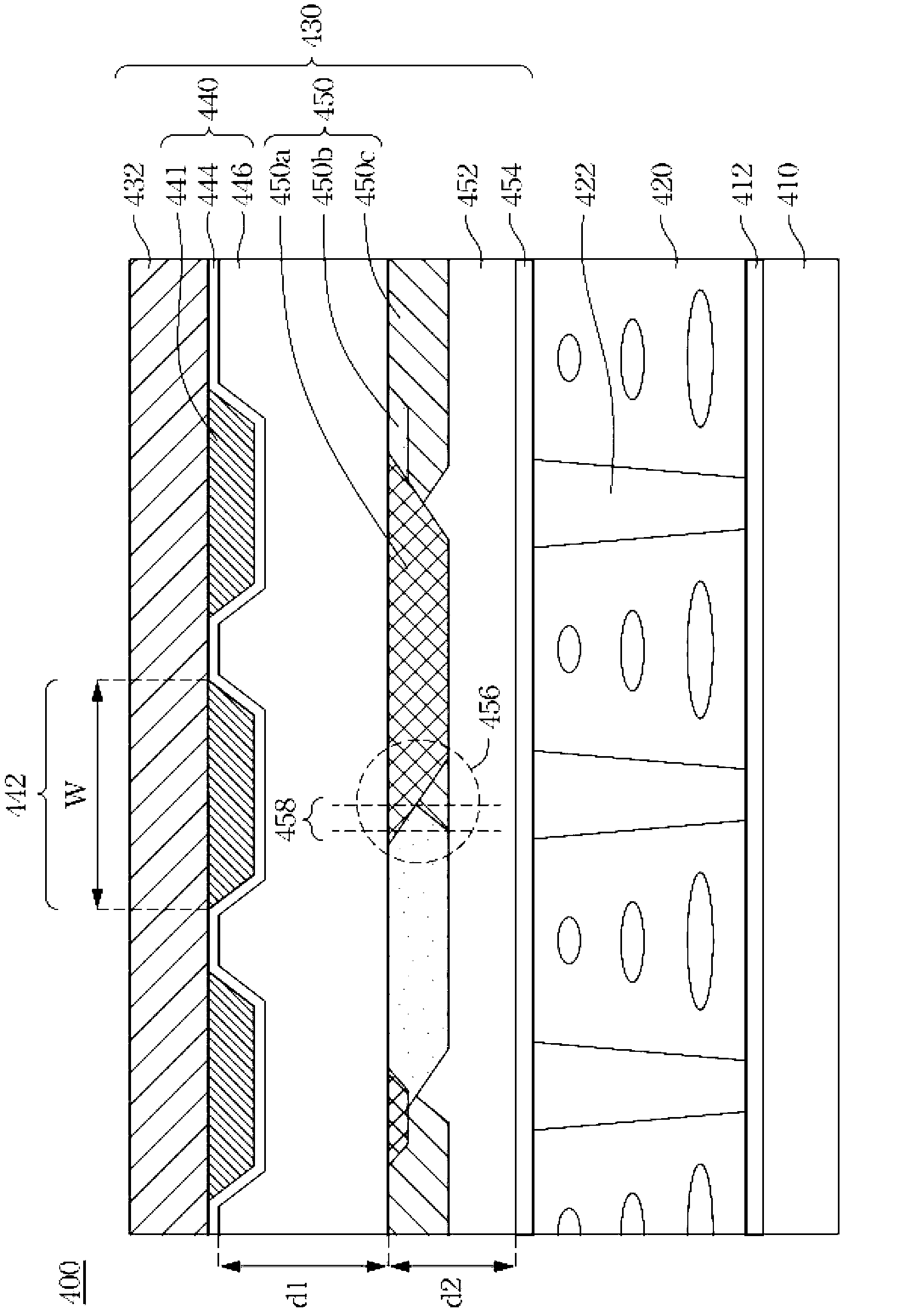

Embedded touch display and manufacturing method thereof

InactiveCN102799020AImprove light leakageImprove color mixingNon-linear opticsInput/output processes for data processingArray data structureGreen materials

The invention provides an embedded touch display which comprises a thin film transistor array substrate, a color filtering array pattern substrate and a liquid-crystal layer, wherein the liquid-crystal layer is arranged between the thin film transistor array substrate and the color filtering array pattern substrate; and the color filtering array pattern substrate comprises a color filtering pattern layer and the filtering patterns are composed of a plurality of red materials, green materials or blue materials. For the embedded touch display, two adjacent filtering patterns on the color filtering array pattern substrate have different colors and at least one adjacent edges of the two adjacent filtering patterns are overlapped, the overlapped part comprises a material having a third color different from the colors of two adjacent materials so as to form a three-color laminated layer; and the three-color laminated layer can be used for improving the problems of light leak or colour mixture. The invention also provides a manufacturing method of the display.

Owner:AU OPTRONICS CORP

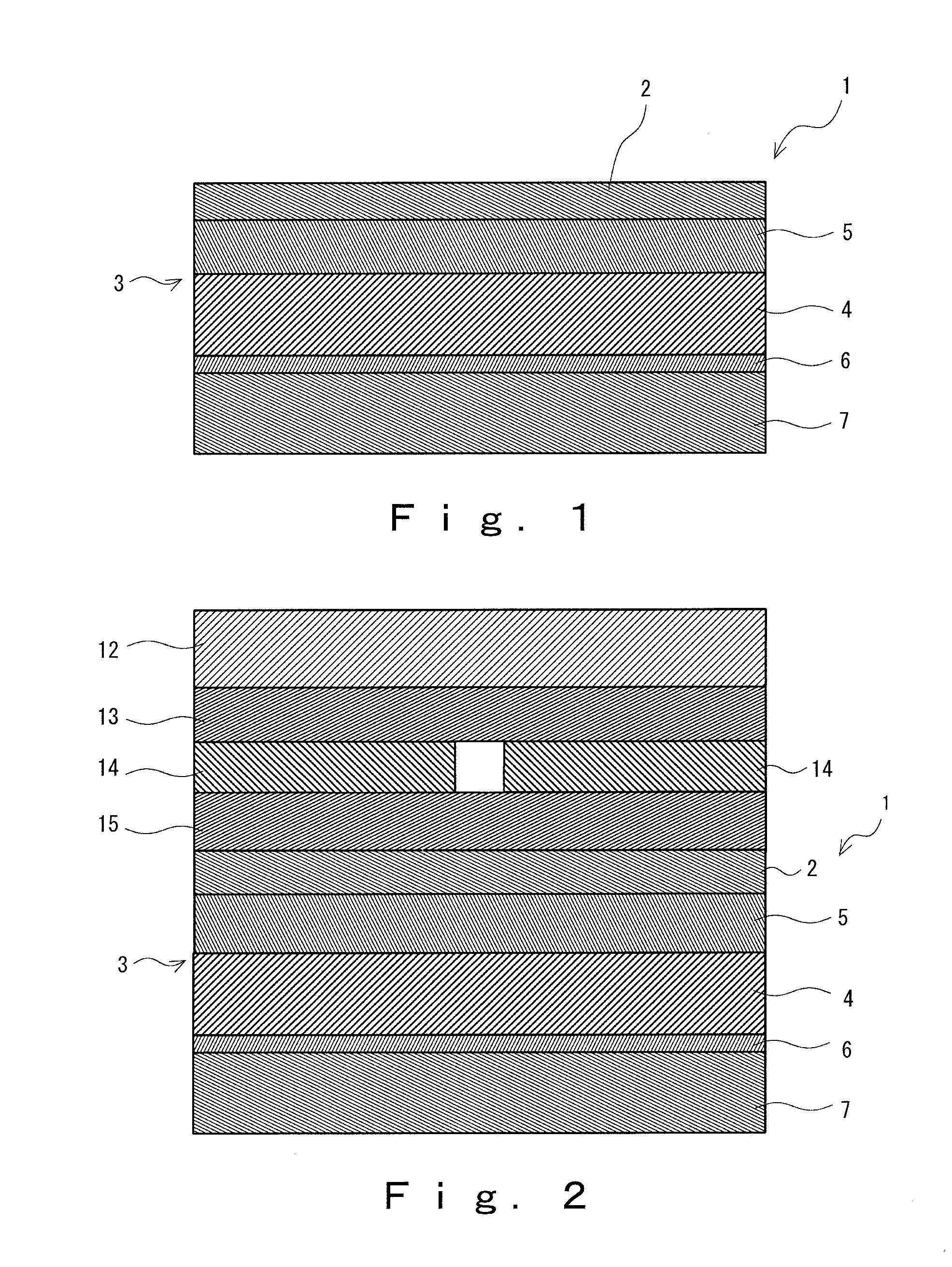

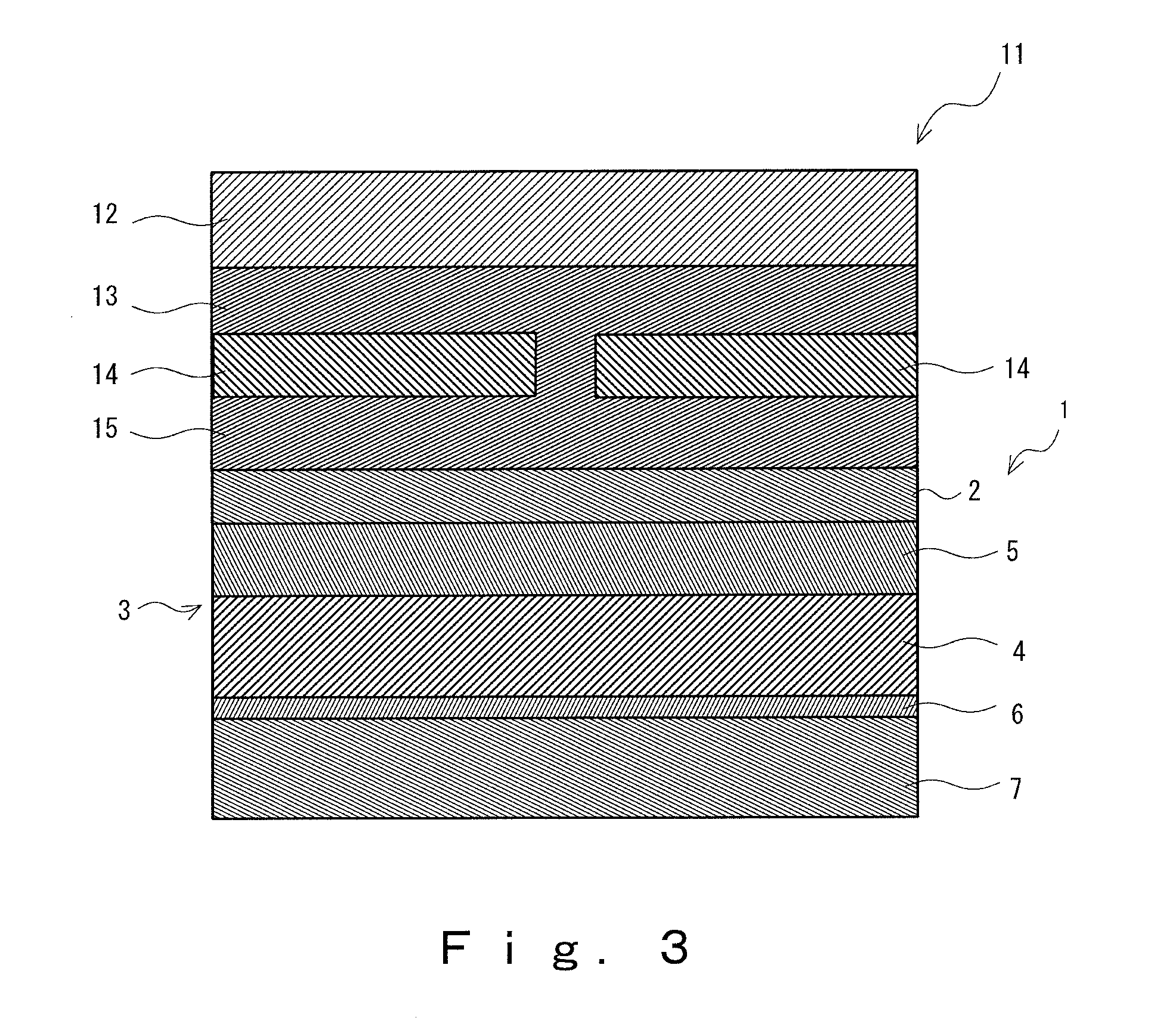

Back sheet for solar battery module, production method of back sheet for solar battery module, and solar battery module

InactiveUS20150075615A1Low costIncrease temperatureOptical filtersSynthetic resin layered productsElectrical batteryEngineering

A back sheet for a solar battery module that is less likely to cause a rise in temperature by irradiation with rays of the sun even though displaying a black color in appearance, and is less likely to discolor even after a long-term use thereof while suppressing a rise in cost. The back sheet for a solar battery module according to the present invention includes a colored layer that includes three or more types of color materials each having a different hue and a brightness L* of no less than 45, the colored layer having a brightness L* of no greater than 40. It is preferred that the three or more types of color materials are constituted with at least a red color material, a blue color material and a yellow color material. Preferably, a base sheet on which the colored layer is laminated is further included. It is preferred that the base sheet displays a white color and the colored layer is laminated on the front face side of the base sheet. Moreover, the base sheet preferably includes a base film and a white layer laminated on the front face side of the base film.

Owner:KEIWA INCORPORATED

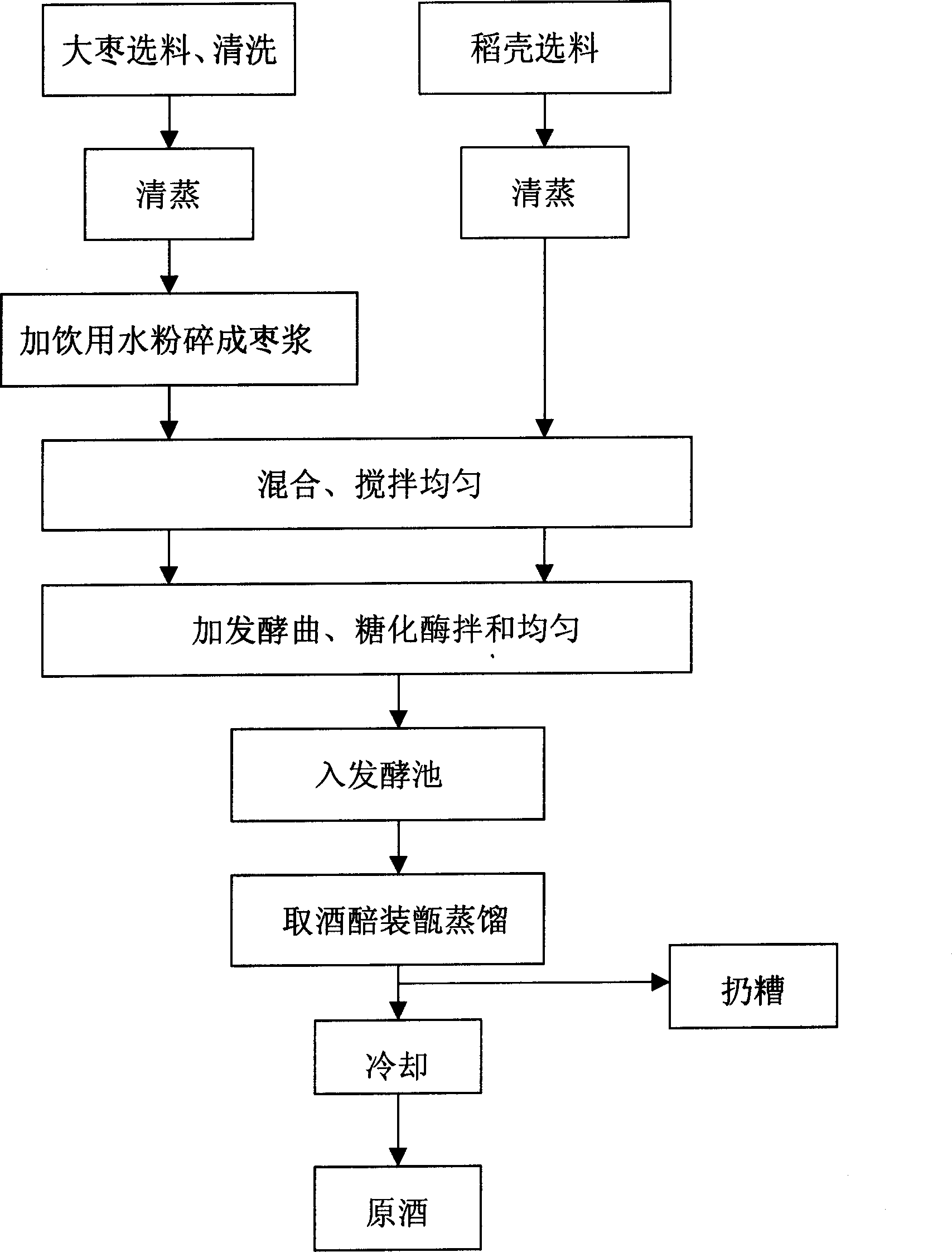

Technique for producing distillate spirits in fragrance of Chinese date by using red material

InactiveCN1696267ASolve the problem of consuming a lot of foodRich in nutrientsAlcoholic beverage preparationHuskSlurry

Owner:陈万福

Low cost permanent magnetic ferrite and preparation method thereof

ActiveCN107337447AImprove magnetismHigh densityInorganic material magnetismInductances/transformers/magnets manufactureMiniaturizationElectronic component

The invention belongs to the technical field of magnetic materials and preparation thereof. The invention discloses a low cost permanent magnetic ferrite with a main phase of A1-XRxFe2n-YTyO19; the invention also discloses a preparation method of the low cost permanent magnetic ferrite, and in the preparation process of the permanent magnetic ferrite, certain content of a red material is added into a pre-sintered material. The low cost permanent magnetic ferrite has higher magnetic performance, can adapt to the miniaturization, high magnetic performance and other trend of electronic components in the prior art; in the preparation method, the certain content of the red material is added into the pre-sintered material to increase the density of the product and refine grains, and the magnetic properties of the material can be improved to a great extent.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

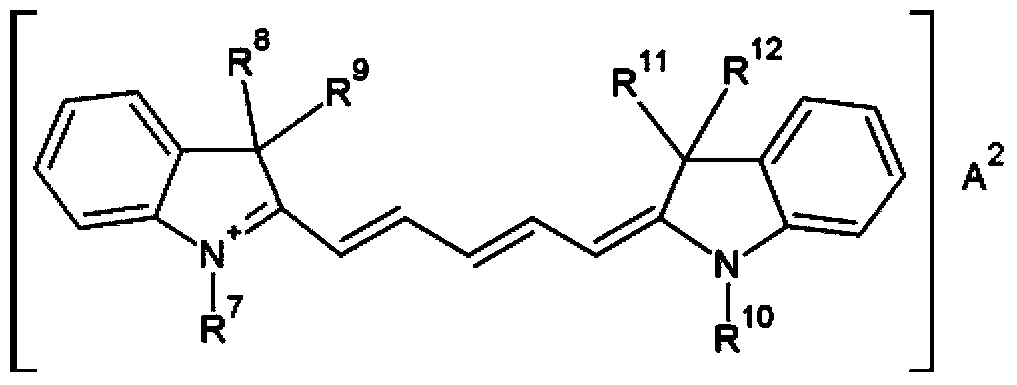

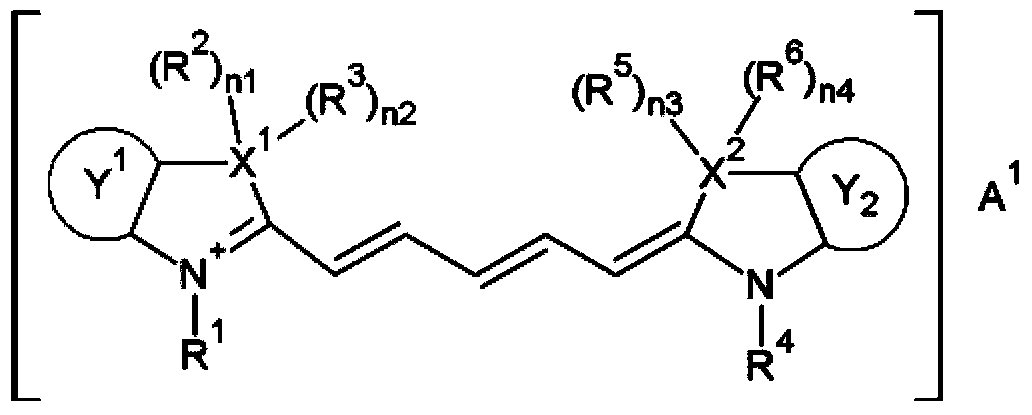

Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method

InactiveCN102268250AReduce generationEnhance proton acidityGroup 8/9/10/18 element organic compoundsLuminescent compositionsIridiumCoordination complex

The invention relates to the synthesis technology of new luminescent materials, and is a new-type electrically neutral tridentate iridium [III] complex red light material and a preparation method thereof. It is a 6-[5-trifluoromethylpyrazole]-2,2'-bipyridine·2,6-diphenylpyridine iridium[III] complex. Under the protection of nitrogen, the trihydrate iridium trichloride [III] metal salt reagent and 6-[5-trifluoromethylpyridine]-2,2'-bipyridine tridentate chelate ligand were heated in ethanol, and the reaction The liquid was pumped dry for recrystallization, filtered, washed, and vacuum-dried to obtain an orange-yellow solid intermediate; in a nitrogen glove box, the orange-yellow intermediate, silver trifluoromethanesulfonate, and 2,6-diphenylpyridine ligand were uniformly mixed , ground into powder, heated, after the reaction solution was cooled to normal temperature, the filtrate was collected and dried to obtain the crude product, the crude product was separated, the second orange-red eluate was collected and dried, and vacuum-dried to obtain the final product, the yield was up to 30-68%.

Owner:JIANGXI UNIV OF SCI & TECH

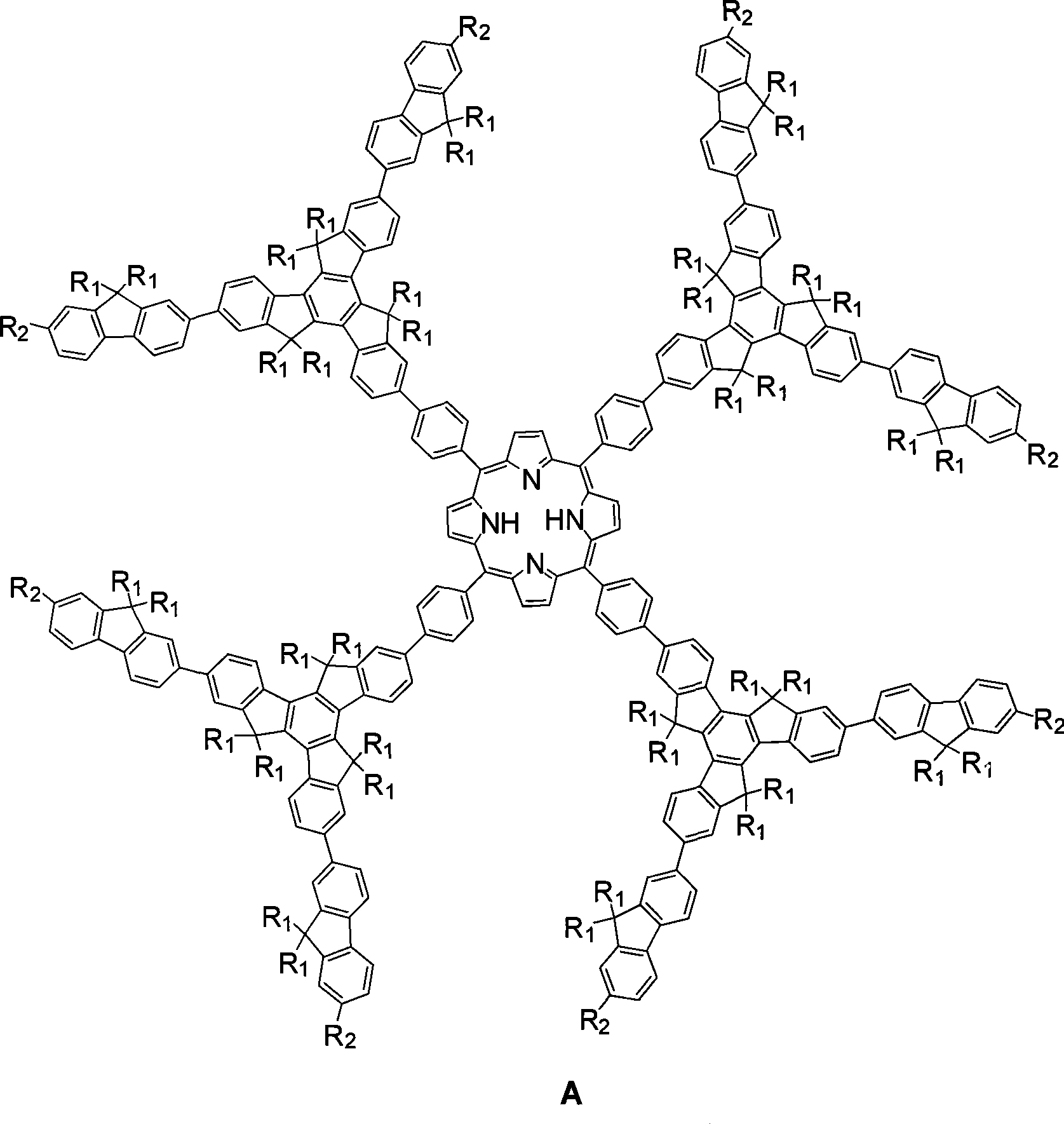

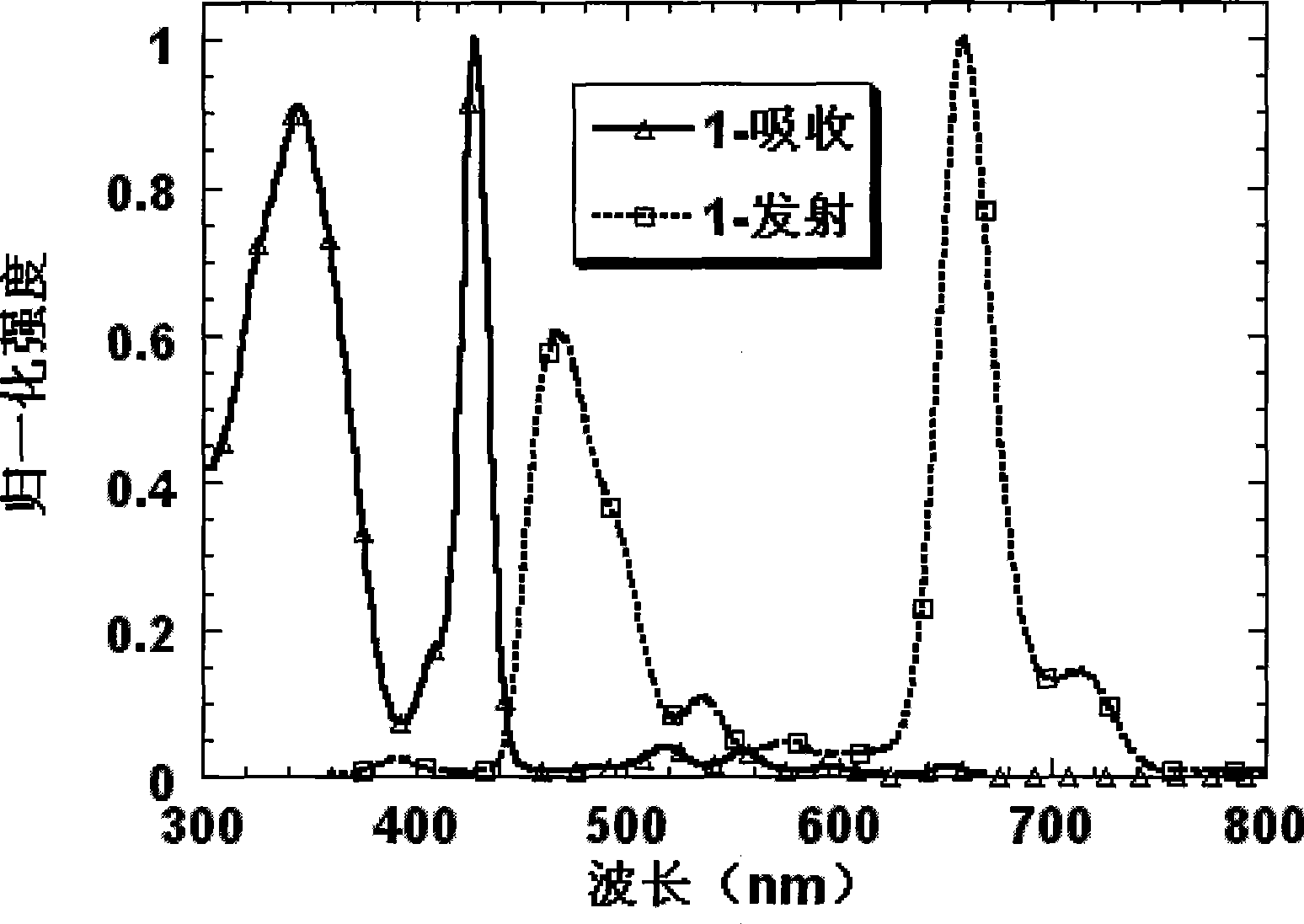

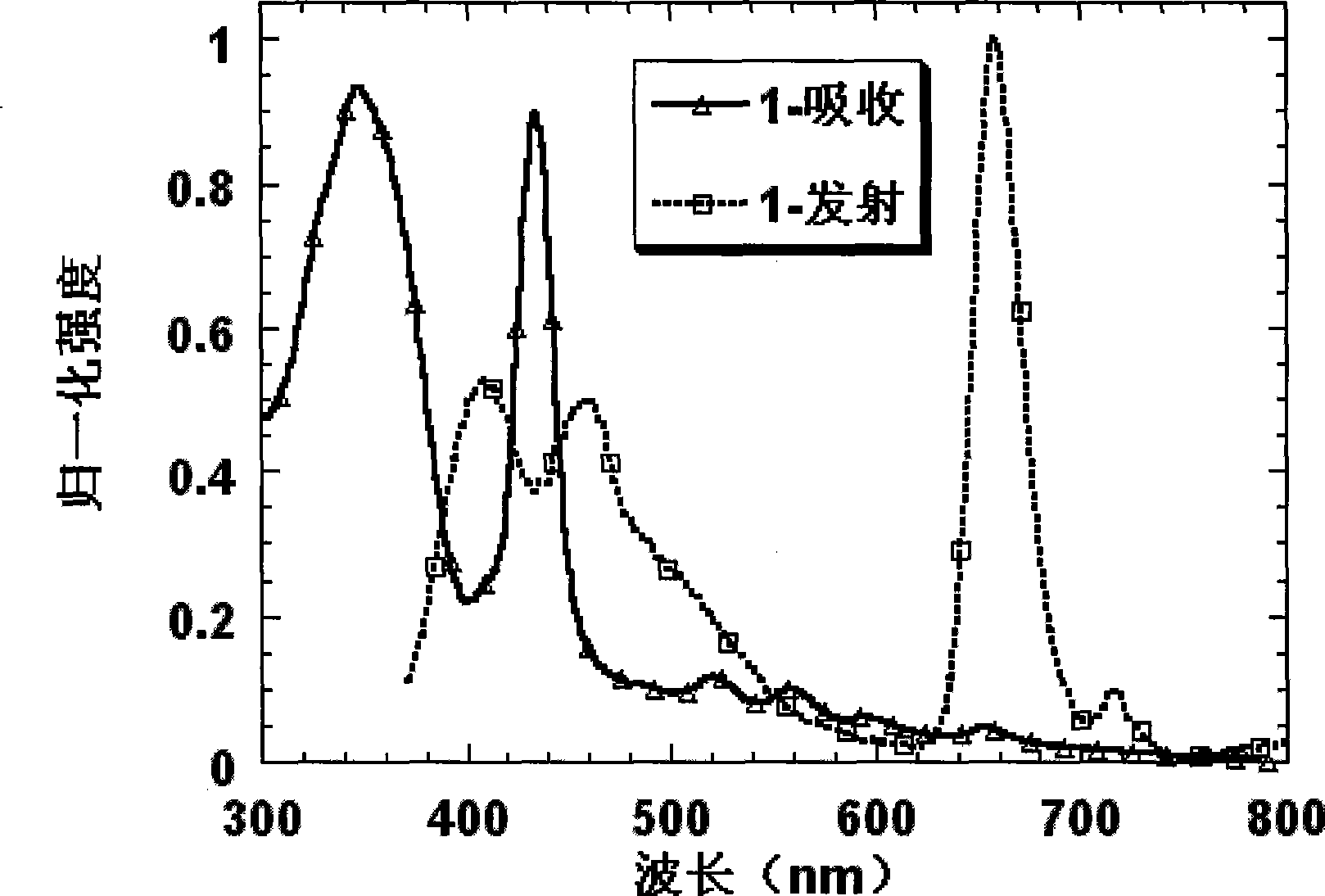

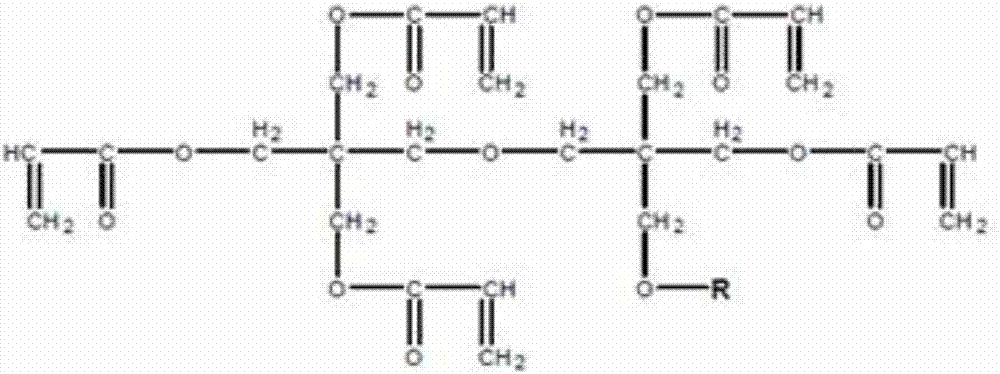

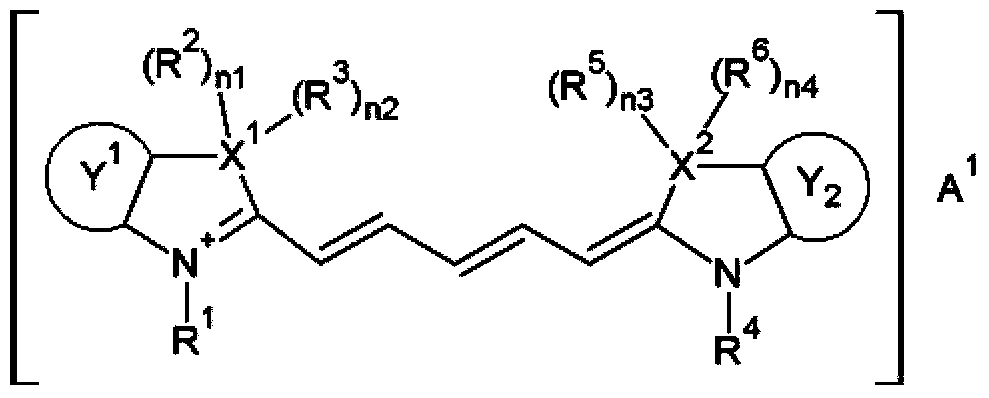

Conjugated dendritic electrically-induced pure red material and preparation method and use thereof

InactiveCN101418002AImprove solubilityEffective isolationOrganic chemistrySolid-state devicesSolubilityPorphyrin molecule

The invention provides conjugated dendritic pure red light emitting electroluminescent material, and a preparation method and application thereof. The material has a conjugated dendritic molecule which takes porphyrin as a core, truxene as a bridge and monofluoride as an antenna molecular and has a structural formula A. The material is prepared by the Lindsey condensation reaction of a derivative having a methanoyl of the truxene and the porphyrin. The method introduces a truxene system having a hydrotropic group to a metaposition of a porphyrin molecule to improve the solubility of the material and suppress fluorescence self-quenching, and increases intramolecular and intermolecular energy transfer through derivatization at 2, 7, 12-position of the truxene, so as to obtain high-efficiency pure light emission. The conjugated dendritic molecules are used as materials for a light emitting layer of an organic electroluminescent diode device and made into films by a simple spin coating process, and generate high-efficiency pure red light electrofluorescence without doping.

Owner:PEKING UNIV

Low-cost preparation method of anhydrous iron phosphate

ActiveCN110002417ASmall particle sizeIncrease concentrationPhosphorus compoundsSteelmakingPhosphoric acid

The invention discloses a low-cost preparation method of anhydrous iron phosphate. The method comprises the following steps: adding iron oxide red wastes produced in a steelmaking plant to a sulfuricacid solution, performing pulpifying, heating and reacting the obtained slurry, filtering the reacted slurry, washing the obtained filter residues with hot pure water, drying the washed filter residues, carrying out jet milling, and allowing the milled filter residues to go through an electromagnetic iron remover to obtain an iron oxide red material; adding the iron oxide red material to phosphoric acid, adding anhydrous alcohol, performing stirring, conveying the obtained solution into a spray dryer through a high-pressure pump, and using hot nitrogen as a heat source to obtain a dry material; and adding the dry material to anhydrous alcohol, washing the dry material, stopping washing when the content of free phosphoric acid in the dry material is less than 20 ppm, and drying the washed material to obtain the anhydrous iron phosphate. The method has the advantages of simple process and low cost, and the obtained anhydrous iron phosphate has the advantages of good dispersibility, highpurity, few impurity phases, large specific surface area, and easiness in subsequent grinding.

Owner:王东升

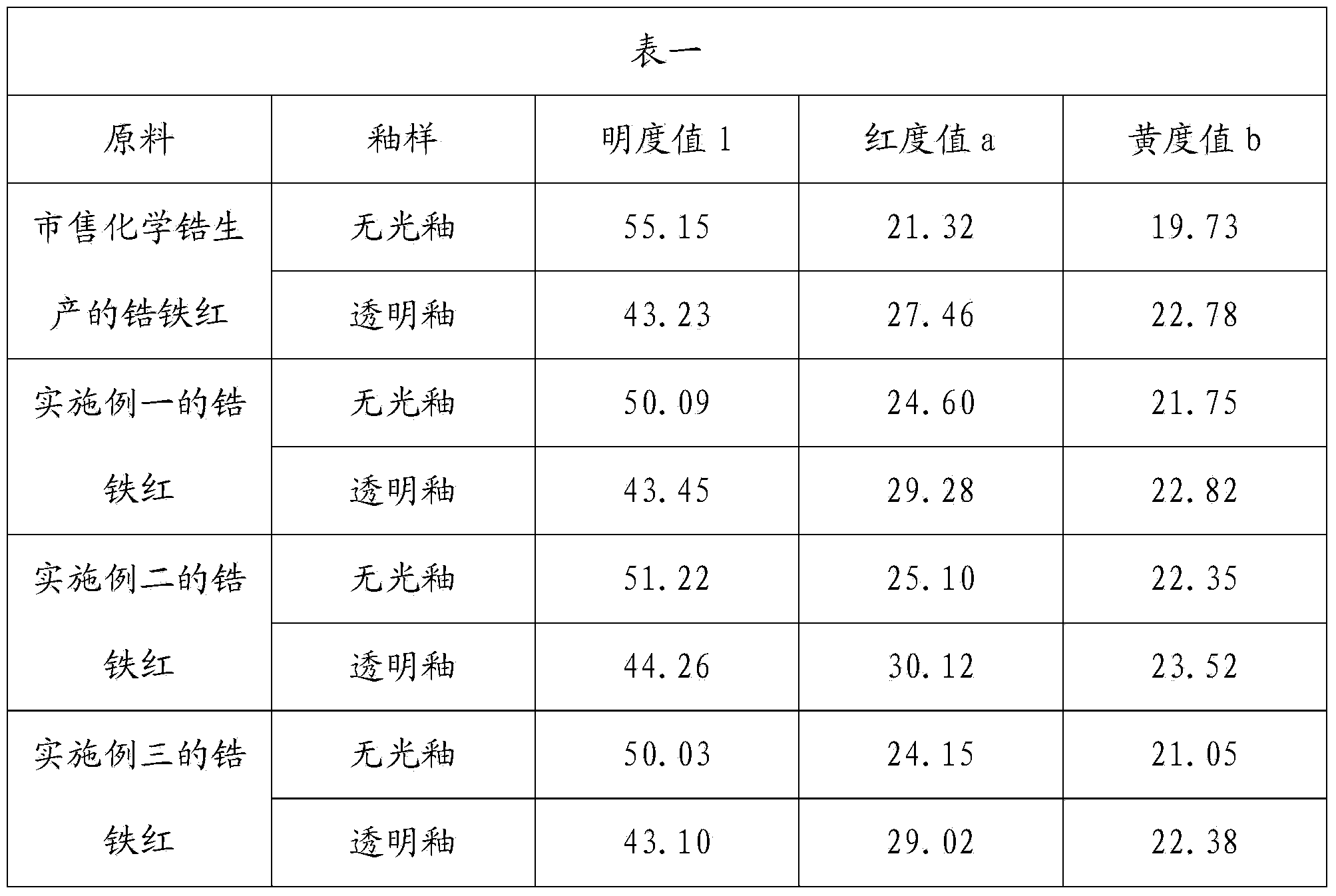

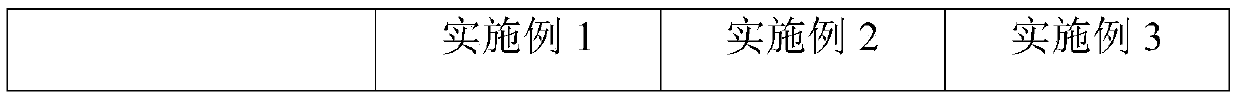

Process for producing ferrozirconium red material

InactiveCN101429053AImprove high temperature resistanceSmall particle sizePigmenting treatmentSodium metasilicateAcid washing

The invention discloses a method for preparing ferrozirconium red stain, which is characterized by comprising the following steps in turn: (1) liquid-phase reaction, which is to perform liquid-phase reaction on zirconium oxychloride, ferrous sulfate and sodium metasilicate pentahydrate in water; (2) separation and drying, which is to separate and dry solid-liquid suspended substances generated by liquid-phase reaction; (3) precalcination, which is to crush dried substances and calcine the crushed substance for 2 to 3 hours at a temperature of between 750 and 850 DEG C; (4) mixing, which is to mix products of precalcination uniformly with lithium fluoride, sodium fluorosilicate and sodium fluoride; (5) calcination, which is to calcine the mixture in the four step for 2 to 5 hours at a temperature of between 900 and 1,000 DEG C; and (6) post processing, which is to treat sintered solid substances by grinding, acid washing, water scrubbing, drying and sieving. The method for combination of liquid-phase reaction and solid-phase reaction improves the encapsulation rate of high-temperature solid-phase reaction, and synthesizes ferrozirconium red stain products which have beautiful chromogenic colors and strong chromogenic force and are stable at high temperature.

Owner:广东万兴无机颜料股份有限公司

Ferrozirconium red material

The present invention discloses a ferrozirconium red material, which is prepared from the following raw materials: silicon dioxide, an iron compound, a mineralizer, a rare earth fluoride, and zirconium dioxide. According to the present invention, the ferrozirconium red material prepared according to the formula has the following characteristics that: the wrapping rate is high, and ion is wrapped into the zirconium silicate crystal lattice in the ferric ion form so as to achieve stable color generation; and the active zirconium dioxide is adopted, and the rare earth fluoride is introduced, such that the prepared ferrozirconium red material has a good coloration effect.

Owner:SHENGQUAN FUJIAN GLAZE MAKING CO LTD

Method for breeding hot pepper stable inheritance selfining line with high haematochrome content and difficult to fade

ActiveCN103798133AHigh priceSolve the problem of reduced separation and difficult selectionPlant genotype modificationVisual observationHot peppers

The invention provides a method for breeding a hot pepper stable inheritance selfing line with high haematochrome content and difficult to fade. The method mainly comprises the steps of (1) primarily selecting through visual observation; (2) screening the thickness of hot pepper peels; (3) finely selecting through spectrophotometer; (4) finally selecting materials difficult to fade; (5) performing circulating polymerization selection. The selfing line bred by adopting the breeding method has high level and excellent target character on fading difficulty, and the bred selfing line can be directly used for combination breeding of hybrid combination.

Owner:QINGDAO AGRI UNIV

Firing technique of blue-and-white underglaze red

The invention discloses a firing technique of blue-and-white underglaze red, which comprises the following steps: 1) preparation of blank and glaze; 2) preparation of billet: making the blank into the billet, trimming, and airing for later use; 3) blue-and-white underglazing: drawing patterns or writing characters on the billet surface with a blue material and a copper red material, carrying out glaze application, and airing to obtain a blue-and-white billet; 4) firing: putting the blue-and-white billet into a kiln, controlling the kiln in an oxidizing atmosphere, heating to 300 DEG C at 100-120 DEG C / hour, and continuing heating to 950 DEG C at 150-200 DEG C / hour; and while controlling the kiln in a reducing atmosphere, heating to 1260-1360 DEG C at 40-60 DEG C / hour, keeping the temperature for 1-2 hours, stopping heating, cooling, and discharging out of the kiln to obtain the finished product. The blue material of the blue-and-white underglaze red porcelain has the advantages of bright color development and stable and uniform coloration, the red material has the advantages of bright coloration, no flying red and no blackening. The blue and red colors of the blue-and-white underglaze red porcelain contrast with each other and benefit each other.

Owner:马健

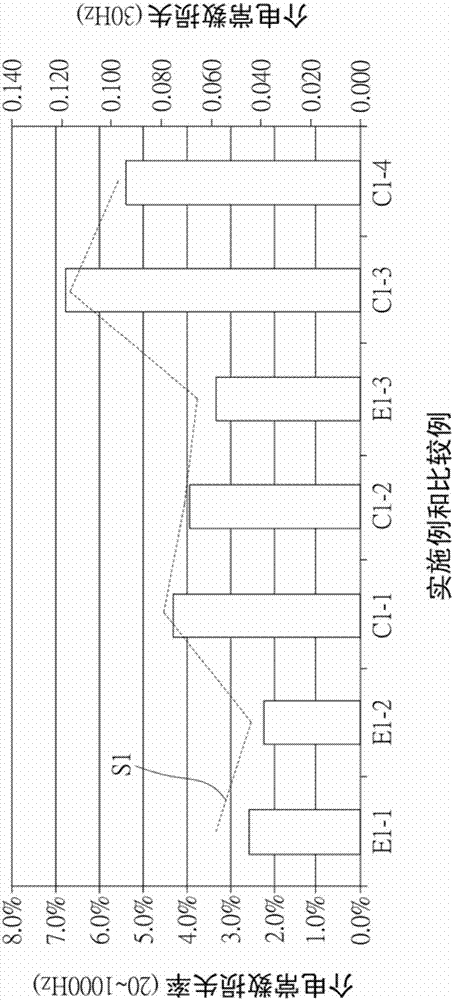

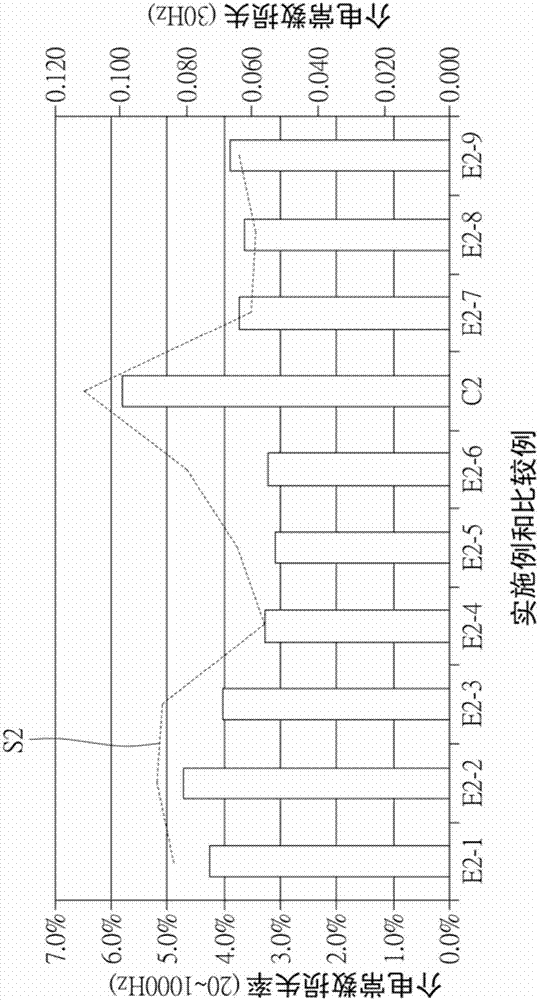

Color photoresist composition and detection method of dielectric constant loss ratio thereof

ActiveCN107450268AGood dielectric constant stabilityExcellent electrical propertiesPhotomechanical apparatusMaterial impedanceEpoxyToluene

The invention discloses a color photoresist composition and a detection method of dielectric constant loss ratio thereof. The color photoresist composition comprises a red material, a resin material, a photopolymerizable monomer and a light initiator, wherein the resin material is a first copolymer or a second copolymer, the first copolymer comprises tricyclodecyl methacrylate, benzene and acrylic acid, the second copolymer comprises epoxy dicyclopentenyl acrylate, dicyclopentenyl acrylate, vinyl toluene and acrylic acid, the weight proportion of the resin material relative to the sum of the resin material and the photopolymerizable monomer is larger than or equal to 30wt%, and the light initiator comprises an oxime light initiator. The color photoresist composition has relatively excellent dielectric constant stability, and thus, a photoresist layer fabricated from the color photoresist composition has relatively excellent electrical property.

Owner:SUMIKA TECH

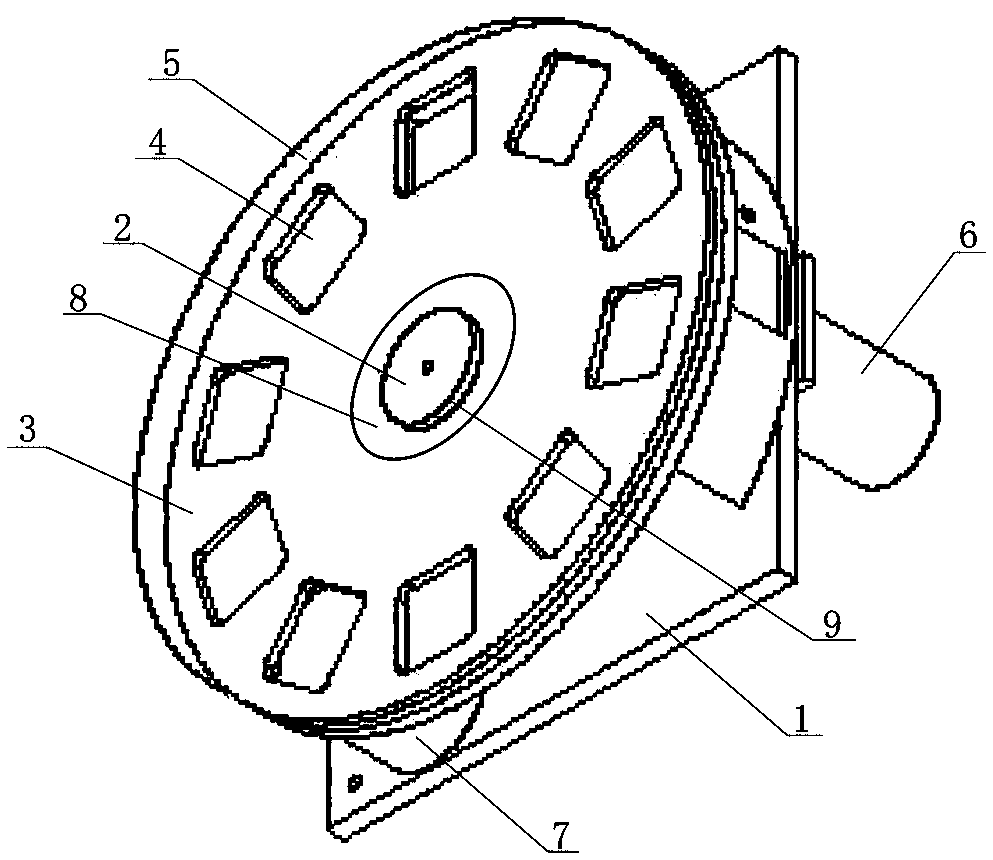

Stamping die device of motor stator piece

A stamping die device for a motor stator sheet, comprising a base, a rotating shaft perpendicular to the base is installed in the middle of the base through a shaft seat, a circular punching plate is fixed on the upper end of the rotating shaft, and the punching material A number of troughs are evenly opened on the plate, and the periphery of the punching plate is provided with a raised ring edge that can position the motor stator sheet on the punching plate, and a stepping motor is installed on the lower part of the base. The above-mentioned stepping motor is meshed with the rotating shaft gear fixed on the rotating shaft extending under the base through a reduction gear box; there are at least three uniformly distributed top pillars installed on the above-mentioned base, and the upper end surface of the top pillar is in line with the circular The punching discs are in contact with each other; a circular groove is arranged in the middle of the circular punching disc, and the upper end of the rotating shaft is fastened with a nut through the thread of the shaft end; it has a simple structure, is convenient and reliable to use, and can improve work efficiency. Good security and other characteristics.

Owner:DEQING ZHENDA ELECTRIC

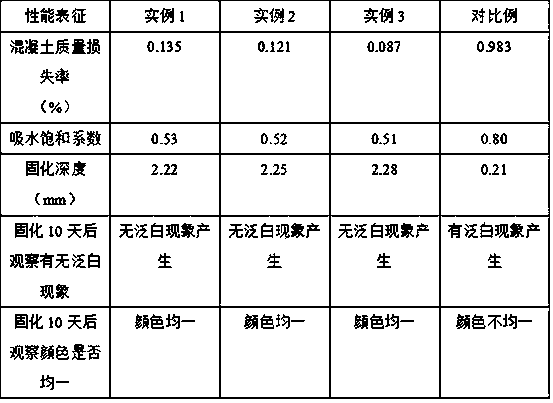

Stable iron red seal curing agent and preparation method thereof

InactiveCN108163899AInhibit aggregationSmall particles and good uniformityFerric oxidesTectorial membraneNano silicon

The invention relates to a stable iron red seal curing agent and a preparation method thereof, and belongs to the technical field of building materials. Transparent nano colloid silicon, a surfactantand an osmotic agent are compounded as a compatibility accelerant. The surface of the nano iron oxide is wrapped with a nano silicon layer, by use of amphoteric inorganic magnesium silicate lithium salt, charged lamella thin slices can be formed in a hydration process, the end faces of lamellas are positively charged, the layer surface of the lamellas are negatively charged, due to the attractionof positive and negative charges, a ''card house'' structure is gradually formed by the lamellas in the hydration process, a colorless transparent gel solution is formed by stripping and dispersing ofmagnesium silicate lithium lamellas in water to form a protective film on the surface of dispersed nano iron oxide particles. The flexible protective film can prevent aggregation of the nano iron oxide, components components inside and outside the protective film are not diffused mutually, a small-particle and homogeneous iron red material is prepared, and phenomena of uneven local color or whitening can be improved.

Owner:翟琳

Automatic feeding device and method for garment manufacturing

The invention discloses an automatic feeding device for garment manufacturing. The automatic feeding device comprises a first conveying machine used for conveying mixed materials, a second conveying machine used for conveying red materials, a third conveying machine used for conveying green materials, a fourth conveying machine used for conveying blue materials, a fifth conveying machine used formanual sorting, a sorting device and a control device; material cylinders are arranged at the tail ends of the second conveying machine, the third conveying machine, the fourth conveying machine and the fifth conveying machine, the first conveying machine, the second conveying machine, the third conveying machine, the fourth conveying machine and the fifth conveying machine are annularly distributed in an array manner with the sorting device as the center, detecting devices used for detecting materials are arranged at the head ends of the second conveying machine, the third conveying machine,the fourth conveying machine and the fifth conveying machine, and a color detection device is arranged at the tail end of the first conveying machine; a joint bearing is arranged on the bottom face ofthe control device. The automatic feeding device for garment manufacturing can reduce worker burdens.

Owner:IANGSU COLLEGE OF ENG & TECH

Low-temperature kiln-changing erythema glaze for light-weight porcelain, its preparation and application method

The invention belongs to the field of ceramic manufacturing, and in particular relates to a kiln-transformed glaze formula, preparation method and application method for firing light-weight porcelain. The formula of the low-temperature kiln-changing erythema glaze for light-weight porcelain includes glass powder, transparent frit glaze, red material, nepheline powder, boric acid, kaolin, and zinc oxide. The kiln-changing erythema glaze formula glaze has low cost, is convenient to use, has a low firing temperature and has a unique artistic sense. The glaze effect produced by this kind of kiln-change erythema glaze has a red or copper-red background color, and irregular black spots are evenly distributed on the background color. The size and density of the black spots depend on the type of ceramic and the glaze The thickness varies, with a unique artistic effect. Porcelain made with this kind of glaze improves the product grade and sales price, and has high economic value; in addition, this kind of glaze can be mass-produced industrially, can be popularized quickly, is easy to use, and has strong competitiveness in the market.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

Composition for manufacturing antenna base and method for preparing base

InactiveCN101775195AImprove insulation performanceStrong impact resistanceAntenna supports/mountingsEpoxyAlkali free

The invention discloses a composition for manufacturing an antenna base and a method for preparing the base. The composition consists of an epoxide resin, a curing agent, an accelerating agent, alkali-free chopped epoxidized glass fiber filament yarns, an ultraviolet absorber or a screening agent, nano-quartz powders, a defoaming agent, a thickening agent and a dye, or consists of a vinyl resin or an unsaturated polyester resin, a red material, a white material, neutral alkali chopped epoxidized glass fiber filament yarns, the ultraviolet absorber or the screening agent, the nano-quartz powders, the defoaming agent, the thickening agent and the dye. The preparation method comprises the following steps: respectively weighing various raw materials in mass ratio; putting the epoxide resin, the curing agent, the accelerating agent and the alkali-free chopped epoxidized glass fiber filament yarns into a stirrer to stir uniformly until the foams disappear; then adding other raw materials, sufficiently stirring the mixture to form a ball mixture; and putting the ball mixture on a heated base die, closing the die and carrying out stepping heating and curing, and naturally cooling and disassembling the die to obtain the antenna base. The antenna base has the advantages of tensile strength of over 18kN, strong impact resistance, strong ageing resistance or ultraviolet resistance, good flame retardance, good toughness and high electrical insulation, and is widely used for army and wireless telecommunication equipment.

Owner:西安永兴科技发展有限公司

Photosensitive resin composition for light blocking layer and light blocking layer using the same

InactiveCN103901723AImprove reliabilityPrevent elutionOptical filtersPhotosensitive materials for photomechanical apparatusSolventRED MATERIAL

The invention discloses a photosensitive resin composition for a light blocking layer and the light blocking layer using the same. The photosensitive resin composition for the light blocking layer includes (A) a colorant including a blue material including a dye represented by the following Chemical Formula 1, and a red material, (B) a binder resin, (C) a photopolymerizable monomer, (D) a photopolymerization initiator, and (E) a solvent, and a light blocking layer using the same. In Chemical Formula 1, each substituent is the same as defined in the detailed description.

Owner:CHEIL IND INC

Rare earth activated aluminate system fluorescent material for electrodeless lamp and preparation method of rare earth activated aluminate system fluorescent material

InactiveCN102311735AImprove luminous efficiencyReduce manufacturing costLuminescent compositionsRare earthEuropium

The invention relates to a rare earth activated aluminate system fluorescent material for an electrodeless lamp. The rare earth activated aluminate system fluorescent material for the electrodeless lamp is a mixture of a red material, a blue material and a green material, wherein the ratio of the red material to the blue material to the green material is 46: 25: 35, the red material, the blue material and the green material are fully mixed and then are mixed with appropriate amount of binder Na2SiO3, thus the product is obtained. The red material comprises yttrium oxide, europium oxide and boron oxide; the blue material comprises aluminium oxide, magnesium oxide, boric acid, barium carbonate, calcium carbonate, europium oxide, cerium oxide and dysprosium oxide; and the green material comprises aluminium oxide, magnesium oxide, boric acid, europium oxide, cerium oxide and terbium oxide. The production process of the preparation method of the rare earth activated aluminate system fluorescent material comprises the steps of sorting, mixing in proportion, placing the materials into a crucible reacting furnace, igniting and heating, insulating heat, cooling, smashing and sieving, carrying out dry grinding and wet grinding, cleaning, dehydrating and stoving, sieving and checking as well as bagging.

Owner:吴振华

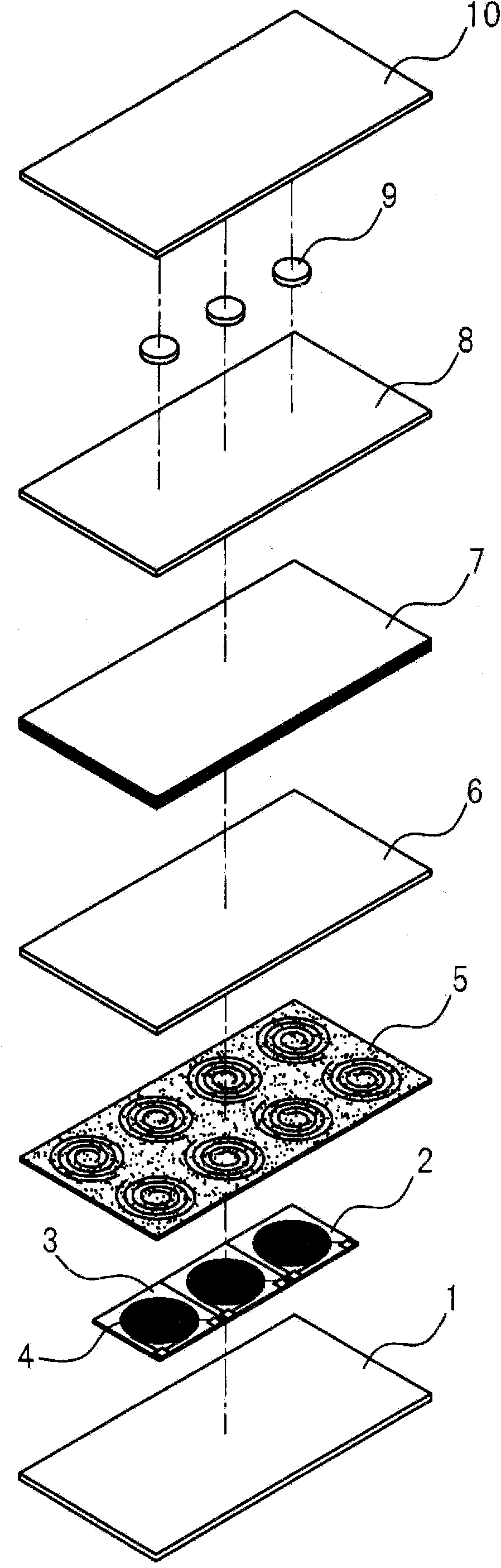

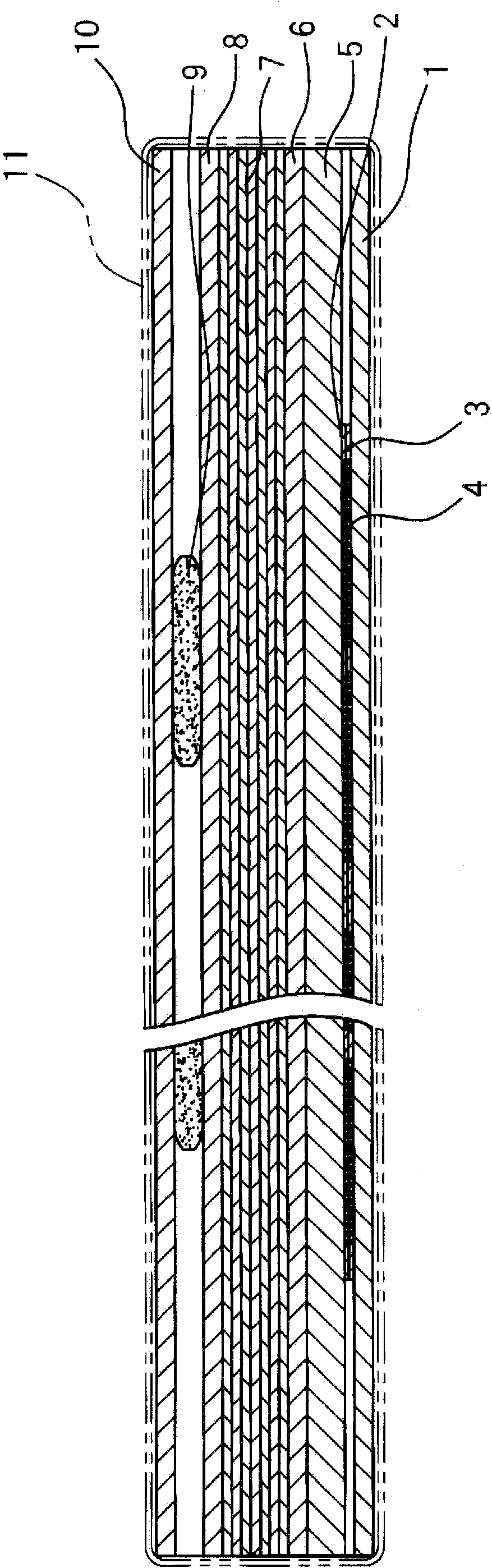

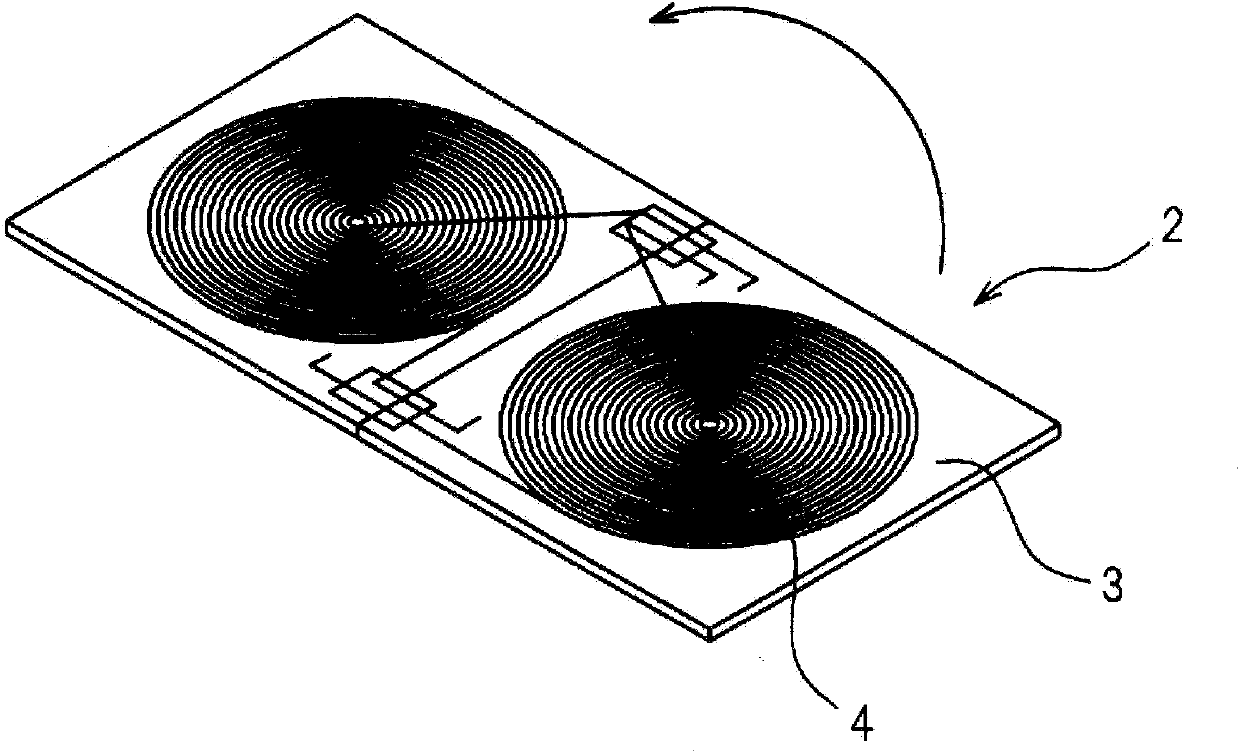

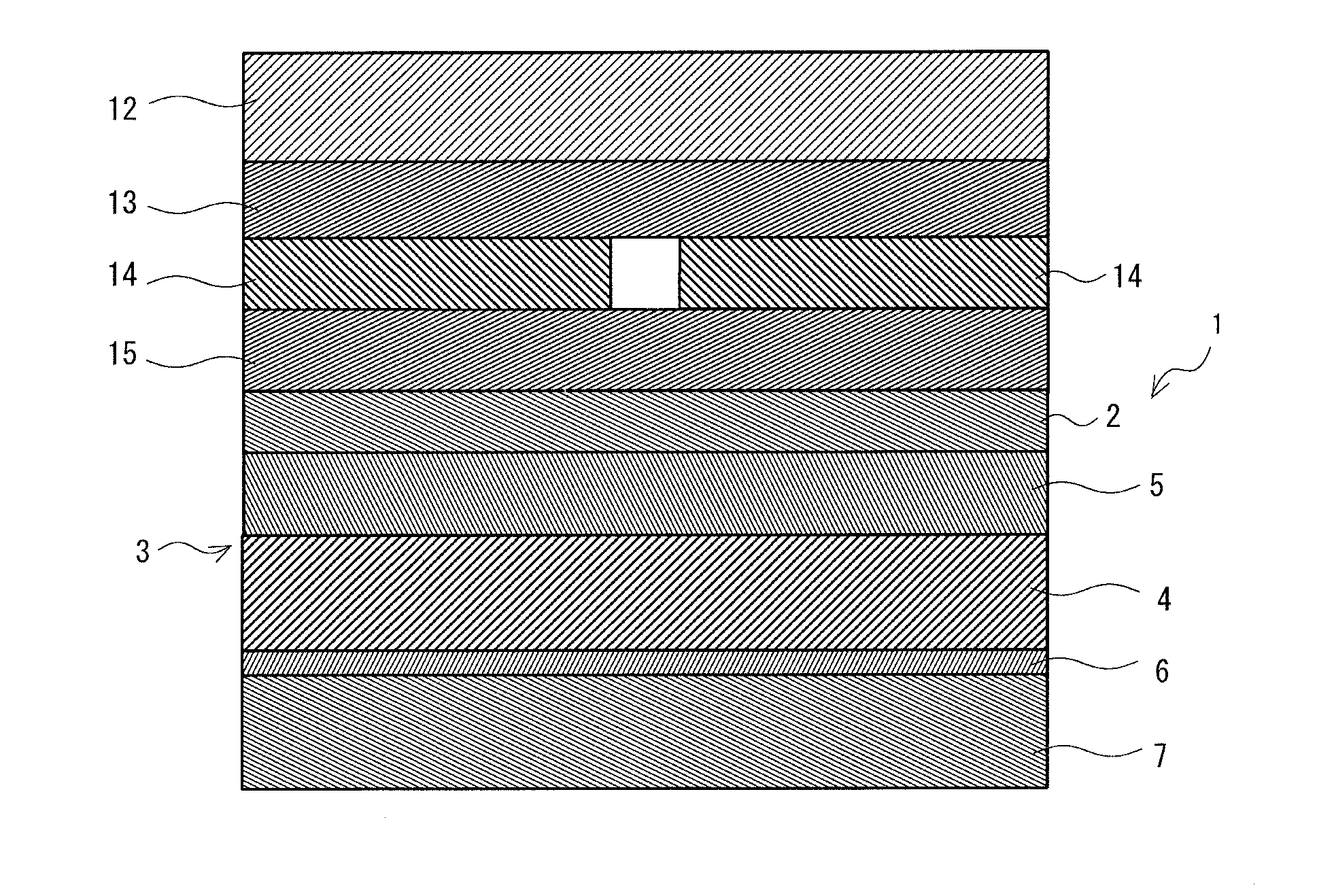

Health/beauty improving device

InactiveCN102886103AMaintain healthPlay beauty effectMagnetotherapy using coils/electromagnetsLight therapyPolymer sciencePtru catalyst

A health / beauty improving device comprises a magnetism generation part (2), an ore energy generation part (5), a first catalyst function part (6), a color energy generation part (7), a second catalyst function part (8), and a Chinese medicament part (9) in overlap arrangement. The magnetism generation part (2) is formed in a manner that a base disc (3) is spirally winded by a thin-line shaped conductive maternal (4); the ore energy generation part (5) is formed in a manner that a synthetic resin sheet is coated by ink containing natural ores in a powder form; the color energy generation part (7) is formed in a manner that a red material layer, an orange material layer, a yellow material layer, a green material layer, a blue material layer, a dark blue material layer, and a purple material layer are sequentially laminated from the ore energy generation part (5) side; and the Chinese medicament part (9) is formed by containing required Chinese medicament. Besides, the catalyst function parts (6, 8) contain gold and silver powders or are constituted by laminated sheets of silicone resin materials and cloth and silk.

Owner:林 竹盛子

A kind of preparation method of α-acetyl-γ-butyrolactone

The invention provides a method for preparing α-acetyl-γ-butyrolactone, which uses γ-butyrolactone and an acetylating agent (ethyl acetate, methyl acetate or a mixture of the two) as starting materials, Sodium metal is used as a catalyst, and the product is obtained through acylation, neutralization and distillation. The advantages of the present invention are: raw materials are used as solvent in the initial stage of acylation reaction, which reduces the environmental pollution caused by the solvent, increases the feeding amount, improves the production efficiency, and reduces the production cost; metal sodium is added into the reaction system in stages or continuously, effectively It avoids safety hazards such as punching and burning caused by the reaction at the melting temperature of metallic sodium, which causes the reaction speed to be difficult to control; by adopting the method of pressure-regulated distillation, the by-products are effectively recovered, reducing environmental pollution and improving comprehensive economic benefits.

Owner:鞠彩霞

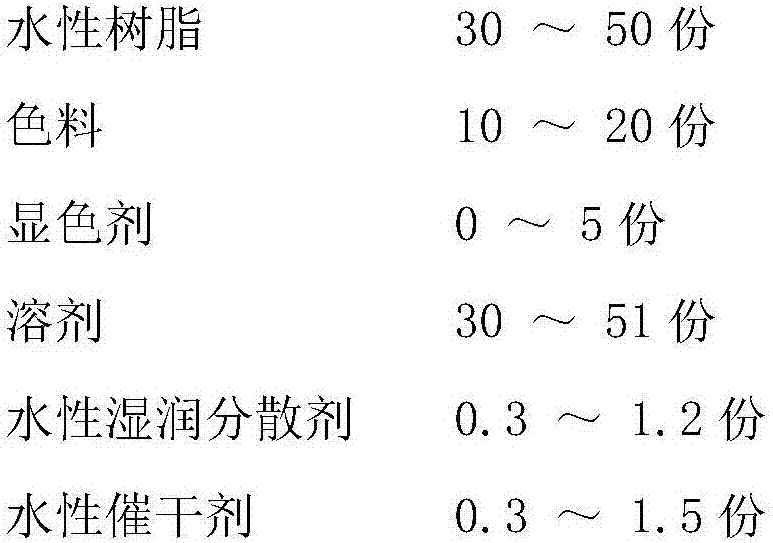

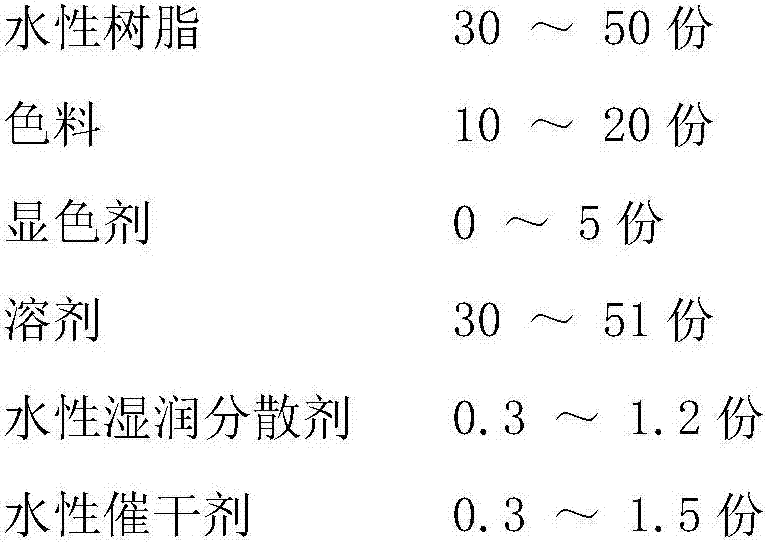

Colored fadable water-based spraying paint

InactiveCN106867339ANo pollution in the processPromote environmental protectionAnti-corrosive paintsPolyester coatingsWater basedPhosphoric acid

The invention provides a color fadeable water-based spray paint, whose components include water-based resin, colorant, color developer, solvent, water-based wetting and dispersing agent and water-based drier; the color developer is bisphenol A, lemon At least one of acid, phosphoric acid, tartaric acid, malic acid, fumaric acid, ascorbic acid and gluconic acid; the color material is white material, red material, blue material, green material, yellow material, orange material, black material of at least one colorant. Its preparation: Take 3 / 4 of the water-based resin according to the mass ratio, take the wetting and dispersing agent, the color developer and the colorant and put them into the reaction kettle, then add nerolidol, and disperse at a high speed for 15-25 minutes; then put in the remaining water-based resin, Solvent, water-based drier, stir well to make water-based spray paint. The prepared water-based spray paint and propellant are potted into an aerosol can equipped with a valve and a press head, and then it can be used. It can be used for temporary painting, wall graffiti, wood or glass spraying, body decoration, graffiti of banners and slogans, map marking, etc.

Owner:SHANXI UNIV

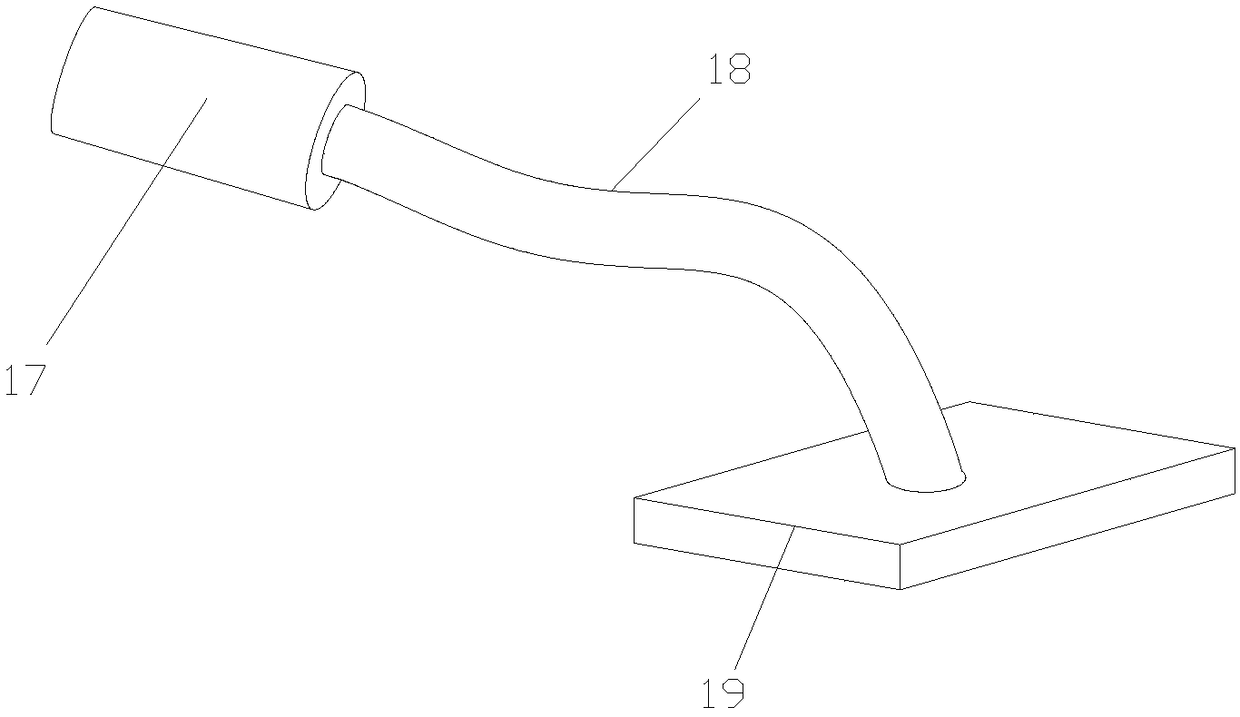

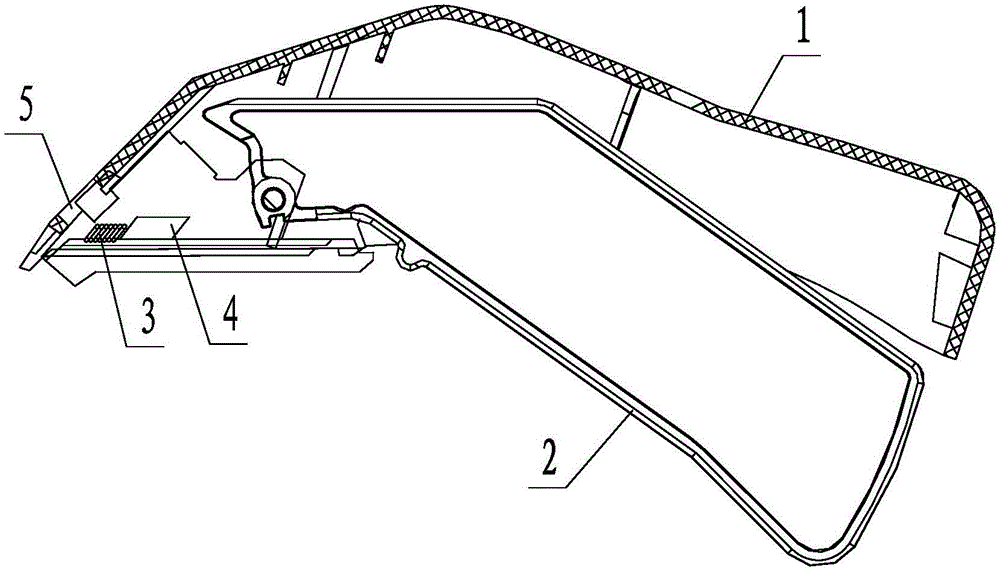

Skin stapler convenient for observing suturing nail

The invention discloses a skin stapler convenient for observing a suturing nail. The skin stapler comprises a fixed handle and a movable handle which is connected with the fixed handle in a rotating manner, wherein a nail compartment component is arranged in the front end of the fixed handle, suturing nails which are sequentially arranged and a nail sending block which is used for pushing the suturing nails to move forwards are arranged in the nail compartment component, a signboard for identifying the amount of the suturing nails is arranged on the side surface of the nail compartment component, an observing window which is convenient for observing the movement of the suturing nails is formed on the front oblique side surface of the fixed handle, and the nail sending block is formed by molding a red material which is convenient to observe. The observing window is formed on the front oblique side surface of the fixed handle, and the red nail sending block is used for pushing the nails to move, so that the remaining quantity of the suturing nails can be more intuitively and clearly observed by a doctor, and a better prompting effect can be achieved.

Owner:JIANGSU BRIGHTNESS MEDICAL DEVICES

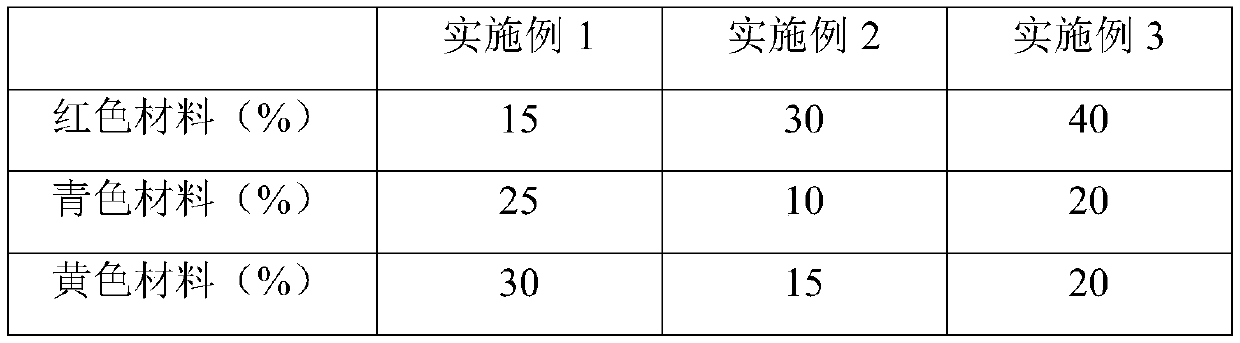

Five-color graphene rice crystal ceramic moxibustion functional material, and preparation method and application thereof

ActiveCN110451913AHumidity Index ImprovementImprove blood stasis indexDevices for heating/cooling reflex pointsSodium metasilicateFar infrared

The invention belongs to the technical field of functional materials, and particularly relates to a five-color graphene rice crystal ceramic moxibustion functional material, and a preparation method and an application thereof. The functional material is prepared from sodium metasilicate, 15-40% of a red material, 10-25% of a cyan material, 11-30% of a yellow material, 10-25% of a black material and 10-20% of a white material, wherein the red material is made from a heat storage material, a high frequency material and serpeggiante; the cyan material is made from the heat storage material, the high frequency material and lasurite; the yellow material is made from the heat storage material, the high frequency material and loess; the black material is made from the heat storage material, the high frequency material and tourmaline; the white material is made from the heat storage material, the high frequency material and seashell powder; the heat storage material is prepared from graphene,kaolin, sepiolite and alumina; and the high frequency material is prepared from terahertz powder, stone needle powder, jade powder, far-infrared powder and germanium powder. The functional material has the efficacy of clearing dampness and dispelling coldness, beautifying skins and reducing fat, and dredging meridians and collaterals. The invention also provides the preparation method and the application of the functional material.

Owner:山东木医健康产业发展有限公司

Xuyi lobster flavoring bag formula

The invention mainly discloses a Xuyi lobster flavoring bag formula which have four flavors, namely a Xuyi lobster sign flavoring bag, a Xuyi lobster classic thirteen-spice flavoring bag, a Xuyi lobster spicy flavoring bag and a Xuyi lobster garlic flavoring bag. The Xuyi lobster flavoring bag is mainly prepared from the following condiments: sugar, salt, monosodium glutamate, chicken powder, red camphor oil, red materials, white materials, thirteen spice, garlic sauce and pickled spicy materials. The lobsters cooked by the formula are delicious in meat flavor, unique in flavor, red and bright in color, smooth and tender in texture and spicy in taste.

Owner:XUYI SIZHOU CITY AGRI DEV

Cleaning device of pot matching machine

PendingCN113145585AImprove cleanlinessRealize fully automatic self-cleaningHollow article cleaningBlowoff valveEnvironmental engineering

The invention discloses a cleaning device of a pot matching machine. The cleaning device comprises a water tank internally provided with an RO water tank, wherein a first conveying pipe on the water tank and a second conveying pipe on the RO water tank are both connected to a circulating storage tank, the circulating storage tank is provided with a backflow input pipe, a low-pressure gas input pipe and a circulating tank output pipe, and the circulating tank output pipe is provided with a blowoff valve; the circulating tank output pipe is connected with a white material cleaning conveying pipe and a red material cleaning conveying pipe, a white material cleaning conveying pipe is connected with white material storage tanks through white material cleaning branch pipes, the red material cleaning conveying pipe is connected with red material storage tanks through red material cleaning branch pipes, and a backflow input control valve is arranged on the backflow input pipe; and the backflow input pipe and a first discharge pipe are connected with a connecting pipe, the first discharge pipe is provided with a first discharge control valve, and the input end of the connecting pipe is provided with a plurality of connecting assemblies in sealed connection with conveying control valves on the white material storage tanks or the red material storage tanks at intervals. The cleaning device has the advantages that the pot matching machine is effectively cleaned, and it is ensured that the pot bottom of a matching pot is clean and sanitary.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Method for manufacturing crystal cinerary casket

The invention relates to a preparing method for crystal cinerary casket and belongs to cinerary casket preparing domain, which is that selecting crystal powder with particle size more than 300 subsections and unsaturated resin of 38%-70% and 30%-62% separated waiting for usage; selecting curing agent with weight of total weight 0.8-2% of crystal powder and resin waiting for usage; selecting accelerating agent with weight of total weight 0.5-1.5% of crystal powder and resin waiting for usage; selecting black, atropurpureus, mauve, carmine or red material with weight of total weight 1-10% of crystal powder and resin waiting for usage; putting materials mentioned above into agitator, and intimate mixing, taking out air in cavity of cinerary casket mould, making it to be vacuum, then injecting the material mixed uniformly into cavity of cinerary casket mould by vacuum impregnation method, forming; or putting material mixed uniformly in cinerary casket stem pressing mould and pressing to form; it's OK that polishing the formed crystal cinerary casket by polishing machine, and crystal cinerary casket formed by stem pressing needs not to polish.

Owner:厉国苗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/164985d5-8176-43e7-989e-b8f2afc13456/BDA0000065013020000011.PNG)

![Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/164985d5-8176-43e7-989e-b8f2afc13456/BDA0000065013020000021.PNG)

![Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method Novel electrically neutral tridentate iridium [iii] complex red light material and preparation method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/164985d5-8176-43e7-989e-b8f2afc13456/FDA0000065013010000011.PNG)