Stable iron red seal curing agent and preparation method thereof

A sealing curing agent, stable technology, applied in the direction of iron oxide/iron hydroxide, iron oxide, etc., can solve problems such as whitening, unsatisfactory curing effect of color curing agent, uneven color, etc., to improve compactness, improve Color unevenness or whitening, water resistance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

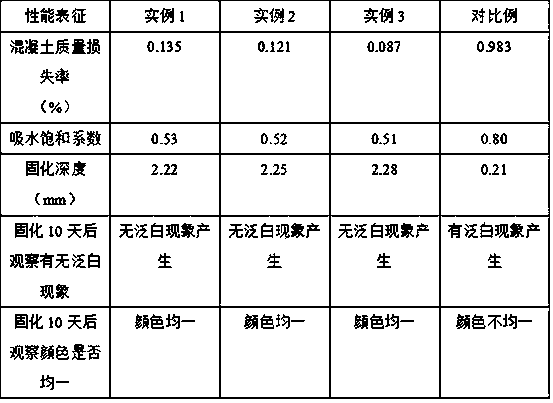

Examples

example 1

[0026] Take 0.3g of cetyltrimethylammonium bromide, add it to 60g of deionized water, stir and heat at 300r / min until boiling for 1h, then add 16g of 10% ferric chloride solution dropwise at 1mL / min, dropwise Continue stirring for 1 h after completion, then adjust the pH to 4 with 5% ammonia water by mass fraction, and then transfer to a rotary evaporator to evaporate to dryness under reduced pressure, place the evaporated product in a muffle furnace, and heat up to 5°C / min. Calcined at 500°C for 1 hour, cooled to room temperature to obtain nano-iron oxide, took 0.3g dispersant, 0.5g penetrating agent, 0.8g surfactant, added to 80g silica sol, stirred at 200r / min for 20min, obtained compatibility accelerator, Add 10g of nano-iron oxide to the compatibility promoter, stir at 200r / min for 20min, then add 10g of magnesium lithium silicate, 1.2g of surface modifier, 1g of defoamer, and stir at 300r / min for 20min to obtain stable iron red Seal curing agent.

example 2

[0028] Take 0.4g of cetyltrimethylammonium bromide, add it to 80g of deionized water, stir and heat at 350r / min until boiling for 1h, then add 21g of 10% ferric chloride solution dropwise at 1mL / min, dropwise Continue to stir for 1 hour after the completion, then adjust the pH to 4.5 with 5% ammonia water by mass fraction, and then transfer to a rotary evaporator to evaporate to dryness under reduced pressure, place the evaporated product in a muffle furnace, and heat up to Calcined at 525°C for 2h, cooled to room temperature to obtain nano-iron oxide, took 0.4g dispersant, 0.65g penetrating agent, 1.0g surfactant, added to 90g silica sol, stirred at 250r / min for 25min, obtained compatibility accelerator, and Add 12g of nano-iron oxide to the compatibility promoter, stir at 250r / min for 25min, then add 13g of magnesium lithium silicate, 1.6g of surface modifier, 2g of defoamer, and stir at 350r / min for 25min to obtain stable iron red Seal curing agent.

example 3

[0030] Take 0.5g of cetyltrimethylammonium bromide, add it to 100g of deionized water, stir and heat at 400r / min until boiling for 2h, then add 27g of 10% ferric chloride solution dropwise at 2mL / min, dropwise After completion, continue to stir for 2 hours, then use 5% ammonia water to adjust the pH to 5, and transfer to a rotary evaporator to evaporate to dryness under reduced pressure. The evaporated product is placed in a muffle furnace, and the temperature is raised to Calcined at 550°C for 2 hours, cooled to room temperature to obtain nano-iron oxide, took 0.5g dispersant, 0.8g penetrant, and 1.2g surfactant, added to 100g silica sol, stirred at 300r / min for 30min to obtain compatibility accelerator, and Add 15g of nano-iron oxide to the compatibility accelerator, stir at 300r / min for 30min, then add 15g of lithium magnesium silicate, 2.0g of surface modifier, 2g of defoamer, and stir at 400r / min for 30min to obtain stable iron red Seal curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com