Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Phenyl beta-naphthylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-heat-conductivity ternary rubber

InactiveCN103044784AImprove thermal conductivityEnhanced interactionHeat conductingVolumetric Mass Density

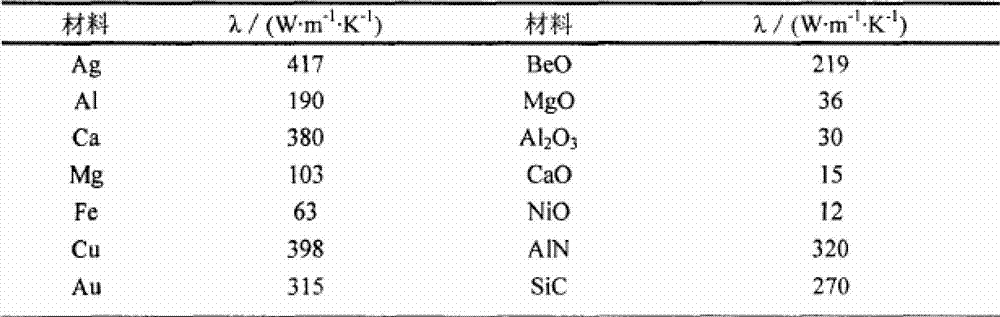

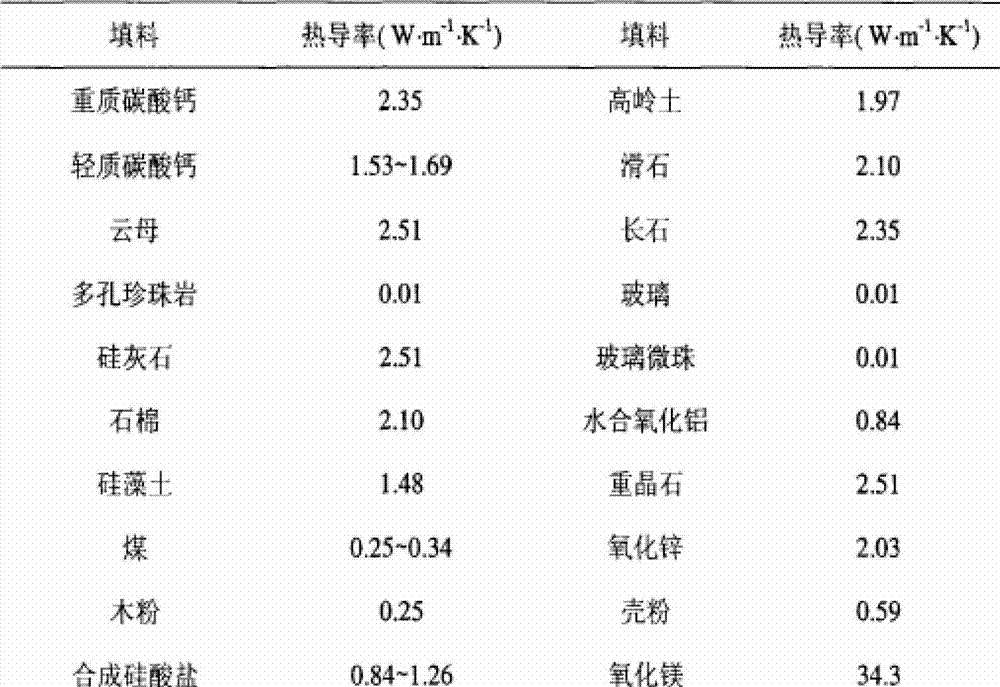

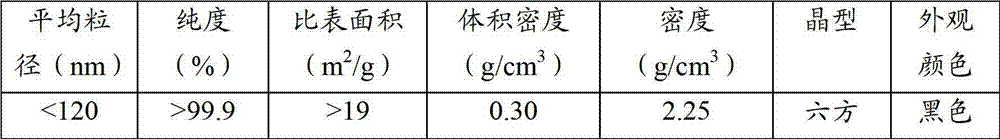

The invention discloses high-heat-conductivity ternary rubber. An anti-aging agent is one type or more types of the following reagents: N-phenyl-alpha-aniline, N-phenyl-beta-naphthylamine, N-phenyl-N'-cyclohexyl p-phenylenediamine, N-phenyl-N'-isopropyl-p-phenylenediamine and N-N'-diphenyl-p-phenylenediamine. An accelerant is one type or more types of the following reagents: an accelerant T, N,N-tetramethyl dithio-dithiocarbonyl amine, tetramethylthiuram disulfide, thiram, a vulcanization accelerant TMTD and tetramethylthiuram disulfide. By adoption of mixed fillers, the heat conductivity of the composite material is greatly improved. Granules and crystal whiskers with a certain length-diameter ratio form continuous heat-conducting network chain; combination of fillers with different grain size is selected, so high filling density is achieved; and the interface of the fillers and a matrix is improved by a coupling agent, so the heat resistance at the interface is reduced.

Owner:深圳桐源科技有限公司

Rubber for automobile absorber

The invention discloses a rubber for an automobile absorber. The rubber for the automobile absorber is prepared from the following raw materials in parts by weight: 15-30 parts of silicone rubber, 10-25 parts of polybutadiene rubber, 20-35 parts of polyurethane rubber, 2-6 parts of a plasticizer, 1-7 parts of an antioxidant, 2-8 parts of an accelerator, 0.5-4 parts of nanometer zinc oxide, 1-5 parts of benzoyl peroxide, 5-10 parts of rosin and 2-10 parts of sulfur, wherein the antioxidant is N-phenyl-beta-naphthylamine, the accelerator is praseodynium aluminum, and the plasticizer is epoxy soybean oil. According to the rubber for the automobile absorber disclosed by the invention, with the silicone rubber, the polybutadiene rubber and the polyurethane rubber, which are good in aseismic performance, as basic raw materials and auxiliaries including the antioxidant, the accelerator, the nanometer zinc oxide and the plasticizer as the auxiliary materials, the formula is reasonable, the production process is simple, the rigidity, the tensile strength and the aging resistance of product are good, and the aseismic performance is remarkably improved.

Owner:LIUZHOU JULONG TECH

Wear-resistant and high temperature-resistant lubricating grease and preparation method thereof

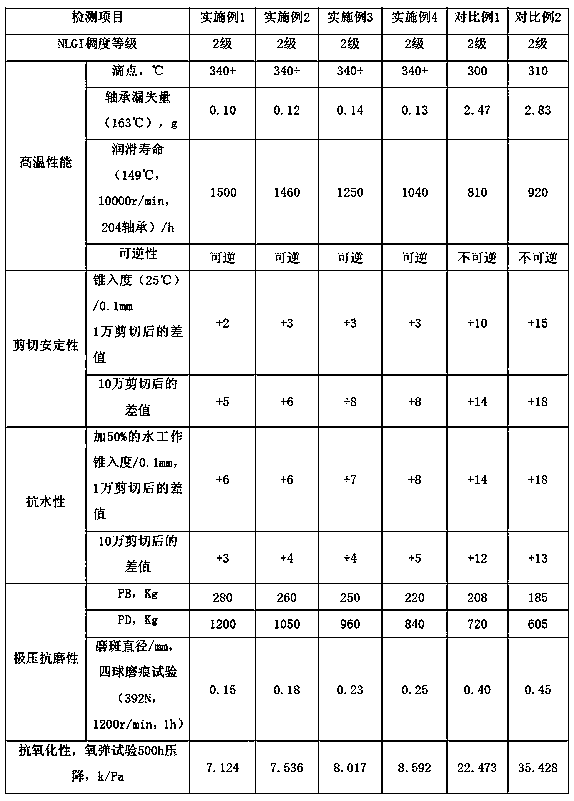

InactiveCN107903987AImprove performanceImprove the immunityLubricant compositionWear resistantHydroxystearic Acid

The invention provides wear-resistant and high temperature-resistant lubricating grease and a preparation method thereof. The wear-resistant and high temperature-resistant lubricating grease is prepared from the following raw materials in part by weight: 40-80 parts of poly alpha-olefin, 10-30 parts of liquid paraffin, 10-30 parts of Turkey red oil, 10-40 parts of attapulgite, 10-30 parts of nanographene, 10-20 parts of a poly-urea thickener, 10-25 parts of 2,5-dibutyl hydroquinone, 9-15 parts of diphenylamine, 7-19 parts of 2,4-methyl phenyl diisocyanate, 6-13 parts of triethanolamine, 8-14parts of tricresyl phosphate, 12-18 parts of 12-oxystearic acid, 10-16 parts of phenyl-beta-naphthylamine, 5-12 parts of ethylene carbonate and 10-25 parts of normal butanol. The lubricating grease provided by the invention has higher high temperature, extreme pressure wear resistance and corrosion resistance, thereby having higher stability and long service life; and the preparation process is simple, excellent in performance and suitable for universal industrial production and application.

Owner:苏州市宽道模具机械有限公司

Weather-resistant water-swelling waterproof rubber sealing material and preparation method thereof

The invention discloses a weather-resistant water-swelling waterproof rubber sealing material and a preparation method thereof. The weather-resistant water-swelling waterproof rubber sealing material consists of the following components in parts by weight: 60 parts of butyl rubber, 40 parts of modified nitrile rubber, 10-16 parts of bentonite-calcium carbonate microspheres, 6-10 parts of SAP resin, 3-5 parts of sodium polyacrylate, 2-6 parts of white carbon black, 1-3 parts of stearic acid, 1-5 parts of N-phenyl-beta-naphthylamine and 1-3 parts of dimethyl methacrylic acid gylcol ester. As butyl rubber, modified nitrile rubber and bentonite-calcium carbonate microspheres are compounded, and with the combination of active components of nano-zinc oxide, white carbon black and the like, the flowability and the plasticity of the water-swelling rubber can be improved, and the weather resistance and the processing property of the waterproof rubber sealing material are effectively improved.

Owner:ANHUI RONGDA VALVE

Method for manufacturing flexible cables

InactiveCN104464958AImprove mechanical propertiesExcellent electrical performanceInsulating conductors/cablesSilanesEngineering

The invention discloses a method for manufacturing flexible cables. The method comprises the following steps that (1) copper monofilaments are pulled and annealed, (2) the multiple copper monofilaments are stranded, and (3) by weight, 24.3 parts of polypropylene, 3.1 parts of N-phenyl-Beta-naphthylamine, 2.8 parts of synthesis of triethylene glycol bis Beta-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate, 0.4 part of VTPS silane coupling agent, 0.8 part of triethoxy ethyl silane and 4.3 parts of phenyl methyl silicone oil are fed into an extruder to be mixed and extruded out to be wrapped on a conductor. The cables manufactured through the method have excellent mechanical performance, electrical performance, corrosion resistance and flexibility.

Owner:江苏戴普科技有限公司

Wear-resistant ageing-resistant rubber sleeve for automotive steering gear bushing

The invention discloses a wear-resistant ageing-resistant rubber sleeve for automotive steering gear bushing. Raw materials of the wear-resistant ageing-resistant rubber sleeve comprise, by weight, 70-100 parts of natural rubber, 20-40 parts of styrene-butadiene rubber, 5-15 parts of cis-polybutadiene, 1-5 parts of N,N'-m-phenylenedimaleimide, 2-5 parts of a vulcanization accelerator CZ, 1-5 parts of zinc oxide, 0.5-2.8 parts of stearic acid, 1-5 parts of epoxy silkworm chrysalis butyl oleate, 10-20 parts of carbon black, 15-30 parts of ceramic fibre, 50-60 parts of nano-glass fiber, 30-60 parts of bentonite glass beads composite microspheres, 2-5 parts of vinylmethyldimethoxysilane, 1-3 parts of N-isopropyl-N-phenyl-p-phenylenediamine and 0.5-2.5 parts of N-phenyl-beta-naphthylamine. The wear-resistant ageing-resistant rubber sleeve of the invention is not easy to deform, has good ageing resistance and has long service life.

Owner:宁国天运橡塑制品有限公司

High-abrasion resistant anti-tear reclaimed rubber material and preparation method thereof

The invention provides a high-abrasion resistant anti-tear reclaimed rubber material and a preparation method thereof. The reclaimed rubber comprises the following raw materials: waste ethylene propylene diene monomer, waste nitrile butadiene rubber, chlorosulfonated polyethylene rubber, a propylene-ethylene semi-crystalline polymer, manganese stearate, ethylene bis-stearamide, kaolin, fly ash, zinc stannate, amino diisopropyl tungsten dithiophosphate, 4-picolinic acid, cellulose acetate, polyoxyethylene ether, p-epichlorohydrin, hydroxypropyl starch ether, di(2-ethylhexyl)phthalate, N-oxydiethylene-2-benzothiazole sulfenamide, a phosphate coupling agent, N-phenyl-beta-naphthylamine, diaminopropane phosphate, oleamide, N-(morpholinothio)phtraldiaimide, bromo-octyl-phenolic curing resin, alkylphenol disulfide, a sulfuric acid aqueous solution, sodium dodecyl sulfate, and ethanol. The reclaimed rubber provided by the invention has all mechanical property indexes reaching the industrial standard level of general rubber, has good abrasion resistance and tear resistance, and has good application prospect.

Owner:潘明华

Glue based on graphene modification

InactiveCN106753153AImprove adhesionHigh bonding strength at room temperatureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePhenyl beta-naphthylamine

The invention discloses glue based on graphene modification. The glue is prepared from polyurethane, chloroprene rubber, polyacrylate, graphene, triallylisocyanurate, ethidene diamine, n-butyl alcohol, methylbenzene, potassium stearate, polyethylene imidacloprid network flavanone and N-phenyl-beta-naphthylamine. A preparation method comprises the following steps of (1) adding the graphene into the n-butyl alcohol and the methylbenzene, and ultrasonically dispersing uniformly to obtain a mixed solution A; (2) adding the polyurethane, the chloroprene rubber and the polyacrylate into a reactor for reaction, and sequentially adding the mixed solution A obtained in the step (1), the triallylisocyanurate, the potassium stearate, the polyethylene imidacloprid network flavanone and the N-phenyl-beta-naphthylamine into the reactor for reaction to obtain a mixture B; (3) stopping the reaction, when the temperature cools to 80 DEG C, adding the ethidene diamine into the reactor, stirring uniformly, and preparing the glue based on the graphene modification. The glue prepared by the invention can maintain higher cohesiveness under a high temperature condition, has better high temperature resistance, and is very suitable to be used as high-temperature glue.

Owner:南京润屹电子科技有限公司

Method for manufacturing vibration isolator

ActiveCN103467784AImprove carrying capacityGood damping energy dissipation capacityCoatingsStearic acidNoise reduction

The invention discloses a method for manufacturing a vibration isolator. The method is as below: first dipcoating 5-10 rubber layers on a whisker surface of tetrpod-like zinc oxide; taking 100 parts by weight of plasticated natural rubber; adding 10-15 parts by weight of the tetrpod-like zinc oxide with rubber layers dip-coated on the whisker surface, 3-5 parts by weight of nano zinc oxide, 0.3-0.8 parts by weight of stearic acid, 15-20 parts by weight of spray carbon black, 1-3 parts by weight of an antioxidant N-phenyl-beta-naphthylamine, 2-3 parts by weight of sulfur and 0.3-0.8 part by weight of an accelerator disulfide benzothiazole; mixing evenly; injecting the mixture into a metal mold cavity of a molding machine injection isolator by an injection molding machine; and vulcanizing the mixture at 150-160 DEG C for 15-20 min to obtain the isolator product. The isolator manufactured by the manufacturing method provided by the invention has strong carrying capacity and high damping dissipation energy, good noise reduction and isolation performance and obvious effects.

Owner:ANHUI HUAJING MACHINERY

Insulating shell of switch cabinet

The invention discloses an insulating shell of a switch cabinet. The insulating shell of the switch cabinet is prepared from the following raw materials in parts by weight: 25 to 28 parts of glass fiber, 6 to 14 parts of silicon dioxide, 9 to 12 parts of fiber cotton, 20 to 24 parts of polycarbonate resin, 7 to 13 parts of polyurethane, 2 to 8 parts of polypropylene, 16 to 20 parts of poly(1-butene), 2 to 4 parts of boric oxide, 7 to 8 parts of calcium carbonate, 8 to 10 parts of barium sulfate, 6 to 14 parts of aromatic polyamide fiber, 2 to 8 parts of molybdenum disulfide, 4 to 8 parts of dibutyl phthalate, 13 to 15 parts of diisobutyl phthalate, 7 to 9 parts of sodium citrate, 3 to 8 parts of zirconium tetrafluoride, 11 to 14 parts of ethyl acetate, 6 to 12 parts of butyl methacrylate and 18 to 20 parts of N-phenyl-beta-naphthylamine. The insulating shell of the switch cabinet has high structure strength, good insulating effect and good anti-ageing effect.

Owner:吕杰

Modified mesoporous molecular sieve/hydrophilic expansion waterproof rubber sealing material and preparation method thereof

The invention provides a modified mesoporous molecular sieve / hydrophilic expansion waterproof rubber sealing material and a preparation method thereof. The modified mesoporous molecular sieve / hydrophilic expansion waterproof rubber sealing material is prepared from the following raw materials in parts by weight: 100 parts of butadiene-acrylonitrile rubber, 8-12 parts of mesoporous molecular sieves, 5-9 parts of graphene, 15-25 parts of bentonite-calcium carbonate microspheres, 10-16 parts of SAP resin, 8-12 parts of tackifying resin, 1-3 parts of stearic acid, 4-6 parts of N-phenyl-beta-naphthylamine and 1-3 parts of a silane coupling agent. The modified mesoporous molecular sieve / hydrophilic expansion waterproof rubber sealing material has the advantages that the mesoporous molecular sieves are added, so that modified hydrophilic expansion rubber has relatively high chemical stability while keeping water absorption to be constant; besides, the modified mesoporous molecular sieve / hydrophilic expansion waterproof rubber sealing material has the advantages of high strength, durability and reusability due to synergistic effect of graphene and the mesoporous molecular sieves.

Owner:ANHUI RONGDA VALVE

Self-adhesive waterproof rubber sealing material with water swelling property and preparation method of self-adhesive waterproof rubber sealing material

The invention discloses a self-adhesive waterproof rubber sealing material with water swelling property and a preparation method of the self-adhesive waterproof rubber sealing material. The self-adhesive waterproof rubber sealing material comprises the following raw materials in parts by weight: 100 parts of butyl rubber, 15-25 parts of bentonite-calcium carbonate microspheres, 10-16 parts of SAP (super absorbent polymer) resin, 10-20 parts of polyisobutene, 8- 12 parts of tackifying resin, 1-3 parts of stearic acid, 5-10 parts of silica, 4-6 parts of N-phenyl-beta-naphthylamine and 1- 3 parts of ethyleneglycol dimethacrylate. The self-adhesive waterproof rubber sealing material prepared with the preparation method has excellent water swelling sealing performance, a full-adhesion effect is formed between the material and concrete mortar during use, penetration of water is effectively prevented, and the sealing effect is better.

Owner:ANHUI RONGDA VALVE

Composite nano mining cable sheath material and preparation method therefor

InactiveCN104927214AHigh mechanical strengthImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideTitanium nitride

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

Fiber modified water-expandable waterproof rubber sealing material and preparation method thereof

The invention provides a fiber modified water-expandable waterproof rubber sealing material and a preparation method thereof. The fiber modified water-expandable waterproof rubber sealing material is prepared from, by weight, 100 parts of nitrile rubber, 8-16 parts of short fibers, 15-25 parts of bentonite-calcium carbonate micro-spheres, 10-16 parts of SAP resin, 8-12 parts of silica, 1-3 parts of stearic acid, 4-6 parts of N-phenyl-beta-naphthylamine and 1-3 parts of a promoter D. The water absorption speed of the sealing material is improved by combining the short fibers and the water absorption component (the bentonite-calcium carbonate micro-spheres and the SAP resin) in use. In addition, the modified water-expandable waterproof rubber sealing material has higher strength and chemical stability and excellent water absorption and stop properties under the synergistic effect of the sealing material.

Owner:ANHUI RONGDA VALVE

Composite material for shielding electromagnetic radiation

InactiveCN108285604AImprove shielding effectExtended propagation pathMagnetic/electric field screeningReflection lossAcrylic resin

The invention discloses a composite material for shielding electromagnetic radiation, and the composite material is prepared from raw materials of silicon carbide fiber, thermoplastic acrylic resin, aferrocene organic magnet, N-phenyl-beta-naphthylamine, zinc stearate, polyvinyl chloride, a conductive filler, a coupling agent, a filler, a stabilizer and other auxiliary agents; the composite material combines the advantages of a multilayer structural material and a gradient structural material, and has the performances superior to that of the two materials. Due to the impedance mismatch between a material absorption layer and a reflection layer, incident electromagnetic wave may generate multiple reflections, propagation paths of the electromagnetic wave in the material can be increased, and by the increase of multiple-reflection loss and absorption loss, the shielding effectiveness of the material become larger; the difference in impedance between the absorption layer and the reflection layer is reduced, so that the electromagnetic wave may not escape the shielding material too quickly due to reflection, and can enter a next shielding unit more, and the shielding effectiveness ofthe material can be further improved. Therefore, the composite shielding material of the structure has better shielding properties.

Owner:孙奉生

Rubber sealing material for sealing automotive oil cylinder and preparation method thereof

InactiveCN106957467AGood oil resistanceImprove high temperature resistancePolymer scienceAcrylonitrile

The invention discloses a rubber sealing material for sealing an automotive oil cylinder. The rubber sealing material is prepared from the following raw materials: butadiene-acrylonitrile rubber, fluorinated silicone rubber, cobalt oxide, magnesium dimethacrylate, fumed silica, stearic acid, an anti-aging agent CPPD, N-phenyl-beta-naphthylamine, ethyltrimethoxysilane, n-butyl titanate, dibutyl phthalate, cadmium oxide, N,N'-meta-phenylene bismaleimide and dicumyl peroxide. The invention also discloses a preparation method of the rubber sealing material for sealing the automotive oil cylinder. The rubber sealing material prepared by the preparation method provided by the invention has favorable oil resistance and high-temperature ageing resistance; a sealing element, which is made by using the rubber sealing material, for the automotive oil cylinder is long in service life and good in use effect; the requirement of a market can be met; the rubber sealing material has a wide market prospect.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Paper tube glue and preparation method therefor

InactiveCN104893596AGood initial adhesionShort tack timeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesivePolyvinyl alcohol

The invention discloses paper tube glue and a preparation method therefor. The paper tube glue is prepared from the following raw materials in parts by weight: 15-35 parts of alpha-ethyl cyanoacrylate, 3-7 parts of coumarone-indene resin, 2-8 parts of dibutyl phthalate, 1-5 parts of calcium carbonate, 3-6 parts of talcum powder, 10-15 parts of 2,6-di-tert-butyl-p-cresol, 4-8 parts of N-phenyl-beta-naphthylamine and 20-35 parts of water. The paper tube glue prepared by the preparation method has the characteristics of good initial adhesion, short initial adhesion time, high bonding strength, fluidity, no warping in bonding and good storage stability; by applying the paper tube glue to the manufacturing of paper tubes, manufactured paper tube products have the advantages of high strength, high stiffness and no embrittlement. The paper tube glue disclosed by the invention can be applied to the mechanical production of all kinds of high, medium and low paper tubes, can also be applied to the production of paper barrels, is used for replacing adhesives for the paper tubes such as white latex, polyvinyl alcohol and the like and is wide in range of application.

Owner:GUANGXI JIN HONG GREEN PACKAGING TECH

Hydrogen sulfide corrosion-resistant water-swellable waterproof rubber sealing material and preparation method thereof

InactiveCN106117844AGood compatibilityImprove gas-liquid barrier performanceOther chemical processesMicrosphereChemistry

The invention discloses a hydrogen sulfide corrosion-resistant water-swellable waterproof rubber sealing material and a preparation method thereof. The sealing material comprises the following raw materials in parts by weight: 60-70 parts of butyl rubber, 30-40 parts of ethylene-propylene-diene monomer, 10-16 parts of bentonite-calcium carbonate microspheres, 10-12 parts of SAP resin, 8-12 parts of organic rectorite, 1-5 parts of zinc oxide, 1-5 parts of N-phenyl-beta-naphthylamine, and 2-3 parts of an organic treatment agent QAS1. The prepared water-swellable waterproof rubber sealing material has the advantages of excellent hydrogen sulfide corrosion resistance.

Owner:ANHUI RONGDA VALVE

Heat-resistant leakproof sealant of alkaline storage battery

InactiveCN106336820AImprove heat resistanceImprove sealingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveGas phaseSealant

The invention discloses a heat-resistant leakproof sealant of an alkaline storage battery. The heat-resistant leakproof sealant is prepared from, by weight, 8-15 parts of molybdenum-containing phenolic resin, 20-40 parts of butyl rubber, 10-16 parts of high density polyethylene, 3-6 parts of ethylenediaminetetraacetic acid, 2-8 parts of gas phase titanium dioxide, 0.5-1.5 parts of 2,5-ditert-butylhydroquinone, 1-2 parts of ferric chloride, 9-14 parts of 1,4-cyclohexanedimethanol, 2-6 parts of methyl methacrylate, 5-9 parts of calcium stearate, 4-7 parts of Tween 40, 5-10 parts of triallyl isocyanurat, 10-15 parts of inorganic additive, 2-6 parts of N-phenyl-beta-naphthylamine and 12-20 parts of water. According to the heat-resistant leakproof sealant of the alkaline storage battery, a sealing material formula with good heat resistance is obtained through many times of experiments, the heat-resistant leakproof sealant is used in the processing, production and maintenance process of the alkaline storage battery, the sealing effect is good, and the ageing resisting performance is good.

Owner:无锡市宝来电池有限公司

Special lubricating grease for telescope

InactiveCN104498156AImprove low temperature performanceImprove oxidation stabilityLubricant compositionEvaporationLanolin

The invention relates to the technical field of lubricating grease and particularly relates to special lubricating grease for a telescope and a preparation process thereof. The lubricating grease comprises the following components in percentage by weight: 60-85% of base oil, 15-30% of a thickener, 1-5% of phenyl-beta-naphthylamine, 5-10% of sulfurized cottonseed oil, 0.1-2% of lanolin magnesium soap and 0.1-1% of benzotriazole. Compared with the prior art, the special lubricating grease for the telescope has the beneficial effects of excellent low temperature property and oxidation stability and low evaporation loss, excellent shear stability and colloidal stability and small oil diffusion, excellent abrasion resistance and lubricity and good protective property against metals, and good water resistance and corrosion resistance and is compatible with a majority of plastics and a rubber body.

Owner:WUXI FEITIAN GREASE

Material for producing composite water block and preparation method thereof

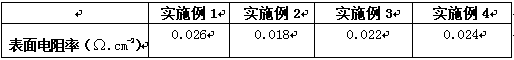

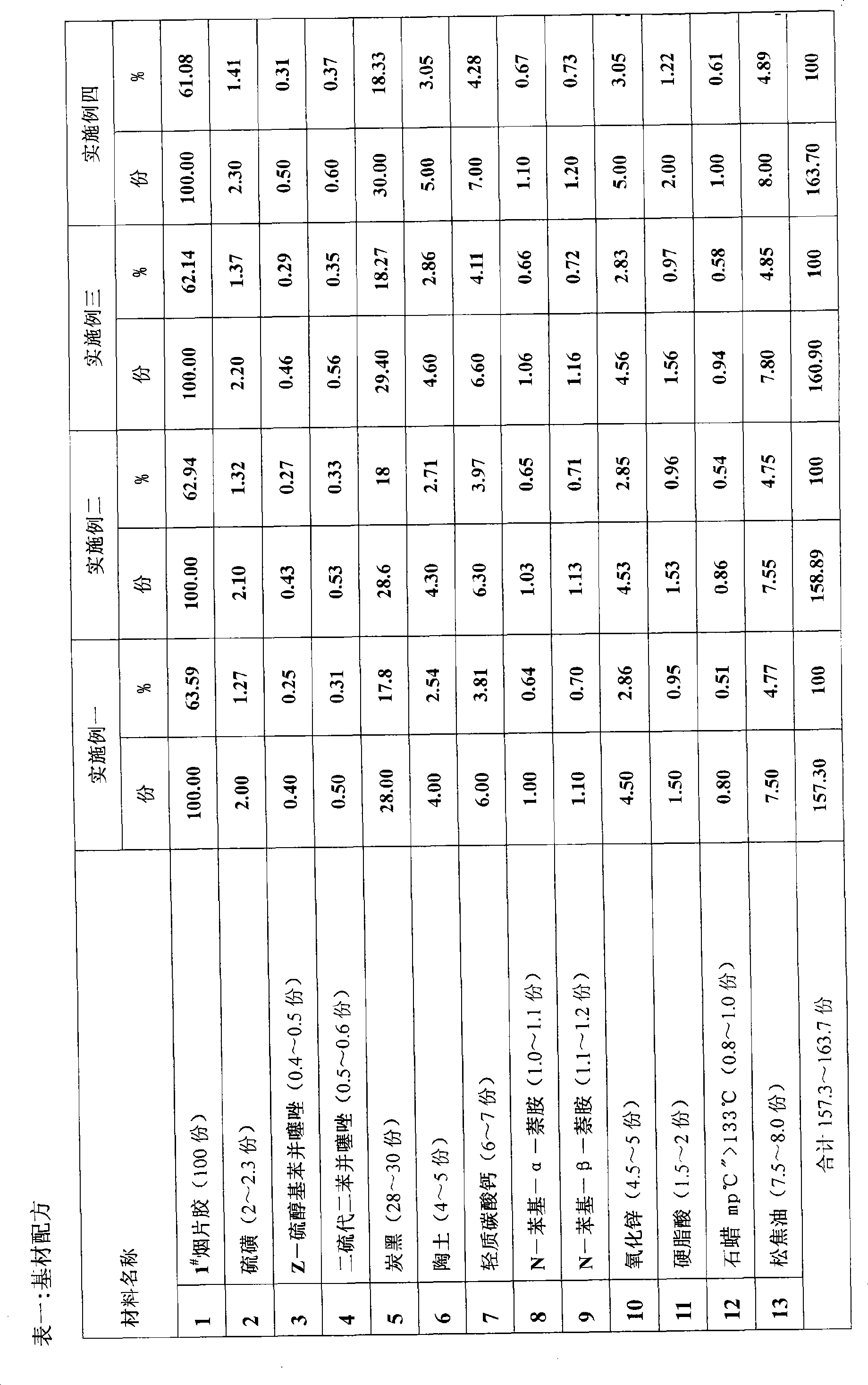

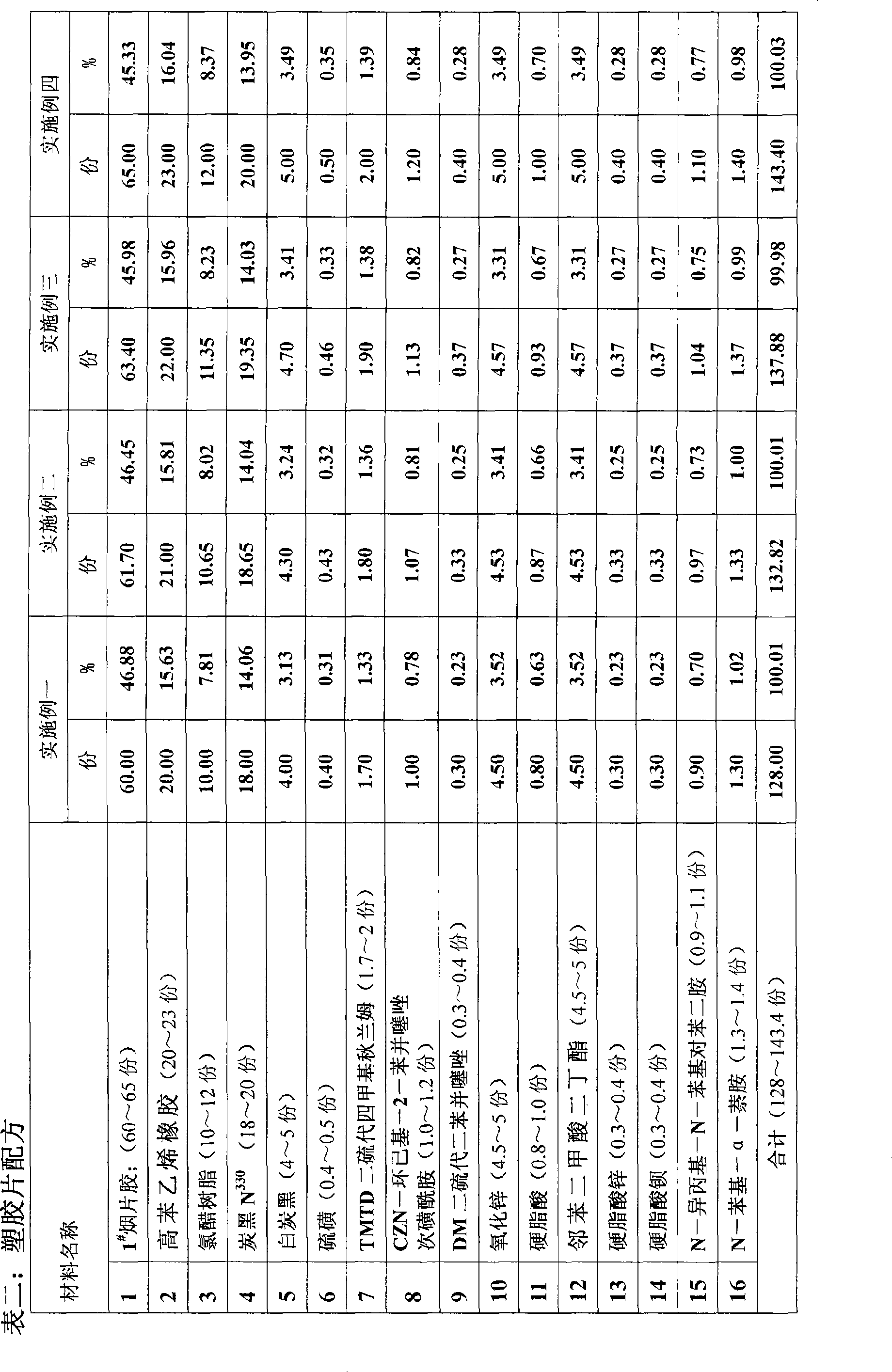

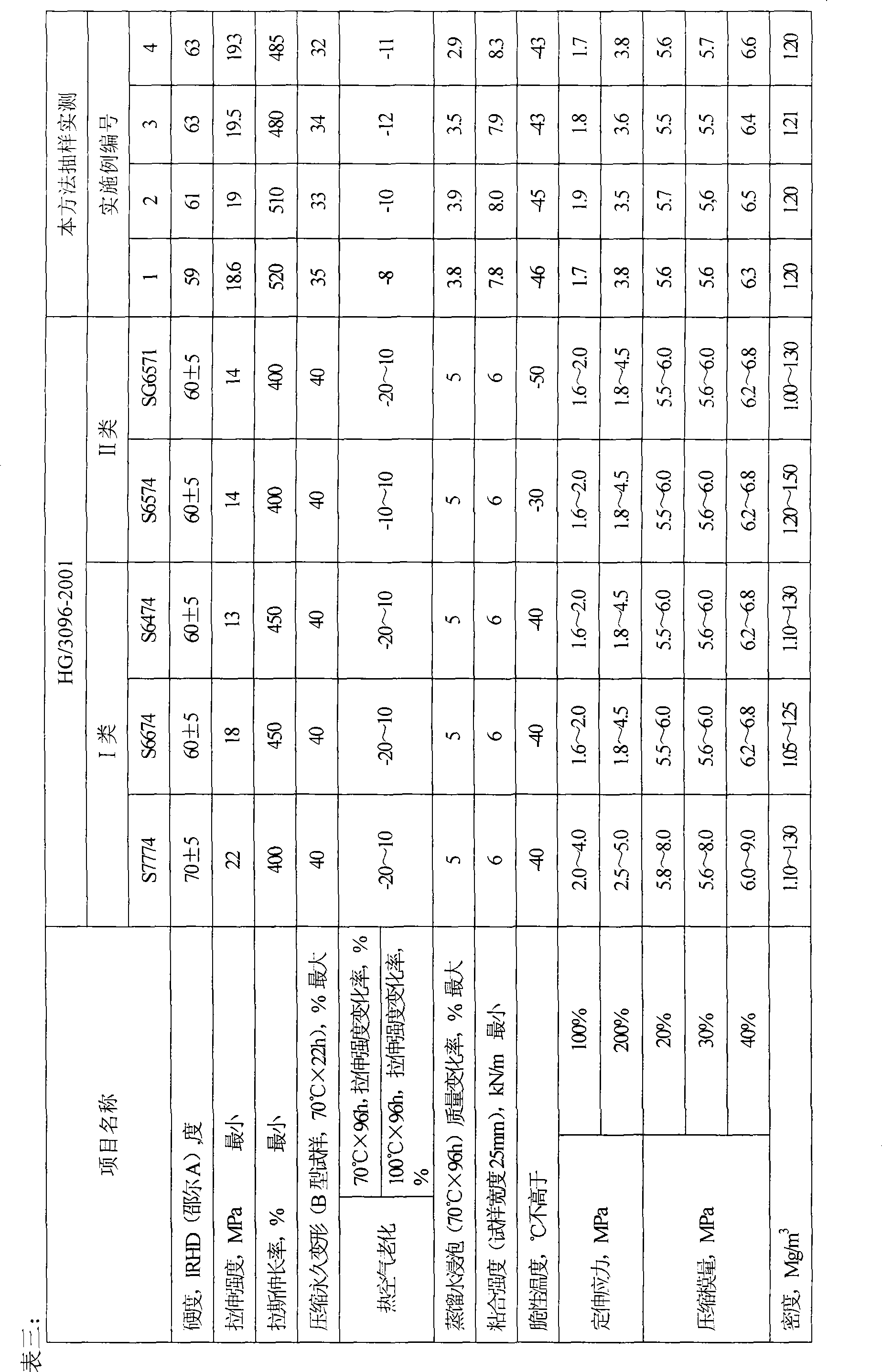

InactiveCN101474905AReduce coefficient of frictionStable coefficient of frictionEngine sealsOther chemical processesHigh ratePolymer science

The invention relates to a material for manufacturing a composite water seal and a preparation method thereof. The material is compounded by a base material and a plastic sheet, wherein the base material is prepared from 1 smoke sheet rubber, sulfur, Z-thiol benzothiazole, dithio-bisbenzothiazole, carbon soot, pottery clay, light calcium carbonate, N-phenyl-alpha-naphthylamine, N-phenyl-beta-naphthylamine, zinc oxide, stearic acid, paraffin and pine tar; and the plastic sheet is prepared from 1 smoke sheet rubber, high styrene rubber, vinyl chloride-acetate copolymer, carbon soot, white carbon black, sulfur, TMTD dithio-tetramethyl thiuram, CZN-cyclohexyl-2-benzothiazole sulfonamide, DM dithio-bisbenzothiazole, zinc oxide, stearic acid, dibutyl phthalate, zinc stearate, barium stearate, N-isopropyl-N-diphenyl-para-phenylene diamine and N-phenyl-alpha-naphthylamine. The frictional coefficient is low, and the product can be bent randomly; the problems of special packing expense and high transportation expense for the water seal are solved, the production process is concise, and the manufactured water seal has higher rate of certified products than other water seals and better economical efficiency.

Owner:江文养

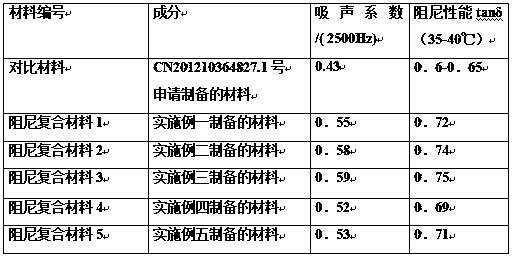

A kind of damping composite material and preparation method thereof

The invention belongs to the functional material field, and relates to a damping composite material and a preparation method. The material comprises the following composition: 2-4% of titanium dioxide, 0.8-1.1% of a catalyst nickel naphthenate-aluminium triisobutyl-boron trifluoride etherate, 0.8-1.1% of an antioxidant N-phenyl-beta-naphthylamines, 4-6% of zinc oxide, 2-5% of stearic acid, 1-3% of sulphur, 16-20% of ABS material slag complex, 1-3% of a promoter N-cyclohexyl-2- benzimidazole sulfenamide and the balance of butadiene rubber. In the preparation method, mass usage of precious material is not required, the raw material cost is reduced, waste material is employed as the raw material, the preparation technology is simple, and process is simple. The material enables sound absorption and damping vibration attenuation, energy can be effectively absorbed when the vibration is generated, the damping composite material can be used in the transportation, building and military fields, and has the effects of shock resistance, impact mitigation, heat insulation and sound insulation.

Owner:江苏丰源布业有限公司

Wear-resistant nano-composite rubber

The invention discloses wear-resistant nano-composite rubber. The wear-resistant nano-composite rubber takes a mixture of raw ethylene propylene diene monomer (EPDM) rubber, a hyperbranched phosphamide modified SBA-15 nanomaterial, turpentine, zinc oxide, carbon black and N-phenyl-beta-naphthylamine as a main raw material; the nano-composite rubber contains the hyperbranched phosphamide modified SBA-15 nanomaterial; the hyperbranched phosphamide modified SBA-15 nanomaterial has high surface activity and fire resistance, thus having higher dispersity, fire resistance and surface tension; therefore, the modified nano-composite rubber has higher wear resistance.

Owner:邳州易萨新型材料有限公司

Antiaging torsion-resistant ethylene-propylene rubber for wires and cables and preparation method thereof

InactiveCN105647094AGood flexibilityImprove torque performanceRubber insulatorsPolymer scienceFire retardant

The invention discloses an antiaging torsion-resistant ethylene-propylene rubber for wires and cables and a preparation method thereof. The ethylene-propylene rubber is prepared from the following raw materials in parts by weight: 80-100 parts of ethylene propylene diene monomer rubber, 4-6 parts of acrylic acid, 1-3 parts of sulfanilic acid, 1-2 parts of ammonium persulfate, 0.6-0.8 part of mercaptopropionic acid, 0.4-0.6 part of phenyl-beta-naphthylamine, 1-3 parts of initiator, 2-4 parts of antiaging agent, 1-2 parts of flame retardant, and 0.4-0.6 part of benzotriazole and vulcanized isobutylene. The weight ratio of the benzotriazole to the vulcanized isobutylene is (3-5):1. The ethylene-propylene rubber disclosed by the invention has excellent aging resistance and torsion resistance, which can be related to the weight ratio of the benzotriazole to the vulcanized isobutylene in the raw materials. When the weight ratio of the benzotriazole to the vulcanized isobutylene is (3-5):1, the ethylene-propylene rubber has the optimal aging resistance and torsion resistance, and is suitable for preparing antiaging torsion-resistant cables.

Owner:刘高志

Composite damping material

InactiveCN104163950AExcellent low-frequency noise reduction performanceWide damping temperature rangeBenzoyl peroxideChlorinated paraffins

The invention discloses a composite damping material. The material is characterized by comprising the following substances by weight: 25 to 60 parts of isoprene rubber, 35 to 46 parts of emulsion polymerized styrene butadiene rubber, 10 to 14 parts of N-phenyl-beta-naphthylamine, 5 to 10 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline, 10 to 23 parts of stannous octoate, 3 to 4 parts of cobalt naphthenate, 1 to 7 parts of N,N-diethylaniline, 10 to 14 parts of benzoyl peroxide, 4 to 7 parts of sulfur, 5 to 17 parts of chlorinated paraffin, 30 to 45 parts of isopropanol, 45 to 70 parts of calcium carbonate, 10 to 17 parts of carbon black, 3 to 9 parts of zinc stearate and 15 to 32 parts of polyisobutylene. The composite damping material has the characteristics of striking low frequency noise reduction performance, light weight, a wide damping temperature range, a wide noise reduction frequency range, aging resistance, etc.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

Hydro-expansive waterproof rubber sealing material containing polyaspartic acid and preparing method thereof

The invention provides a hydro-expansive waterproof rubber sealing material containing polyaspartic acid and a preparing method thereof. The sealing material is prepared from, by weight, 100 parts of nitrile rubber containing polyaspartic acid, 20-30 parts of polyaspartic acid, 15-25 parts of bentonite-calcium carbonate microspheres, 6-12 parts of SAP resin, 8-12 parts of white carbon black, 3-5 parts of styrene / maleic anhydride copolymer, 4-6 parts of N-phenyl-beta-naphthylamine and 5-10 parts of polyethylene glycol. Polyaspartic acid and bentonite-calcium carbonate microspheres are added and combined with SAP resin to serve as the water absorbing component, the formula of hydro-expansive waterproof rubber is optimized, and the obtained hydro-expansive waterproof rubber sealing material has the advantages of being excellent in water absorption performance, high in water absorption rate, high in repeated water absorption capacity and excellent in mechanical property, has good environmental compatibility and achieves the purpose of environment protection.

Owner:ANHUI RONGDA VALVE

High-proportion rubber and preparation method thereof

ActiveCN103739897AMeet the requirements of shock absorption and noise reductionIn line with the development trendPolymer scienceAccelerant

The invention discloses high-proportion rubber which comprises the following components: natural rubber #1, magnesium oxide or zinc oxide, scorch retarder N-cyclohexyl sulfo-o-phenyl dicarboximide, anti-aging agent N-phenyl-beta-naphthylamine or N-isopropyl-N'-phenyl p-phenylenediamine, N330 carbon black powder and the like. The invention also discloses a production method of the high-proportion natural rubber. The production method comprises the following steps: 1, mixing the natural rubber #1, plasticizer transformer oil #46 zinc stearate and environment-friendly iron in a sealed manner in an internal mixer; 2, further mixing the product, then adding magnesium oxide or zinc oxide, scorch retarder, anti-aging agent and the like and mixing again; 3, further mixing the product obtained in the step 2 for 5 minutes; then adding 3-6 parts of soluble sulfur vulcanizing agent or accelerant and mixing for 10 minutes; 4, performing compression molding on the product obtained in the step 3. The rubber disclosed by the invention can meet the application requirements of micro electronic products on damping and silencing and meets the development tendency of modern electronic products.

Owner:四川隆盛科发实业有限公司

High-flexibility compound adhesive

InactiveCN107474749AQuality assuranceHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesCyanoacrylatePhenyl beta-naphthylamine

The invention discloses a highly flexible composite adhesive, which belongs to the field of adhesives, and comprises the following components and weight ratios: 100-150 ethylene-vinyl acetate copolymer, 90-120 cyanoacrylate, and 85-50 epoxy resin 100. Diisodecyl phthalate m-phenylenediamine 30‑70, polymerized rosin 30‑50, diaminodiphenylmethane 10‑50, butyl rubber 10‑35, toluenediamine 5‑35, paraffin wax 5 ‑20, N‑phenyl‑β‑naphthylamine 5‑10, polyoxyethylene sorbitan monostearate 2‑6, antioxidant 1‑3, can effectively solve the problem of poor flexibility and easy twisting of common adhesives Corruption problem.

Owner:成绵广

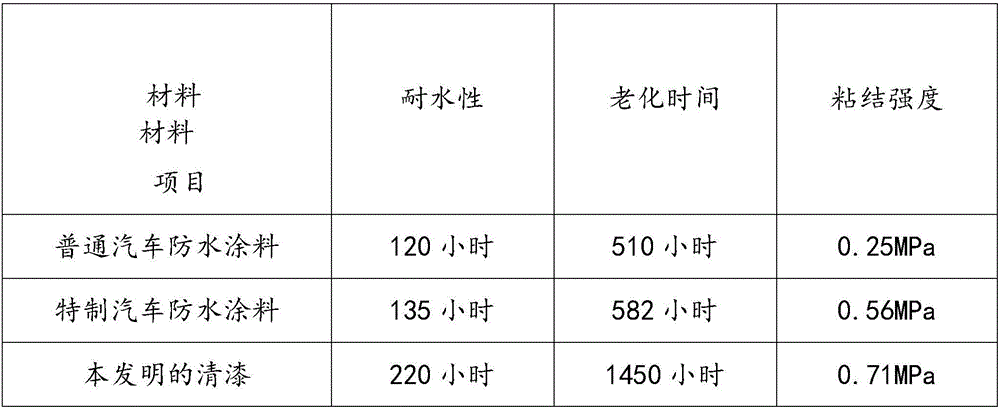

Waterproof paint for automobile chassis and preparation method of waterproof paint

InactiveCN106833147AImprove water resistanceHigh bonding strengthConjugated diene hydrocarbon coatingsPolyamide coatingsTurpentineCarvacryl acetate

The invention discloses a waterproof paint for an automobile chassis. The waterproof paint is prepared from the following materials in parts by weight: 13-15 parts of an acrylic emulsion, 25-30 parts of polyvinyl acetate, 33-38 parts of butadiene styrene rubber latex, 5-8 parts of dimethicone, 6-11 parts of talcum powder, 9-15 parts of sodium hexametaphosphate, 5-10 parts of diacetone acrylamide, 7-10 parts of turpentine, 8-14 parts of zinc stearate, 13-18 parts of triethoxysilane, 22-24 parts of polyisocyanate, 9-16 parts of tetrabutyl phosphoric chloride, 8-14 parts of polyamide wax, 17-20 parts of carboxymethylcellulose, 9-13 parts of sodium polyacrylate, 7-8 parts of xanthan gum, 12-16 parts of difenoconazole, 6-10 parts of bentonite, 11-17 parts of N-phenyl-beta-naphthylamine and 9-14 parts of p-phenylenediamine. The waterproof paint for the automobile chassis is good in water resistance, high in bonding strength and good in anti-ageing effect.

Owner:芜湖天鸿汽车零部件有限公司

Damping rubber part for bushing of automobile

The invention discloses a damping rubber part for a bushing of an automobile. The damping rubber part comprises raw materials in parts by weight as follows: 40-50 parts of butadiene rubber, 15-35 parts of chloroprene rubber, 5-15 parts of modified rosin, 0.5-1.5 parts of zinc oxide, 1-2 parts of sulfur, 1-3 parts of a vulcanization accelerator ZBX, 1-3 parts of a vulcanization accelerator CZ, 1-3 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 40-60 parts of white carbon black, 5-15 parts of titanium dioxide, 20-35 parts of calcium sulfate, 5-15 parts of diatomite, 1-3 parts of coumarone, 1-3 parts of a plasticizer DOP, 1-3 parts of stearic acid, 1-3 parts of N-phenyl-alpha-aniline and 1-3 parts of N-phenyl-beta-naphthylamine. The product has good mechanical performance, high elasticity and excellent anti-aging performance.

Owner:宁国天运橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com