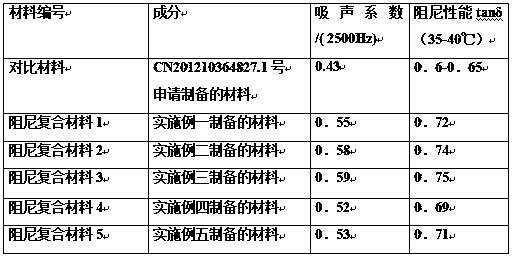

A kind of damping composite material and preparation method thereof

A damping composite material and composite technology, applied in the field of functional materials, can solve the problems of low sound absorption coefficient and low damping performance, and achieve the effects of simple preparation process, reduced cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Damping composite material of the present invention, its preparation method is as follows:

[0022] (1) Preparation of slag

[0023] Get the above-mentioned slag, grind it into a slag powder with a particle size of 30-50 microns, and set aside;

[0024] (2) Preparation of ABS recycled materials

[0025] Heating the ABS regrind to 220°C to obtain molten ABS regrind for later use;

[0026] (3) Preparation of ABS regrind slag composite

[0027] Add the slag powder obtained in step (1) to the molten ABS regrind obtained in step (2) at a weight ratio of 2:10, and stir evenly, then naturally cool to room temperature to obtain the ABS regrind slag composite; then The ABS recycled material slag complex is put into the upper space of liquid nitrogen in the liquid nitrogen pool, kept at -170°C for 10 minutes, and then taken out for crushing. The powder of the crushed ABS recycled material slag complex has a particle size of 90-120 microns;

[0028] (4) Preparation of damping...

Embodiment 2

[0031] Damping composite material of the present invention, its preparation method is as follows:

[0032] (1) Preparation of slag

[0033] Get the above-mentioned slag, grind it into a slag powder with a particle size of 30-50 microns, and set aside;

[0034] (2) Preparation of ABS recycled materials

[0035] Heating the ABS regrind to 230°C to obtain molten ABS regrind for later use;

[0036] (3) Preparation of ABS regrind slag composite

[0037] Add the slag powder obtained in step (1) to the molten ABS regrind obtained in step (2) at a weight ratio of 2.5:10, and stir evenly, then cool naturally to room temperature to obtain the ABS regrind slag composite; then The ABS recycled material slag complex is put into the upper space of liquid nitrogen in the liquid nitrogen pool, kept at -175°C for 13 minutes, and then taken out for crushing. The powder of the crushed ABS recycled material slag complex has a particle size of 90-120 microns;

[0038] (4) Preparation of dampi...

Embodiment 3

[0041] Damping composite material of the present invention, its preparation method is as follows:

[0042] (1) Preparation of slag

[0043] Get the above-mentioned slag, grind it into a slag powder with a particle size of 30-50 microns, and set aside;

[0044] (2) Preparation of ABS recycled materials

[0045] Heating the ABS regrind to 235°C to obtain molten ABS regrind for later use;

[0046] (3) Preparation of ABS regrind slag composite

[0047] Add the slag powder obtained in step (1) to the molten ABS regrind obtained in step (2) at a weight ratio of 3:10, stir evenly, and then cool naturally to room temperature to obtain the ABS regrind slag composite; then The ABS recycled material slag complex is put into the upper space of liquid nitrogen in the liquid nitrogen pool, kept at -180°C for 15 minutes, and then taken out for crushing. The powder of the crushed ABS recycled material slag complex has a particle size of 90-120 microns;

[0048] (4) Preparation of damping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com