Wear-resistant and high temperature-resistant lubricating grease and preparation method thereof

A high-temperature-resistant lubricating grease and lubricating grease technology, applied in the field of lubricating grease, can solve the problems of complex lubricating grease production process, poor high-temperature resistance performance, poor lubrication stability, etc., and achieve the effect of good resistance to high temperature, long service life and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

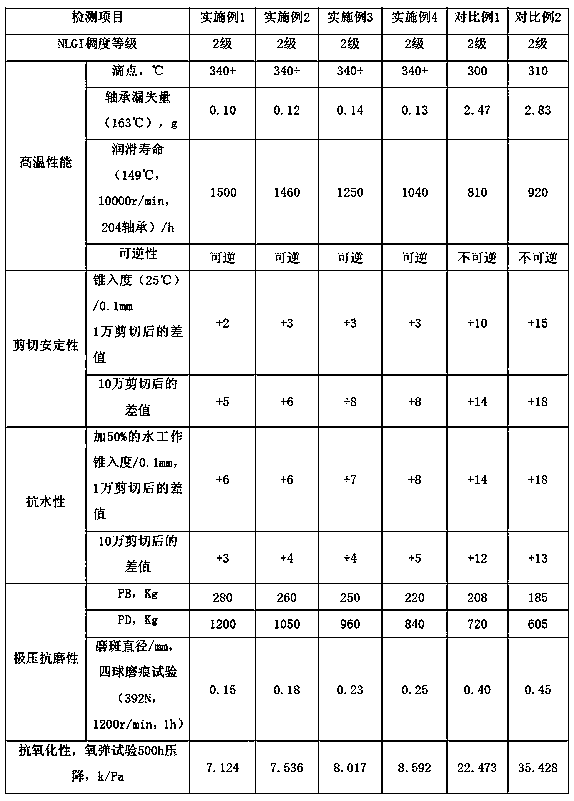

Examples

Embodiment 1

[0017] An anti-wear and high-temperature resistant lubricating grease, which is prepared from the following raw materials in parts by weight: 60 parts of polyalphaolefin, 20 parts of liquid paraffin, 20 parts of swire oil, 25 parts of attapulgite, and 20 parts of nano-graphene 15 parts of polyurea thickener, 18 parts of 2,5-di-tert-butyl hydroquinone, 12 parts of diphenylamine, 12 parts of 2,4-tolyl diisocyanate, 9 parts of triethanolamine, tricresyl phosphate 11 parts, 15 parts of 12-hydroxystearic acid, 13 parts of phenyl-β-naphthylamine, 8 parts of ethylene carbonate, and 18 parts of n-butanol.

[0018] A preparation method of anti-wear and high temperature resistant lubricating grease, comprising the following steps:

[0019] (1) Weigh the corresponding weight of polyalphaolefin, liquid paraffin, and swire oil into the reaction kettle, heat it up to 110°C under stirring, continue to stir for 15 minutes, continue to heat up to 150°C, and then add attapulgite , nano-graphen...

Embodiment 2

[0022] An anti-wear and high-temperature resistant lubricating grease, the lubricating grease is prepared from the following raw materials in parts by weight: 40 parts of polyalphaolefin, 10 parts of liquid paraffin, 10 parts of swire oil, 10 parts of attapulgite, and 10 parts of nano-graphene 10 parts of polyurea thickener, 10 parts of 2,5-di-tert-butyl hydroquinone, 9 parts of diphenylamine, 7 parts of 2,4-tolyl diisocyanate, 6 parts of triethanolamine, tricresyl phosphate 8 parts, 12 parts of 12-hydroxystearic acid, 10 parts of phenyl-β-naphthylamine, 5 parts of ethylene carbonate, and 10 parts of n-butanol.

[0023] A preparation method of anti-wear and high temperature resistant lubricating grease, comprising the following steps:

[0024] (1) Weigh the corresponding parts of polyalphaolefin, liquid paraffin, and swire oil into the reaction kettle, heat up to 100°C under stirring and continue to stir for 10 minutes, continue to heat up to 140°C, then add attapulgite , nan...

Embodiment 3

[0027] An anti-wear and high-temperature resistant lubricating grease, the lubricating grease is prepared from the following raw materials in parts by weight: 80 parts of polyalphaolefin, 30 parts of liquid paraffin, 30 parts of swire oil, 40 parts of attapulgite, and 30 parts of nano-graphene 20 parts, 20 parts of polyurea thickener, 25 parts of 2,5-di-tert-butyl hydroquinone, 15 parts of diphenylamine, 19 parts of 2,4-tolyl diisocyanate, 13 parts of triethanolamine, tricresyl phosphate 14 parts, 18 parts of 12-hydroxystearic acid, 16 parts of phenyl-β-naphthylamine, 12 parts of ethylene carbonate, and 25 parts of n-butanol.

[0028] A preparation method of anti-wear and high temperature resistant lubricating grease, comprising the following steps:

[0029] (1) Weigh the corresponding parts of polyalphaolefin, liquid paraffin, and Swire oil into the reaction kettle, heat up to 120°C under stirring and continue to stir for 20 minutes, continue to heat up to 160°C, and then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com