Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "N-propyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal propyl acetate (also known as n-propyl acetate or 1-propyl acetate) is an organic compound with a molecular formula of C5H10O2. It is commonly used as a solvent in coatings and printing inks.

Lithium ion battery electrolyte with both high and low temperature performances

The invention relates to the technical field of lithium ion electrolytes, and in particular relates to a lithium-ion battery electrolyte with both high and low temperature performances. The electrolyte comprises lithium hexafluorophosphate, mixed organic solvents, filming additives, additives for improving the dielectric constant and the low temperature infiltration capability, and a lithium salt type additive, wherein the mixed organic solvents comprise a carbonic ester solvent and a linear carboxylic ester solvent; the linear carboxylic ester solvent in the mixed organic solvents is one or a mixture of more than two of ethyl propionate, propionic acid n-propyl ester, n-propyl acetate, acetic acid n-butyl ester and isobutyl acetate; and the additives for improving the dielectric constant and the low temperature infiltration capability are one or a mixture of more than two of fluoro ethylene carbonate, difluoro ethylene carbonate and 4-trifluoromethyl ethylene carbonate. A battery prepared from the lithium-ion battery electrolyte with both high and low temperature performances is long in service life, and both the good low temperature discharge performance of the battery is ensured, and the storage performance of the battery at the high temperature of 60 DEG C is effectively considered.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

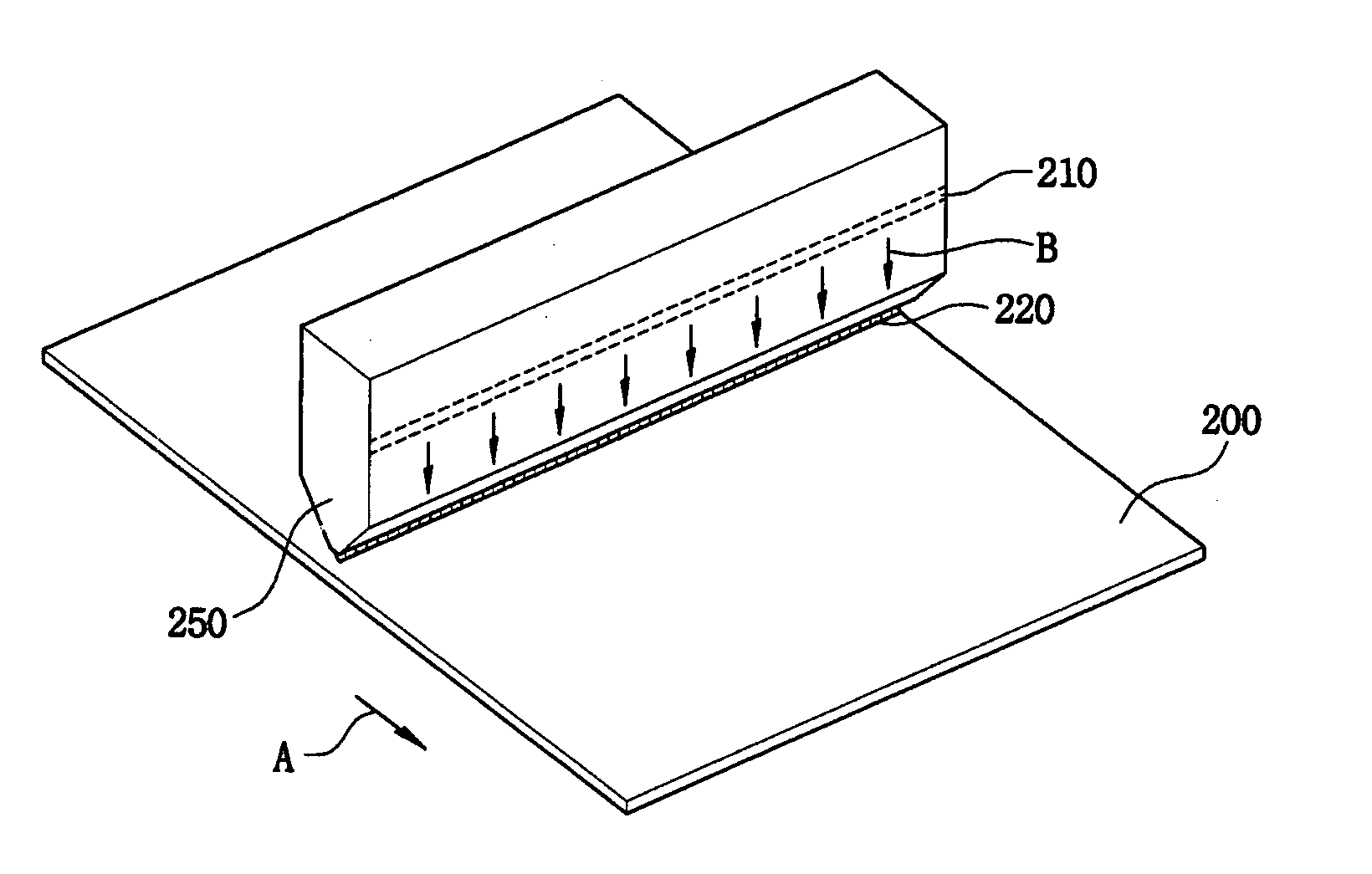

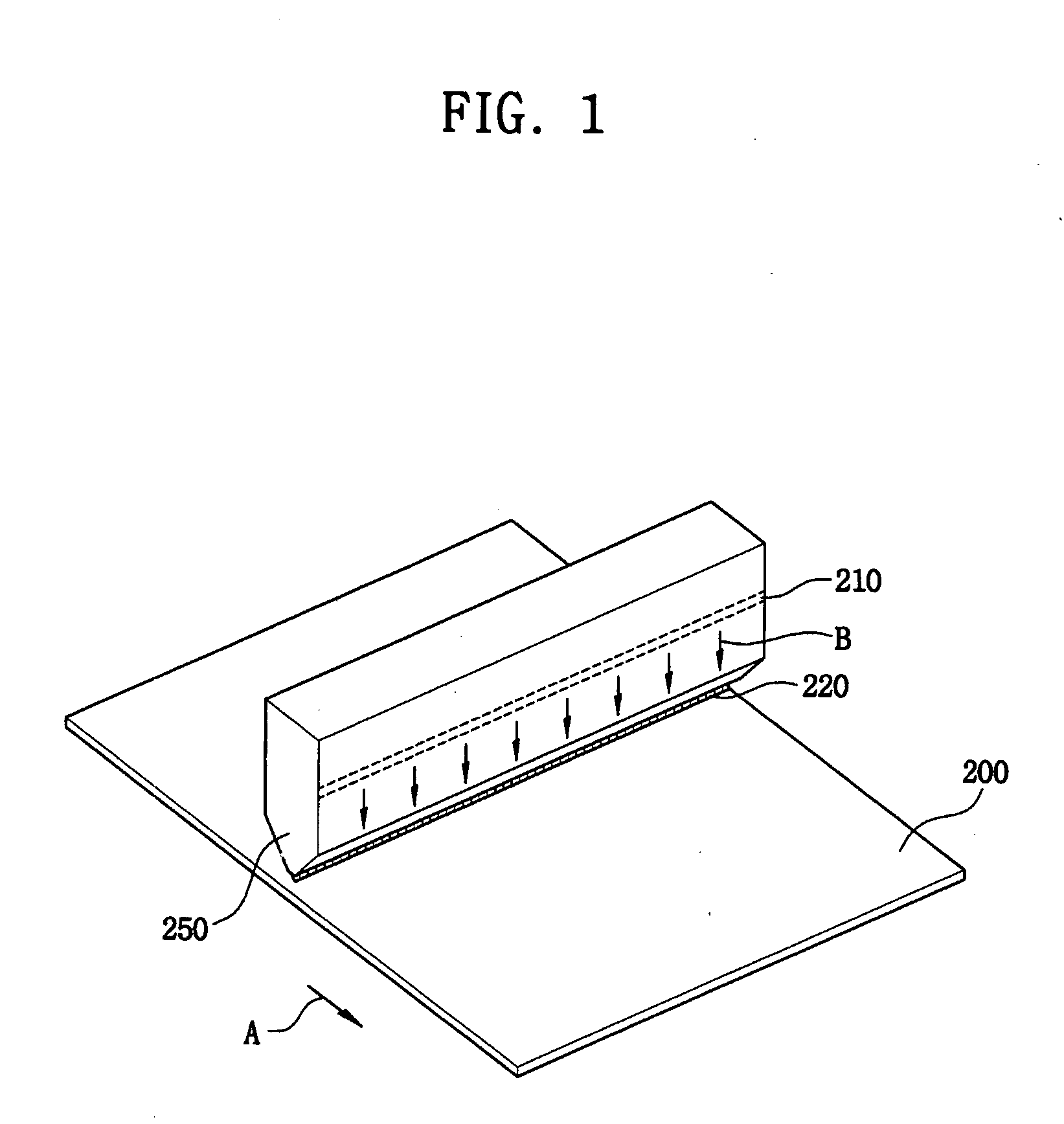

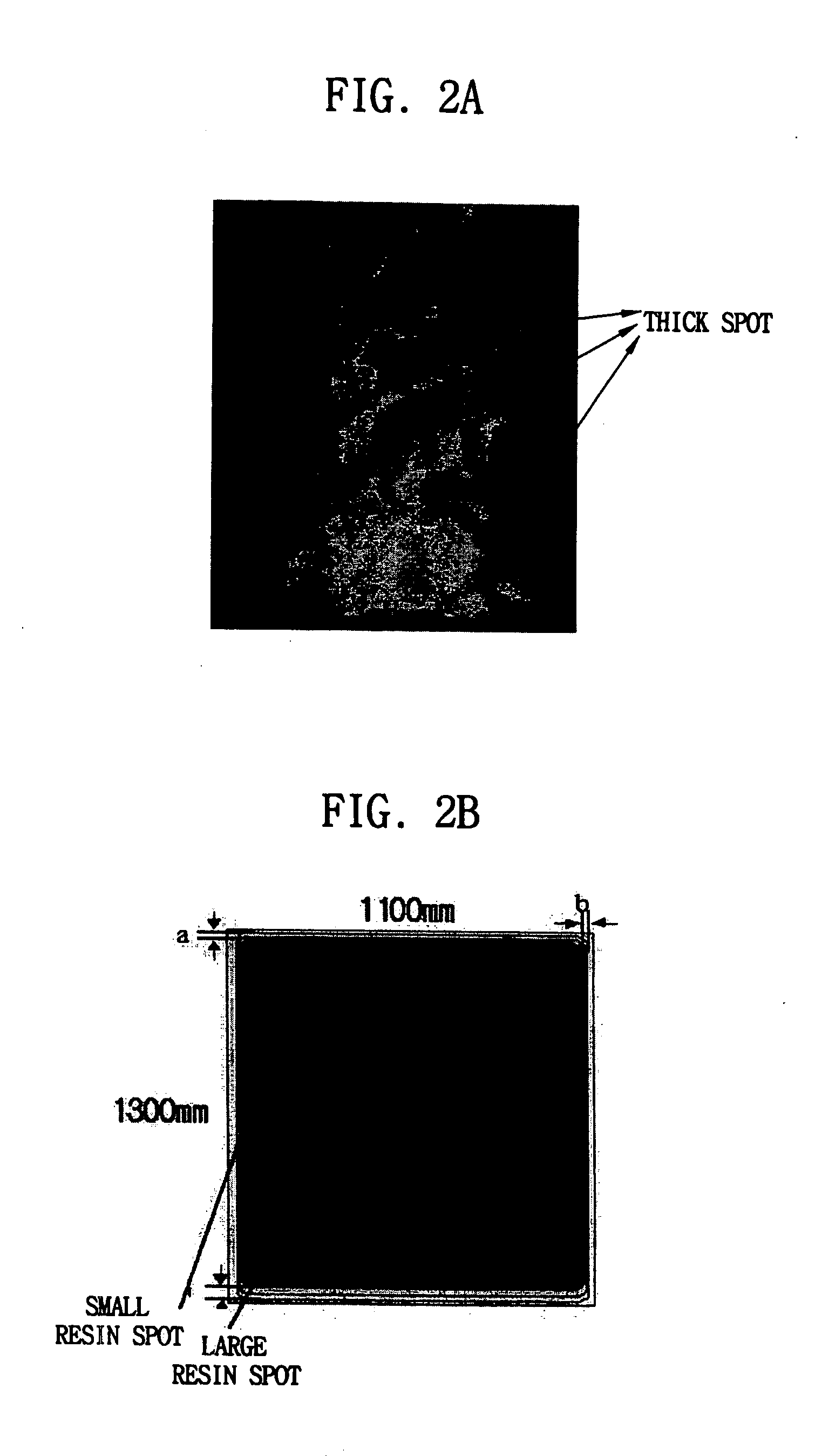

Photoresist composition for a spinless coater and method of forming a photoresist pattern using the same

InactiveUS20050089790A1Low costShorten the timePhotoprinting processesPhotosensitive materials for photomechanical apparatusLiquid-crystal displayOrganic solvent

A photoresist composition for a spinless coater includes a novolak resin having a weight average molecular weight of about 2,000 to about 15,000, a diazide based photosensitive compound and a volatile organic solvent. The photoresist composition is applied to a substrate of a liquid crystal display apparatus to reduce blots and enhance application uniformity. A highly volatile solvent, such as n-propyl acetate (nPAC) or n-butyl acetate (nBA) is used in the photoresist composition as the volatile organic solvent. The photoresist composition including the volatile organic solvent gives a photoresist film that has a uniform thickness. Hence, the generation of small resin blots and thick blots may be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

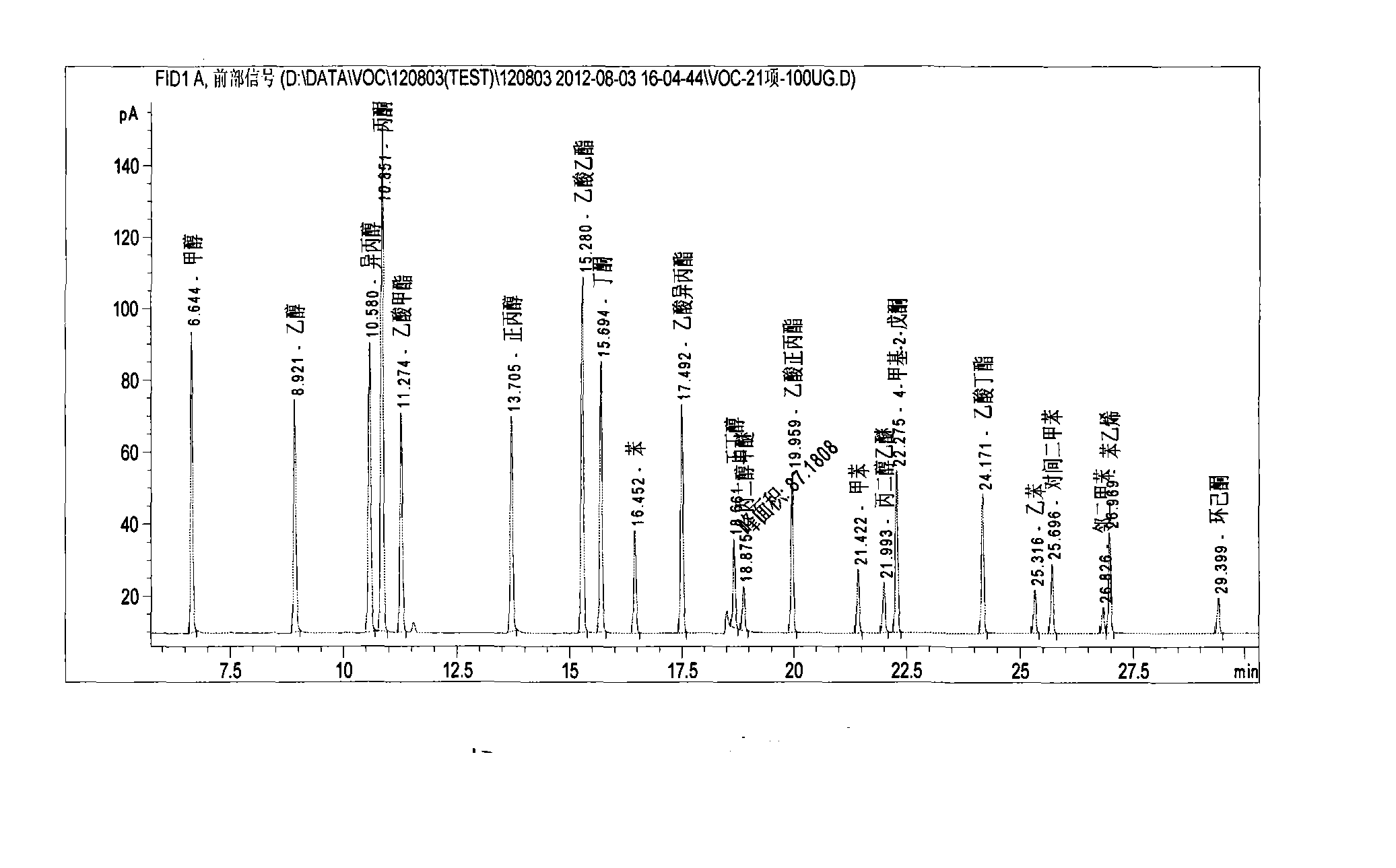

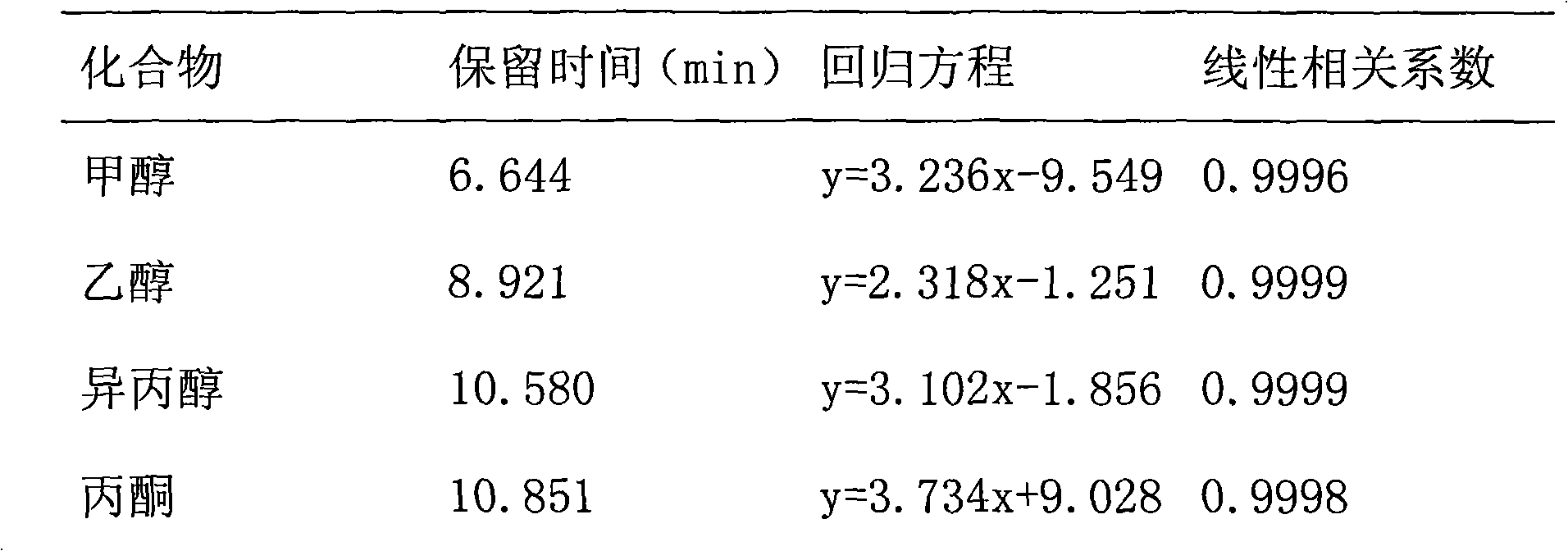

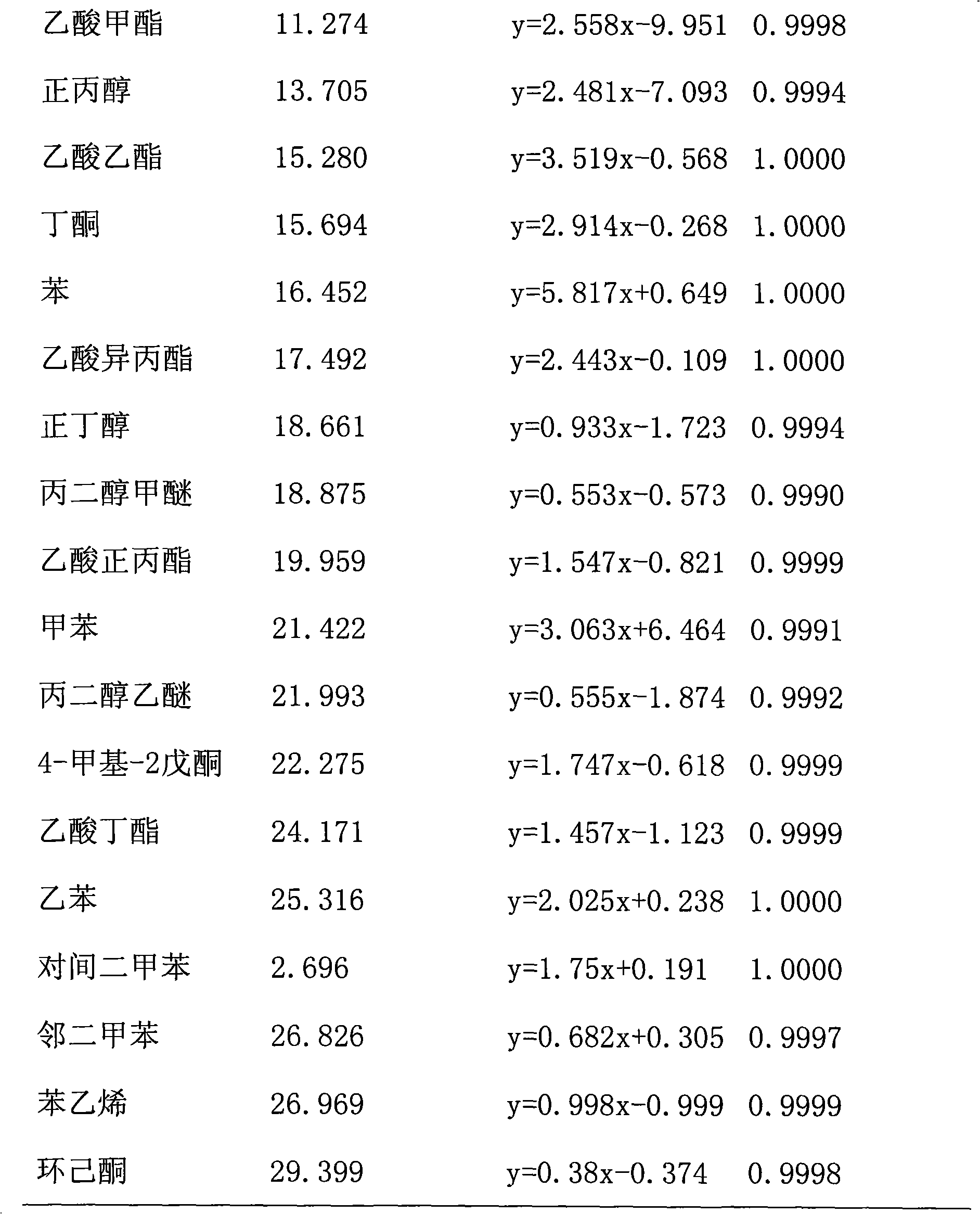

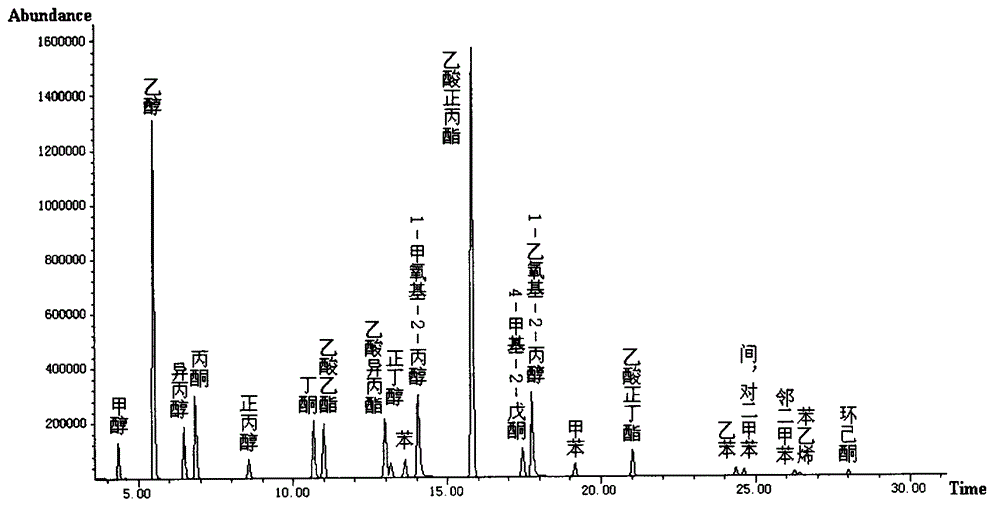

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

Transfer printing ink with release function

The invention relates to a transfer printing ink with a release function. The transfer printing ink comprises, by weight, 16 to 25% of a polymethacrylate resin, 1.5 to 2.5% of a cellulose acetate resin, 7 to 30% of a pigment, 50 to 62.5% of a mixed solvent, 0 to 2% of an auxiliary agent, 0 to 1% of matt powder and 0 to 2% of wax powder, wherein the mixed solvent is a mixture of two or more selected from the group consisting of ethyl acetate, n-propyl acetate, isopropyl acetate, n-butyl acetate, toluene, butanone, methyl isobutyl ketone, isopropanol, propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate mixed at any ratio, the auxiliary agent is one or a mixture of more selected from the group consisting of a dispersant, an antistatic agent and an organosilicon leveling agent, the matt powder is gas phase silica, and the wax powder is polymer micro wax powder. The transfer printing ink provided by the invention has all the properties of a traditional transfer printing ink, e.g., pigment concentration, brilliance and good printability and heat resistance, further has excellent release performance and can be used as a release agent in a transfer printing process.

Owner:BAUHINIA VARIEGATA INK ZHEJIANG

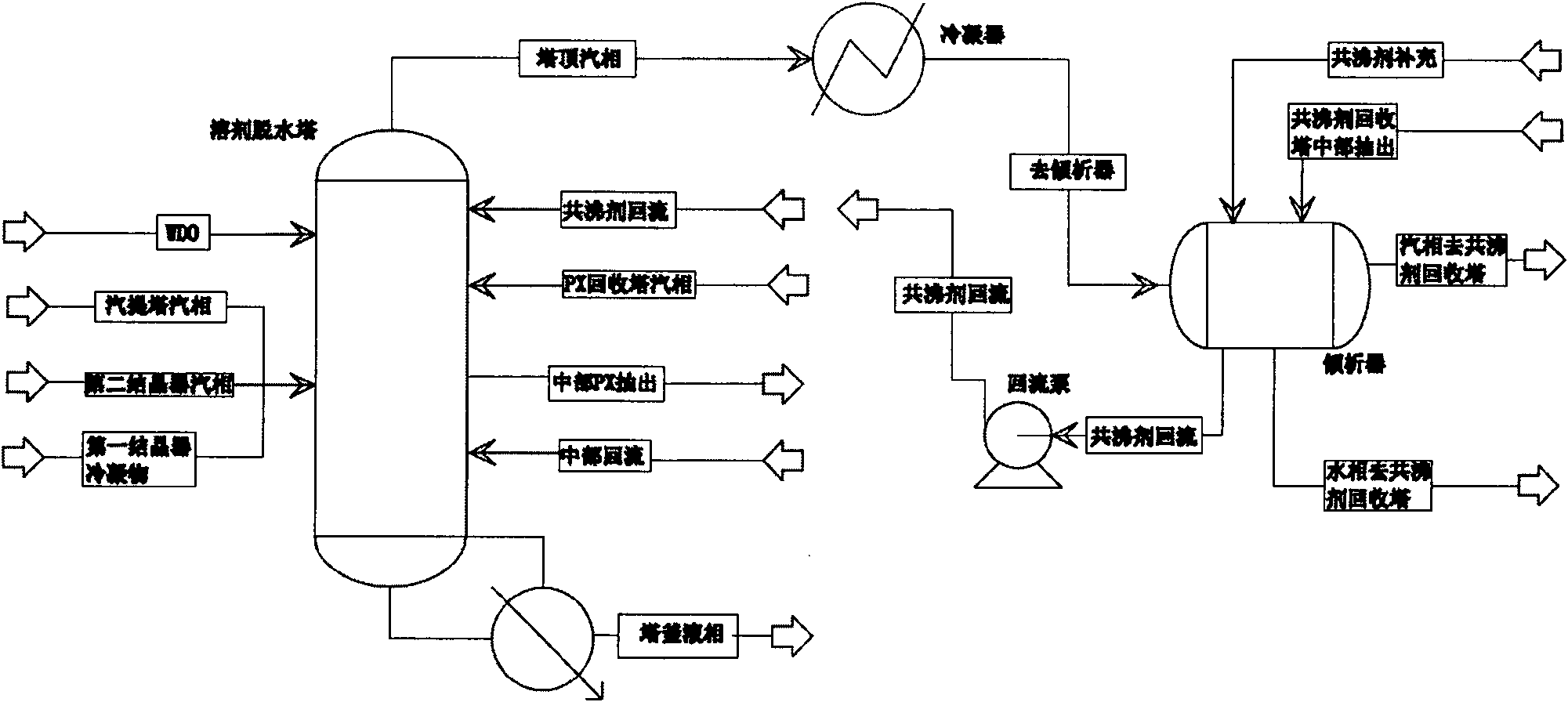

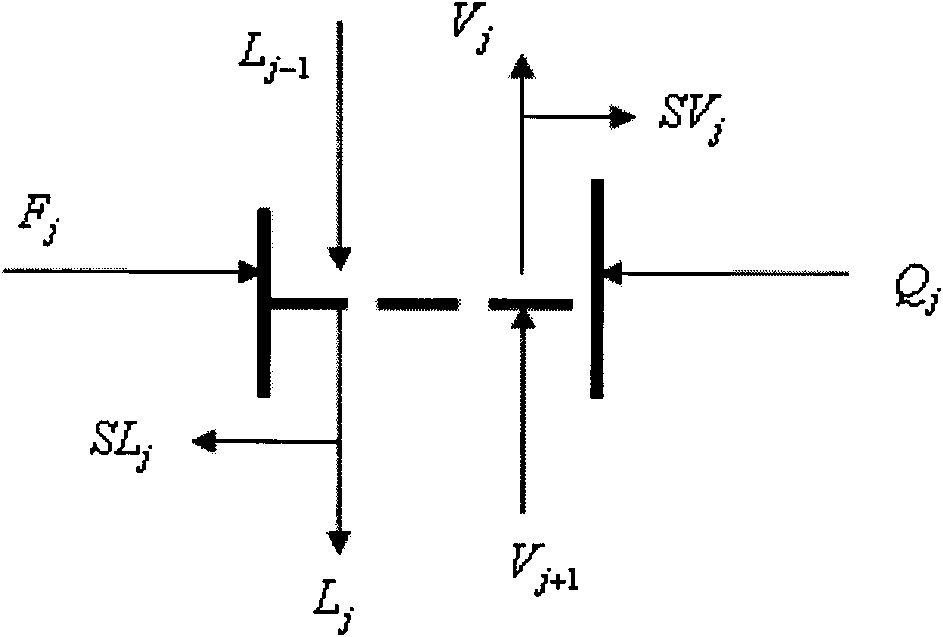

Modeling method for heterogeneous azeotropic rectification solvent dehydrating tower of industrial purified terephthalic acid (PTA) device

ActiveCN101986320AAvoid blind operationReduce optimization costsSpecial data processing applicationsCarboxylic compound separation/purificationVapor liquidProcess mechanism

The invention relates to a modeling method for a heterogeneous azeotropic rectification solvent dehydrating tower of an industrial purified terephthalic acid (PTA) device. In the method, the vapor-liquid balance experimental data of an acetic acid, n-propyl acetate, water, p-xylene and methyl acetate quinary mixture system are associated and fitted with the binary interaction parameters of the quinary mixture system according to a thermodynamic property model; and according to the process data of the solvent dehydrating tower under the actual device design condition, a heterogeneous azeotropic rectification solvent dehydrating tower model of the industrial PTA device under the design condition is established, the accuracies of the thermodynamic model and parameters thereof of the quinary mixture system in a laboratory and a rectification tower mathematical steady model are verified, key parameters representing the separating property of the solvent dehydrating tower under the actual condition are acquired, the model is corrected and a process mechanism steady model capable of accurately describing the operating characteristics of the solvent dehydrating tower under the actual condition is established.

Owner:EAST CHINA UNIV OF SCI & TECH

Silver ink with good metal printing effect and printing process using silver ink

ActiveCN104403407AGood metal effectImprove surface smoothnessInksOther printing apparatusCardboardSilver ink

The invention provides silver ink with a good metal printing effect and a printing process using the silver ink. The printing process comprises the steps that first, a coated surface of a white cardboard with a single side coated is coated with water-soluble varnish or UV (ultraviolet) varnish, images and texts are printed with well mixed gravure silver ink in a gravure manner, and finally, a layer of water-soluble varnish or UV varnish is printed on an image and text area with the gravure silver ink. The gravure silver ink is formed by blending the following materials in percentage by weight: 60-68% of silver powder, 24-30% of n-propyl acetate, 1-3% of methyl methacylate, 1-3% of butyl acrylate, 1-2% of methacrylic acid, 1-2% of N-hydroxymethyl acrylamide, 0.5-1% of allyl methacrylate, 0.5-1% of isooctyl thioglycolate, 0.2-0.5% of alkylphenol ethoxylates sodium sulfate, 1-2% of water-resistant agents and 0.1-0.5% of drying agents. By means of the silver ink and the printing process, a metal ink layer has a refraction effect, the metal effect is more obvious and an optimal metal effect is achieved.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Non-treatment frosted varnish ink for PET (polyethylene terephthalate) film gravure

ActiveCN104861775AImprove aestheticsAchieve freedom of controlInksWaxPolyethylene terephthalate glycol

The invention discloses non-treatment frosted varnish ink for PET (polyethylene terephthalate) film gravure. The ink is characterized by comprising varnish, a diluent and a curing agent in the weight ratio being 10:(4-18):0.5, wherein the varnish comprises components in percentage by weight as follows: 25%-40% of a polyurethane resin liquid, 3%-7% of butyl acetate, 8%-12% of ethyl acetate, 8%-25% of an inorganic pigment, 1%-3% of PE wax powder, 2%-4% of a dispersing agent, 15%-20% of a modified material and 20%-35% of n-propyl acetate. With the adoption of the ink prepared with the formula, a common PET light film can be locally matted or completely matted through printing, and the beauty of a product is improved; the matt degree of the product is freely controlled to range from 2 degrees to 15 degrees through adjustment of the addition proportion of the diluent of the varnish ink and the depth of a printing plate; the matt effect is realized through the common PET film, the cost is low, and preparation is convenient.

Owner:DONGCHANG IND LINHAI CO LTD

Alcohol-soluble environment-friendly high-speed surface printing ink and preparation method thereof

The invention discloses alcohol-soluble environment-friendly high-speed surface printing ink. The alcohol-soluble environment-friendly high-speed surface printing ink is prepared from the following ingredients in parts by mass: 8-12 parts of polyamide resin, 0-5 parts of nitro-cotton resin, 10-30 parts of pigment, 5-20 parts of ethyl acetate, 5-20 parts of n-propyl acetate, 15-25 parts of isopropanol, 15-30 parts of ethanol, 0.5 part of adhesion promoter, 1 part of polyethylene wax powder and 0.5 part of anti-sticking agent. The ink disclosed by the invention is prepared through the steps of weighing materials, preparing a nitro-cotton resin solution, pre-dispersing, grinding to disperse, adjusting viscosity, carrying out chromatography, filtering and packaging. The ink is higher in fineness, is more uniform, can adapt to the print speed of 300m / min, and is excellent in freezing resistance and anti-adhesion property and good in print effect.

Owner:SUZHOU ZHONGYA INK

Method for treating coated layer on surface of metal material and making pattern

InactiveCN1390650AImprove adhesionGood filter layerPretreated surfacesCoatings3d patterningPolyester

A process for coating on the surface of metal material and then preparing pattern on it includes such steps as immersing metal material in solution of H2SO4, water flushing, drying, coating acetone, benzene and n-propyl acetate, blowing surface by air compressor, baking, electrostatic spraying of polyester epoxy powder, baking, making pattern with the mixture of epoxy resin powder, butyl acetate and pigment by rolling or manually, baking and spraying BJS varnish. Its advantages are low cost, high resistance to chemical corrosion and oxidation, and clear 3D pattern.

Owner:钟烈侯

Stability of covert pigments

ActiveUS20060011730A1Difficult to manufactureInksRecord carriers used with machinesPolyesterPolyolefin

Owner:L 1 SECURE CREDENTIALING

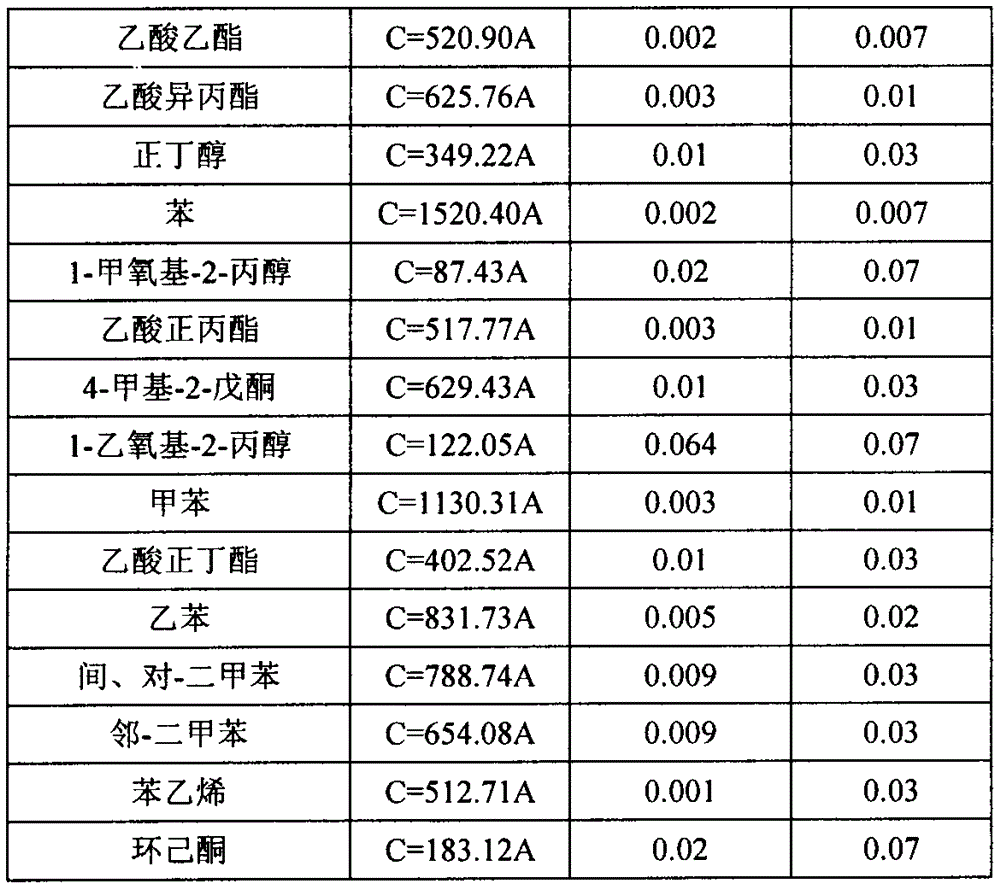

Method for detecting volatile organic compounds in cigarette tipping paper printing ink

InactiveCN104597166AEasy to handleAchieving Simultaneous DetectionComponent separationCyclohexanoneN-Propyl alcohol

The invention relates to a method for detecting the contents of 22 kinds of volatile organic compounds in cigarette tipping paper printing ink, including benzene, toluene, ethylbenzene, ortho / meta / para-xylene, phenethylene, methanol, ethanol, isopropyl alcohol, n-propyl alcohol, n-butanol, acetone, 4-methyl-2-pentanone, butanone, cyclohexanone, ethyl acetate, n-propyl acetate, n-butyl acetate, isopropyl acetate, 1-methoxy-2-propyl alcohol and 1-ethoxy-2-propyl alcohol. Detection is performed by headspace gas chromatography by taking glyceryl triacetate as a matrix rectifier. According to the method provided by the invention, a sample pretreatment process is simple, the automation degree of the whole operation is high, the simultaneous detection of various volatile organic compounds can be realized, and the detection sensitivity, the recovery rate and the result precision are high.

Owner:GUANGXI ZHENLONG IND

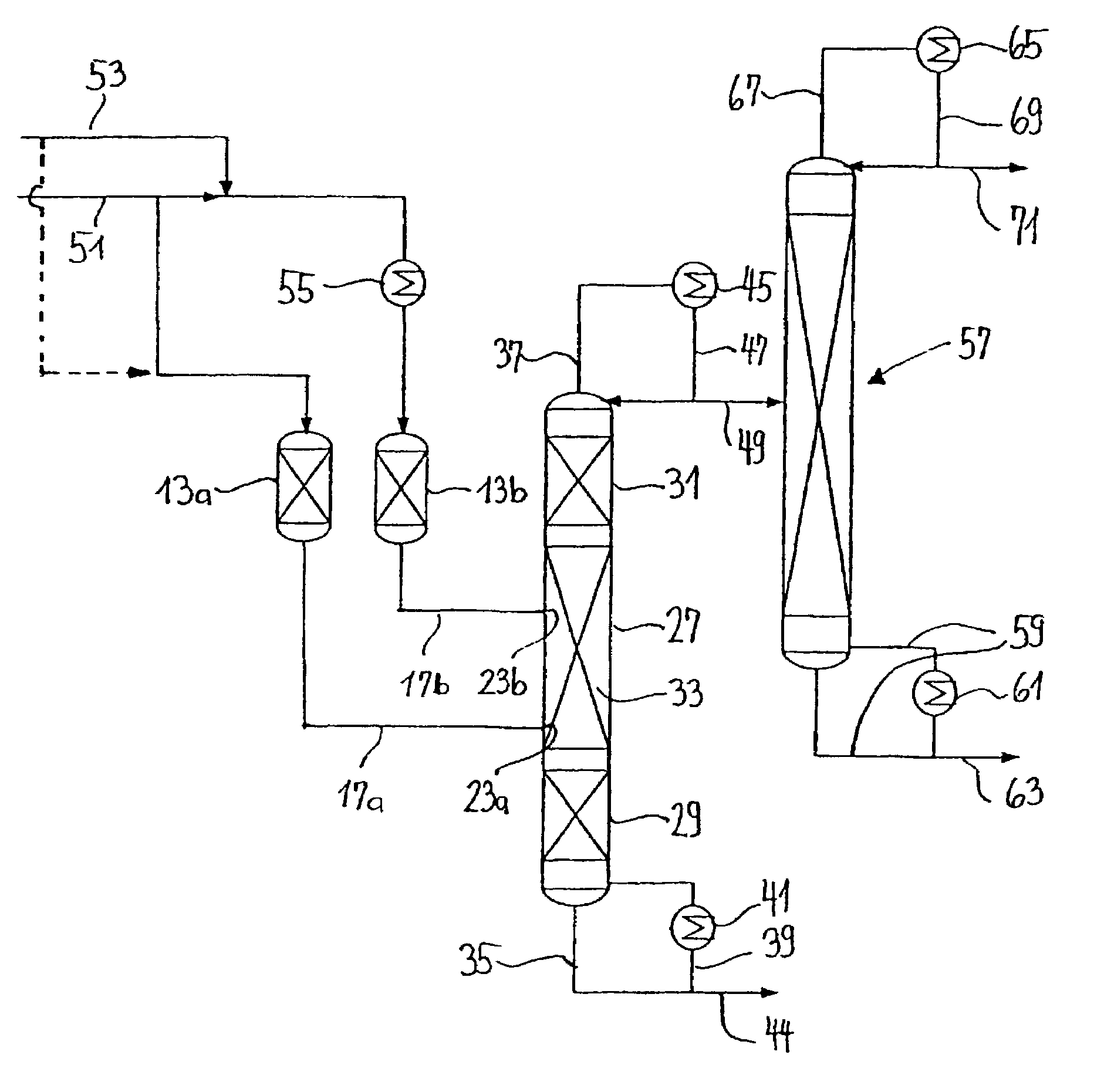

Process and device for hydrolytically obtaining a carboxylic acid alcohol from the corresponding carboxylate

InactiveUS7041199B1Raise the ratioConvenience to workSolvent extractionOrganic chemistry methodsAllyl acetateAlcohol

A process and a device for the catalytic hydrolysis of a carboxylate, e.g., methyl acetate, ethyl acetate, i- or n-propyl acetate, i- or n-butyl acetate, allyl acetate and methyl formate, into the corresponding carboxylic acid and alcohol, by a combination of a pre-reactor and a reactive distillation column are disclosed. By the combination of a pre-reactor and a reactor distillation column, the conversion ratio can be substantially improved. The device can compensate for fluctuations in the supply quantity or in the composition of the feed flow. The product composition can also be controlled in a wide range.

Owner:SULZER CHEMTECH AG +1

Stability of covert pigments

ActiveUS8002190B2Easy authenticationEasy to identifyInksRecord carriers used with machinesPolyesterPolyolefin

A covert material for printing onto a printing medium is provided, the covert material comprising a covert pigment and a binder encapsulating the covert pigment into a particle, where the binder comprises at least one of cellulose acetate butyrate (CAB), butyral vinyl acetate, acetyl butyrate, and acetate butyrate. Alternatively, the binder comprises at least one of polyester, polyolefin, acetyl butyrate, acetate butyrate, polystyrene copolymer, and polystyrene-polyvinylpyridine. The covert material can comprise additional components, such as ethyl acetate and / or n-propyl acetate. In one embodiment, the covert pigment comprises about 0.5-5% of the covert material. In one embodiment, the binder comprises about 5-30% of the covert material. In one advantageous embodiment, the covert pigment comprises at least 2% of the covert material and the binder comprises about 20-25% of the covert material. The covert material can further comprise at least one of a colorant, a surface additive, and a magnetic particle. The covert material can be part of a toner or ink. In at least some embodiments, the particle can have many different sizes, including sizes greater than 1 micron, greater than 5 microns, and greater than 20 microns. In one embodiment, the covert printing material is constructed and arranged to be printed using a printer having a predetermined resolution, wherein the particle has a size that is substantially the same as the size of a single pixel or dot printed using the predetermined resolution. The covert material can be constructed and arranged to satisfy a predetermined number of the NCITS 322 tests.

Owner:L 1 SECURE CREDENTIALING

Biaxially-oriented polypropylene (BOPP) pearlised film environment-friendly ink and preparation method thereof

The invention discloses biaxially-oriented polypropylene (BOPP) pearlised film environment-friendly ink, and relates to ink. The BOPP pearlised film environment-friendly ink is prepared by the following raw materials by weight percent: 15-35% of combined resin, 8-11% of organic color pigment, 2-5% of auxiliary agent and 55-65% of combined solvent, wherein the combined resin comprises alcohol soluble polyamide resin liquid, alcohol soluble aldehyde ketone resin liquid, alcohol ester soluble nitrocellulose resin liquid and maleic acid resin liquid; the auxiliary agent comprises polyethylene wax, an anti-settling agent, Texanol ester alcohol and acrylate; the combined solvent comprises absolute ethyl alcohol, isopropanol, n-propyl acetate and acetic ether. Compared with the prior art, the BOPP pearlised film environment-friendly ink has the advantages of being environment-friendly, non-toxic, bright in color, high in color saturation, good in shallow network transfer performance and good in level reproducibility.

Owner:CHENGDU PRESSTER NEW MATERIALS

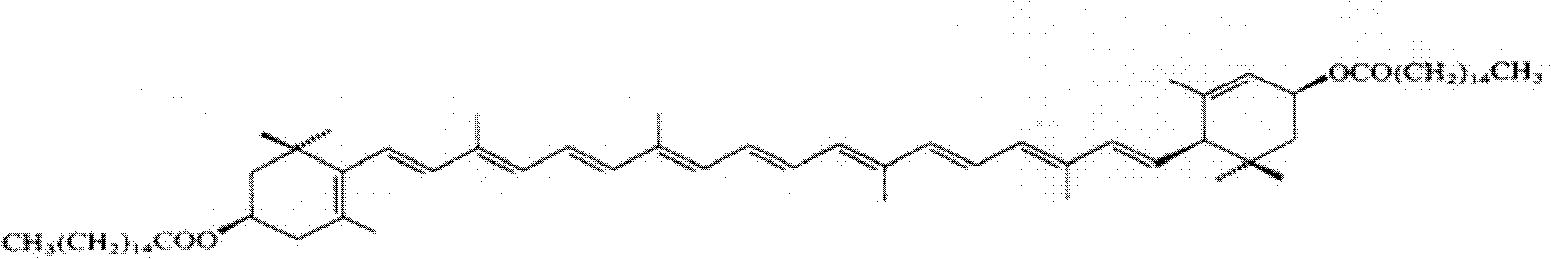

Combination containing lutein ester and preparation method thereof

The invention relates to a combination containing lutein ester and a preparation method thereof. The preparation method comprises the steps of: decreasing the temperature of solution of a marigold extract solvent A to 20-28 DEG C, maintaining the temperature for 0.5-4 hours, decreasing the temperature to 5-18 DEG C, maintaining the temperature for 0.5-4 hours and filtering to obtain a filter cake I; and under the condition of 30-70 DEG C, dissolving the filter cake I in a mixed solvent A, agitating for 0.5-5 hours, decreasing the temperature to 10-28 DEG C, keeping the temperature for 0.5-5 hours, filtering to obtain a filter cake II and conducting subsequent steps, wherein the mixed solvent A is the mixed solvent of methyl acetate, acetic ether, n-propyl acetate or butyl acetate and C1-3 alcohol. By adopting the method provided by the invention, the process is simple and feasible, the industrialization is easy to realize, all operations are conducted at low temperature and the stability of the product is guaranteed. The yield of the obtained product highly reaches more than 25 percent, the content of total esters in the product is more than 70 percent, the content of trans-lutein highly reaches 90-93 percent and the bioactivity of the product during use is greatly improved.

Owner:INNOBIO CORP LTD

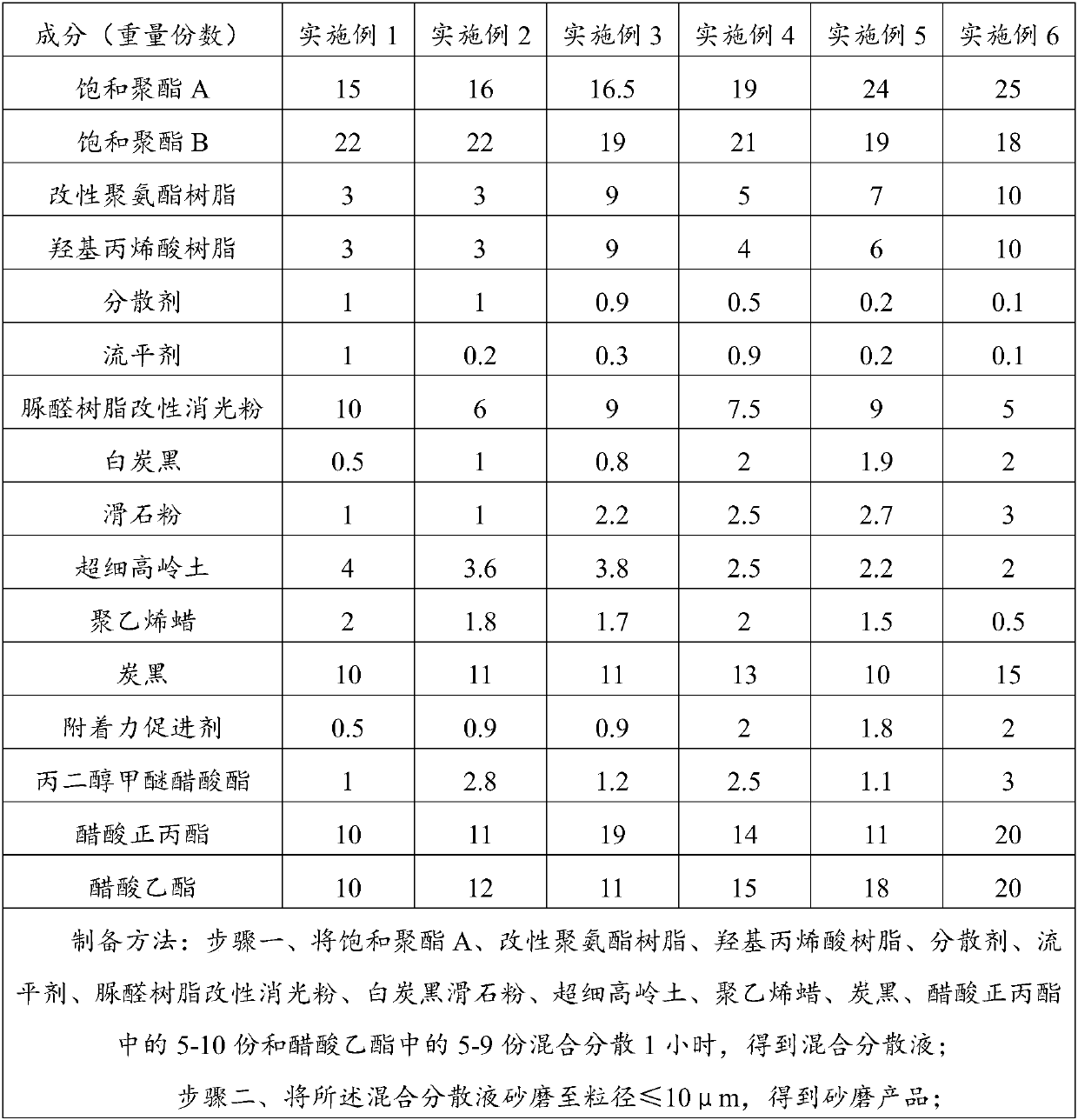

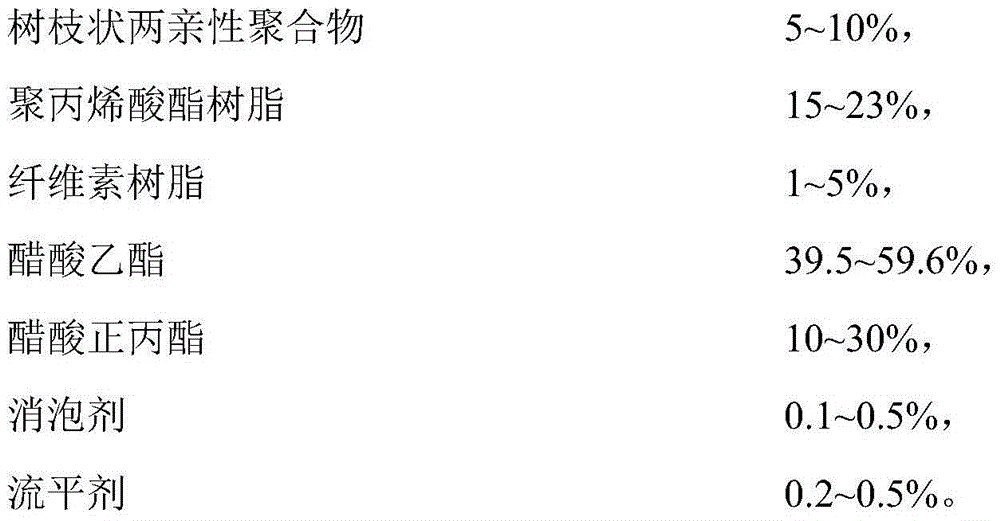

General insulation matte black electron gravure printing ink for PET and PI films and preparation method

The invention provides general insulation matte black electron gravure printing ink for PET and PI films and a preparation method thereof. The general insulation matte black electron gravure printingink comprises saturated polyester, modified polyurethane resin, hydroxyl acrylic resin, 0.1-2 parts of a dispersing agent, a leveling agent, urea formaldehyde resin modified extinction powder, white carbon black, talcum powder, ultrafine kaolin, polyethylene wax, carbon black, n-propyl acetate, ethyl acetate, saturated polyester B, an adhesion promoter and propylene glycol monomethyl ether acetate. The general insulation matte black electron gravure printing ink provided by the invention has the advantages that resin components, such as modified polyurethane resin and hydroxyl acrylic resin, with different physical and chemical properties are used, and adhesion of the gravure printing ink on base materials such as the PET and PI films is improved, so that the gravure printing ink can be respectively used on the two base materials, namely the PET film and the PI film, the work of using the printing ink on the different base materials is simplified, the cost of printing ink printing workis reduced, and the working efficiency is improved.

Owner:广东顺德洋紫薇化工有限公司

Formula and preparation method of strip copper gold powder

The invention discloses a formula of strip copper gold powder. The strip copper gold powder is prepared from copper gold powder with mass percentage of 80-85% and a liquid medicine A with mass percentage of 15-20%, wherein, the liquid medicine A comprises the following components based on mass percentage: 18-30% of rosin glycerol resin and 70-82% of n-propyl acetate. The preparation method comprises the following steps: (1) mixing the rosin glycerol resin with the n-propyl acetate according to the mass percentage, and uniformly stirring to obtain the liquid medicine A; (2) pouring the liquid medicine A into the copper gold powder according to the mass percentage, uniformly stirring and infiltrating; and (3) putting the infiltrated copper gold powder in a molding press to be extruded into strips, and air drying to obtain the strip copper gold powder. The strip copper gold powder prepared by the method has the advantages that the powder does not contain benzene, methanol and ketone, thus the environmental protection requirement is improved; the dust pollution is avoided when a user uses the strip copper gold powder so as to improve production conditions of an operation workshop; the damage on top-grade printing equipment can be avoided; and the powder has low cost and is convenient for sale and transportation.

Owner:SUZHOU DIAMOND METAL POWDER

Sun-proof printing ink as well as preparation method and application thereof in sun-proof transfer film

The invention relates to the technical fields of a transfer film and a printing ink formulation, and particularly relates to sun-proof printing ink as well as a preparation method and an application thereof in a sun-proof transfer film. The sun-proof printing ink is prepared from the following components in parts by mass: 18-20 parts of inorganic paint, 1-1.5 parts of a wetting agent, 45-50 parts of acrylic resin liquid, 12-18 parts of cellulose acetate resin liquid, 1-1.5 parts of a dispersing agent, 1-1.5 parts of fumed silica, 5-6 parts of isopropanol and 12-15 parts of n-propyl acetate. The inorganic paint and the wetting agent are mixed and ground, so as to obtain paint powder with high fineness; the printing ink is uniformly mixed. The sun-proof printing ink is applied to the sun-proof transfer film, has a sun-proof level up to an 8 level, and is particularly suitable for printing outdoor products.

Owner:DONGGUAN ZHUOYI PRINTING PROD

Solvent type gravure pearlescent ink and preparation method thereof

Owner:XUZHOU SUNUP INK CHEM

Gravure antibiotic printing ink of cork paper

The invention relates to gravure antibiotic printing ink of cork paper, which is characterized in that the product is composed of the following raw materials by weight: 15 to 35 parts of pigment, 10 to 25 parts of resin, 30 to 60 parts of solvents, 0.5 to 3 parts of antiseptic A and 0.2 to 1 parts of antiseptic B. The mentioned resin is a mixture composed of one selected from polyvinyl butyral, nitrocellulose and polyurethane, and one of modified abietate and polyketone resin; the mentioned solvent is selected from one or more than one of ethyl acetate, n-propyl acetate, isopropyl acetate, ethanol, isopropanol and n-propanol; the mentioned antiseptic A is a nanometer level modified titanium dioxide; and the mentioned antiseptic B is is one selected from sulphadimethoxine, sulphamethazine, trimethoprim and dimethoxypyrimidine. The gravure antibiotic printing ink of cork paper of the invention has reasonable formulation, can realize gravure on cork paper and has antibiotic and bacteriostasis effects.

Owner:江苏泰格油墨有限公司

Method for preparing matt laser alumite chromatograph coating

The invention relates to a method for preparing a matt laser alumite chromatograph coating. The method comprises the following steps of firstly weighting 95-100 parts of alumite crylic acid resin ester and 2-5 parts of matt powder according to weight part and then mixing, adding a flatting agent and a defoaming agent after uniform mixing into the mixture, wherein the amount of the flatting agent and the defoaming agent is 3-7 per mill of the total amount of the mixture, then adding ethyl acetate, butyl acetate, butanone and / or n-propyl acetate solvent, and preparing the matt laser alumite chromatograph coating product containing 16-20% by weight of alumite crylic acid resin ester and matt powder. The matt laser alumite chromatograph coating can be used for matt treatment on the alumite chromatograph on dazzling laser packing, so that the pack can present a new appearance, the matt not only represents the change of angle of view, but also has more practical application. The matt laser alumite chromatograph coating has wide application prospect in packing field.

Owner:GUANGDONG BANGGU CHEM TECH

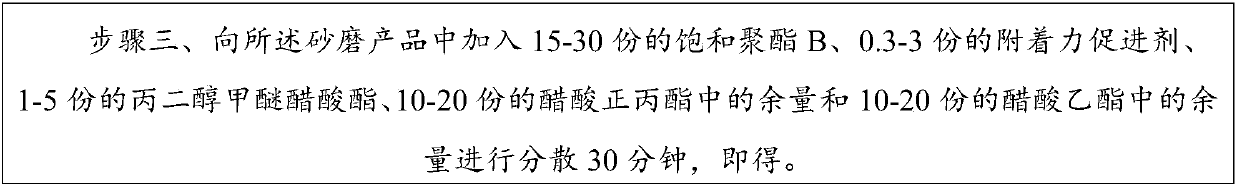

High-flatness water transfer film coating and preparation method thereof

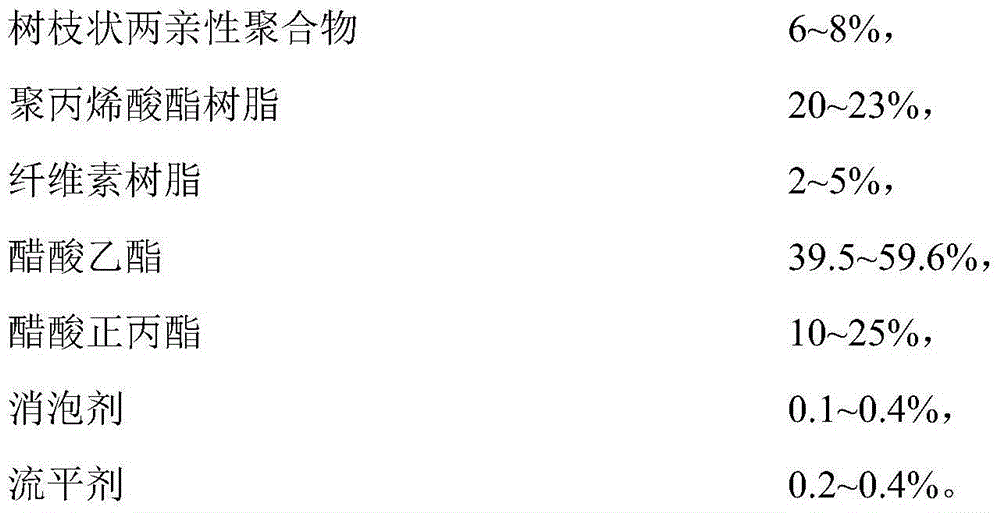

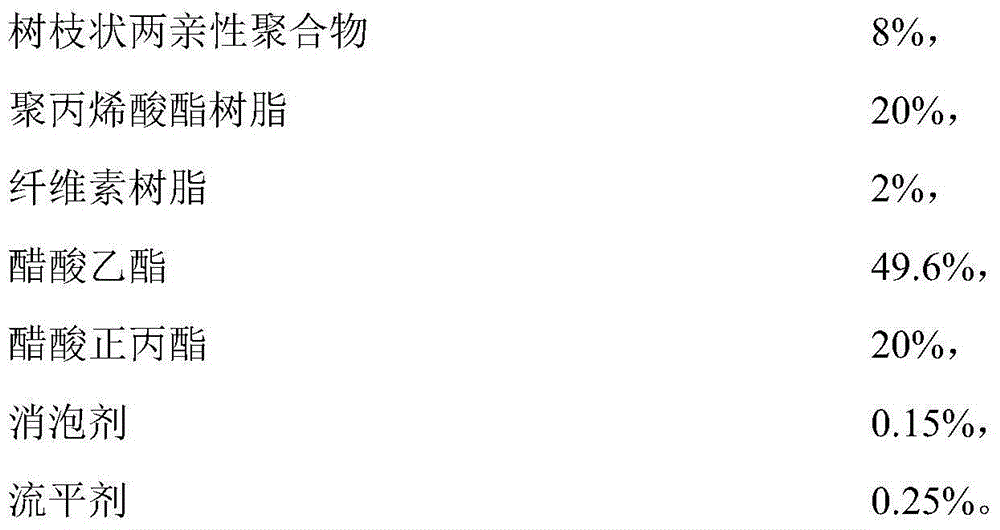

The invention discloses a high-flatness water transfer film coating and a preparation method thereof. The coating comprises the following components in percentage by weight: 5-10% of a dendritic amphiphilic polymer, 15-30% of polyacrylate resin, 1-5% of cellulose resin, 39.5-59.6% of ethyl acetate, 10-30% of n-propyl acetate, 0.1-0.5% of a defoaming agent and 0.2-0.5% of a flatting agent. According to the high-flatness water transfer film coating, based on a traditional water transfer formula, a certain proportion of the functional amphiphilic dendritic polymer is added so that by using the amphiphilic advantage of the functional amphiphilic dendritic polymer in water, the entire flatness of the water transfer coating in the water solubilization process of polyvinyl alcohol-based film is improved, the local wrinkling of the traditional water transfer coating is improved so that the entire bearing article flower pattern is flat and entirely aesthetic.

Owner:SHANGHAI CHENGYING NEW MATERIALS

Printing ink for various compound processes

ActiveCN104212232AImprove high temperature resistanceImprove permeabilityInksSolvent freePrinting ink

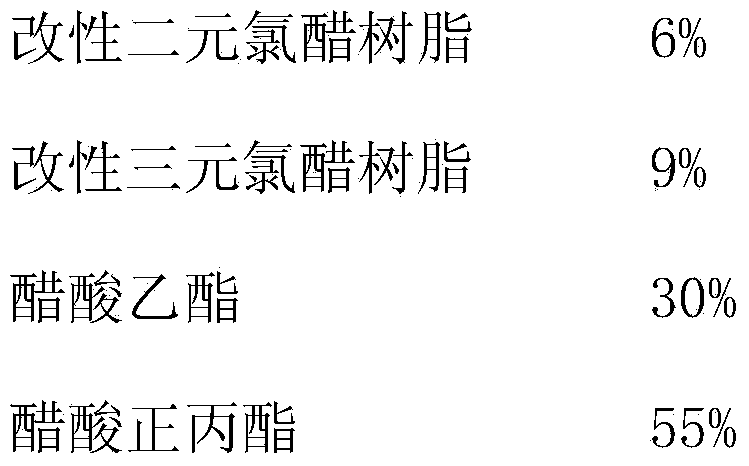

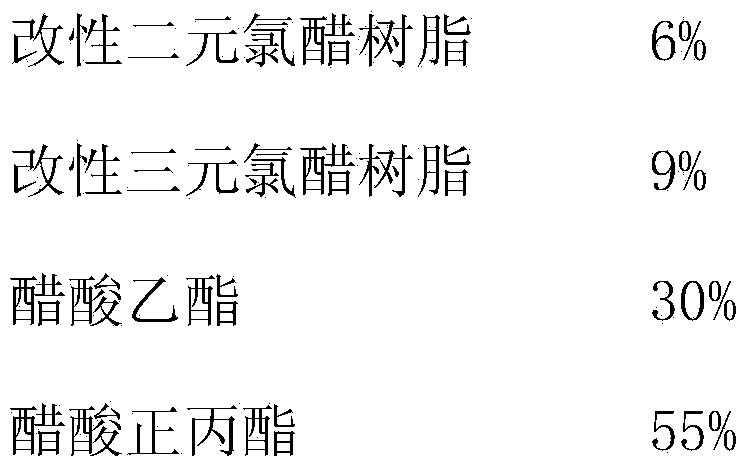

The invention provides printing ink for various compound processes. The printing ink comprises the following raw materials: 30% modified polyurethane resin liquid, 15% modified binary and ternary vinyl chloride and vinyl acetate copolymer mixed liquid, pigment, fillers, polyethylene wax, a special assistant, n-propyl acetate, isopropanol, ethyl acetate and a silane coupling agent. The printing ink is improved aiming at a compound process technology of flexible package printing; by improving components in a formula system, especially adopting the silane coupling agent and the special assistant, the permeation of an ink printed product on low-weight molecules of solvent-free glue is improved to the maximum extent, the high-temperature resistance of the printing ink in an extrusion compound process is improved, the problems of white spots and low compound strength of a compound product are solved, and the product quality is ensured.

Owner:HUANGSHAN SHINING INK TECH

Environment-friendly low-temperature heat-set type transparent matte gloss oil

InactiveCN105907207AImprove poor flexibilityExcellent adhesionPolyurea/polyurethane coatingsAcrylic resinPliability

The invention discloses environment-friendly low-temperature heat-set type transparent matte gloss oil. The oil is prepared from, by mass, 7-9 parts of vinyl chloride-vinyl acetate resin liquid, 16-20 parts of polyurethane resin liquid with mass percentage of 30%, 8-10 parts of matting agent, 0.5-2 parts of polyethylene wax, 25-35 parts of n-propyl acetate, 3-5 parts of isopropanol, 0.5-1.5 parts of adhesion promoter and 25-40 parts of acrylic resin. The mass percentage of vinyl chloride-vinyl acetate resin liquid is 20%. Vinyl chloride-vinyl acetate resin powder is dissolved in solvent to be stirred so that vinyl chloride-vinyl acetate resin liquid can be prepared. Solvent is formed by mixing n-propyl acetate with isopropanol according to the mass ratio of 8:2. The problem that gloss oil flexibility is poor when gloss oil is applied to a printed product at low temperature can be remarkably improved, adhesion of the gloss oil is improved, the matte effect required by the printed product is achieved, and weather resistance, waterproofing performance and wear resistance of the printed product are improved.

Owner:SUZHOU ZHONGYA INK

Method for detecting migration amounts of volatile organic compounds in paper packaging material to dry simulants

PendingCN110780000AHigh detection sensitivityImprove simplicityComponent separationPropanolEthyl acetate

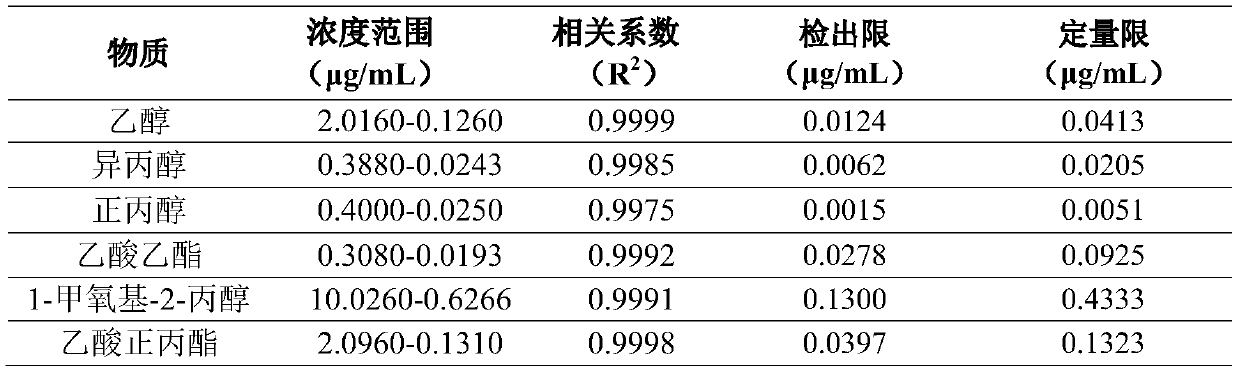

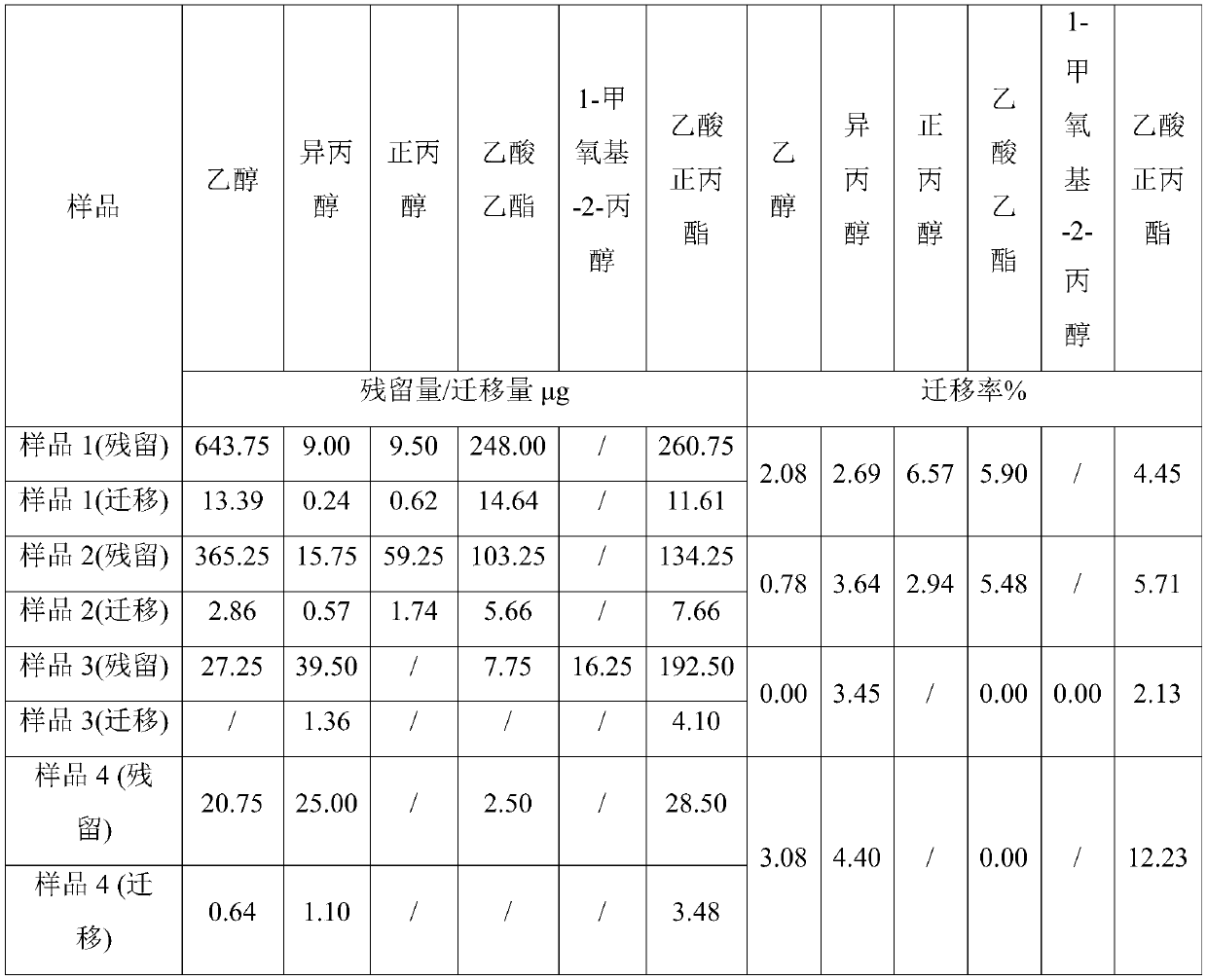

The invention provides a method for detecting migration amounts of volatile organic compounds in a paper packaging material to dry stimulants. According to the method, a standard sample and a to-be-detected sample are respectively used for trapping the volatile organic compounds by adopting a purging and trapping method, the standard sample is a standard working solution formed by respectively adding a certain amount of dry simulants into a series of volatile organic compounds with different concentrations, the volatile organic compounds comprise ethanol, isopropanol, n-propanol, ethyl acetate, 1-methoxy-2-propanol and n-propyl acetate, the to-be-detected sample is an aqueous solution formed by adding the same amount of dry stimulant into water after migration treatment is carried out by adopting the paper packaging material, and the addition volume of the water is the same as the addition volume of the volatile organic compounds during the preparation of the standard sample. The method improves the detection sensitivity, and is simple and environmentally friendly.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Surface treating method of the aluminum alloy decorative sheet

InactiveCN101116858AStrong and clear three-dimensional senseNo sheddingLiquid surface applicatorsCoatingsEpoxyPolyester

The invention relates to a surface treatment method for aluminium alloy decorated board, the aluminium alloy is soaked in sulfuric acid solution, washed by clear water, dried naturally and coated with acetone, benzene, and n-propyl acetate on the surface, blown on the surface by an air pump; and then is heated by a thyristor rectifier infrared heating device, coated with the polyester epoxy powder coating on the surface and heated by the thyristor rectifier infrared heating device again; and are roll coated with epoxy resin powder, butyl acetate, and industry paint color masterbatch to be made of lathework, heated, coated with varnish on the surface, and is heated again to get finished product of the aluminium alloy decorated board with the lathework. The invention has the advantages that the invention is acid resistant, alkali resistant, chemical corrosion resistant, and is not easy to paste with the chimney soot, and is of high inoxidability. The invention has no phenomenon of peeling and dulling, the varnish has no abscission. The pattern is of strong third dimension, soft and bright color, no discoloration and fastness. The manufacturing cost is lower.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Reversible pressure-sensitive-discoloration anti-counterfeiting ink and preparation method thereof

The invention relates to the technical field of anti-counterfeiting ink and particularly relates to reversible pressure-sensitive-discoloration anti-counterfeiting ink and a preparation method thereof. The anti-counterfeiting ink disclosed by the invention contains the following ingredients in parts by weight: 11.64-12.6 parts of 1 / 4-second nitro-cotton, 7.76-8.4 parts of polyamide resin, 29.1-31.5 parts of reversible pressure-sensitive-discoloration capsule powder, 29.1-31.5 parts of n-propyl acetate, 19.4-21 parts of isopropanol, 0.19-0.21 part of leveling agent and 0.19-0.21 part of defoamer. Compared with the prior art, the reversible pressure-sensitive-discoloration anti-counterfeiting ink disclosed by the invention is in reversible color development, and a face printed with the ink is white; when the face is scratched by a nail, the face shows blue and returns to white a few seconds later, so that the ink can be repeatedly used; the principle of color restoration is as follows: achromatic restoration is achieved after substance molecules in capsule cores are re-crystallized, and the speed of re-crystallization is the speed of color restoration.

Owner:林友康

High-speed hot-stamping gloss oil type tipping paper electrochemical aluminum foil hot melt adhesive and preparation method thereof

ActiveCN109593494ALower surface energyIncrease moistureNon-macromolecular adhesive additivesMacromolecular adhesive additivesHot stampingPolymer science

The invention provides a high-speed hot-stamping gloss oil type tipping paper electrochemical aluminum foil hot melt adhesive and a preparation method thereof, and aims to solve the phenomena that anexisting hot melt adhesive is not compatible with a wax material with low surface energy and easily shelled. The hot melt adhesive is prepared from the following raw materials in parts by weight: 5-10parts of vinyl chloride-vinyl acetate-maleic anhydride terpolymer, 1-5 parts of aldehyde ketone resin, 1-5 parts of cellulose acetate butyrate, 1-5 parts of rosin modified resin, 0.1-0.5 part of a wetting agent, 1-5 parts of fumed silica, 50-80 parts of ethyl acetate and 1-5 parts of n-propyl acetate. According to the hot melt adhesive, the surface energy of hot melt adhesive can be greatly reduced under a melting condition, and the wetting and penetrating performance of hot melt adhesive on the low-surface-energy tipping paper base material can be effectively improved; resin is reasonably matched in the formula for mixing and modifying preparation, and initial adhesion and persistent adhesion of the hot melt adhesive can be taken into consideration, and the aim of firm adhesion and high-speed hot stamping can be achieved.

Owner:云南玉溪东魅包装材料有限公司

Single-component solvent ink and preparation method thereof

The invention discloses single-component solvent ink and a preparation method thereof. The ink consists of the following components in parts by mass: 12-17 parts of a chloric ether resin, 0.75-1 partof cellulose acetate butyrate, 0.3-0.5 part of polyethylene wax powder, 10-15 parts of a pigment and 65-75 parts of a solvent. The preparation method of the ink with the components comprises the following steps: weighing materials, performing pre-dispersion, performing grinding and dispersion, adjusting the viscosity, and performing filtering and packaging. According to the ink, n-propyl acetate is adopted as a single solvent, the solvent is high in reuse rate after being recycled, and thus relatively low environment protection cost is needed; the ink is relatively good in adhesion property for materials such as PVC, PET and PETG, and relatively good in universality; the ink is relatively good in gloss, relatively good in printing effect, relatively good in shallow net transferring and relatively good in printing adaptability.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

High-solid low-viscosity laser alumite imaging layer coating and preparation method thereof

The invention discloses a high-solid low-viscosity laser alumite imaging layer coating and a preparation method thereof. The high-solid low-viscosity laser alumite imaging layer coating is prepared from the following raw materials in parts by weight: 10-30 parts of polymethyl methacrylate resin, 5-10 parts of styrene-maleic anhydride resin, 1-5 parts of cellulose acetate butyrate, 5-10 parts of isobornyl methacrylate, 1-5 parts of fluorine-containing polyacrylate, 50-70 parts of butanone, 1-8 parts of n-propyl acetate and 1-5 parts of propylene glycol ether. Polymer monomers contained in the formula of the imaging layer coating are of special structures or functional groups, and meanwhile comprehensive performance of polymer is taken into consideration; under the condition that the performance, such as heat resistance, of the polymer coating is not influenced, the viscosity of polymer solution can be obviously reduced, the using amount of an organic solvent is reduced, the leveling property of a coating film in the coating process is improved, and the coating film also has relatively low surface energy, so that acting force between a laser operating plate and a polymer coating layer in a high-temperature mold pressing process is reduced to achieve an effect of preventing plate adhesion.

Owner:玉溪春和纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com