Printing ink for various compound processes

A compounding process and ink technology, applied in inks, applications, household appliances, etc., can solve problems such as extrusion compounding and solvent-free compounding, high temperature resistance of ink, and darkening of compound products, etc., to improve penetration, Improve high temperature resistance and reduce volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

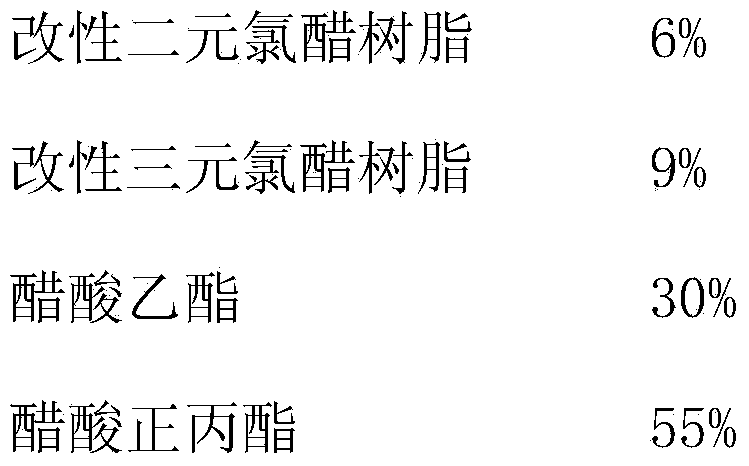

[0066] 1, at first adopt ethyl acetate, n-propyl acetate to dissolve 20% modified binary, ternary chlorine vinegar resin to prepare 15% modified binary, ternary chlorine vinegar mixed resin liquid, wherein the weight percent of each component is:

[0067]

[0068] 2. Then, according to the following formula system:

[0069] 30% modified polyurethane resin liquid: 25%

[0070] 15% modified binary and ternary chlorine vinegar mixed resin solution: 15%

[0071] Pigment: 10%

[0072] Filler: 3%

[0073] Polyethylene wax: 3%

[0074] Special additives: 5%

[0075] n-Propyl acetate: 13%

[0076] Isopropanol: 10%

[0077] Ethyl acetate: 15%

[0078] Silane coupling agent: 1%

[0079] Wherein the component and weight percent of special auxiliary agent are:

[0080] 2400 hyperdispersant 20%

[0081] Antistatic agent 40%

[0082] Antioxidant 40%

[0083] Wherein the component and weight percent of silane coupling agent are:

[0084] Aminopropyltrimethoxysilane (A~1110) 50%...

Embodiment 2

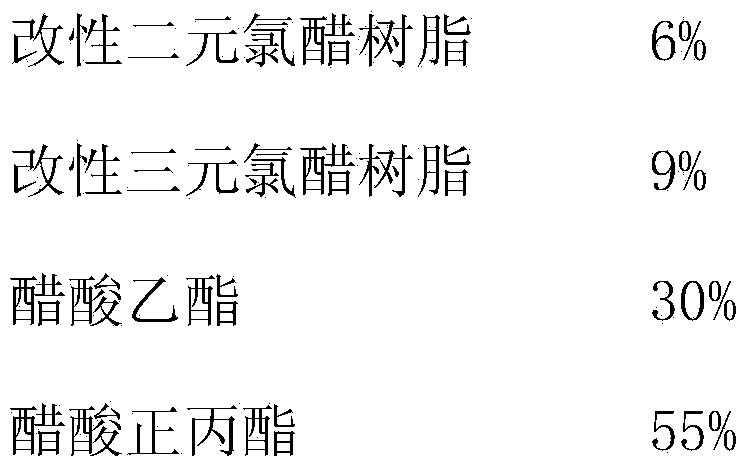

[0097] 1. The preparation of 15% modified binary and ternary chlorine vinegar mixed resin liquid is the same as in Example 1.

[0098] 2. Then, according to the following formula system:

[0099] 30% modified polyurethane resin liquid: 32%

[0100] 15% modified binary and ternary chlorine vinegar mixed resin solution: 10%

[0101] Pigment: 20%

[0102] Filler: 4%

[0103] Polyethylene wax: 1%

[0104] Special additives: 1%

[0105] n-Propyl acetate: 14%

[0106] Isopropanol: 5%

[0107] Ethyl acetate: 10%

[0108] Silane coupling agent: 3%

[0109] Wherein the component and weight percent of special auxiliary agent are:

[0110] 2400 hyperdispersant 20%

[0111] Antistatic agent 40%

[0112] Antioxidant 40%

[0113] Wherein the component and weight percent of silane coupling agent are:

[0114] Aminopropyltrimethoxysilane (A~1110) 50%

[0115] Vinylethoxysilane (A~151) 35%

[0116] Isobutyltriethoxysilane (TMA) 15%

[0117] The ink used in various composite pro...

Embodiment 3

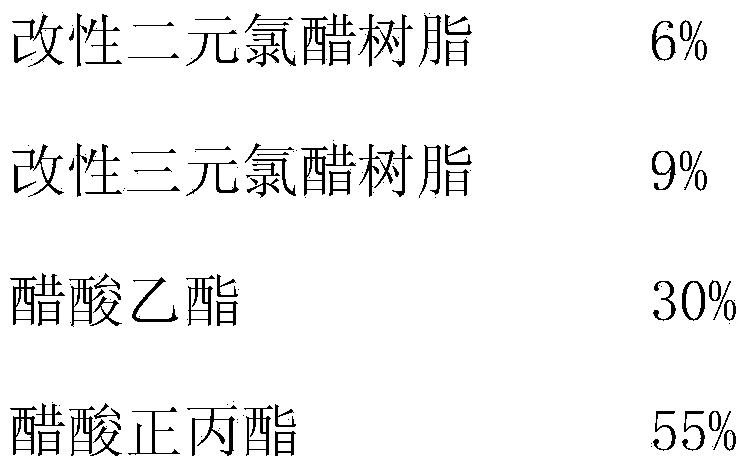

[0120] 1. The preparation of 15% modified binary and ternary chlorine vinegar mixed resin liquid is the same as in Example 1.

[0121] 2. Then, according to the following formula system:

[0122] 30% modified polyurethane resin liquid: 25%

[0123] 30% modified polyurethane ~ acrylic emulsion: 6%

[0124] 15% modified binary and ternary chlorine vinegar mixed resin solution: 10%

[0125] Pigment: 8%

[0126] Filler: 7%

[0127] Polyethylene wax: 1%

[0128] Special additives: 1.5%

[0129] n-Propyl acetate: 10%

[0130] Isopropanol: 20%

[0131] Ethyl acetate: 10%

[0132] Silane coupling agent: 1.5%

[0133] Wherein the component and weight percent of special auxiliary agent are:

[0134] 2400 hyperdispersant 20%

[0135] Antistatic agent 40%

[0136] Antioxidant 40%

[0137] Wherein the component and weight percent of silane coupling agent are:

[0138] Aminopropyltrimethoxysilane (A~1110) 50%

[0139] Vinylethoxysilane (A~151) 35%

[0140] Isobutyltriethoxys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com